PROGRAM MANAGEMENT

NASA ORGANIZATION

The Saturn V development program comes under the direction of the NASA Office of Manned Space Flight, Washington, D. C. That office assigned development responsibility to the Marshall Space Flight Center, one of the three Manned Space Flight field centers. Another of those field centers, the Kennedy Space Center, has been delegated the responsibility of launching the Saturn V. (Development of the Apollo spacecraft, the first “payload" for the Saturn V, was assigned to the Manned Spacecraft Center, the other MSF field organization.)

Marshall Center Project Management Organization

More than 125,000 prime and subcontractor employees and 7,500 civil service employees are working on the Saturn program. Saturn industrial activities are scattered nationwide but there are three major areas of concentration:

1. the Northeast, with its grouping of electronic industries.

2. the Southeast, for production, test, and launch operations.

3. the West Coast, with its concentration of aerospace industries for design, production, and test w’ork.

In addition, various research’ projects by scientific – institutions and subcontractor production efforts contributing to the Saturn program are spread throughout the nation.

The wide dispersion makes necessary very comprehensive and reliable management systems and control techniques to manage the program effectively. The geographic dispersion of the Saturn effort requires excellent communications. The Marshall Center must be aware of related programs carried out by other NASA centers—especially the Manned Spacecraft Center, managing the Apollc spacecraft program, and Kennedy Space Center, responsible for Saturn/Apollo launches.

The Marshall Center has found that one of the more effective tools for total program visibility is especially constructed and outfitted rooms called Program Control Centers. The Saturn V launch vehicle program office and other major groups have such centers.

The budget for the current fiscal year at the MSFC is about SI.7 billion. The center must have a well staffed organization responsive to the many changes which can take place in a program of this magnitude.

The budget for the current fiscal year at the MSFC is about SI.7 billion. The center must have a well staffed organization responsive to the many changes which can take place in a program of this magnitude.

SATURN V NEWS REFERENCE

Program management is vested in the program manager. Technical project management, so far as NASA is concerned, occurs at the stage or project level. The program and stage managers are fully responsible for technical adequacy, reliable performance, and for management of all related contractor activity.

These program and project managers must be backed up and supported by technical competence in depth. This in-depth support is provided, to a degree, by a staff of competent technical and business management people in the program manager and stage manager office, and to a much larger degree, by Research and Development Operations,

There is a resident manager at each of the contractor plants to act as the “official" voice for the Marshall Center, All MSFC instructions to the contractor

are transmitted through the resident manager. Through the resident manager, MSFC maintains a direct contact with contractor operations and is kept informed of the status of all significant program events.

Marshall Center laboratory technical personnel are assigned to the resident managers’ staffs. These technical people are assigned to each resident manager’s office to provide him with assistance in resolving technical problems, and to keep the MSFC technical laboratories directly informed of field technical effort. Laboratory participation is dictated by need as determined by project management.

Many people are involved in attaining the final goal. Project management, technical, and contractor personnel are tied in a close knit group capable of managing this country’s large launch vehicle program.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

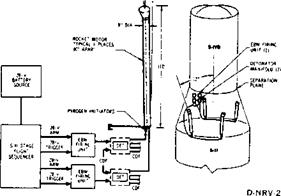

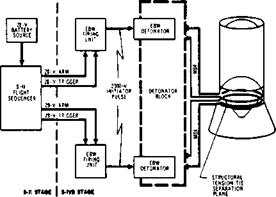

The severable tension strap houses two redundant MDF cords in a “V” groove circumventing the stage between the aft skirt and aft interstage at the separation plane. Ignition of the MDF cords is triggered by a signal from the second stage sequencer through the EBW and EBW firing units about 3 seconds after second stage engine cutoff.

The severable tension strap houses two redundant MDF cords in a “V” groove circumventing the stage between the aft skirt and aft interstage at the separation plane. Ignition of the MDF cords is triggered by a signal from the second stage sequencer through the EBW and EBW firing units about 3 seconds after second stage engine cutoff.

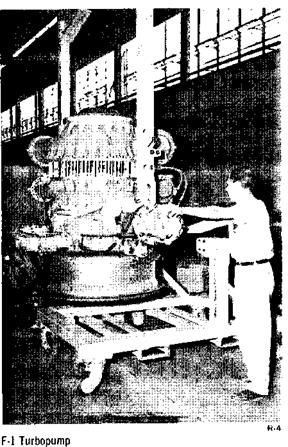

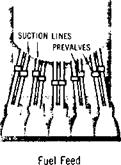

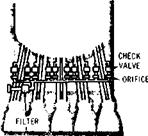

Fuel Pump

Fuel Pump S-19

S-19