FIRST STAGE SYSTEMS Fuel System

The first stage fuel system supplies RP-1 fuel to the F-l engines. The system consists of a fuel tank, fuel feed lines, pressurization system, fill and drain components, fuel conditioning system, and associated hardware to meet the propulsion system requirements.

FUEL TANK

The fuel tank, previously described, holds 203,000 gallons of kerosene and is capable of providing 1,350 gallons of fuel per second to the engines through 10 fuel-suction lines.

FUEL FILL AND DRAIN SYSTEM

The fuel tank is filled through a 6-inch duct at the bottom of the tank. Fill rate is 200 gallons per minute until the tank is 10 per cent full. After reaching the 10 per cent mark, filling is increased to 2,000 gallons per minute until the tank is full. Normal nonemergency drain takes place through the same duct. A ball-type valve in the fill and drain line provides fuel shutoff.

|

|

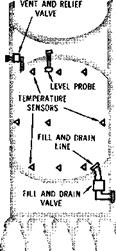

Fuel Fill and Drain

The fuel fill and drain system consists of a fill and drain line, a fill and drain valve, a fuel loading level probe, and nine temperature sensors. During fuel fill, the temperature sensors provide continuous fuel temperature information used to compute fuel density. When the fuel level in the fuel tank rises to about 102 per cent of flight requirements, the fuel loading probe indicates an overload.

After adjusting fuel to meet requirements, the fill and drain valve is closed.

The fuel tank can be drained under pressure by closing the fuel tank vent and relief valve, supplying a pressurizing gas to the tank through the fuel tank prepressurization system, and opening the fuel fill and drain valve.