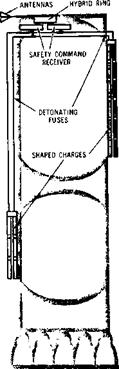

SEPARATION SYSTEM

A redundant initiation system actuates the separation of the first stage from the second stage. A command signal for arming and another for firing the initiation systems are programmed by the instrument unit computer.

After LOX depletion, the computer signals operate relays in the switch selector and sequence and control distributor to control the exploding bridgewire firing units. When armed, the firing units store a high voltage electrical charge. When fired, the electrical charge actuates the ordnance.

Two firing units are installed on the first stage for the eight retrorockets, and two are installed on the second stage for the separation ordnance.

Range Safety System

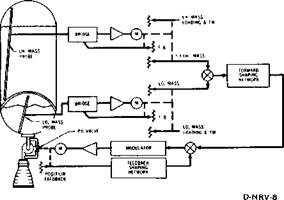

The function of the range safety system is to provide ground command with the capability of flight termination by shutting off the engines, blowing open the stage propellant tanks, and dispersing the fuel in event of a flight malfunction.

The system is redundant, consisting of two identical, independent systems, each made up of electronic and ordnance subsystems.

SATURN V NEWS

Flight termination by way of the range safety system goes into effect upon receipt of the proper radio frequency commands from the ground. A frequency-modulated RF signal transmitted from the ground range safety transmitter is received by the antennas and transmitted by way of a hybrid ring to the range safety command receiver. There, the signal is conditioned, demodulated, and decoded.

|

|

Range Safety System

The resulting signal simultaneously causes arming of the exploding bridgewire firing unit and shutdown of the stage engines. A second command signal transmitted by the ground range safety transmitter ignites the explosive train (detonating fuses and shaped charges) to blow open the stage propellant tanks.

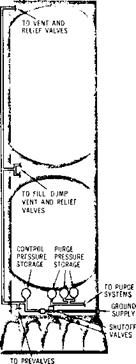

Control Pressure System

The control pressure system supplies pressurized gaseous nitrogen for the pneumatic actuation of propellant system valves and purging of various F-l engine systems.

The complete integrated system is made up of an onboard control pressure system, a ground control

2-14

REFERENCE

pressure system, and an onboard purge pressure system. The object in each system is to deliver an actuating or purge medium to an interfacing stage system.