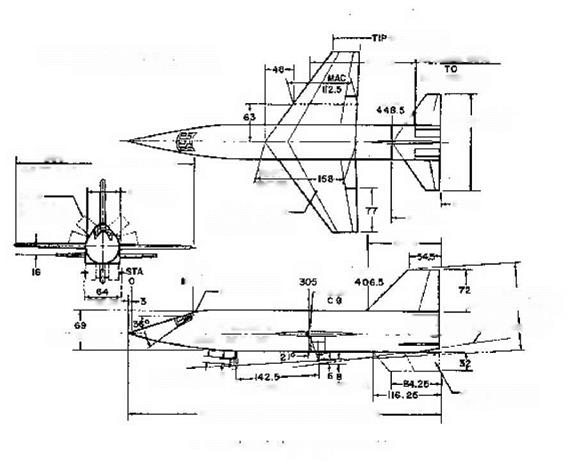

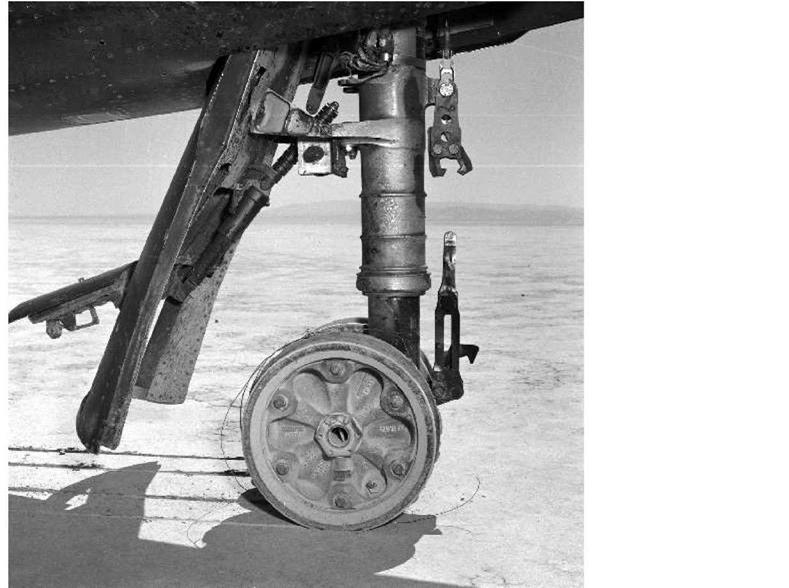

The X-15 landing gear was somewhat unusual, both in its approach and in its simplicity. The system consisted of a dual nose wheel and a pair of aft skids. Initially the cast magnesium nose wheels were fitted with standard aircraft tires pressurized with 240-psi nitrogen. The skids consisted of a 4130-steel skid and an Inconel X strut that was attached to the fuselage by trunnion fittings and through bell crank arms that were attached to shock struts inside the aft fuselage. The skids were free in pitch and roll, but fixed in yaw for parallel alignment. Drag braces attached to the fuselage ahead of the trunnion fittings and to the skids at the strut attachment pin. Bungee springs kept the skid in a nose-up position just before landing. Instead of retracting inside the fuselage, the skids and struts folded forward against the outside of the fuselage when retracted. The pilot lowered the landing gear by pulling a handle in the cockpit that attached via

cable to the uplock hooks and released the gear. North American designed the landing gear for an 11,000-pound airplane with a sink rate of 9 fps, touching down between 190 and 230 mph at an angle of attack of approximately 6 degrees.-1124

Three major test series of the landing-gear system were conducted prior to the first glide flights: 1) a dynamic-model test of stability during the landing run, 2) nose-wheel shimmy tests using the actual nose gear, and 3) full-scale skid tests at the lake-bed landing site.-1125

North American used the model tests to investigate the stability of the tricycle arrangement. Engineers constructed a 1/10-scale model that accurately reflected the size, weight, and mass moments of inertia for yaw and roll, but did not simulate the aerodynamic characteristics of the X-15. Scale-size metal skids were manufactured so that they could be installed in either the original mid-fuselage location proposed by North American, or the aft fuselage location eventually built. North American catapulted the model along a concrete runway using a 100-foot length of 0.625-inch-diameter shock cord. High-speed movie cameras on overhead towers recorded each run. The tests revealed some minor nose-wheel instability, which the company subsequently corrected.-1124

Researchers at Langley then tested the revised full-scale nose gear using the landing-loads track facility at speeds up to 125 mph. These tests evaluated the nose gear on smooth concrete, uneven concrete, wet pavement, sandy pavement, uneven tire pressure, one flat tire, and unbalanced wheels. Given that the X-15 was to land only on dry lake beds, some of the tests seemed extreme. Throughout the tests the co-rotating wheel arrangement proved extremely stable, with no tendency to shimmy. Researchers, therefore, concluded the shimmy damper and torque links were unnecessary and North American subsequently removed them, saving 25 pounds.-1127

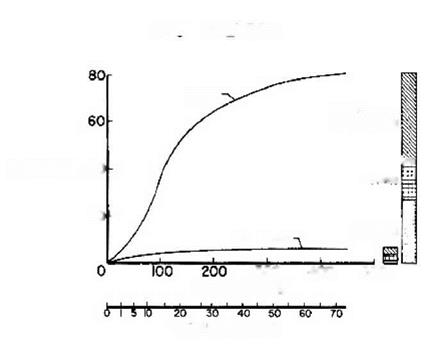

North American conducted the landing-gear-skid tests on Rogers Dry Lake during April 1958. For these tests, researchers mounted the complete main gear on a two-wheel trailer vehicle and towed it behind a truck at speeds up to 70 mph. After the truck reached full speed, an electric switch actuated a bomb-release solenoid that dropped a 6,000-pound load on the skid landing gear. Instruments on the gear recorded vertical and drag loads, and shock-strut position. Highspeed cameras mounted in the truck and trailer recorded the motion of the gear and skids. Test runs included straight-line landing on smooth lake surfaces, "fishtail" runs on rutted and bumpy areas near the edges of the lake, and one landing on the concrete runway just to make sure. The results of all the tests were satisfactory. Skid wear on the lake beds was light, and engineers determined that the skids would last for three or four landings. The tests revealed that the X-15 should leave depressions approximately 0.03 inch deep in the lake bed. As expected, wear on the concrete runway was severe, but the tests showed the X-15 could land on concrete if necessary.-1124

Despite all the tests, the first four actual landings pointed out several deficiencies in the landing gear, mainly because the aircraft was heavier than anticipated and sink rates were slightly higher. North American replaced the shock struts with higher-capacity units, and strengthened some of the structure inside the fuselage. The fourth landing resulted in X-15-1 breaking in half. This was not strictly a design error; Scott Crossfield had been unable to fully jettison the propellants prior to an emergency landing, and the airplane was significantly overweight. However, the landing gear contributed because the gas and oil mixture in the shock strut foamed, keeping the rear skids from absorbing as much of the impact as they should have. This forced a higher than normal load on the nose gear, aggravating the structural problem caused by being overweight.729

|

|

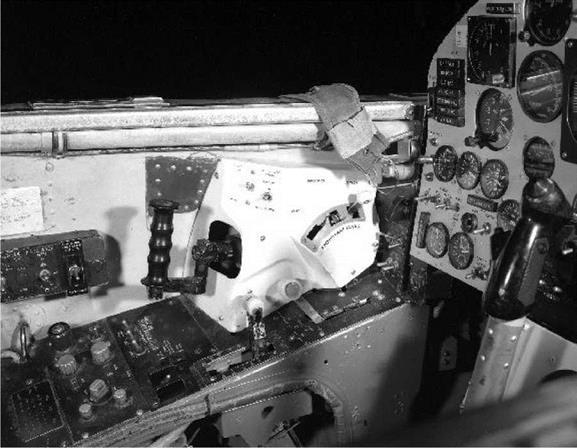

The X-15 was unique, even among X-Planes, in using a landing gear consisting of rear skids and a nose wheel. The skids solved several problems for designers since they were relatively small and could be stowed mostly outside the airframe. Interestingly, the X-15 landing gear was lowered by the pilot pulling a mechanical handle that was connected to a cable that released the uplock hooks and allowed a bungee to extend the skids. A similar system would have been used on the X-20 Dyna-Soar if that program had not been cancelled. (NASA)

In addition, during some of the early landings, engineers found that the nose wheel tire marks left on the dry lake bed were not continuous. After initial contact, the tire marks became very faint or disappeared for short distance and then reappeared. This puzzled the engineers since all of the early drop tests of the landing gear had been satisfactory.-1^00

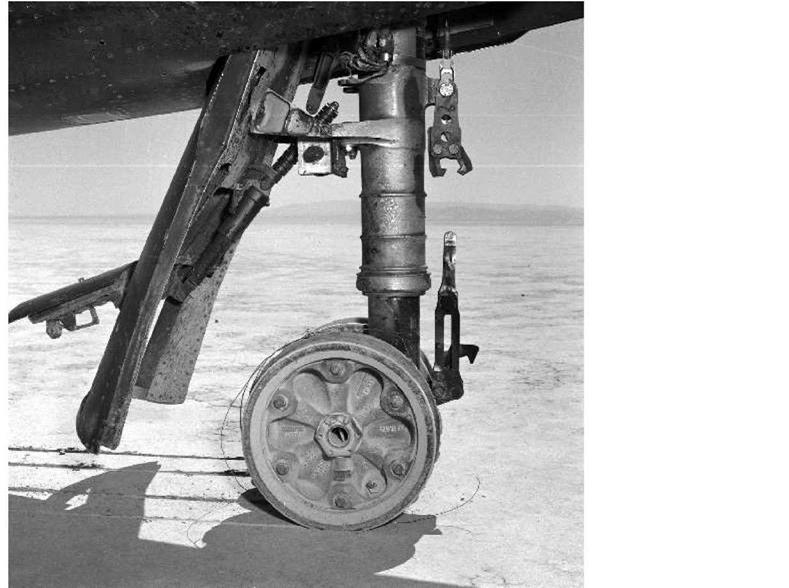

The engineers became concerned that the nose-gear extension mechanism was not working properly. Normally, technicians manually retracted the nose gear after attaching the X-15 to the NB-52, and then they pumped dry nitrogen gas into the shock strut to preload it to 1,404 psi. Charlie Feltz had suggested this method as a way to minimize the size and weight of the nose gear compartment. What the engineers discovered was that upon lowering the landing gear, an orifice in the strut trapped the nitrogen gas below it and most of the shock-absorption oil above it. The design of the metering valve was such that it prevented a rapid change in position of the oil and nitrogen in the 10 seconds between gear extension and wheel touchdown. To better understand the problem, engineers conducted additional dynamic tests using the original test apparatus. Initial tests operated the apparatus with the nose gear serviced in the extended position, as had been done in the original tests. The performance appeared normal. The engineers then modified the test rig to allow the gear to be serviced in the retracted position, as was done on the airplane. A delay of 10 seconds was introduced between the gear being lowered and touching down, and the abnormal behavior was reproduced almost exactly.-1201

At first, engineers modified the orifice in the shock, but this failed to resolve the problem. After additional tests, the engineers determined that they could not pressurize the strut in its retracted (compressed) position. Unfortunately, the nose wheel compartment was not large enough to allow the nose gear to be retracted in its extended position. The final solution was to mount redundant nitrogen bottles on the gear strut itself. When the gear reached its fully extended position, a valve actuated and released the nitrogen to pressurize the strut. This worked and the first modified nose gears were available in July 1960. However, the engineers kept evaluating the problem and, later in the program, changed the design again. This time they installed a floating piston inside the strut that kept the oil and gas separated. Technicians could now pressurize the strut in the compressed position before flight, allowing the removal of the nitrogen bottles.-1202

During 1961, engineers instrumented the skids to gather additional data on skid landing gear in support of the Dyna-Soar program and possible future vehicles, such as the space shuttle. Standard NASA instrumentation was used to provide airplane upper-mass response, shock-strut force and displacement, main – and nose-gear drag forces, nose-gear vertical force, horizontal – and vertical-stabilizer setting, horizontal stabilizer load, airplane angle of attack, and airplane pitch velocity during the impact and slideout portion of a landing. Tests were conducted at the end of normal research flights while the pilots landed normally and performed specific control movements during slideout. Phototheodolite cameras on the ground furnished data for landing coordinates, airplane altitude, flight-path velocity, and vertical velocity at touchdown. The instrumentation remained on all three airplanes for the remainder of the flight program to monitor the severity of each landing.-1203

Landing-gear loads continued to be high, despite the minor modifications made early in the flight program. An analytical study of the landing dynamics showed that several important parameters affecting the landing loads were actually aerodynamic factors. One of the primary culprits was a down-load from the horizontal stabilizer caused by both the pilot and SAS. Immediately prior to touchdown, the stabilizer trim position was set to between 4 and 5 degrees with the leading edge down. If the pilot pulled back on the stick and put the leading edge further down, the landing loads increased. If the pilot pushed the stick forward to get the leading edge up, the loads decreased. Another factor affecting the gear loads was lift from the wing. Unfortunately, the severe nose-down angle of the X-15 after nose-gear touchdown effectively pushed the airplane into the ground, further increasing the stress on the landing gear. Unfortunately, this was an unchangeable consequence of the airplane configuration, and a similar problem occurred on the space shuttle orbiters.[204]

The most severe problem, however, was weight. The design landing weight had been 11,000 pounds. The initial landing weight of the airplane was 13,230 pounds, and by 1965 this had crept up to 15,500 pounds on a routine basis. Emergency landings with a partial propellant load could be as high as 17,000 pounds. The only way to execute safely a landing at 17,000 pounds was for the pilot to perform an active push maneuver to obtain low horizontal stabilizer settings. This would still exceed the design load on the airplane, but would most probably be below the yield (destructive) limit.-1203

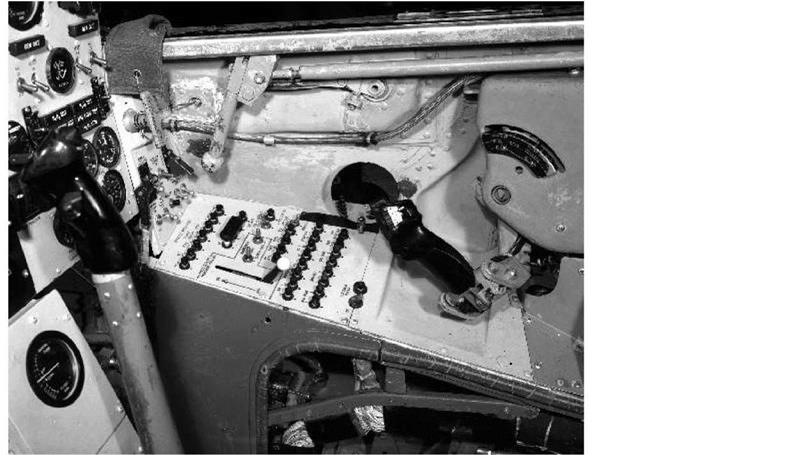

The nose gear was more conventional, consisting of a pair of wheels and tires. Note how short the nose gear strut is, resulting in severe loads during landing. The length of the nose strut was largely dictated by the amount of room available to stow it when retracted. Space shuttle orbiters suffer from a similarly short nose gear strut. (NASA)

By 1965 the problem was no longer one of understanding the nature of the loads, but rather one of how best to reduce them. North American introduced a near-constant series of minor modifications to the skids, their struts, and the surrounding structure in an effort to provide additional margin for the landing gear. Of all the factors that affected gear loads, the most

difficult to control—without restricting the research role of the airplane—was weight. Engineers determined they could reduce landing gear loads if they prevented the stabilizer angle from moving in the leading-edge-down direction during landings. Training the pilots to perform a push maneuver during landing accomplished this. In addition, North American installed a switch in the cockpit that disengaged the SAS at main gear touchdown to prevent the dampers from forcing the stabilizer leading edge down. Experience showed that under normal circumstances the pilots were efficient at pushing the stick at the right moment, even though the maneuver had to occur within 0.4 second after main gear touchdown to be effective in reducing gear loads. However, this maneuver was unnatural for the pilots, who tended to revert to habits formed through long hours of previous experience during emergencies and pull back on the stick. For this reason, the FRC began developing an automatic stick-kicker.-1206

In fact, this very condition occurred during the Jack McKay’s accident in X-15-2. The airplane was 1,000 pounds heavy with residual propellants, and as he landed, McKay pulled back on the stick, driving the stabilizer leading edge down to its maximum value. As it happened, the flaps failed on this flight and resulted in a down-load on the main wing, and therefore on the main landing gear. The combined resulted was a severely overstressed gear that, of course, failed.-207

Following the accident with X-15-2, engineers considered designing a new landing gear for the modified X-15A-2. The original location of the nose gear was approximately 23 feet ahead of the center of gravity, and moving the landing gear back could significantly reduce main-gear loads, with the forward bulkhead of the liquid-oxygen tank representing the rear-most location in the existing airframe. One of the ideas engineers investigated was moving the nose landing gear rearward to the instrumentation compartment behind the pilot. The nose gear would occupy the lower half of the compartment, with most of the instrumentation that normally resided there being moved forward to the old nose-gear compartment ahead of the pilot.208

However, fiscal and schedule constraints involved with repairing the aircraft precluded such major modifications, and the existing gear locations were reused on the modified airplane. Nevertheless, engineers made some basic changes, such as increasing the shock strut stroke from 3.66 inches to 5.03 inches, and modifying the relief valve setting from 17,000 pounds to 22,000 pounds.

North American manufactured two sets of strengthened struts—one set that was the same length as the original units, and another set that was lengthened from 53.6 inches to 59.0 inches. The longer units provided sufficient ground clearance to land with the functional ramjet sill attached to the ventral, but it appears that all flights of the X-15A-2 used the shorter units. Engineers also lengthened the skid 6.75 inches. In addition, engineers made some changes to the nose gear, primarily increasing the shock strut stroke to accommodate the increased length of the airplane. North American lowered the trunnion 9 inches to allow an attitude at nose-gear touchdown similar to that of the basic X-15. Despite these changes, the landing dynamics of the new gear were not appreciably changed, and X-15A-2 inherited most of the deficiencies of the basic system.209-

In addition, during the first part of 1965, North American investigated increasing the capability of the X-15A-2 gear. NASA wanted the maximum landing weight with the "short" main landing gear to increase to 16,374 pounds normal and 18,519 pounds emergency. The "long" gear used with the ramjet would increase to 17,855 pounds normal and 20,000 pounds emergency. A preliminary analysis indicated that incorporating the stick-kicker and changing the shock-strut relief valve setting would allow these increases. However, at 20,000 pounds there were concerns about whether the fuselage structure just behind the cockpit would be strong enough.219

Researchers installed a prototype stick-kicker in the FRC fixed-base simulator in May 1965 to determine the optimum stick forces. Subsequently, engineers installed the first stick-kicker in X – 15-3 during the weather down period at the beginning of 1966, and in X-15-1 by the end of that year. Apparently, NASA never installed the stick-kicker in X-15A-2. An emergency landing at 17,700 pounds, the highest landing weight yet encountered by the program, illustrated the effectiveness of the stick-kicker.-211

North American also conducted an investigation during early 1965 to determine the modifications needed to increase the landing weight of X-15-1 and X-15-3 to 16,000 pounds normal and 17,000 pounds emergency. The analysis included the use of the stick-kicker to rotate the horizontal stabilizer at landing to reduce main skid loads, although this would not eliminate the need to modify the skids for the higher weights. Preliminary studies showed that relocating the nose gear trunnion (as done on X-15A-2) would appreciably reduce landing loads on the other two airplanes, even without the addition of a stick-kicker.-212-

At the same time, engineers studied the feasibility of incorporating a third main skid attached to the fixed portion of the ventral stabilizer. This third skid could redistribute the landing loads and relieve the critically stressed gear components, particularly if either the stick-kicker of the landing flaps failed to operate. NASA installed the skid on X-15-3 in time for flight 3-52-78 on 18 June 1966, and by the end of 1966 it had used the third skid for four landings. These landings, however, were not at a sufficient weight to require the skid, and during the slideout the third skid contacted the lake surface with little or no load applied to it. Nevertheless, the third skid seemed like a good idea and NASA modified X-15-1 in time for flight 1-71-121 on 22 March 1967.

NASA did not install the third skid on X-15A-2 since it would have interfered with the ramjet installation.215-

The X-15A-2 experienced some of the more bizarre problems with landing gear. On the second flight (2-33-56) of the modified aircraft, after obtaining a maximum Mach number of 5.23, the nose gear unexpectedly extended as the airplane decelerated below Mach 4.2. William P. Albrecht, the X-15 project engineer for the flight, wrote that "[u]pon arrival in the Edwards area, chase aircraft confirmed that the nose gear was extended fully, and that the tires appeared badly burned, although still inflated. Major Rushworth elected to land the X-l5, and skillfully did so. The tires remained intact on touchdown but disintegrated after approximately 300 feet of rollout, the remainder of the 5,630 foot rollout being taken by the magnesium rims of the nose wheels." Considering the circumstance, it was a good landing.-214!

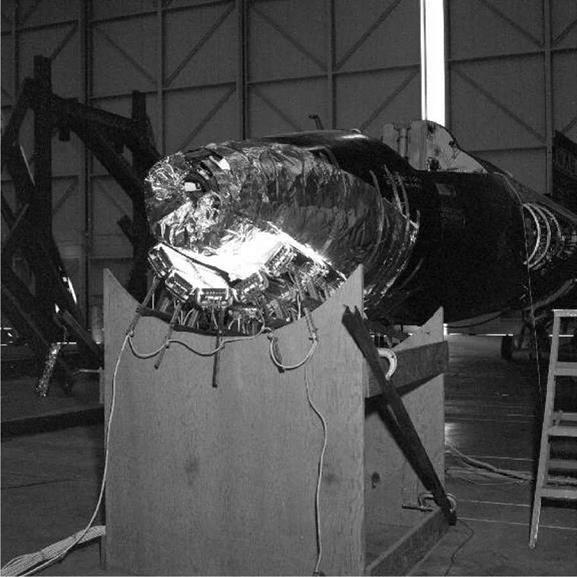

The subsequent investigation revealed that the nose-gear uplock hook was severely bent, the point of the hook having opened by approximately 0.25 inches. However, engineers determined the hook had not bent far enough to release the gear without the occurrence of some other deflection. The pilot lowered the X-15 landing gear via a simple cable arrangement that connected the landing gear extension handle in the cockpit to the uplock hook. Engineers measured the slack in the landing gear actuating cable (used to compensate for fuselage expansion due to heating effects) at 1.18 inches after the flight, within the specified limits. However, an analysis by North American indicated that the thermal growth of the fuselage was approximately 1.90 inches for this flight. This pointed out that the slack allowance was inadequate. Since the same mechanism operated all three landing gear components, it could not be ascertained in advance which of the three landing gears (left main, right main, or nose) would be first affected by partial actuation of the extension system, since that one with the least cable loading (due to friction, air loads, etc.) would tend to operate first. NASA duplicated the failure in the High-Temperature Loads Calibration Laboratory by simulating the fuselage expansion and applying heat to the nose-gear door. As Albrecht observed afterward, "Needless to say some modification to the landing gear mechanism seems to be in order."-215-

North American modified the cable to provide 2.25 inches of slack to compensate for thermal expansion. Although the engineers did not believe the problem affected the other two airplanes, they also received the modification. The only major drawback to this modification was that the pilot now had to pull the gear handle through almost 14 inches of travel to release the landing gear, which led to several complaints. Subsequently, engineers at the FRC designed a differential pulley that shortened the pull to 11 inches.-1216

These modifications, however, did not totally fix X-15A-2. During the next flight (2-34-57) on 29 September 1964, Bob Rushworth experienced a similar, but less intense, noise and aircraft trim change at Mach 4.5: the small nose-gear scoop door opened. This had already happened several times during the flight program on all three airplanes, fortunately without disastrous results.

There were two initial thoughts on how to fix the problem. The first was to eliminate the scoop door altogether; except for inspection and servicing, the door would be bolted shut prior to flight. Alternately, engineers could design a new uplock for the scoop door that featured a positive retention of the door roller on the uplock hook. In the end, NASA selected the second route and installed a new uplock hook, scoop door hook, and associated bell cranks.-217

NASA conducted two captive-carry flights of X-15A-2 to verify proper deployment of the redesigned nose scoop door and nose landing gear after cold soak. During flight 2-C-58 the nose gear required approximately 5.4 seconds to lock down—an unacceptably long time. Subsequent inspection showed that an incorrect orifice had been installed in the nose-gear snubber (which controlled the deployment rate). NASA installed the correct orifice, and the deployment time on flight 2-C-59 was an acceptable 2.7 seconds. Researchers collected data on both these captive flights data regarding the scoop door hook position and scoop door roller loads. Hook movement was negligible (less than 1/16 inch) and NASA subsequently modified the other two airplanes as well. Jack McKay took X-15A-2 on a perfect flight (2-35-60) on 30 November 1964.

|

|

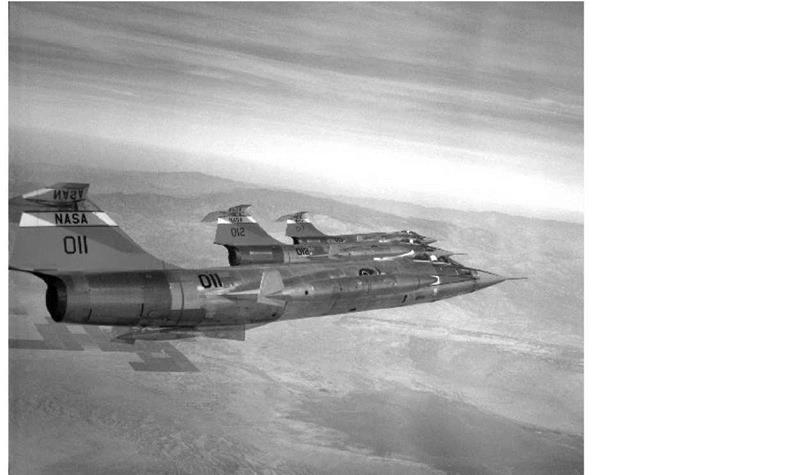

Like the rear skids, the nose wheel was lowered by the pilot pulling a handle that was connected to a cable that released the uplocks. On two separate flights, the nose gear extended while Major Robert A. Rushworth was flying the X-15A-2 above Mach 4, resulting in some interesting flying characteristics and two sets of burned tires. Researchers finally deduced that the fuselage of the airplane was expanding due to heat, and that the landing gear release cable did not have enough slack to compensate. North American increased the slack in the cable, but the pilots now had to pull the release handle more than 14 inches to get the landing gear to deploy. (NASA)

However, it did not end there. Rushworth was in the cockpit again for the next fight (2-36-63) of X-15A-2 on 17 February 1965 when the right main skid extended at Mach 4.3 and 85,000 feet. The chase pilot was able to verify that the gear appeared structurally sound, and Rushworth managed to make a normal landing. Investigation of the right-hand main skid uplock revealed that thermally induced bowing of the main strut caused excessive loading of the main uplock hook. Ground heating tests of the main-gear struts during a "hot-flight" profile caused bending of the hook and release of the gear. Consequently, NASA modified the main-gear uplock to include a stronger hook, a Belleville washer mounting system to accommodate approximately 0.14 inch bowing of the strut, and a stronger support structure. In addition, it was necessary to reinforce the sheet-metal fuselage longeron structure around the main-gear drag-brace anchor fittings. While the repair itself was not complicated, access was extremely difficult since it

|

|

|

|

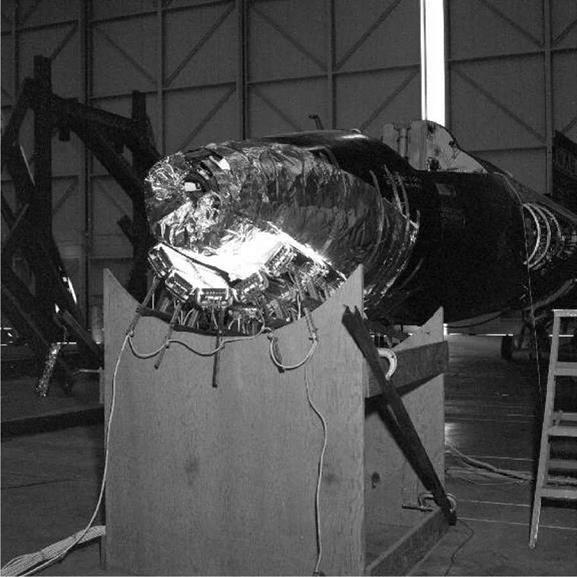

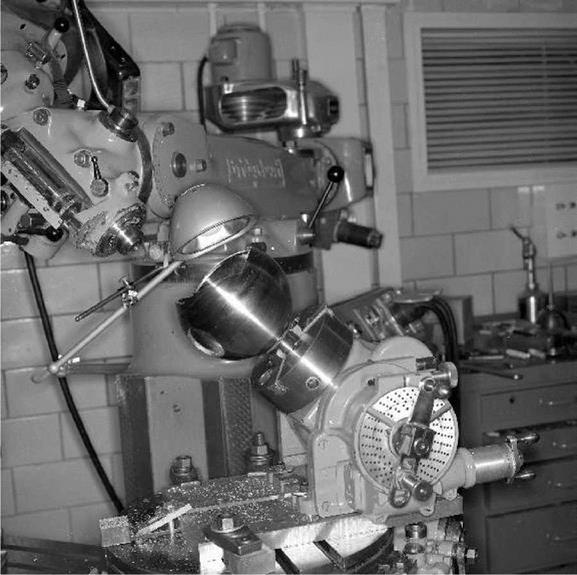

To test the hypothesis that the fuselage expanded more than the release cable, researchers at the Flight Research Center heated one of the X-15 forward fuselages using heat lamps. The test confirmed the theory. (NASA)

This ended the significant problem with the landing gear on the X-15A-2 (and the other airplanes), although the ever-increasing landing weight continued to be a concern and a set of small modifications (such as stronger struts) continued to be implemented until the end of the flight program.

TOTAL HOURS

TOTAL HOURS