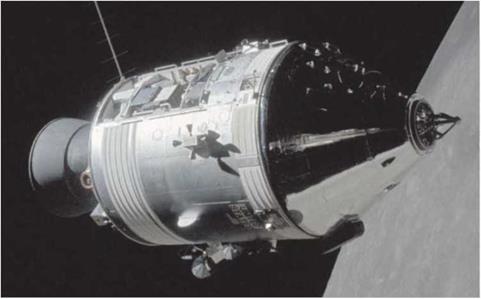

After Neil Armstrong and Buzz Aldrin had landed their LM Eagle on the Moon and while they were preparing for their foray onto the surface, Mike Collins made strenuous efforts to locate the tiny LM among the monotonous wastes of craters on Mare Tranquillitatis by aiming his sextant where mission control reckoned they were. Getting the optics around to face the lunar surface and back again involved carrying out a number of manoeuvres. It was during the manoeuvres after one such viewing opportunity that Collins got a call from Capcom Owen Garriott.

“Columbia, Houston. Over.”

“Columbia. Go,” replied Collins.

“We noticed you are manoeuvring very close to gimbal lock. I suggest you move back away.”

“Yes. I am going around it,” said Collins. “Doing this СМС-auto manoeuvres to the PAD values of roll 270, pitch 101, yaw 45.”

“Roger, Columbia,” said Garriott.

“How about sending me a fourth gimbal for Christmas,” commented Collins, showing his annoyance at the restriction imposed by gimbal lock. Garriott could not make him out. “Columbia, Houston. You were unreadable. Say again please.” Collins let it lie in the spirit of their triumph. “Disregard.”

What was rankling him was a weight-saving decision that had the downside of

substantially complicating some of the operational aspects of a mission because it limited the range of attitudes that the spacecraft could adopt. Because of this, the crew and flight controllers had to avoid orientating the spacecraft in certain directions with respect to the guidance platform.

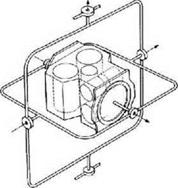

This characteristic was inherent in the system as designed by the MIT team who had settled on a three-gimbal mounting for the platform, similar to the system they had designed for the Polaris missile, and unlike the four gimbals employed in the Saturn V instrument unit and the Gemini spacecraft. Collins was a veteran of Gemini, and knew the advantage given by the fourth gimbal. But there were solid reasons for implementing only three gimbals. As well as saving the weight of a heavy outer gimbal, trade-offs included greater accuracy and a reduced tendency for the platform to drift in its orientation. However, the three-gimbal arrangement had this unfortunate side effect whereby, if the gimbals were moved in a particular fashion, the assembly lost its ability to maintain the platform’s alignment – a condition termed gimbal lock, and one that meant that the system had lost all knowledge of the direction in which the spacecraft was pointing. Having a fourth gimbal would have avoided this problem. As a result, care had to be taken during the flight-planning process, and throughout the flight itself, to avoid risking gimbal lock.

If gimbal lock did occur, it was a time-consuming procedure to fully realign the platform, possibly with the loss of important operational work. Even worse, if it occurred in the run up to a time-critical manoeuvre where good platform alignment was important, there would be no time available to take corrective action. To help crews to steer clear of it, two areas on the 8-ball’s surface were marked in red – it was these red spots that prompted the reference to the Pool ball. Manoeuvring the spacecraft in a manner that would bring either of these spots towards the centre of the display meant risking gimbal lock.

If gimbal lock did occur, it was a time-consuming procedure to fully realign the platform, possibly with the loss of important operational work. Even worse, if it occurred in the run up to a time-critical manoeuvre where good platform alignment was important, there would be no time available to take corrective action. To help crews to steer clear of it, two areas on the 8-ball’s surface were marked in red – it was these red spots that prompted the reference to the Pool ball. Manoeuvring the spacecraft in a manner that would bring either of these spots towards the centre of the display meant risking gimbal lock.

The mechanism that causes gimbal lock is not easy to describe. As previously discussed, the platform was mounted within three nested gimbals. Each had a rotation axis which was arranged 90 degrees away from the axis of the adjacent gimbals). In normal circumstances, this

arrangement allowed three degrees of freedom because the axes were pointing in three different directions. The problem arose when an attitude was adopted that allowed the axes of the outer and inner gimbals to line up. When this condition was approached, the gimbal system lost its ability to isolate the platform from the spacecraft’s rotations because there were now only two degrees of freedom. All the gimbal axes were now on a single plane, so any rotation of the spacecraft around an axis outside that plane could not be accommodated by any of the gimbal axes. Since the region that flirted with gimbal lock was defined by the current REFSMMAT. it followed that whenever the spacecraft needed to manoeuvre to an attitude that might approach gimbal lock mission control had to give the crew a new REFSMMAT. The platform could then be realigned so as to allow the otherwise awkward attitude to be adopted.

Of course, all this was worked out during mission planning. As many as eight REFSMMATs might be used during a mission, switching as the operational requirements changed. Each Lime the REFSMMAT changed, the platform would be duly realigned. But the avoidance of gimbal lock w as only one reason for changing the REFSMMAT. A more important reason was to aid the monitoring of critical events, such as launch, re-entry, and the major manoeuvres that required long engine burns or where the correct attitude of the spacecraft was paramount. By aligning the guidance platform to an appropriate REFSMMAT that matched the required attitude for the manoeuvre, the crew would find the 8-ball display easier to interpret when the spacecraft was pointing in the correct direction. Attitude errors, which must be avoided during an engine burn, could therefore be easily spotted and corrected.

When Apollo 8 made the first manned flight to the Moon, only three REFSMMATs were required. The purpose of the mission was simple – get to the Moon, orbit it ten Limes, and get back. There was little reason for the spacecraft to adopt widely varying attitudes. For the journey to the Moon, the platform was aligned to the launch pad REFSMMAT. This represented the launch pad’s attitude in space at the moment of launch, as determined with respect to the stars. This orientation made it easy for the crew? to monitor the progress of their ascent from Earth’s surface into orbit and during the translunar injection burn. Later, as they approached the Moon, they realigned their platform to a new REFSMMAT which coincided with their ideal attitude for the engine burns that Look them into lunar orbit. Choosing such an orientation for their platform made it much easier for them to monitor their attitude on the spacecraft’s displays. Once they had left the Moon, Jim Lovell realigned Apollo 8’s platform to a suitable REFSMMAT for re-entry into Earth’s atmosphere, again to make it easier to monitor this critical event.

As missions progressed, the number of REFSMMATs increased to facilitate a more sophisticated use of the hardware. Apollos 12 and 14 had six REFSMMATs while for the advanced J-missions that concluded the programme there were eight. The start of the journey began with the platform aligned with the launch pad. as with Apollo 8. Coasting to the Moon required the spacecraft to be turned slowly to evenly distribute heat around its surface. As this rotation had to avoid gimbal lock, a special REFSMMAT was invented. Each of the three major manoeuvres by the

CSM at the Moon had its own REFSMMAT in order to simplify crew monitoring. Two additional REESMMATs were defined to aid the lunar landing and lift-olT. each representing the orientation of the landing site at the times of these events. Finally, as with Apollo 8, a REFSMMAT was defined for re-entry.

If gimbal lock did occur, it was a time-consuming procedure to fully realign the platform, possibly with the loss of important operational work. Even worse, if it occurred in the run up to a time-critical manoeuvre where good platform alignment was important, there would be no time available to take corrective action. To help crews to steer clear of it, two areas on the 8-ball’s surface were marked in red – it was these red spots that prompted the reference to the Pool ball. Manoeuvring the spacecraft in a manner that would bring either of these spots towards the centre of the display meant risking gimbal lock.

If gimbal lock did occur, it was a time-consuming procedure to fully realign the platform, possibly with the loss of important operational work. Even worse, if it occurred in the run up to a time-critical manoeuvre where good platform alignment was important, there would be no time available to take corrective action. To help crews to steer clear of it, two areas on the 8-ball’s surface were marked in red – it was these red spots that prompted the reference to the Pool ball. Manoeuvring the spacecraft in a manner that would bring either of these spots towards the centre of the display meant risking gimbal lock.

Arranged around the pad’s central hill were ancillary buildings and equipment for storing and feeding propellants, gases, water and power to the vehicle, ponds for fuel spills, a hydrogen-burning pond and a network of roads.

Arranged around the pad’s central hill were ancillary buildings and equipment for storing and feeding propellants, gases, water and power to the vehicle, ponds for fuel spills, a hydrogen-burning pond and a network of roads.

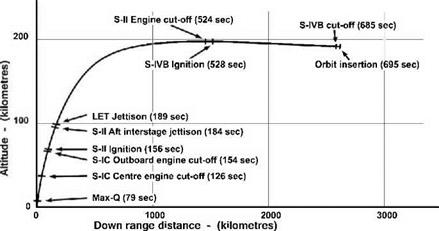

At an altitude of about eight kilometres, the Saturn V attained the speed of sound, or Mach 1, and went supersonic. It was approaching a dangerous region of the ascent. As the stack rose, the density of the air around it gradually diminished, yet as the rocket gained speed, it continued to ram air onto its forwardfacing surfaces, thereby raising the aerodynamic pressure, especially at the conical sections, and increasing the stresses on the skin. At about 14 kilometres, this dynamic pressure, known as ‘Q’, reached its greatest extent, a point in the flight called hnax-Q’. Beyond this point, the rapidly thinning air reduced these aerodynamic stresses.

At an altitude of about eight kilometres, the Saturn V attained the speed of sound, or Mach 1, and went supersonic. It was approaching a dangerous region of the ascent. As the stack rose, the density of the air around it gradually diminished, yet as the rocket gained speed, it continued to ram air onto its forwardfacing surfaces, thereby raising the aerodynamic pressure, especially at the conical sections, and increasing the stresses on the skin. At about 14 kilometres, this dynamic pressure, known as ‘Q’, reached its greatest extent, a point in the flight called hnax-Q’. Beyond this point, the rapidly thinning air reduced these aerodynamic stresses.