PILOTS

|

T |

he X-15 program was a success, thanks in no small part to the men who flew the airplane. Each of the X-15 test flights was an example of intense man-machine interaction, and each of the twelve pilots who flew the X-15 were as finely tuned and technologically sophisticated as the machine itself. They set speed and altitude records for a manned airplane that still stand today, and they pioneered new piloting techniques for hypersonic aircraft that were not only adapted for the Space Shuttle but will continue to be used for future manned hypersonic aircraft. The X-15 pilots were brave and professional, venturing into a totally unknown regime of flight, and they helped to write the book on manned hypersonic flight for the next generation.

he X-15 program was a success, thanks in no small part to the men who flew the airplane. Each of the X-15 test flights was an example of intense man-machine interaction, and each of the twelve pilots who flew the X-15 were as finely tuned and technologically sophisticated as the machine itself. They set speed and altitude records for a manned airplane that still stand today, and they pioneered new piloting techniques for hypersonic aircraft that were not only adapted for the Space Shuttle but will continue to be used for future manned hypersonic aircraft. The X-15 pilots were brave and professional, venturing into a totally unknown regime of flight, and they helped to write the book on manned hypersonic flight for the next generation.

![]()

|

|

All of the X-15 pilots at one time or another were members of the elite NASA Flight Research Center at Edwards Air Force Base. The flight research team was under the direction of Walter C. Williams, who managed a group that planned all the flights, determined what data to acquire, gave the pilots what they needed to obtain the data in an effective and safe manner, and determined how to react in emergencies. Williams and his team were in charge of the flight testing of all the X-airplanes through transonic and supersonic regimes leading up to the X-15, namely the X-1, X1A, D558-2, and the X-2. This center had started out as a small group of about 27 people in 1946 dealing with the X-1 and grew to about 500 at the time of the X-15. These people collectively:

1) Maintained the aircraft, housed, repaired, modified, and prepared the airplane for each flight.

2) Provided for each flight. This included ground crew efforts to ready the airplane, provide the instrumentation, assure the safety for the airplane, provide the chase aircraft and their pilots, and provide emergency gear like the fire trucks and helicopters, as well as the communication links.

3) Provided plans and procedures for each flight, including a detailed pilot checklist for the X-15 and the B-52 mother ship.

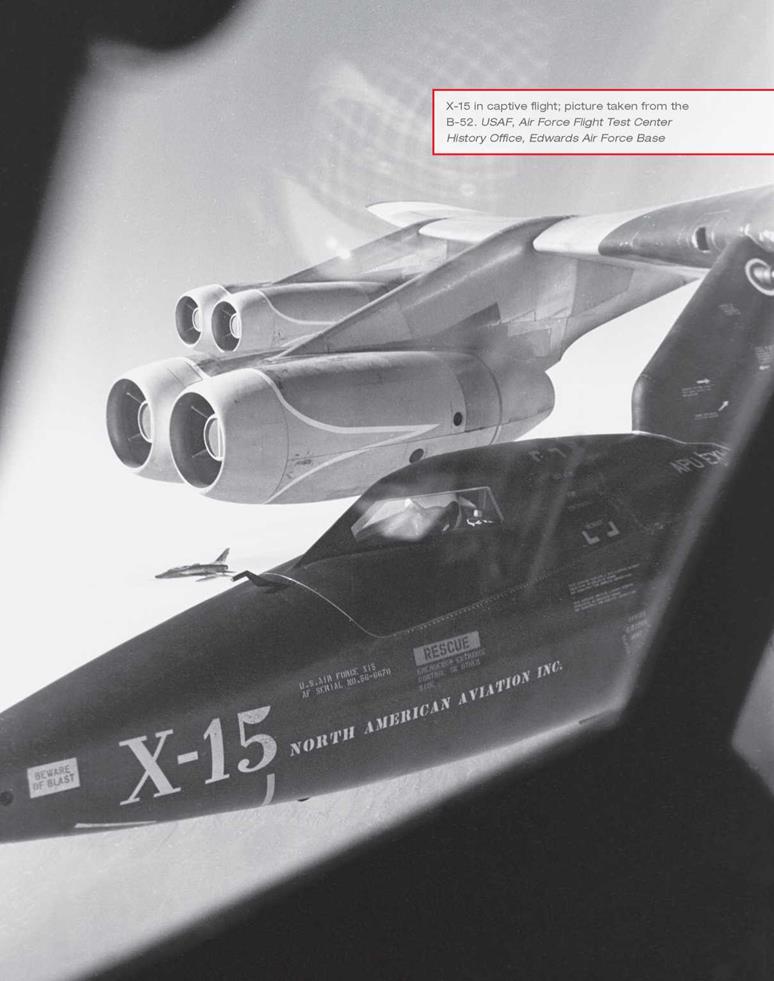

4) Provided a flight plan for the X-15 to obtain the requisite data. This sequence included the drop from the B-52, rocket firing and powered flight, climb and transition to level flight, unpowered flight to the speed and altitude required for the data, and finally return to base and landing.

5) Provided a simulation plan to train the pilot for obtaining the data in flight, alternate flight paths to the desired data points if the airplane was over or under the speeds and altitudes planned, and emergency response to various potential problems during the flight. The Flight

Research Center had a special flight simulator designed for the hypersonic regime.

6) Conducted the flights with all the equipment, chase pilots and planes, and communication lines to assist the X-15 pilot to assure safety and performance.

7) Reduced and evaluated the flight data, and utilized the results in future activities.

In September 1959, Walter Williams left the Flight Research Center for the first of many executive positions in the space program, beginning with director of operations for Project Mercury. He was replaced at the Flight Research Center by Paul F. Bikle, who continued Williams’s rigorous professional standards. All the important accomplishments of the X-15 program were performed under Bikle.

The first flight of the X-15 took place on June 8, 1959. Carried aloft under the wing of a B-52, the experimental vehicle was released with its pilot at an altitude of 37,550 feet. Unlike all subsequent X-15 flights, however, there was no roar of the rocket engine. Indeed, there were no propellants aboard; this was intended to be a gliding flight, pure and simple. Its purpose was as a familiarization flight, the first checkout of the flight characteristics of the airplane in its glide down to landing, the response to the control system, the stability of the airplane, the handling of the control forces by the pilot, the response rate of the airplane to the controls, and its motion at touchdown and landing.

Nevertheless, the X-15 reached a speed of Mach 0.79 on its maiden descent to the desert floor. Moreover, as with all the other 198 X-15 test flights, a problem occurred. The airplane began to pitch up and down, a longitudinal oscillation that rapidly increased in amplitude.

The pitch damper designed to avoid this oscillation was discovered to be inoperable. Fortunately, the X-15 touched down safely at the bottom of an

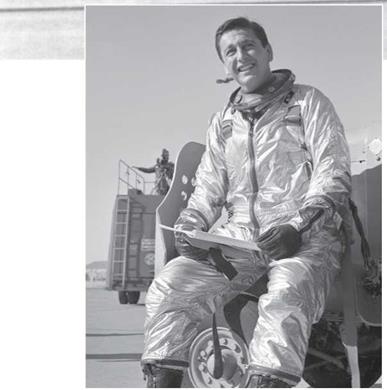

oscillation, suffering damage only to the landing gear. A. Scott Crossfield, the pilot who had the most influence of all the X-15 pilots on the design and flight performance of the airplane, performed the difficult maneuver. In all other aspects, the plane performed as anticipated by the designers.

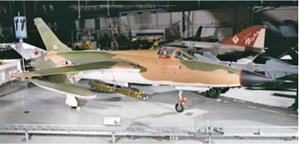

Powered by a rocket engine, and developed by Douglas for the U. S. Navy, the Douglas D-558-2 explored transonic and supersonic flight and the flight characteristics of swept-wing supersonic aircraft. Flight tested at the Muroc Flight Test Facility alongside other research aircraft such as the X-1, X-1A, and X-2, the D-558-2 was the Navy’s venture into the mysteries of supersonic flight. Controversy persists as to who deserves credit for the first Mach 2 flight. Crossfield reached Mach 2 in the D-558-2, but in a shallow dive. Just twenty-two days later, Chuck Yeager flew the Bell X-1A to Mach 2.44 in level flight.

Powered by a rocket engine, and developed by Douglas for the U. S. Navy, the Douglas D-558-2 explored transonic and supersonic flight and the flight characteristics of swept-wing supersonic aircraft. Flight tested at the Muroc Flight Test Facility alongside other research aircraft such as the X-1, X-1A, and X-2, the D-558-2 was the Navy’s venture into the mysteries of supersonic flight. Controversy persists as to who deserves credit for the first Mach 2 flight. Crossfield reached Mach 2 in the D-558-2, but in a shallow dive. Just twenty-two days later, Chuck Yeager flew the Bell X-1A to Mach 2.44 in level flight.

As a research airplane, the X-15 was also a useful platform for doing experiments at hypersonic speeds. Most important, the repeated and successful utility of this airplane over highly accelerated and decelerated flight from space to landing demonstrated that piloted aircraft are suitable for manned controlled return from space and for missions in the hypersonic regime.

As a research airplane, the X-15 was also a useful platform for doing experiments at hypersonic speeds. Most important, the repeated and successful utility of this airplane over highly accelerated and decelerated flight from space to landing demonstrated that piloted aircraft are suitable for manned controlled return from space and for missions in the hypersonic regime. Joe Walker flew the X-15 for his first time on March 25, 1960, during which he achieved Mach

Joe Walker flew the X-15 for his first time on March 25, 1960, during which he achieved Mach

program, commanded Gemini 8, and on July 20, 1969, as commander of Apollo 11, became the first human to walk on the moon. His next position in NASA was deputy associate administrator for aeronautics at NASA headquarters. He left NASA to become professor of aeronautics at the University of Cincinnati, after which he served on the boards of several corporations. Neil Armstrong passed away on August 25, 2012.

program, commanded Gemini 8, and on July 20, 1969, as commander of Apollo 11, became the first human to walk on the moon. His next position in NASA was deputy associate administrator for aeronautics at NASA headquarters. He left NASA to become professor of aeronautics at the University of Cincinnati, after which he served on the boards of several corporations. Neil Armstrong passed away on August 25, 2012.

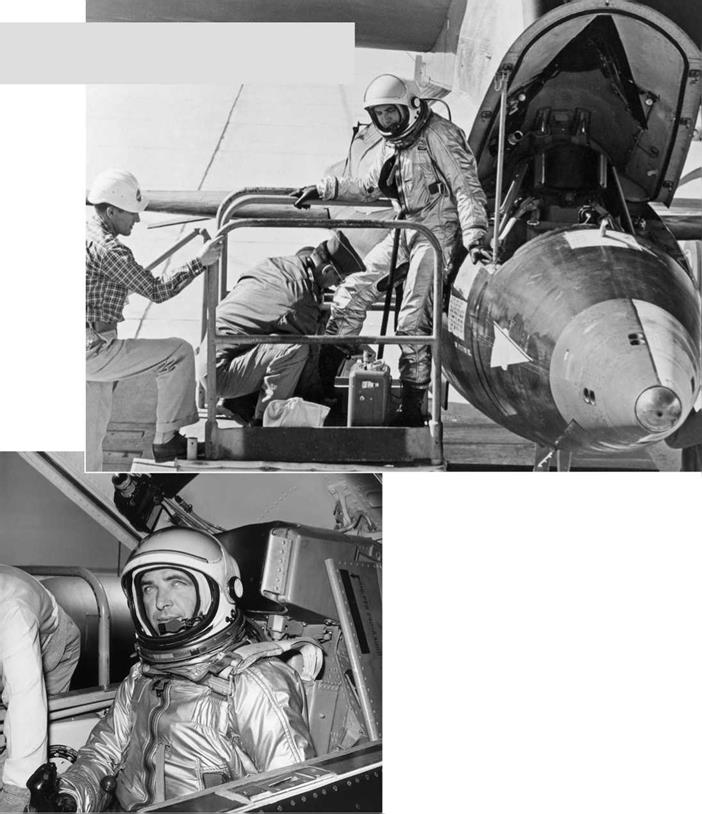

White entering the X-15 under the wing of the B-52. USAF, Air Force Flight Test Center History Office, Edwards Air Force Base

White entering the X-15 under the wing of the B-52. USAF, Air Force Flight Test Center History Office, Edwards Air Force Base

the research airplane program was “generally unsatisfactory” and had not contributed to the practical design of tactical aircraft. Johnson was the only dissenter; he later appended a minority opinion to the majority report. The spectacular success of the X-15 program and the volumes of hypersonic data it contributed to the design of the Space Shuttle later proved Johnson wrong. The X-15 program was launched.

the research airplane program was “generally unsatisfactory” and had not contributed to the practical design of tactical aircraft. Johnson was the only dissenter; he later appended a minority opinion to the majority report. The spectacular success of the X-15 program and the volumes of hypersonic data it contributed to the design of the Space Shuttle later proved Johnson wrong. The X-15 program was launched.

achieved Mach 2.02 and an altitude of 50,700 feet. As frequently occurred on the X-15 flights, there was a technical problem. In this case, the ventral chute did not open upon landing. McKay went on to achieve his highest Mach number of 5.65 on August 26, 1964, and his highest altitude of 295,600 feet on September 28, 1965.

achieved Mach 2.02 and an altitude of 50,700 feet. As frequently occurred on the X-15 flights, there was a technical problem. In this case, the ventral chute did not open upon landing. McKay went on to achieve his highest Mach number of 5.65 on August 26, 1964, and his highest altitude of 295,600 feet on September 28, 1965.