This volume has been prepared by the five Saturn V major contractors: The Boeing Company; Douglas Aircraft Company: Space Division of North American Aviation, Inc.; Rocketdyne Division of North American Aviation, Inc.; and International Business Machines Corporation in cooperation with the National Aeronautics and Space Administration.

It is designed to serve as an aid to newsmen in present and future coverage of the Saturn V in its role in the Apollo program and as a general purpose large launch vehicle. Every effort has been made to present a comprehensive overall view of the vehicle and its capabilities, supported by detailed

The Boeing Company P. 0. Box 29100 New Orleans, La. 70129 Attention: William W. Clarke

Douglas Aircraft Company Missile & Space Systems Division Space Systems Center 5301 Bolsa Avenue Huntington Beach, Calif. 92647 Attention: Larry Vitskv

International Business Machines Corporation

Federal Systems Division

150 Sparkman Drive

Huntsville, Ala. 35807

Attention: James F. Harroun

information on the individual stages and all major systems and subsystems.

Weights and measurements cited throughout the book apply to the AS-501 vehicle, the first flight version of the Apollo/Saturn V.

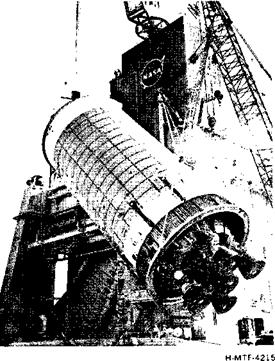

All photographs and illustrations in the book are available for general publication. The first letter in each photo number is a code identifying the organization holding that negative: В for Boeing; R for Rocketdyne Division of North American; D for Douglas; IBM for IBM; S for Space Division of North American; H for NASA, Huntsville, Ala.; and К for NASA, Kennedy Space Center, Fla.

s are:

Rocketdyne Division

North American Aviation, Inc.

6633 Canoga Avenue Canoga Park, Calif. 91304 Attention: R. K. Moore

National Aeronautics and Space Administration George C. Marshall Space Flight Center Public Affairs Office Huntsville, Ala. 35812 Attention: Joe Jones

National Aeronautics and Space Administration Public Affairs Office Kennedy Space Center, Fla. 32931 Attention: Jack King

Space Division

North American Aviation, Inc. Seal Beach, Calif. 90241 Attention: Richard E. Barton

^ SATURN V NEWS REFERENCE

SATURN V FACT SHEET

|

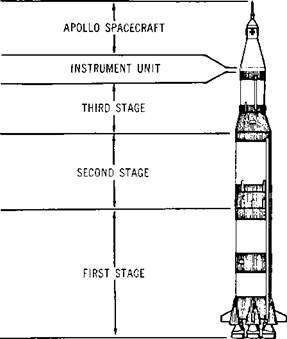

PHYSICAL CHARACTERISTICS

OVERALL VEHICLE

|

DIAMETER

|

HEIGHT

|

WEIGHT

|

|

33 ft.

|

364 ft.*

|

6,100,000 lb.

|

|

FIRST STAGE

|

33 ft.

|

138 ft.

|

(total liftoff) 300,000 lb. (dry)

|

|

SECOND STAGE

|

33 ft.

|

81 ft. 7 in.

|

95,000 lb. (diy)‘

|

|

THIRD STAGE

|

21 ft. 8 in.

|

58 ft. 7 in.

|

34,000 lb. (dry)’

|

|

INSTRUMENT UNIT

|

21 ft. 8 in.

|

3 ft.

|

4,500 lb.

|

|

APOLLO SPACECRAFT

|

|

80 ft.

|

95,000 lb.

|

‘SINCE INDIVIDUAL STAGE DIMENSIONS OVERLAP IN SOME CASES, OVERALL VEHICLE

LENGTH IS NOT THE SUM OF INDIVIDUAL STAGE LENGTHS

“INCLUDES AFT INTERSTAGE WEIGHT

PROPULSION SYSTEMS

FIRST STAGE —Five bipropellant F-l engines developing 7,500,000 lb. thrust

RP-1 Fuel-203,000 gal. (1,359,000 lb.), LOX-331,000 gal. (3,133,000 lb.)

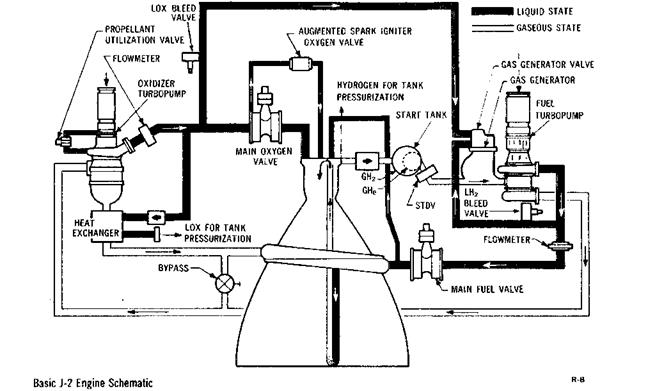

SECOND STAGE Five bipropellant J-2 engines developing more than 1,000,000 lb. thrust LH2—260,000 gal. (153,000 lb.), LOX-83,000 gal. (789,000 lb.)

THIRD STAGE —One bipropellant J-2 engine developing up to 225,000 lb. thrust LH2—63,000 gal. (37,000 lb.), LOX—20,000 gal. (191,000 lb.)

CAPABILITY

FIRST STAGE —Operates about 2.5 minutes to reach an altitude of about 200,000 feet (38 miles) at burnout

SECOND STAGE Operates about 6 minutes from an altitude of about 200,000 feet to an altitude of 606,000 feet (114.5 miles)

THIRD STAGE —Operates about 2.75 minutes to an altitude of about 608,000

feet (115 miles) before second firing and 5.2 minutes to translunar injection

PAYLOAD —250,000 lb. into a 115 statute-mile orbit

I SATURN V NEWS REFERENCE

SATURN V NEWS REFERENCE

SATURN V NEWS REFERENCE