GROUND CONTROL PRESSURE SYSTEM

The ground control pressure system provides a direct ground pressure supply for some of the first stage pneumatically actuated valves. The valves are involved with propellant fill and drain and emergency engine shutdown system operations. Direct ground control assures a backup system in case of emergency and conserves the onboard nitrogen supply.

ONBOARD PURGE PRESSURE SYSTEM

The onboard purge pressure system consists of three high-pressure nitrogen storage bottles identical to the onboard control pressure storage bottle, an umbilical coupling and tubing for filling the bottles, and a manifold assembly and tubing for receiving and delivering the gas to the engine and calorimeter purge systems. These purge systems expel propellant leakage and are necessary from the time of loading throughout flight.

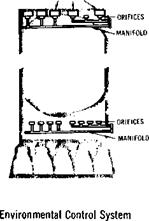

Environmental Control System

The environmental control system protects stage equipment from temperature extremes in both the forward skirt and thrust structure areas and provides a nitrogen purge during prefiring and firing

operations. INSTRUMENTATION

CANISTERS

|

|

Temperature-controlled air is provided by a ground air conditioning unit from approximately 14 hours before launch to approximately 6 hours before launch. At this time, gaseous nitrogen from an auxiliary nitrogen supply unit is introduced into the system and used to purge and condition the forward skirt and thrust structure areas until umbilical disconnect at launch.

A distribution manifold vents air and gaseous nitrogen through orifices into the thrust structure to maintain proper temperature. Air and nitrogen are supplied from the ground.

The system also distributes air and gaseous nitrogen to instrumentation canisters mounted in the forward skirt. Temperatures in the canisters are held to meet requirements of electrical equipment. From the canisters, the conditioning gas is vented into the forward skirt compartment.

Visual Instrumentation

Visual instrumentation, presently planned to be installed on two flight stages, is designed to monitor critical stage functions prior to and during static test and flight conditions.