The Feeling of Flying

On the one hand is the idea. On the other, the reality.

Sometimes the latter fails to live up to the former. The reality of experience doesn’t always measure up to the way we picture it. So often in the case of space exploration, however, it is the idea that utterly fails to do justice to the reality.

For example, countless descriptions of the Space Shuttle document its specifications to the smallest of details. But knowing that the vehicle stands 184 feet tall and weighs 4.5 million pounds fueled for launch doesn’t begin to capture the experience of standing at the base of the vehicle as it towers on the launchpad.

“I wasn’t intimidated by it,” recalled astronaut Mike Lounge of the first time he saw the fully stacked vehicle. “Well, that’s not exactly true. The first time we went down to the Cape on our class tour, my reaction when seeing the pad, at seeing the orbiter and all that, is, ‘My God, this stuff’s too big. It can’t possibly fly.’ I think that’s a common reaction. I knew how big it was, but it’s different when you actually see it and you’re walking underneath the orbiter and all this stuff. But having gotten over that, it was kind of fun to be there with the hardware. Everyone enjoys hardware over simulations and paper.”

If the vehicle itself transcends expectations, NASA’s astronauts found that so, too, did the experience of actually flying aboard the Space Shuttle. Those expectations would have gradually mounted during months of mission preparation and training, but the experience would truly begin in earnest when the highly anticipated launch day arrived.

For an astronaut, that first launch day comes only after years with NASA. Since 1978 astronauts have first been selected as “candidates” and must complete an initial orientation period, replete with training in almost every aspect of the agency’s work, before becoming official members of the corps.

Then there are ground assignments supporting the program in ways that have nothing to do with getting ready for a mission.

And then, finally, years after selection, there’s the crew assignment. Followed by more training and preparation. There’s practice on the general things that will occur during the mission, like launch and landing, to make sure everyone is ready. There’s practice for all the things that theoretically could occur during the mission but shouldn’t, the potential anomalies and malfunctions the astronauts have to be ready for. There’s training on mission-specific tasks, the unique things each astronaut will have to do on this particular flight. There’s preparation, working with the scientists or engineers or companies or countries responsible for the mission payloads to make sure that those, too, are ready to go. So when launch day finally arrives, it’s a long-awaited culmination of a great deal of time and effort.

Astronaut Terry Hart recalled his launch day at NASA’s Kennedy Space Center (ksc) in Florida, home of the Space Shuttle’s launch complexes: “It was a clear, cool morning there and we went through the whole morning, going through the traditions of having breakfast together, and there was always a cake there for the crew before they go out. And then going into the van and realizing that all the Mercury guys went on that van, it was really a very heady experience.”

For three-time shuttle veteran David Leestma, that experience of waving to people while walking out to the Astrovan, suited up and ready for launch, was a memorable moment. “We always called that the last walk on Earth,” Leestma said. “There’s always crowds of people there to see you in case you never come back or something. It was one of those little bits of kind of gruesome humor. And then you go out to the launchpad, and you’ve been through this. You’ve been there many times before, because you train in the orbiter a few times and you have countdown demonstration tests and things. And this time you get to the pad and there’s nobody there. You go, ‘Ooh.’ And the vehicle is steaming and creaking and groaning and you go, ‘This is for real.’”

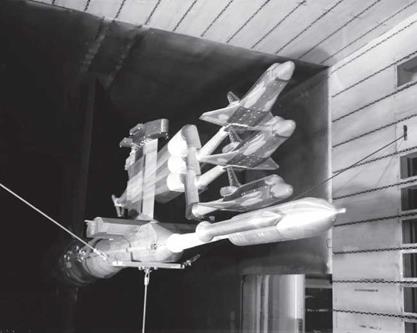

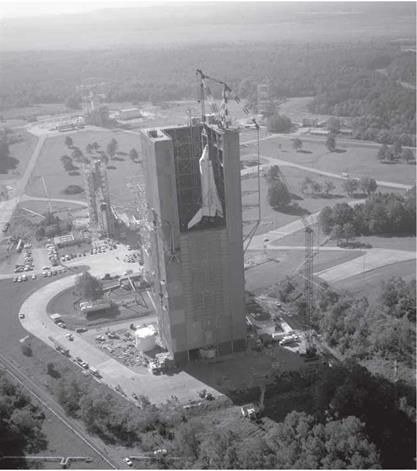

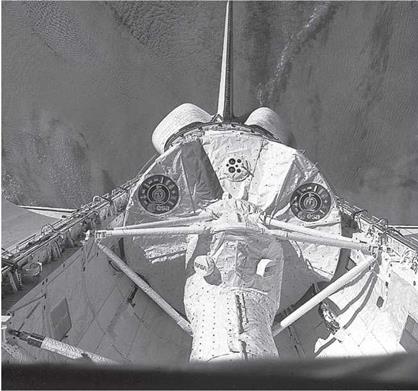

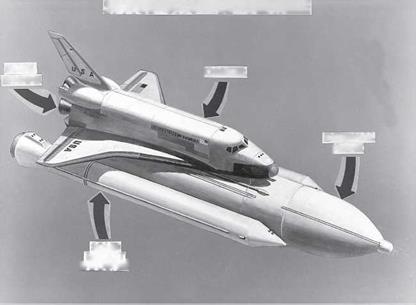

On the launchpad, the Space Shuttle is positioned vertically, its three major components having been stacked together in the enormous Vehicle Assembly Building at Kennedy Space Center before having been rolled out—slowly—to the launchpad atop a huge crawler. Standing tallest is the orange-brown external tank. The external tank has no engines of its own but carries the liquid fuel for the launch in two separate tanks, one containing liquid oxygen and the other holding liquid hydrogen. The tanks are supercooled to maintain the fuels at the cryogenic temperatures needed to keep them in liquid state—below minus four hundred degrees Fahrenheit in the case of the hydrogen. Fully fueled, the external tank weighs about 1.7 million pounds.

On either side of the external tank is a slender, white solid rocket booster (srb), the two of which together provide the bulk of the power for the first two minutes of the launch. Once ignited, they together provide 6.2 million pounds of thrust. Their name comes from the fact that they carry their propellant—consisting largely of aluminum mixed with an oxidizer to cause it to burn—in a solid, rubbery form.

And then there’s the orbital spacecraft itself, the winged, white-and-black orbiter. Near the nose of the orbiter is the crew cabin, where the astronauts fly the vehicle and live during their mission. Farther aft is the payload bay, with its two large doors. And in the rear are the three Space Shuttle main engines, fueled by the external tank, each capable of generating a thrust of almost half a million pounds.

By launch day, the launch complex’s servicing structure has been rotated back, revealing the orbiter. The shuttle is ready for its crew. The entrance to the orbiter is through a hatch in the side of the crew cabin, near the top of the vertically stacked vehicle, almost 150 feet above the launchpad.

Leestma recalled the process of boarding the vehicle via an elevator in the launch tower and a gantry arm near the top of the structure:

As usual, people don’t say much in elevators. It’s true whether you’re in a hotel or on the launchpad. You kind of watch the numbers tick by, and instead offloors, they do everything in feet in the elevators, so you’re so many feet above sea level. And then across the gantry, and when you walk across the gantry you’re looking down into the flame trench. And you’ve been there before, but the obvious thing that’s striking you is that this is for real, we’re going to go. At least you hope we’re going to go today. . .. You get up to the White Room, the access arm, and there’s only two, maybe three people there and that’s it. There’s nobody else on the pad and everybody’s blocked off for four or five miles away. This is for real. And it’s groaning and moaning and you know that it’s going to launch, and it’s fueled and ready to go. It’s a big bomb there, sitting on the pad. And you hope that all the fire goes down and you go up, and let’s go, let’s get on it with it. It’s great…. We got strapped in, and again, the guys strapping us in were a lot of the same guys that strapped in Al Shepard on his flight [to become the first American in space during Project Mercury]. So it was a very heady time. . . . You get in and you just cant wait for it to happen.

Astronaut Jerry Ross, who was the first to launch into space seven times, said journeying out to the launchpad when the vehicle is fully fueled and ready to go is quite different than going out there any other time, not only because of the reality of the situation, but because the shuttle itself is different.

The vehicle really does give you this sense that it’s an animal that’s awake and just ready to go do something. When you go out there and the vehicle’s not fueled, it’s not hissing, it’s not boiling off vapors, it’s not making noises that you don’t hear, that you do hear when it’s fueled. And there’s the tremendous amount of anticipation. My first flight was the twenty-third flight of the shuttle, and I had listened to every crew come back, and I took very detailed notes of their debriefings, which were quite exhaustive early on. I listened to everything they said, and they would give us a very detailed description of what it was like, what the sensations were of launch. I put that into my databank, and I would daydream about that when I’d go running or work out at the gym or something like that. I knew it was going to be a pretty exciting ride.

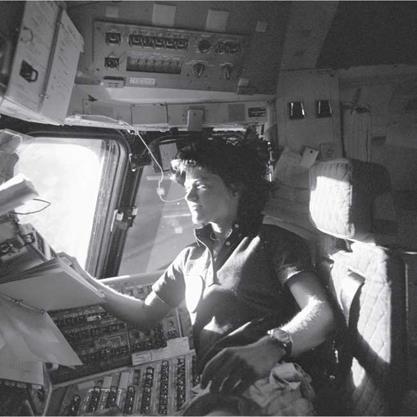

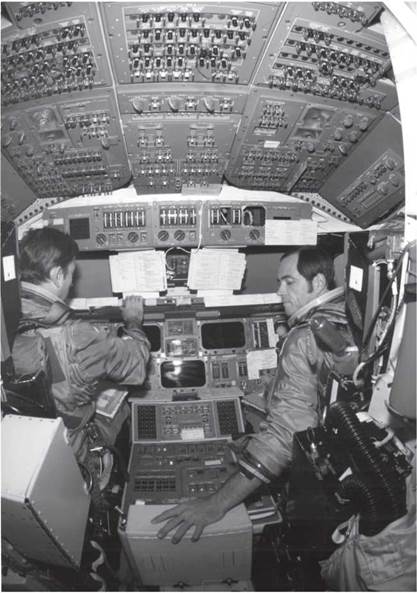

The crew cabin of the shuttle has two levels. The “upper” deck is the flight deck, where the commander and pilot sit at the vehicle’s controls, with a bank of large windows in front of them. The flight deck has room for up to two more astronauts to sit during launch, and behind them are windows looking into the payload bay and the controls for the orbiter’s robotic arm.

Below the flight deck is the mid-deck, where the rest of the crew sits during launch. Once in orbit, the mid-deck serves as the primary living area for the crew, with storage lockers and the orbiter’s kitchen and bathroom and main sleeping area. The mid-deck also provides access to the vehicle’s payload bay. During launch, the mid-deck has very limited visibility, and the astronauts sitting there depend largely on word from the flight deck and the very obvious physical sensations of launch to know what’s going on during ascent.

Prior to launch, once the crew members have boarded the orbiter and been strapped into their seats, the waiting begins. Traditionally, the astro-

|

nauts board about three hours before the scheduled launch time, lying on their backs in their chairs until launch.

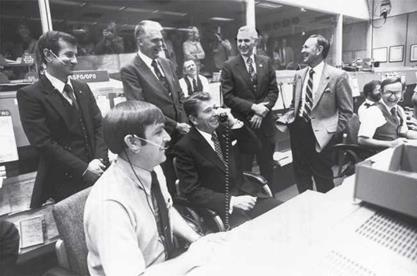

Very often, this is as far as things get. Any number of issues, from unacceptable weather conditions to a technical glitch with the vehicle and more, can result in the launch being scrubbed and pushed back. In those cases, the astronauts are helped out of the vehicle, and work begins to prepare for the next launch attempt. “Probably one of the most frustrating things is when you get near your takeoff time, your launch time, and then you know there’s a problem, and you go, ‘Please solve it. We don’t want to wait here. Get us off the pad,’” noted Leestma. “The last people you want to have to make the real technical decision whether you go or not is the crew, because they’re always, ‘Go.’ ‘Yeah, we’ll be fine. Let’s go.’ That’s why you’ve got a whole team of folks in the launch control room doing that.”

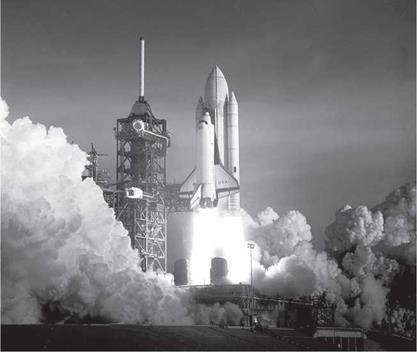

But on other occasions, the weather does what it’s supposed to, the vehicle is operating properly, any number of other factors come together as they should, and launch preparations continue to proceed. Finally, as launch nears, the Space Shuttle main engines “gimbal,” or tilt, to test that they will move properly, and at five seconds before launch they are ignited to make sure all three engines are functioning properly. The vehicle continues to sit on the pad, but the firing of the engines causes it to pitch slightly. It then rocks slightly back, a process called the “twang,” and when the stack is vertical again, at T minus zero, a spark at the top of the fuel casing of the solid rocket boosters ignites the propellant. With more than seven and a half million pounds of thrust pushing the Space Shuttle upward, it begins to move.

Shuttle pilot and commander Fred Gregory recalled the feeling of the main engines first firing, describing it as almost a nonevent. “You could hear it; you were aware of it. It sounded like some kind of an electric motor at some distance, but you looked out the window and you saw the launch tower there and the launch tower moved back. At least that’s what you thought, but then you realized the orbiter was moving forward and then back, and when it came back to vertical, that’s when those solids ignited and there was no doubt about it. You were going to go someplace really fast, and you just watched the tower kind of drop down below you.”

At the very beginning of the ascent, there’s the brilliant light of the engines, which no photograph or video can truly capture: a brightness that seems to puncture the sky. The brilliance of the flames from the engine is dramatic during the day, and far more so when they light up the sky at night. Payload specialist astronaut Charlie Walker recalled the experience of launching on the Space Shuttle in the dark:

At night, you look outside, and this launchpad is a blue gray from the xenon light reflections bouncing off of it, with a completely black background behind it. All of a sudden the launchpad brightens up with the solid rockets igniting. The launchpad brightens up to a yellow gray, but then the whole background, suddenly there’s like a sunrise that’s happened over Florida. You can see the Florida landscape for miles back that way. Sure, the sky is still black, but suddenly Florida has been illuminated by a new sunrise. I can see the Florida countryside, and it’s a yellow, white-yellow-orange color, the coloration of the brilliant, hot flame from the solid rocket boosters.

Like Gregory, Jerry Ross recalled that, while he was aware when the main engines first ignited, things didn’t really get exciting until the solid rocket boosters fired.

As the shuttle’s main engines came up, you could really feel the vibrations starting in the orbiter, but when the solid rocket motors hit, when they ignite, it’s somebody taking a baseball bat and swinging it pretty smartly and hitting the back of your seat, because it’s a real “bam!" And the vibration and noise is pretty impressive. The acceleration level is not that high at that point, but there is that tremendous jolt as the solid rocket motors ignite, and you’re off I’ll never forget the vibrations of the solid rocket motors. As we accelerated in the first thirty seconds or so, the wind noise on the outside ofthe vehicle just became really intense, like it was just screaming. It was screeching on the outside. I was already thinking about “what am I doing here" before then, but [it was] just a sheer, incredible experience ofthe energy.

In many ways the flight deck, with its large windows, is the superior seating for experiencing the launch. In one way, however, the mid-deck has the advantage. Since the pilot and commander are busy with the tasks of making sure the vehicle is operating properly during ascent, they don’t have the luxury of stopping to really take in the experience of the launch. While the astronauts on the mid-deck don’t have the same view as those on the flight deck, they have the freedom to focus more on the sensations. Hart, for example, recalled being able, as a mission specialist, to really enjoy the experience.

You talk a lot [to other astronauts about what launch is like], obviously, and you see a lot of pictures, and you think about it a lot, so you think you’re pretty well prepared and you probably wont have too many surprises, but I had a couple of surprises. The shake, rattle, and roll for the first two minutes, that was about what I thought, maybe even a little bit less than what I thought it would be, because the solid rockets kind of have a “whoof-whoof" [rumble]. You don’t really hear it; you more feel it. It’s like a very low-frequency rumble, and just a tremendous sense of power as you lift off and all.

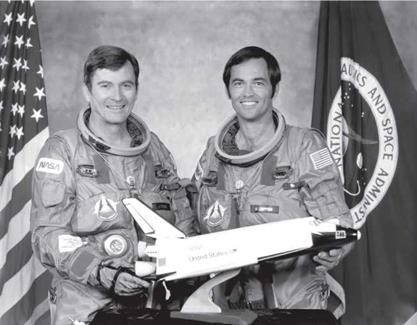

Another part of the experience that simply cannot be replicated on the ground is the pressure of the g-forces during ascent, according to sts-6 commander P. J. Weitz: “The value of our simulators ends when those engines light and you lift off. They try to fake you out a little bit by tipping the Shuttle Orbiter Simulator and that, but it doesn’t compare with three shuttle main engines and two solids going. As I tell people, I said, ‘You know you’re on your way and you’re going somewhere and you hope they keep pointed in the right direction, because it’s an awesome feeling.’”

Weitz compared the launch of the Space Shuttle to the launch of a Saturn IB, which he took into space on the first Skylab mission. The Saturn, he said, produced about half again as much acceleration force as the shuttle’s three gs, and the force was felt in somewhat different ways on the two vehicles. In the Saturn, the thrust was “actual,” or directly in line with the vehicle, so the crew was pressed directly back into the couches. With the shuttle, on the other hand, because of the way the orbiter is stacked on the external tank, the thrust from the main engines is offset from the vehicle’s center of gravity, meaning that the crew members aboard felt the pressure pushing them not only into the back but also into the bottom of their seats.

After clearing the launchpad, the shuttle begins to roll so that the orbit – er is below the external tank, to better allow its engines to offset the tank’s weight. Around one minute into flight, the shuttle encounters “Max Q,” the period in which the increasing velocity of the vehicle produces the maximum amount of pressure on the shuttle before the decreasing resistance of the atmosphere reduces that pressure. To reduce the strains of the pressure of Max Q, the vehicle throttles down its engines and then, seconds later, past the point of maximum pressure, throttles back up.

Just over two minutes into the launch, the solid rocket boosters separate from the vehicle, and the orbiter and external tank continue toward orbit. The solids deploy parachutes and land in the ocean, where recovery ships locate them and bring them back for refurbishment and reuse.

“At the solid rocket motor separation. . . there was this brilliant orange flash, orangeish-yellow flash across the windscreen, and then the solid rocket motors are gone,” Ross recalled. “As the solid rocket motors tailed off, like at a minute forty-five or so, it almost felt like you had stopped accelerating, almost like you’d stopped going up. At that point we were already Mach 3-plus and well above most of the sensible atmosphere at that point, some twenty miles high or so. And at solid rocket motor jettison, then you’re at four times the speed of sound and twenty, twenty-five miles high.”

Hart also recalled the separation of the solid rockets as a memorable experience. For the first two minutes of ascent, the g-forces that the crew experiences have been building up, and then, at srb separation, they drop off dramatically.

Very quickly, then, the solid rockets taper off and separate, and that was the first surprise I had. . .. The sensation that you have at that point I wasn’t quite prepared for, because you go from two and a half gs back to about one and a half. Well, when you get used to two and a half, and it feels pretty good. You’re going somewhere, you know. When you go back to one and a half, [it] feels like about a half. So you don’t think like you’re accelerating as much as you should be to get going. And, of course, I had worked the main engine program anyway, so I was very familiar with what the engines could do or not do. And I think in the next minute, every five seconds I checked the main engines to make sure they were running, because I swear we only had two working, because it just didn’t feel like we had enough thrust to make it to orbit. But then gradually the external tank gets lighter, and as it does, of course, then, with the same thrust on engines, you begin to accelerate faster and faster. So after a couple of minutes I felt like, yes, I guess they’re all working.

Ross also had the experience of worrying that all main engines were not working when they actually were.

I literally had to look to see that the three main engines were still working, because it became so smooth, and it almost felt like you weren’t going anywhere;

you weren’t accelerating at all. . . . At one point I can remember looking back behind me out the overhead windows again. In artists’ renditions of the flames coming out of the three main engines, it’s a nice, uniform cone of fire back there and stuff. Not true. The fire was all over the place. It was not static. It was dancing. It was not uniform. And again you go, “Is this thing working okay?" You don’t know what to expect.

As the shuttle nears the end of its powered ascent, with the bulk of the atmospheric drag behind it, it begins to accelerate dramatically. “As we got up to about the seven-and-a-half-minute point, then, is when you get to the three gs of acceleration, and that’s a significant acceleration,” Ross said.

It feels like there’s somebody heavy sitting on your chest, and it makes it pretty hard to breathe. I mean, you kind of have to grunt to talk, and you’re just waiting for this three gs to go away. . . . You’re accelerating at 100 feet per second, which is basically like going from 0 to 70 miles per hour every second. So it’s pretty good. And then at the time that the computers sense the proper conditions, the main engines. . . shut off and you’re in zero g. And for me, the first flight, sitting in the back seat, I had the sensation of tumbling head over heels, a weird sensation. And it was the three-g transition, from three gs to zero gs…. But as soon as I got out of the seat, then I was okay.

The main engine cutoff, or meco, comes around eight and a half minutes into the launch, and shortly thereafter the external tank separates from the orbiter and reenters Earth’s atmosphere. As the only major component of the shuttle stack that isn’t reusable, the external tank burns up on reentry.

Gregory explained how he felt in that moment, when the main engines cut off and he was floating in the microgravity of space: “The first indication that this was not a simulation was when the main engines cut off and we went to zero g, and though [Steven] Hawley, I think, had been attributed with this comment, it was a common comment: ‘Is this space? Is this it? Is this real?’ And it was an amazing feeling. I’d never sensed anything like this before. So this sensation of zero g was like a moment on a roller coaster, when you go over the top and everything just floats.”

Hart described being surprised once in orbit, but unlike Ross and Gregory, not by the experience of zero g.

The zero g I was pretty well prepared for. As a fighter pilot and the experience at NASA in the zero-g trainer, you’re pretty familiar with what it feels like to be weightless. But what I wasn’t prepared for was the first look out the window. You don’t know what black is until you see space. I mean, I was startled with just how black it was. You don’t see stars. You could barely see the moon; it’s because there’s so much light coming off the Earth and off the tiles of the shuttle, that there’s a tremendous ambient light from all those sources, so your eyes are constricted greatly. And then because of that constriction, when you look into space you can’t see the stars or anything. I mean, it’s like really black. It’s palpable. You think you can almost reach out and touch it. I don’t know quite how to describe it. It’s sort of like black velvet, but it’s just totally palpable. . . . I guess I knew that I wouldn’t be able to see the stars when we were on the day side of the Earth. But still, when you look out there and see the blackness, it really was striking to me.

While most astronauts report experiencing an overwhelming excitement or elation upon their first arrival in orbit, Fred Gregory jokingly recalled an odd bit of disappointment stemming from his first ascent. “Since we had trained constantly for failures, I anticipated failures and was somewhat disappointed that there were no failures, because I knew that any failure that occurred, I could handle. It was where I slipped back into an ego thing. I anticipated failures that I would correct and then the newspaper would say, ‘Gregory Saves Shuttle,’ but heck, none of that happened. It just went uphill, just as sweet as advertised.”

As pilot, Gregory said his main job once the vehicle was on orbit was to make sure it was working properly. Since there were no major issues, he found that he had frequent opportunities for looking out the window. Said Gregory,

You immediately realize that you are either a dirt person or a space person. I ended up being a space person, looking out in space. It was a high-inclination orbit, so we went very low in the southern hemisphere, and I saw a lot of star formations that I had only heard about before and never seen before. I also saw aurora australis, which is the southern lights. I was absolutely fascinated by that. But if you were an Earth person, or dirt person, you were amazed at how quickly you crossed the ground; how, with great regularity, every forty-five min – utesyou’d either have daylight or dark; how quickly that occurred, about seven miles per second; how quickly you crossed the Atlantic Ocean.

Although he was a self-described “space person,” Gregory still enjoyed occasionally gazing down on Earth below him and found it a fascinating experience.

The sensation that I got initially was that from space you cant see discernible borders and you begin to question why people don’t like each other, because it looked like just one big neighborhood down there. The longer I was there, the greater my “a citizen of" changed. The first couple of days DC was where I concentrated all my views, and I was a citizen of Washington DC. I was confused because I thought everybody loved DC, but [Bob] Overmyer was from Cleveland [Ohio], and Don Lind was Salt Lake [City, Utah], and Norm [Thagard] was Jacksonville, Florida, and Lodewijk [van den Berg] was the Netherlands, and Taylor Wang was Shanghai [China], so each had their own little location for the first couple of days. After two days, I was from America, looked at America as our home. Taylor, China. Europe for Lodewijk. And after five or six days, the whole world became our home.

During his flight, Gregory developed a sense not only of Earth as a whole being his home but of just how interconnected the global community truly

is, and the extent to which all people are sharing one planet.

You could see this kind of sense of ownership and awareness. We had noticed with interest the fires in Brazil and South Africa and the pollution that came from Eastern Europe, but it was only with interest. After five or six days, then it was of concern, because you could see how the particulates from the smokestacks in Eastern Europe, how that circled the Earth and how this localized activity had a great effect. When you looked down at South Africa and South America, you became very sensitized to deforestation and what the results of it was with the runoff how it affected the ecology. Then you’d have to back up and say, well, this is not an intentional thing to destroy; this is something that they use coke as part of their process, and in order to get coke, you’ve got to burn. So you began to look at things from different points of view, and it was a fascinating experience. So that was the science that I was engaged in, but never anticipated

it. And it was a discovery for me, so as each of these other great scientists who were with us discovered something that they had never anticipated, I also did, and I think the whole crew had.

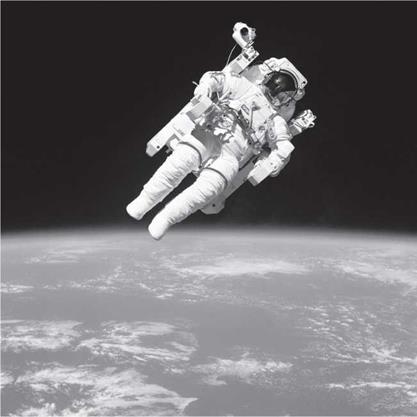

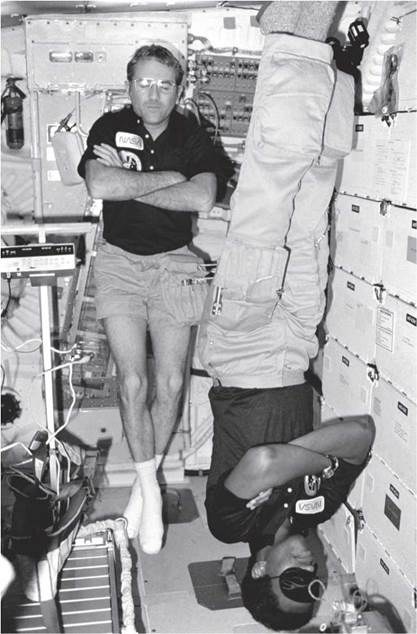

In order to live and work in space during their missions, astronauts must learn to adapt to the microgravity environment, and that adaptation varies from individual to individual. Part of the adaptation is simply learning to get around; moving through the vehicle without gravity is an entirely different process than walking through it on the ground. For many other astronauts, adaptation involves a physical unease as the vestibular system adjusts to the lack of the orienting influence of gravity.

While it may take different amounts of time for astronauts to be back to 100 percent, most are at least functioning fairly quickly, Gregory said.

Whatever the adaptation was, within a day, everybody had adapted to it and so it was just a matter of working on all the programs and projects of the projects that you had. The body very quickly adapted to this new environment, and it began to change. You could sense it when you were on orbit. You learned that your physical attitude in relation to things that looked familiar to you, like walls and floors and things like that, didn’t count anymore, and you translated [from thinking about] floors and ceilings and walls to [thinking]your head is always up and your feet are always down. That was a subconscious change in your response; it was an adjustment that occurred up there. You also learned that you didn’t go fast, that you could get from one place to the other quickly, but you didn’t have to do it in a speedy way. You always knew that when you started, you had to have a destination, and you had to have something that you could grab onto when you got there. But, again, this was a transition that occurred, perhaps subtly, but over a very short period of time. I can remember we all kind of joked up there that we had become space things, and we were no longer Earth things anymore. The first couple of days, a lot of bloated faces, because there was no gravity settling of the liquids. But after a couple of days, you lost that liquid in your body, and you looked quite normal. So it was a fascinating experience. I think it was surprising to us how quickly we adapted to this microgravity environment.

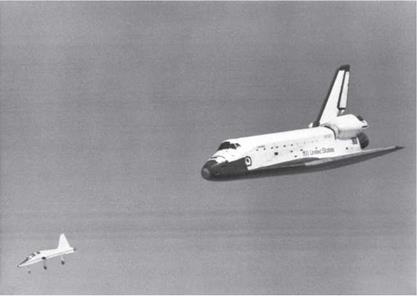

With launch complete and their bodies adapting to space, the astronauts would go about their mission, spending days on any variety of different tasks carried out by shuttle crews during the early years of the program. Finally, though, the time would come to return to Earth. The orbiter would turn backward relative to its velocity and fire its engines to slow itself down, before rotating back to begin its descent.

|

The experiences of launch and landing are very different, Gregory said. Ascent is relatively quick and marked by rapid changes in the g-forces experienced by the crew. Landing, on the other hand, is far more gradual.

On reentry, it is entirely different. Though it takes eight and a half minutes to get up to orbit, it takes more than an hour to reenter, and it feels very similar to an airplane ride that most people have been on. You get an excellent view of the Earth. If it’s night when you reenter the atmosphere, then you see a kind of a rolling plasma over the windows. . . . But other than the onset of g that occurs at less than 400,000 feet above the Earth, it is like flying in an airplane. The sensations that you have are very similar to a normal domestic airplane flight. You’re going pretty fast, but you are not aware ofit because you’re so high.

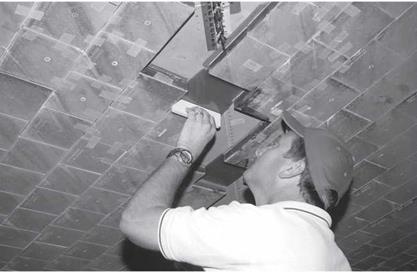

It’s an amazing vehicle, because you always know where you are in altitude and distance from your runway. You know you have a certain amount of energy and velocity, and so you also know what velocity you’re supposed to land, and you can watch this amazing electric vehicle calculate and then compensate and adjust as necessary to put you in a good position to land. We normally allow the automatic system to execute all the maneuvers for ascent and for reentry, but as we proceed through Mach 1, slowing down for landing, it is customary for the pilot, the commander, to take command of the orbiter and actually fly it in, using the typical airplane controls. But, you know, as I look at it, the ascent is very dramatic. It’s very fast, a lot of movement, but quick. The entry is more civilized but exposes the orbiter to actually a greater danger than the ascent, as far as the influence of the atmosphere on the orbiter. The temperatures on the outside of the orbiter really get hot on reentry, and that’s not the case on ascent.

Astronaut Charlie Bolden flew on the Space Shuttle four times, two of those as commander, and became nasa administrator in 2009. A former naval aviator, Bolden described landing the Space Shuttle as a unique experience. “The entry and landing is unlike almost anything you ever experience in any other kind of aerospace machine because it’s relatively gentle,” Bolden said.

In terms of g-forces and stuff like that, it’s very docile. Unless you do something wrong, you don’t even get up to two gs during the reentry, the entire time of the reentry. When you bank to land, you come overhead the landing site, and then you bank the vehicle and you just come down like a corkscrew. . . . It feels like you’ve got gorillas sitting on your shoulder because you’ve been weightless for x number of days. And so it’s just a really different feeling. You have to hold your head up because you’ve got this big old heavy helmet on and it probably weighs [a few]pounds, but it feels like it weighs a hundred. It takes a little bit ofenergy to get your hands up offthe console, because once you start feeling gravity again, your hands just kind ofgo down and they want to stay there; everything does. So the two pilots on board are doing a lot of isometric exercises all the way down.

Even when an astronaut lands the shuttle for the first time after a mission, Bolden said, it already feels very familiar because of all the training in preparation for the missions. “It’s like you’ve done it all your life, because you have,” Bolden said.

You’ve done it thousands of time by now in the shuttle training aircraft for real, and you’ve done it probably tens of thousands of times in the simulator. So it doesn’t look abnormal at all; it’s just something that you ’re accustomed to. When you touch down, if you do it right, again, you hardly know you touched down. As big as the orbiter is, the way that we land it is we just get it into an extremely shallow approach to the landing, and so it just kind of rolls out on the runway, and if you do it right, you all of a sudden notice that things are starting to slow down real quick and you’re hearing this rumble because the vehicle’s rolling down the runway on this grooved runway. So you know you’re down, put the nose down and step on the brakes and stop. That’s it. And then you go, “Holy G. I wish it hadn’t been over so quick. " I don’t think it makes a difference how long or how short you’ve been there, it’s over too quick. You’re ready to come home, but once you get back, you say, “Boy, I wish I had had a few more days," or something like that. And for me, my last two, being the commander and actually being the guy that had the opportunity to fly it to touchdown, was thrilling.

Once the landing is completed and the orbiter is safely back on Earth, the crew begins the process of reacclimating to the planet’s strong gravity after days of feeling weightless. Charlie Walker, the first commercial payload specialist, who flew on the shuttle three times, recalled waiting in the orbiter at the end of the mission.

The guys on the flight deck were going through the closeout procedures. Ground crews were closing in. We sat unstrapped, but we would sit in our seats for another ten, fifteen minutes as the ramp was brought up, the sniffers checked for ammonia leaks and/or hypergolic propellant leaks, found none, and put the stairway [up to the hatch], and opened the hatch. All that time, all of us are beginning to get our land legs back, unbuckle, start to try to stand up. “Ah, this doesn’t feel good yet. Wait a little bit longer." So you kind of move around, move your arms first, your feet first, your legs first, then stand up, make sure you’ve got your balance back. The balance is the one thing that you just don’t have. Again, the brain hasn’t been utilizing the inner ear or senses of where the pressure is on the bottom of feet, for instance, to use as cues to balance itself against gravity. It hasn’t done that for a week. So you’ve got to carefully start through all that and consciously think about balance and consciously think about standing up, and we very consciously do that, because the last thing you want to do, in front ofhundreds ofmil – lions of people watching on television, is to fall down the ramp leaving the orbiter.

Normally, on Earth, the body works hard to make sure the brain is adequately provided with blood. From a circulatory perspective, the brain, the part of the body that most needs blood, is located inconveniently at the top of the body, so the heart has to pump blood against gravity to get it there. In orbit, on the other hand, blood flows much more easily to the head, but it doesn’t fill the legs the same way without gravity pulling blood into them. Astronauts develop bloated heads and “chicken legs” due to the body’s confusion over how to distribute blood without gravity. The body takes the increased fluid flow to the head as a sign that it is overly hydrated and begins to shed what it sees as excess fluid. After the return to Earth, fluid redistributes again, which can cause problems.

“The body adapts by, among other things, letting go of a lot of fluid, about a liter of liquid, which makes you clinically dehydrated while you’re in space, except the whole condition of the body is different up there, so you’re really not dehydrated in that environment,” Walker said.

But if you come back without replacing that liter of fluid, then you are dehydrated. You try to stand up with not so much fluid to go to the head, and so you literally could pass out. Nobody did that, but I know I had sensations of lightheadedness for the first few minutes until I just literally worked at getting my balance back and focusing attention, and the body was adapting all that time, too. But leaving the spacecraft, I was holding onto the handrail as I went down the stairway. Got to the bottom of the stairs, and I was walking like a duck, because I was trying to keep my balance.

Once they’ve adjusted enough to walk, crew members board the Astrovan, which takes them to the medical quarters for postflight medical exams and a shower. Walker said it felt good to take a shower after days without one.

Every sensation for the next many hours, normal sensations of water running over you in a shower, [felt] strange. Because again, here this water’s hittingyou, and it’s running down. And hours later, I found that I still could at any moment just think about the sensations in my body, and it was odd to feel this pull down toward the surface of the Earth, to be stuck to the surface of the Earth. [When I flew], it was still fairly new to hear comics or some wag note that this or that “sucks." [Coming back] the astronauts were saying, “Well, the Earth really does suck." So it keeps me drawn right down to the surface. Gravity is really real, and it stands out in your mind to, again, the freedom of weightlessness when you’ve had that opportunity. And that was just very much on my mind. I remember even a day, two days later, probably like a day later at a meal, I was sitting down, and I could not easily figure out whether I should sit back against the back of the seat or lean forward, because my head was telling me I was leaning forward at an angle, and, in fact, I was sitting almost straight up and down. So the inner ear is still adapting to its own senses and the body’s cues to orient itself and still doesn’t have itself figured out completely yet.

Even if an astronaut spends only a few days in orbit after a lifetime of living in the gravity of Earth, habits developed during those few days of weightlessness can persist for a little while after the mission. “I also remember waking up the next morning back here in Houston, waking up and going into the bathroom and wanting to brush my teeth, and I did that, and I remember letting go of the toothbrush, and it fell to the sink top, and I probably laughed,” Walker noted.

Then I pick up the cup of water to rinse my mouth out, and then proceed to let that cup go again. It’s like, again, you’re still thinking weightlessness, and you’re really used to that. Finding the situation where gravity is ever-present is just such an interesting experience, because now, again, you’ve had that contrast of a different place where that wasn’t part of the environment and you note when you get back how remarkable and how constraining gravity is. . . . We’ve all grown up for some decades, before we go fly in space, in gravity, and it’s just natural. Except it is programmed in, and that programming is submerged with new habits that you gained to work in weightlessness, and you have to pull that programming back, or the brain does, and it does so at different rates, I think. So within tens of minutes, you can walk comfortably. You may look a little odd, because you’re not walking as expertly as you had done for twenty, thirty, forty years before. It takes a few more hours, maybe a couple hours to do that. But you can walk, so balance comes back pretty darn quickly. But it’s probably the nonautomatic stuff like I’ve remarked about just automatically leaving a glass hanging in the air, thinking it’s going to stay there. You just get into habits there that are semiconscious, and it takes a little while for the body and the brain to let go of that and to relearn that, no, I’m stuck here again to the surface of the Earth. I’ve got to put the glass right up here on the table directly.

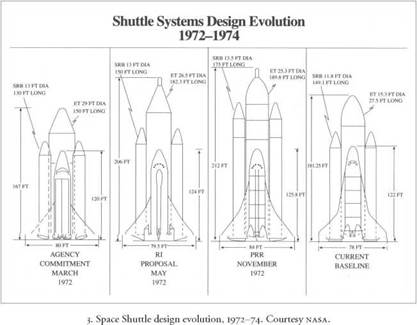

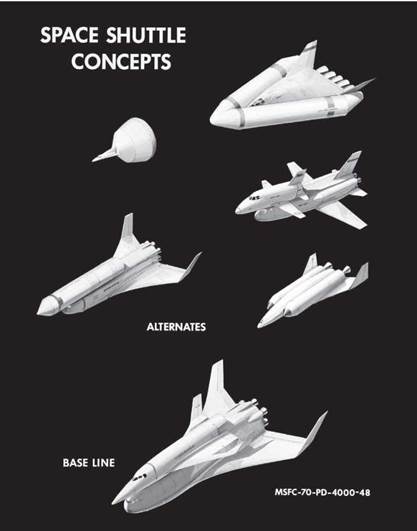

SPACE SHUTTLE VEHICLE

SPACE SHUTTLE VEHICLE