The Million-Horsepower Engine

Although the hypersonic research airplane concept developed at Langley had met with almost unanimous endorsement by the Air Force, the lack of a suitable powerplant was a major shortcoming in the eyes of the WADC Power Plant Laboratory. The Langley study had determined that an engine (or engines) that could produce roughly 50,000 lbf was needed for the research airplane. The flight profiles developed by John Becker and his researchers showed that the ability to vary the thrust during flight would provide much better data and allow pilots to repeat maneuvers with some precision. The laboratory thought the Hermes A1 engine used in the Becker study was not capable of evolving into a man-rated engine, and suggested several engines it believed were "more suitable" for a manned aircraft. Despite these suggestions, however, the laboratory believed further study was required before any engine could be selected.-^

By October 1954, researchers from the Air Force, Navy, and the NACA had selected four existing or proposed power plants for possible use in the X-15. These included the Aerojet XLR73, Bell XLR81, North American NA-5400, and Reaction Motors XLR10. Despite the tentative selections, the Power Plant Laboratory thought that any engine would require major modifications to meet the needs of the X-15. The laboratory also believed the Air Force needed to "accept responsibility for development of the selected engine and…provide this engine to the airplane contractor as government furnished equipment." The primary consideration, for both the laboratory and the NACA, was that the engine be able to operate safely under any condition (acceleration in any axis) the X-15 was likely to experience. Maintenance and reliability (as defined by time between overhauls) did not need to be up to production standards.-21

The 30 December 1954 invitation-to-bid letter from the Air Materiel Command included summaries of the four engines recommended by the Power Plant Laboratory. However, although the stated preference to use one of these engines did not forbid bidders from using other engines, it did require the bidder and engine manufacturer to justify the selection. The bidder needed to present the justification to the X-15 Project Office for approval.

The powerplant that was ultimately selected for the X-15 was not one of the four recommended ones, but became known during discussions with Reaction Motors concerning the XLR10 from the Viking missile. During a meeting with the Air Force, the company promoted "a larger version of the Viking engine" that was under development for the Navy as the XLR30. After these discussions, the Power Plant Laboratory estimated that Reaction Motors could develop the XLR30 into a suitable engine for less than $5,000,000 in approximately two years. It was not even close.-31

On 25 January 1955, the Air Force requested additional information from Reaction Motors. The company replied on 3 February 1955 with details on the XLR10 and XLR30, and recommended four possible combinations for the X-15 program. These included an oxygen-ethanol XLR10, an oxygen-ammonia XLR30, an oxygen-hydrocarbon XLR30, and an oxygen-ethanol engine using two XLR10 chambers fed by a single XLR30 turbopump. Each of the engines used hydrogen peroxide to drive the turbopump. After it was briefed on the Becker study, Reaction Motors doubted that a single XLR10 was "adequate to perform the objectives of this type of aircraft."-41

Although it suggested a combination of XLR10 thrust chambers and an XLR30 turbopump, Reaction Motors believed this engine would be overly complicated and predicted it would weigh 815 pounds (compared to 420 pounds for either of the XLR30 configurations). The company suggested that relatively minor modifications to the XLR30 would allow throttling between 17,000 and 57,000 lbf with a specific impulse of 278 seconds. The XLR30 installation required a

space 70 inches long and 30 inches in diameter, considerably less than that required for the larger XLR10-XLR30 combination.-51

|

|

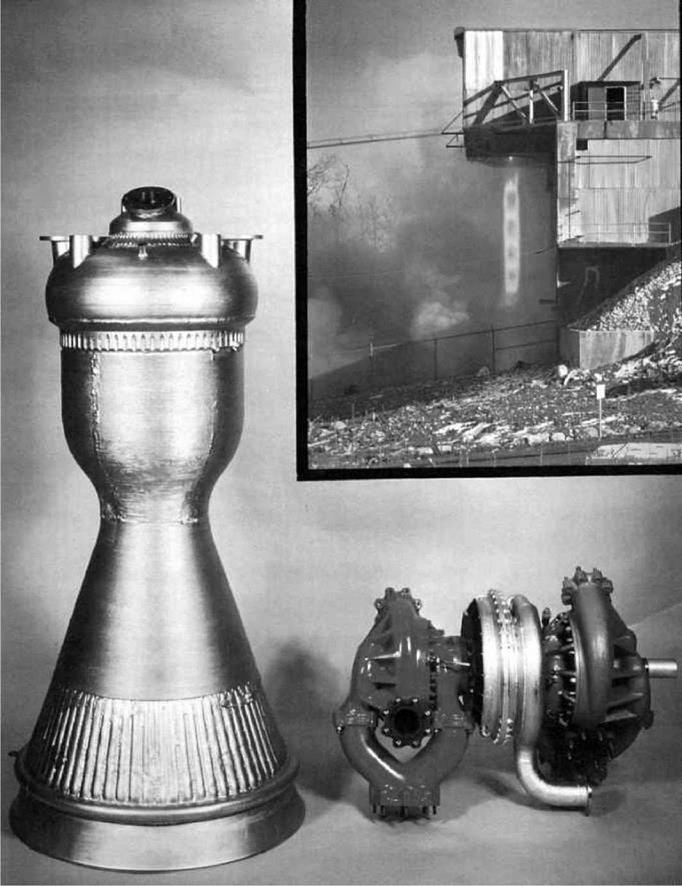

between 1949 and 1955. (Reaction Motors Inc.)

Independently, Reaction Motors determined that the two most important safety requirements were the propellant combination and the means of achieving combustion during ignition and shutdown. The company reviewed seven propellant combinations in depth, and eventually narrowed the choices to liquid oxygen and anhydrous ammonia. Reaction Motors based this choice largely on its significant experience with this combination, which had shown that ammonia had fewer critical starting characteristics than most hydrocarbon fuels. Additionally, the propellants were ideal for the regenerative cooling of the proposed engine’s thrust chamber.

The Air Force, however, was still more interested in the XLR10, and on 4 February 1955 it asked Reaction Motors for additional information on that engine. On the same day, however, Reaction Motors and the X-15 Project Office held a meeting during which the company detailed a significant development program to man-rate the XLR-10 for the X-15. Given the development effort required for either engine, the company believed the XLR30 would ultimately be a better engine. After a meeting between the Air Materiel Command and the X-15 Project Office, the government advised Reaction Motors to "make all further estimates on the basis of the XLR30’s development." [6]

Concurrently, the Air Materiel Command had also been in discussions with the other three engine manufacturers. The fact that the other manufacturers showed a somewhat lower level of interest than Reaction Motors is understandable-after all, Reaction Motors engines had powered most of the rocket-equipped X-planes since the original XS-1. In fact, by this time North American had already requested that the Air Force withdraw the NA-5400 from consideration. On 18 March 1955, the Air Force supplied the prospective airframe contractors with the specifications on the three remaining engines. The Air Force expected that a flight engine would be available to the winning contractor within 30 months.-^

The X-15 Project Office released its analysis of the data provided by the engine manufacturers on 22 March 1955. One of the comments was that generating the necessary 50,000 lbf would require multiple Bell and Aerojet engines. The X-15 Project Office made clear that the final engine was not a production item, and that the amount of available propellants was the only limit to the operating time of the engine.[8]

After much discussion, the Air Force decided to release a request for proposal for the X-15 engine that was separate from the airframe competition. On 26 April, Headquarters ARDC requested that "the engine program be subjected to a final critical review apart from, but concurrent with the evaluation of the airframe proposals." The Power Plant Laboratory, NACA, and Navy would complete their engine evaluations by 12 July. The evaluation was to come to one of three conclusions: 1) that one engine was so superior to the others that its use would be mandated, 2) that one engine was so inferior that its use would be forbidden, or 3) that all of the engines were so nearly comparable that the choice would be left to the airframe contractor. The WADC scheduled the final engine evaluation meeting for 28 June, although this later slipped to 67 July.[9]