FLIGHTS

RISKS IN RESEARCH AIRCRAFT

When we talk about risk, we mostly mean the life of the pilot, the dangers to the man who governs the airplane through its flight path to the new conditions in flight that the new airplane will investigate. This is the life of a person who is talented, productive, and well experienced in test flying—and a human being unique in his flying abilities in high-speed and high-altitude flight.

These characteristics are in addition to all the other attributes that pertain to each person’s life. We also mean the risk to the airplane, which is important enough to have had many years of development, thousands of man-hours of workmanship, and millions of dollars in cost. If the airplane is lost, the research program for which it was designed is jeopardized.

These characteristics are in addition to all the other attributes that pertain to each person’s life. We also mean the risk to the airplane, which is important enough to have had many years of development, thousands of man-hours of workmanship, and millions of dollars in cost. If the airplane is lost, the research program for which it was designed is jeopardized.

![]()

|

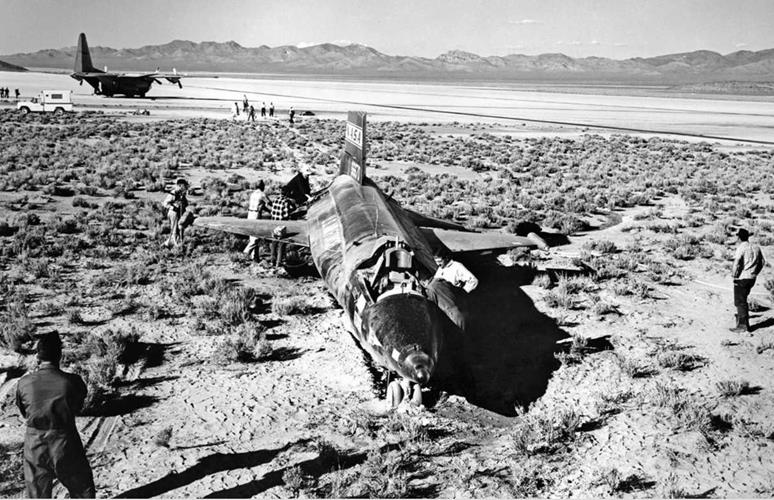

This research aircraft was designed to explore regions for flight at altitudes and speeds not yet then achieved. It incorporated a new, advanced design using new materials that allowed it to operate at higher temperatures than previously experienced. It had new and multiple control systems. It used a new rocket engine with a new fuel-oxidizer combination. It had twin skids rather than wheels for a landing gear.

Wind tunnel data existed for the aerodynamics in this new speed region, but it had not been evaluated and confirmed in flight. Moreover, not all the conditions of hypersonic flight that it experienced in the wind tunnel had been previously analyzed or fully understood. Some problems were not known until they were

discovered in flight. Therefore, they could not have been addressed in advance.

Before this aircraft could achieve hypersonic speeds and high altitudes, it still had to traverse all the flight regions previously explored. The new design had to prove that it could safely fly in those known flight regions. For example, it had to be able to take off on its own or be air-dropped in the subsonic regime. It then need to accelerate to high subsonic speeds, go through transonic flight, experience shock waves beginning at Mach 1, and accelerate to supersonic speeds, experiencing stability changes longitudinally, and thereafter in regions of reduced lateral-directional stability with increasing Mach number. It also had to decelerate and return to the landing site with normal

approach, descent, and landing, all without using thrusting power. It should be noted that although low-speed subsonic flight and landing had been analyzed for the X-15 for these conditions, they were not the primary focus of the design.

approach, descent, and landing, all without using thrusting power. It should be noted that although low-speed subsonic flight and landing had been analyzed for the X-15 for these conditions, they were not the primary focus of the design.

The pilots controlled many aspects of the flight, such as the handling and control actions about the three axes of the airplane and the application of thrust. But the pilots could not control other factors, such as the strength of materials at high temperatures and the effect of temperature gradients on the design and strength caused by high aerodynamic heating on the outside and cool internal temperatures.

The characteristics of the X-15 would not be definitively known and understood until verified or determined in actual flight. The handling characteristics in these regions were unique, controlled by the pilot with three different control systems: a traditional stick on the floor between the legs and a rudder; a small control stick on the right console, with power assist or electronic force amplification when experiencing dynamic pressures too high for normal pilot forces; and a rocket power control on the left console for use in space where the air is too thin and the dynamic pressure too low for aerodynamic control surfaces to be effective. In the X-15, the pilot experienced for the first time these new controls, designed for this airplane, following his drop from the B-52 at altitudes of about 40,000 feet and speeds of about Mach 0.8. There were no ground trials with the controls during taxiing or on short hops prior to a real test flight, as is possible while familiarizing oneself with the controls of a conventional aircraft that has wheels rather than skids and that has a jet or reciprocating engine instead of a rocket.

Pilots had to address new interfaces in each new test aircraft. For example, the X-15 was taken aloft by the B-52 and attached under the

B-52’s right wing, unlike the other rocket research aircraft. These previous X-airplanes were attached under the fuselage, allowing the test pilot to ride in the mother craft’s cabin and enter the test aircraft only after everything had been checked out. In the X-15, located out on the wing, the pilot had to enter his aircraft before B-52 takeoff, and he was at risk as the two airplanes climbed to altitude. He had to also check out the X-15 systems while riding in the X-15 after takeoff and prior to drop. He thus had to deal with the interface with the mother airplane mechanically and electronically, including communications, and also operationally by topping off the liquid oxygen and checking other conditions before separation and drop occurred in midair. In

both the X-15 and B-52, the interfaces included the mechanical ties between subsystems and components, each of which had their own requirements, as well as continuity of electrical and electronic signals that signaled to and from the pilot’s cabin and the operating systems, as well as the thermal interfaces that controlled the heating and cooling needs of particular subsystems and components. Repairs could have adversely affected these initial design conditions. An example of this occurred when extra cooling was needed for a component after problems in flight and an extra cooling line was installed to fix the problem. This new cooling line ran alongside an APU hydraulic line that caused its hydraulic fluid to freeze, preventing the APU from functioning.

A conventional aircraft has a shakedown period in which the newly installed subsystems first operate together as a complete aircraft system. Then interfaces with other elements of the airplane are tested mechanically, electrically, and thermally in actual flight conditions when they can be fine- tuned. Experience has shown that many changes

or improvements are necessary in a new airplane. Routinely, there are bugs to work out, safety issues to resolve, and procedures to establish. For the flight-test program, there is a new support team from management through inspection. For an airliner, it may take two years of testing before it is put into use. There is no such luxury for these high-performance research aircraft. They start out in their very first flight at 40,000 feet in the air. Experience also has shown that unexpected difficulties are uncovered in air-launched research aircraft such as the X-1, X-1A, and X-2, in the increasing velocity regions of transonic and supersonic flight.

or improvements are necessary in a new airplane. Routinely, there are bugs to work out, safety issues to resolve, and procedures to establish. For the flight-test program, there is a new support team from management through inspection. For an airliner, it may take two years of testing before it is put into use. There is no such luxury for these high-performance research aircraft. They start out in their very first flight at 40,000 feet in the air. Experience also has shown that unexpected difficulties are uncovered in air-launched research aircraft such as the X-1, X-1A, and X-2, in the increasing velocity regions of transonic and supersonic flight.

Such a flight program is necessarily risky.

This was a new airplane. The old flight regimes in which this plane had to traverse were not the prime focus in design. New equipment, previously untested in flight, was necessary, and the exploration was conducted in a new flight regime to ascertain the validity and shortcomings of the applicable theories, which were approximated with many simplifying assumptions and the use of wind tunnel test data.

Since the X-15 followed the course of the previous X-aircraft, it also had numerous difficulties with equipment—such as the auxiliary power units, landing gear, windshield and cockpit seals, stability in landing, and so forth—that required pilot experience, fortitude, and ingenuity to overcome. In the 199 flights, the problems were frequent, unanticipated, and in many instances life-threatening. It was the piloting excellence, the prior experience of the pilots and engineers, and the extensive preparation for each flight—including hours of simulation—that permitted these many flights to be completed with only one fatality.

Another difference from conventional aircraft testing relates to the lack of any power when the rocket fuel is expended. The fuel is used up in just about 90 seconds of flight. Conventionally

The David Clark full-pressure suit was developed by Dr. David Clark and produced in his small factory in Worcester, Massachusetts. Unlike previous partial-pressure suits that pressurized only parts of the human body, Clark’s full – pressure suit provided pressurization for the whole body. It was made from his patented Link-Net nylon fabric, which consisted of two layers of nylon arranged with opposite bias that provided maximum strength in high-stress areas while also allowing the suit to deform easily to the pilot’s movement. It was lightweight, but it held its shape under pressure. The suits were custom-made for each pilot, who had to make several trips to Worchester for fitting. Clark made improvements to the suit throughout the X-15 program. It became the standard full-pressure suit for the Air Force and NASA, being used by pilots of the U-2 and SR-71 high-altitude spy planes as well as the Space Shuttle astronauts. Several photographs in Chapter 5 show some X-15 pilots in their David Clark full-pressure suits.

powered aircraft can reposition themselves if in trouble or when in descent, approach to landing, and during the landing itself. All X-15 flight positions and corrections have to be done with aerodynamic controls alone, not with power. If the landing approach is too high or too low, the pilot must bring it down safely without power. He cannot go around the field a second time to try again. His first attempt must be successful.