At the October 1953 meeting of the Air Force Scientific Advisory Board (SAB) Aircraft Panel, Chairman Clark B. Millikan asked panel members for their ideas on future aircraft research and development programs. The panel decided that "the time was ripe" for another cooperative (USAF – NACA) research airplane project to further extend the frontiers of flight. Millikan released a statement declaring that the feasibility of an advanced manned research aircraft "should be looked into." The panel member from NACA Langley, Robert R. Gilruth, would later play an important role in coordinating a consensus between the SAB and the NACA.-1771

Contrary to Sanger’s wartime conclusions, by 1954 most experts within the NACA and industry agreed that hypersonic flight would not be possible without major advances in technology. In particular, the unprecedented problems of aerodynamic heating and high-temperature structures appeared to be a potential "barrier" to sustained hypersonic flight. Fortunately, the perceived successes enjoyed by the X-planes led to increased political and philosophical support for a more advanced research aircraft program. The most likely powerplant for the hypersonic research airplane was one of the large rocket engines from the missile programs. Most researchers now believed that manned hypersonic flight was feasible, but it would entail a great deal of research and development. Fortunately, at the time there was less emphasis than now on establishing operational requirements prior to conducting basic research, and, perhaps even more fortunately, there were no large manned space programs that would compete for funding. The time was finally right.1781

The hypersonic research program most likely originated during a meeting of the NACA Interlaboratory Research Airplane Projects Panel held in Washington, D. C., on 4-5 February 1954. The panel chair, Hartley A. Soule, had directed the NACA portion of the cooperative USAF-NACA research airplane program since 1946. In addition to Soule, the panel consisted of Lawrence A. Clousing from Ames, Charles J. Donlan from Langley, William A. Fleming from Lewis, Walter C. Williams from the HSFS, and Clotaire Wood from NACA Headquarters. Two items on the agenda led almost directly to the call for a new research airplane. The first was a discussion concerning Stone’s proposal to use a modified X-2, with the panel deciding that the aircraft was too small to provide meaningful hypersonic research. The second was a proposal to develop a new thin wing for the Douglas D-558-2. This precipitated a discussion on the "advisability of seeking a completely new research airplane and possible effects on such a proposal on requests for major changes to existing research airplanes." The panel concluded that the research utility of the D – 558-2 and X-2 was largely at an end, and instead recommended that NACA Headquarters request detailed goals and requirements for an entirely new vehicle from each of the research laboratories. This action was, in effect, the initial impetus for what became the X-15.1791

On 15 March 1954, Bob Gilruth sent Clark Millikan a letter emphasizing that the major part of the research and development effort over the next decade would be "to realize the speeds of the existing research airplanes with useful, reliable, and efficient aircraft under operational conditions" (i. e., developing Mach 2-3 combat aircraft). Gilruth further noted that a "well directed and sizeable effort will be required to solve a number of critical problems, by developing new materials, methods of structural cooling and insulation, new types of structures, and by obtaining a thorough understanding of the aerodynamics involved." Because many of the problems were not then well defined, "design studies should be started now for manned research aircraft which can explore many of these factors during high-speed flight" and which would be capable of "short excursions into the upper atmosphere to permit research on the problems of space flight and reentry." It was a surprising statement.1801

During the late 1940s and early 1950s, the overwhelming majority of researchers thought very little about manned space flight. Creating a supersonic airplane had proven difficult, and many researchers believed that hypersonic flight, if feasible at all, would probably be restricted to missiles. Manned space flight, with its "multiplicity of enormous technical problems" and "unanswered questions of safe return" would be "a 21st Century enterprise."1811

Within a few years, however, the thinking had changed. By 1954 a growing number of American researchers believed that hypersonic flight extending into space could be achieved much sooner, although very few of them had the foresight to see it coming by 1960. Around this time, the military became involved in supporting hypersonic research and development with a goal of creating new weapons systems. During 1952, for example, the Air Force began sponsoring Dornberger’s manned hypersonic boost-glide concept at Bell as part of Project BoMi.-82

BoMi (and subsequently RoBo) advanced the Sanger-Bredt boost-glide concept by developing, for the first time, a detailed thermal-protection concept. Non-load-bearing, flexible, metallic radiative heat shields ("shingles") and water-cooled, leading-edge structures protected the wings, while passive and active cooling systems controlled the cockpit temperature. NACA researchers, including the Brown study group, read the periodic progress reports of the Bell study-classified Secret by the Air Force-with great interest. Although most were skeptical, a few thought that the project just might work. The Air Force would also fund similar studies by other contractors, particularly Convair and, later, Boeing.-1831

In response to the recommendation of the Research Airplane Projects Panel, NACA Headquarters asked its field installations to explore the requirements for a possible hypersonic research aircraft. Based on the concerns of the 1952 Langley study group, as well as data from Bell regarding BoMi research, it was obvious that a primary goal of any new research airplane would be to provide information about high-temperature aerodynamics and structures. The missile manufacturers concurred.-1841

In response to NACA Headquarters’ request, all of the NACA laboratories set up small ad hoc study groups during March 1954. A comparison of the work of these different NACA groups is interesting because of their different approaches and findings. The Ames group concerned itself solely with suborbital long-range flight and ended up favoring a military-type air-breathing (rather than rocket-powered) aircraft in the Mach 4-5 range. The HSFS suggested a larger, higher – powered conventional configuration generally similar to the Bell X-1 or Douglas D-558-1 research airplanes. The staff at Lewis questioned the need for a piloted airplane at all, arguing that ground studies and the PARD rocket-model operation could provide all of the necessary hypersonic information at much less cost and risk. Lewis researchers believed that possible military applications had unduly burdened previous research airplane programs, and there was no reason to think anything different would happen in this case.-1851

On the other hand, Langley chose to investigate the problem based largely on the hypersonic research it had been conducting since the end of World War II. After the 11-inch hypersonic tunnel became operational in 1947, a group headed by Charles McLellan began conducting limited hypersonic research. This group, which reported to John Becker, who was now the chief of the Aero-Physics Division, provided verification of several newly developed hypersonic theories while it investigated phenomena such as the shock-boundary-layer interaction. Langley also organized a parallel exploratory program into materials and structures optimized for hypersonic flight. Perhaps not surprisingly, Langley decided to determine the feasibility of a hypersonic aircraft capable of a 2- to 3-minute excursion out of the atmosphere to create a brief period of weightlessness in order to explore the effects of space flight. Hugh Dryden would later liken this excursion to the leap of a fish out of water, and coined a new term: space leap.-861

|

|

Three men that played important parts in the X-15 program. On the right is Walter C. Williams, the head of the High-Speed Flight Station and a member of the Research Airplane Projects panel that guided the X-15 through its formative stages. In the middle, Hugh L. Dryden, the Director of the NACA. At left is Paul F. Bikle, who came late to the X-15, but guided it through most of its flight program as the director of the Flight Research Center. (NASA)

Langley’s ad hoc hypersonic aircraft study group consisted of John Becker (chairman); Maxime A. Faget,[87] a specialist in rocket propulsion from the Performance Aerodynamics Branch of PARD; Thomas A. Toll, a control specialist from the Stability Research Division; Norris F. Dow, a hot – structures expert from the Structures Research Division; and test pilot James B. Whitten. Unlike the earlier Brown study group, this group intentionally included researchers with previous experience in hypersonics.[88]

The group reached a consensus on the objectives of a hypersonic research aircraft by the end of its first month of study. Although one of the original goals was to investigate the effects of weightlessness, the members soon realized "that the problems of attitude control in space and the transition from airless flight to atmospheric flight during reentry were at least equally significant." The group also began to consider the dynamics of the reentry maneuvers and the associated problems of stability, control, and heating as the most pressing research need. However, another objective would come to dominate virtually every other aspect of the aircraft’s design: research into the related fields of high-temperature aerodynamics and high-temperature structures. Thus, it would become the first aircraft in which aero-thermo-structural considerations constituted the primary research problem, as well as the primary research objective.-1891

10 vehicle "would require a much greater expenditure of time and effort" yet "would add little in the fields of stability, control, piloting problems, and structural heating." Considering that no human had yet approached Mach 3, even Mach 7 seemed a stretch.[90]

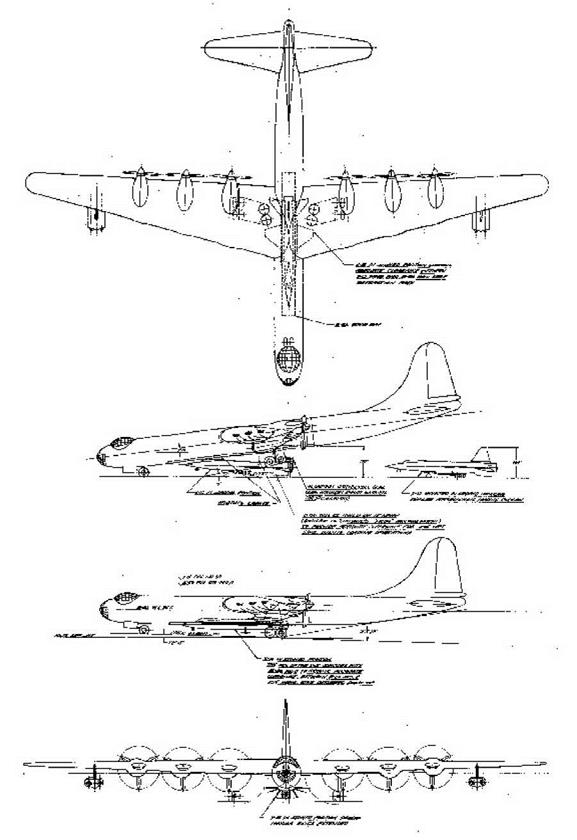

By the end of April 1954, Becker’s group had completed a tentative design for a winged aircraft and an outline of proposed experiments. The group kept the configuration as conventional as possible to minimize the need for special low-speed and transonic developments without compromising its adequacy as a hypersonic, aerodynamic, and structural research vehicle. However, acknowledging what would become a continuing issue; the group did not consider any of the large rocket engines then under development entirely satisfactory for the airplane. In the absence of the rapid development of a new engine, the group hoped a combination of three or four smaller rocket motors could provide hypersonic velocities.-1911

At this point Floyd Thompson, by now the associate director at Langley, influenced the direction of the Becker study. He made a suggestion that echoed John Stack’s 1945 recommendation that the Bell XS-1 transonic research airplane use a 12% thick wing that would force it to encounter the compressibility efforts that aerodynamicists were most interested in studying. Since the hypersonic airplane would be the first in which aero-thermal-structural considerations constituted the primary research problem, Thompson argued that the aim of the aircraft "should be to penetrate as deeply as possible into the region of [high aerodynamic] heating and to seek fresh design approaches rather than makeshift modifications to conventional designs." His suggestion became policy.-192

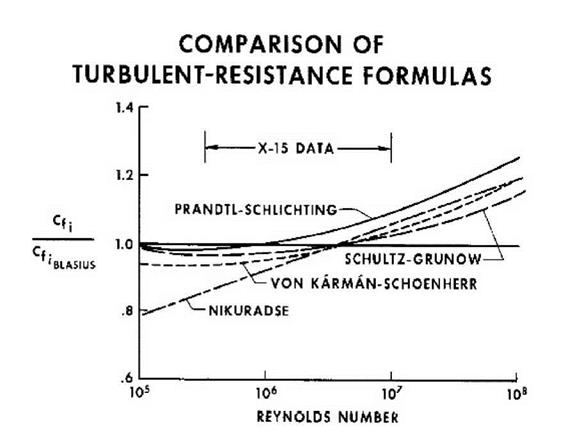

Wind-tunnel testing began in mid-1954 and continued through the end of 1955 using the basic Becker design. David E. Fetterman, Jr., Jim A. Penland, and Herbert W. Ridyard led the tests, mainly using the 11-inch tunnel at Langley. The researchers noted that previous hypersonic designs had "been restricted mainly to missile types which were not required to be able to land and which, therefore, had relatively small wings or wings of very low aspect ratio." The researchers concentrated on extrapolating existing data to the Becker design while making sure the concept would be acceptable for a manned aircraft, including the ability to land.-93

One particular feature, however, differed from later concepts. The initial wind-tunnel tests used a design that incorporated relatively large leading-edge radii for both the wing and vertical stabilizer. The large radii were believed necessary to keep the heat transfer rates within feasible limits. Eventually the researchers discovered the beneficial effects of a leading-edge sweep and found materials capable of withstanding higher temperatures. These allowed smaller radii, resulting in less drag and generally better aerodynamic characteristics. Although the baseline design changed as a result, by this time the researchers were concentrating on evaluating various empennage configurations and elected not to change the wing design on the wind-tunnel models to avoid invalidating previous results.94

While performing the original heating analysis of the proposed reentry from the "space leap," Becker and Peter F. Korycinski from the Compressibility Research Division ran head-on into a major technical problem. At Mach 7, reentry at low angles of attack appeared impossible because of disastrous heating loads. In addition, the dynamic pressures quickly exceeded, by large margins, the limit of 1,000 pounds per square foot (psf) set by structural demands. New tests of the force relationships in the 11-inch tunnel provided Becker and Korycinski with a surprising solution to this problem: if the angle of attack and the associated drag were increased, deceleration would begin at a higher altitude. Slowing down in the thinner (lower-density) atmosphere made the heat-transfer problem much less severe. In other words, Becker and Korycinski surmised, by forcing deceleration to occur sooner, the increased drag associated with

the high angle of attack would significantly reduce the aircraft’s exposure to peak dynamic pressure and high heating rates. Thus, by using "sufficient lift," the Langley researchers found a way to limit the heat loads and heating rates of reentry. Interestingly, this is the same rationale used 15 years later by Max Faget when he designed his MSC-002 (DC-3) space shuttle concept at the Manned Spacecraft Center.1951

On reflection, it became clear to the Becker group that the sufficient-lift concept was a "new manifestation" of Allen’s blunt-body theory and was as applicable to high-lift winged reentry as to the non-lifting missile warheads studied at Ames during 1952. As the group increased the angle of attack to dissipate more of the kinetic energy through heating of the atmosphere (and less in the form of frictional heating of the vehicle itself), the configuration became increasingly "blunt." Some form of speed brakes, again in accord with Allen’s concept, could increase drag and further ease the heating problem.1961

Throughout 1954 the heating problems of high-lift, high-drag reentry came under increasing scrutiny from key Langley researchers. However, another problem soon outweighed the heating consideration: making the configuration stable and controllable at the proposed high-angle-of – attack reentry attitude. Because they were venturing into a new flight regime, the researchers could not determine the exact hypersonic control properties of such a configuration. Nor were they certain they could devise a structure that would survive the anticipated 2,000°F equilibrium temperatures.-1971

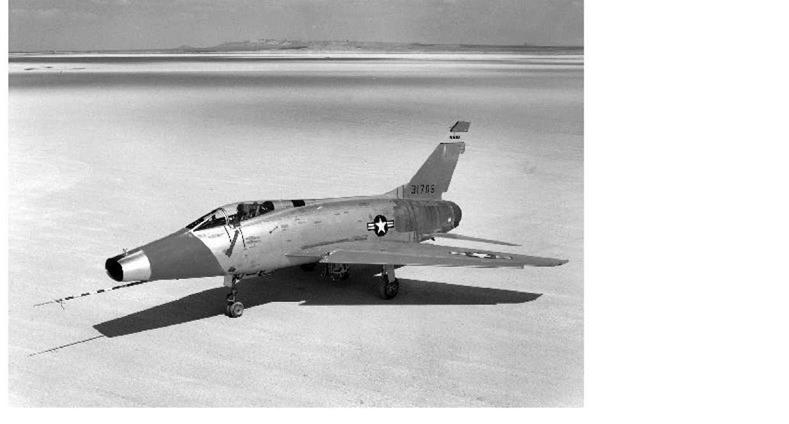

The HSFS had forewarned Langley about potential hypersonic stability problems. In December 1953, Air Force Major Chuck Yeager had pushed the Bell X-1A far beyond its expected speed range. As the aircraft approached Mach 2.5, it developed uncontrollable lateral oscillations that nearly proved disastrous.1981 While Yeager frantically tried to regain control, the airplane tumbled for over a minute, losing nearly 10 miles of altitude. At subsonic speed, the aircraft finally entered a conventional spin from which Yeager managed to recover. This incident led to a systematic reinvestigation of the stability characteristics of the X-1A. By mid-1954, findings indicated that the problem that had almost killed Yeager was the loss of effectiveness of the X- 1A’s thin-section horizontal and vertical stabilizers at high speed. The HSFS was not equipped to conduct basic research into solutions, but it coordinated with Langley in an attempt to overcome this problem.

At the same time, Langley and the HSFS began investigating the inertial-coupling phenomenon encountered by the North American F-100A Super Sabre.1991

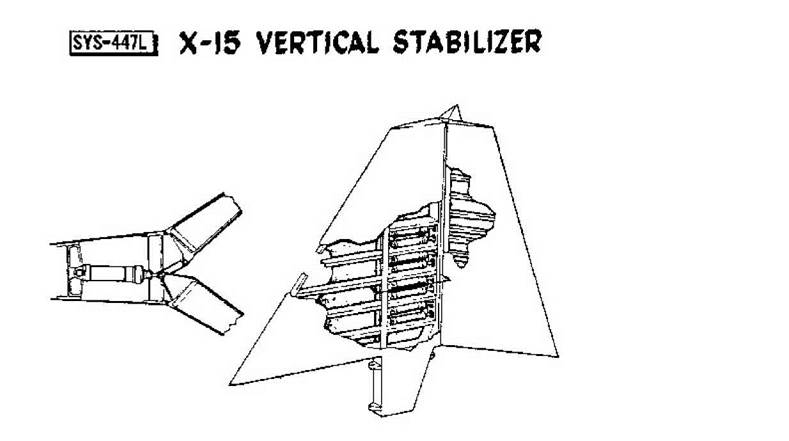

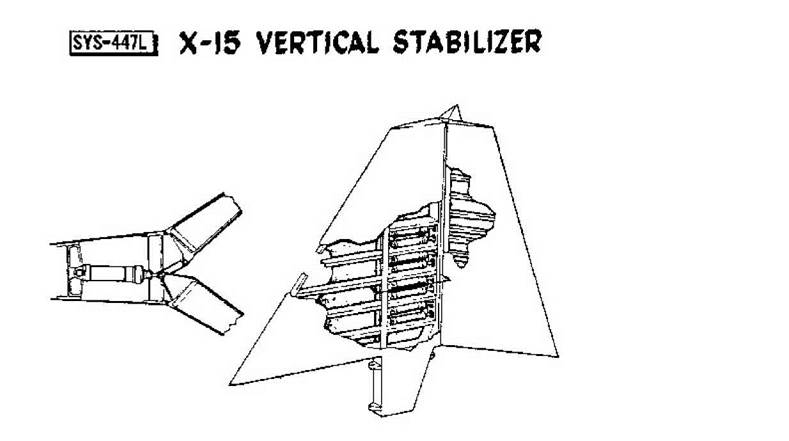

The Becker group faced a potential stability problem that was several times more severe than that of the X-1A. Preliminary calculations based on data from X-1A wind-tunnel tests indicated that the hypersonic configuration would require a vertical stabilizer the size of one of the X – 1’s wings to maintain directional stability-something that was obviously impractical. Stumped by this problem, Becker sought the advice of his 11-inch hypersonic tunnel researchers. The consensus, reached by wind-tunnel testing and evaluating high-speed data from earlier X-planes, was that an extremely large vertical stabilizer was required if the thin-section stabilizers then in vogue for supersonic aircraft were used. This was largely because of a rapid loss in the lift-curve slope of thin airfoil sections as the Mach number increased. In a radical departure, however, Charles McLellan suggested using a thicker wedge-shaped section with a blunt trailing edge. Some time before, McLellan had conducted a study of the influence of airfoil shape on normal-force characteristics, and his findings had been lying dormant in the NACA literature. Calculations based on these findings indicated that at Mach 7 the wedge shape "should prove many times more effective than the conventional thin shapes optimum for the lower speed." By modifying the proposed configuration to include the wedge-shaped vertical stabilizer, McLellan believed that a reasonably sized vertical stabilizer could correct most directional instability.11001

|

|

Charles H. McLellan at NACA Langley, one of the researchers that defined much of the X-15 configuration, proposed the use of a split training edge on the vertical stabilizer to form speed brakes. Perhaps even more importantly, these could also be opened to form a variable-wedge vertical stabilizer as a means of restoring the lift-curve slope at high speeds, thus permitting much smaller surfaces that were easier to design and imposed a smaller drag penalty at lower speeds. The ultimate X-15 configuration did not incorporate the split trailing edge, but the much – later space shuttles did. (NASA)

A new series of experiments in the 11-inch tunnel verified that a vertical stabilizer with a 10- degree wedge angle would allow the proposed aircraft to achieve the range of attitudes required by heating considerations for a safe high-drag, high-lift reentry. Further, it might be possible to use a variable-wedge vertical stabilizer as a means of restoring the lift-curve slope at high speeds, thus permitting much smaller surfaces that would be easier to design and would impose a smaller drag penalty at lower speeds. McLellan calculated that this wedge shape should eliminate the disastrous directional stability decay encountered by the X-1A.-1101

Becker’s group also included speed brakes as part of the vertical stabilizers to reduce the Mach number and heating during reentry. Interestingly, the speed brakes originally proposed by Langley consisted of a split trailing edge; very similar to the one eventually used on the space shuttles. As the speed brakes opened, they effectively increased the included angle of the wedge-shaped vertical stabilizer, and variable deflection of the wedge surfaces made it possible to change the braking effect and stability derivatives through a wide range. The flexibility this made possible could be of great value because a primary use of the airplane would be to study stability, control, and handling characteristics through a wide range of speeds and altitudes. Furthermore, the ability to reenter in a high-drag condition with a large wedge angle greatly extended the range of attitudes for reentry that were permissible in view of heating considerations.-102

Up until this time, the designers of supersonic aircraft had purposely located the horizontal stabilizer well outside potential flow interference from the wings. This usually resulted in the horizontal stabilizer being located partway up the vertical stabilizer, or in some cases (the F-104, for example) on top of the vertical stabilizer. However, researchers at the HSFS suspected that this location was making it difficult, or at times impossible, for aircraft to recover from divergent maneuvers. The same investigations at Langley that verified the effectiveness of the wedge-shape also suggested that an X-shaped empennage would help the aircraft to recover from divergent maneuvers.-110^

The Becker group recognized that the change from a conventional "+" empennage to the "X" configuration would present at least one major new problem: the X-shape empennage projected into the high downwash regions above and below the wing plane, causing a potentially serious loss of longitudinal effectiveness. Researchers at Langley looked for solutions to this new problem. By late 1954 they had an unexpected answer: locate a conventional "+" horizontal stabilizer in the plane of the wing, between the regions of highest downwash. This eliminated the need to use an X-shaped empennage, allowing a far more conventional tail section and control surfaces.^

Although it would come and go from the various preliminary designs, the use of a ventral stabilizer was beginning to gain support. Charles McLellan observed, "At high angles of attack, the effectiveness of the upper and lower vertical stabilizers were markedly different. Effectiveness of the upper tail decreases to zero at about 20 degrees angle of attack. The lower tail exhibits a marked increase in effectiveness because of its penetration into the region of high dynamic pressure produced by the compression side of the wing. Assuming the wing is a flat plate and the flow is two-dimensional, the dynamic pressure below the wing increases with angle of attack.

Since only a part of the lower tail is immersed in this region its gain in effectiveness is, of course, less rapid, but the gain more than offsets the loss in effectiveness of the upper tail."[105]

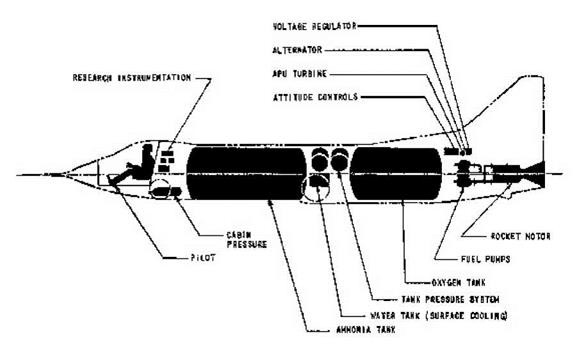

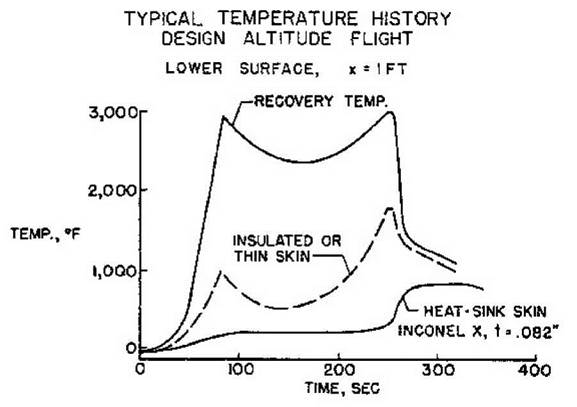

On the structural front, the Becker study evaluated two basic design approaches. In the first, a layer of assumed insulation protected a conventional low-temperature aluminum or stainless steel structure. The alternative was an exposed "hot structure." This design approach and the materials used permitted high structural temperatures without insulation.[106]

Surprisingly, the temperatures expected on the high-altitude "space leap" were significantly higher than for the basic hypersonic research flights. Establishing a design that could withstand the 2,000°F equilibrium temperature was a challenge, and ultimately resulted in the hot-structure concept shown on the lower line of this chart. (NASA)

Analysis of the heating projections for various trajectories showed that the airplane would need to accommodate equilibrium temperatures of over 2,000°F on its lower surface. Unfortunately, no known insulating technique could meet this requirement. Bell was toying with a "double-wall" concept in which a high-temperature outer shell and a layer of insulator would protect the underlying low-temperature structure. This concept would later undergo extensive development, and several contractors proposed it during the X-15 competition, but in 1954 it was in an embryonic state and not applicable to the critical nose and leading-edge regions. However, the Becker group believed that the possibility of local failure of any insulation scheme constituted a serious hazard, as was later tragically demonstrated on the Space Shuttle Columbia. Finally, the problem of accurately measuring heat-transfer rates—one of the primary objectives of the new research aircraft program—would be substantially more difficult to accomplish with an insulated structure.[107]

At the start of the study, it was by no means obvious that the hot-structure approach would prove practical either. The permissible design temperature for the best available material was about 1,200°F, which was far below the estimated equilibrium temperature of 2,000°F. It was clear that some form of heat dissipation—either direct internal cooling or absorption into the structure itself —would be necessary. It was thought that either solution would bring a heavy weight penalty.

The availability of Inconel X and its exceptional strength at extremely high temperatures made it, almost by default, the structural material preferred by Langley for a hot-structure design.-11081 In mid-1954, Norris Dow began an analysis of an Inconel X structure while other researchers conducted a thermal analysis. In a happy coincidence, the results showed that the skin thickness needed to withstand the expected aerodynamic stresses was about the same as that needed to

absorb the thermal load. This meant that it was possible to solve the structural problem for this transient condition of the Mach 7 research aircraft with no serious weight penalty for heat absorption. This was an unexpected plus for the hot structure. Together with the fact that none of the perceived difficulties of an insulated-type structure (particularly the difficulty of studying structural temperatures) were present, this led the study group to decide in favor of an uninsulated hot-structure design.

Unfortunately, it later proved that the hot structure had problems of its own, especially in the area of non-uniform temperature distribution. Detailed thermal analyses revealed that large temperature differences would develop between the upper and lower wing skins during the pull – up portions of certain trajectories, resulting in intolerable thermal stresses in a conventional structural design. To solve this new problem, researchers devised wing shear members that did not resist unequal expansion of the wing skins. The wing thus was essentially free to deform both span-wise and chord-wise with asymmetrical heating. Although this solved the problem for gross thermal stresses, localized thermal-stress problems still existed near the stringer attachments. The study indicated, however, that proper selection of stringer proportions and spacing would produce an acceptable design that would be free of thermal buckling.-1109

Unfortunately, it later proved that the hot structure had problems of its own, especially in the area of non-uniform temperature distribution. Detailed thermal analyses revealed that large temperature differences would develop between the upper and lower wing skins during the pull – up portions of certain trajectories, resulting in intolerable thermal stresses in a conventional structural design. To solve this new problem, researchers devised wing shear members that did not resist unequal expansion of the wing skins. The wing thus was essentially free to deform both span-wise and chord-wise with asymmetrical heating. Although this solved the problem for gross thermal stresses, localized thermal-stress problems still existed near the stringer attachments. The study indicated, however, that proper selection of stringer proportions and spacing would produce an acceptable design that would be free of thermal buckling.-1109

The analyses produced other concerns as well. Differential heating of the wing leading edge resulted in changes to the natural torsional frequency of the wing unless the design used some sort of flexible expansion joint. The hot leading edge expanded faster than the remaining structure, introducing a compression that destabilized the section as a whole and reduced its torsional stiffness. To negate these phenomena, researchers segmented and flexibly mounted the leading edge to reduce thermally induced buckling and bending. Similar techniques found use on the horizontal and vertical stabilizers.

COMFARISQN OF INCONEL X WITH OTHER ALLOYS

TENSILE YIELO STRESS*

К 51

DESIGN TEMR

BTU/SQ FT/SEC

Langley evaluated many materials for the proposed hypersonic research airplane, but the availability of Inconel X and its exceptional strength at extremely high temperatures, made it,

almost by default, the preferred material for a hot-structure design. Coincidently, the researchers at NACA Langley discovered that the skin thickness needed to withstand aerodynamic stress was about the same as the amount of structure needed to absorb the thermal load from the high – altitude mission. (NASA)

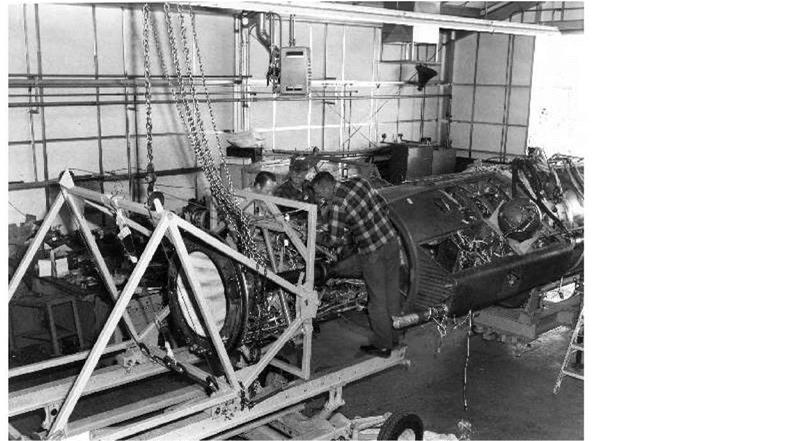

Perhaps more worrisome was the question of potential propulsion systems. The most promising configuration was found to be four General Electric A1 or A3 rocket engines, due primarily to the "thrust stepping" this configuration provided.-1110! At the time, rocket engines could not be throttled (even today, most rocket engines cannot be). Several different techniques can be used to throttle a rocket engine, and each takes its toll in mechanical complexity and reliability. However, a crude method of throttling did not actually involve changing the output of the engine, but rather igniting or extinguishing various numbers of small engines. For instance, in a cluster of three 5,000-lbf engines, the available thrust levels (or "steps") would be 5,000, 10,000, and 15,000 lbf. Since most rocket engines were not restartable (again, the concept adds considerable mechanical complexity to the engine), once an engine was extinguished it could not be restarted. Thrust stepping or throttling allowed a much more refined flight profile, and largely defined the propulsion concept for the eventual X-15.-1111-

At this stage of the study, the vehicle concept itself was "little more than an object of about the right general proportions and the correct propulsive characteristics" to achieve hypersonic flight. However, in developing the general requirements, the Langley group envisioned a conceptual research aircraft that would serve as a model for the eventual X-15. The vehicle they conceived was "not proposed as a prototype of any of the particular concepts in vogue in 1954…[but] rather as a general tool for manned hypersonic flight research, able to penetrate the new regime briefly, safely, and without the burdens, restrictions, and delays imposed by operational requirements other than research." 112

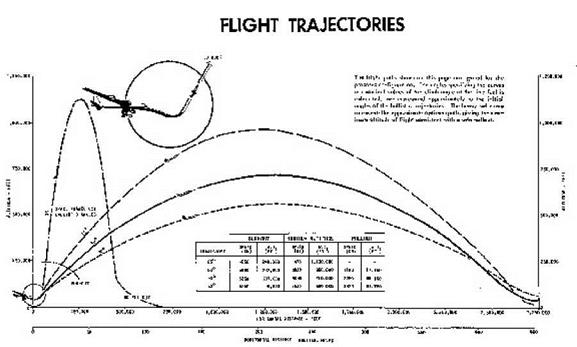

Although the Becker group was making excellent progress, their continued investigation of the "space leap" caused considerable controversy. The study called for two distinct research profiles. The first-the basic hypersonic research flights—consisted of a variety of constant angle-of-attack, constant-altitude flights to investigate aero-thermodynamic characteristics. However, the second flight profile explored the problems of future space flight, including investigations into "high-lift and low-L/D [lift over drag] during the reentry pull-up maneuver." Researchers recognized that this was one of the principal problems for manned space flight from both a heating and piloting perspective.-113!

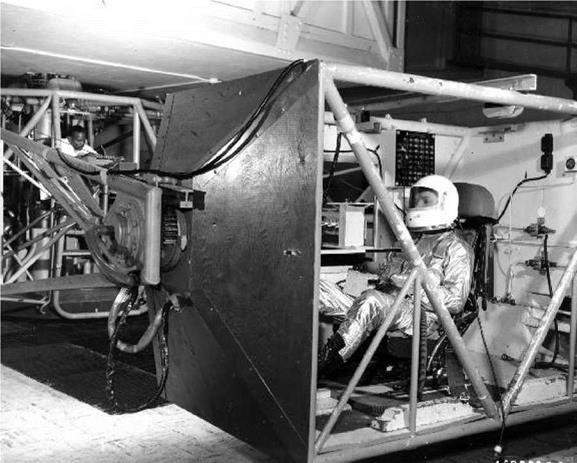

This brought yet more concerns: "As the speed increases, an increasingly large portion of the aircraft’s weight is borne by centrifugal force until, at satellite velocity, no aerodynamic lift is needed and the aircraft may be operated completely out of the atmosphere. At these speeds the pilot must be able to function for long periods in a weightless condition, which is of considerable concern from the aeromedical standpoint." By employing a high-altitude ballistic trajectory to roughly 250,000 feet, the Becker group expected that the pilot would operate in an essentially weightless condition for approximately 2 minutes. Attitude control was another problem since traditional aerodynamic control surfaces would be useless at very high altitudes. To solve this problem, the group proposed using small hydrogen-peroxide thrusters for attitude control outside the sensible atmosphere.

While the hypersonic research aspect of the Langley proposal enjoyed virtually unanimous support, it is interesting to note that in 1954 most researchers viewed the space-flight aspect with, at best, cautious tolerance. There were few who believed that any space flight was imminent, and most believed that manned space flight in particular would not be achieved until many decades in the future, probably not until the 21st century. For instance, John Becker remembers that even the usually far-sighted John Stack was "not really interested in the reentry problem or in space flight in general." Several researchers opined that the space-flight research was premature and recommended it be eliminated. Fortunately, it remained.114-

Langley’s work throughout 1954 demonstrated one thing: the need for flexibility. Since their inceptions, the Brown and Becker groups had run into one technical problem after another in the pursuit of a conceptual hypersonic aircraft capable of making a space leap. Conventional wisdom had provided experimental and theoretical guidance for the preliminary design of the configuration, but had fallen far short of giving final answers. Contemporary transonic and supersonic aircraft designs dictated that the horizontal stabilizer should be located far above or well below the wing plane, for example, but that was wrong. Ballistics experts committed to pointy-nosed missiles had continued to doubt the worth of Allen’s blunt-body concept, but they too were wrong. Conversely, the instincts of Floyd Thompson, who knew very little about hypersonics but was a 30-year veteran of the vicissitudes of aeronautical research, had been sound. The design and research requirements of a hypersonic vehicle that could possibly fly into space were so radically new and different, Thompson suggested, that only "fresh approaches" could meet them. He was correct.

Unfortunately, it later proved that the hot structure had problems of its own, especially in the area of non-uniform temperature distribution. Detailed thermal analyses revealed that large temperature differences would develop between the upper and lower wing skins during the pull – up portions of certain trajectories, resulting in intolerable thermal stresses in a conventional structural design. To solve this new problem, researchers devised wing shear members that did not resist unequal expansion of the wing skins. The wing thus was essentially free to deform both span-wise and chord-wise with asymmetrical heating. Although this solved the problem for gross thermal stresses, localized thermal-stress problems still existed near the stringer attachments. The study indicated, however, that proper selection of stringer proportions and spacing would produce an acceptable design that would be free of thermal buckling.-1109

Unfortunately, it later proved that the hot structure had problems of its own, especially in the area of non-uniform temperature distribution. Detailed thermal analyses revealed that large temperature differences would develop between the upper and lower wing skins during the pull – up portions of certain trajectories, resulting in intolerable thermal stresses in a conventional structural design. To solve this new problem, researchers devised wing shear members that did not resist unequal expansion of the wing skins. The wing thus was essentially free to deform both span-wise and chord-wise with asymmetrical heating. Although this solved the problem for gross thermal stresses, localized thermal-stress problems still existed near the stringer attachments. The study indicated, however, that proper selection of stringer proportions and spacing would produce an acceptable design that would be free of thermal buckling.-1109