|

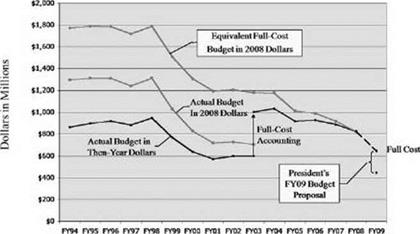

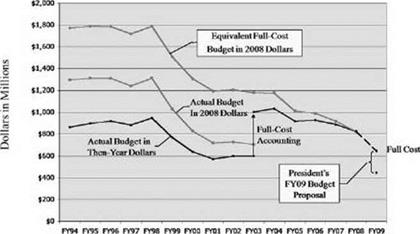

The above chart shows the decrease in NASA’s aeronautics budget. Courtesy of Roy Harris, chief technical adviser to NASA’s aeronautics support team. Not official NASA budget data.

|

Raymond Colladay recently argued. “Ever since NACA was morphed into NASA, the role of aeronautics in NASA has been kind of a stepchild.”[381] Aeronautics, Colladay explained, has been threatened by so many cuts, and there is now no strong aeronautics advocate or leadership within the administration. “In the last 6 years or so," he said, “the aeronautics program has been continually cut to the point where it was on a glide-slope to go to zero.” The cuts were difficult to fight because they were subtle and quiet, but not anymore. Colladay concluded. “It wasn’t over any big ideological or political kind of battle which we faced in the eighties, it just was more from benign neglect.”

Perhaps the era of neglect is over. Immediately after Barack Obama was elected President in November 2008,60 Minutes interviewed him. and he discussed the wild fluctuations in the price of oil. The question posed to him was: “When the price of oil was at SI47 a barrel, there were a lot of spirited and profitable discussions that were held on energy independence.

Now you’ve got the price of oil under S60. . . . Does doing something about energy is it less important now. …” Before the interviewer had a chance to finish the question. Obama said, “It’s more important. It may be a little harder politically, but it’s more important." When asked why it is more important now when oil is so inexpensive. Obama explained that this was because this has been the pattern in recent American history. As oil prices go up. Obama explained, there is a political will to solve the problem. But he lamented that as soon as prices went back down, “suddenly we act like it’s not important, and we start, you know, filling up our SUVs again." Obama called this phenomenon “from shock to trance" and said it was all a part of “our addiction.” Obama concluded the interview with a vow that this pattern had to be broken: “Now is the time to break it.”[382] [383] Breaking this pattern will be much more difficult, with NASA having a significantly weakened aeronautics capability thanks to years of low funding and support. Much of its DOD connections were cut during the administration of Daniel Goldin, which removed yet another funding opportunity. As Langley engineer Joseph Chambers observed, “Today’s NASA aeronautics program is virtually invisible and without a large focused effort. Since the 1990s new embryonic starts are enthusiastically briefed to industry and DOD, advocacy gained within peer groups, and initiated with great fanfare, only to be canceled within a year or so.”14 Although NASA, the Government, industry, and the public are all aware of the importance of fuel efficiency in this time of crisis, there is no guarantee that we have yet learned our lesson. As one reporter suggested in 2008, “If things settle down and seem less crisis-like in the future, are we going to lose interest? Will our attention spans be longer than they have been in the past? I don’t know the answers to those questions.”[384] Time will tell if we have become wiser and more able to enact policies and change public opinion that can endure longer than the latest oil price cycle. It will require a political will to impart a long-term vision to a country that changes policy all too often to respond to immediate problems. What is needed is the will to break the trance and establish a lasting, structural, foundational plan to develop fuel-efficient aeronautics technologies. Does President Obama have this political will? At the time of this writing, it is still too early to tell. The only thing for certain is that the sooner we come to this understanding, the better. We cannot make more oil. It is a finite resource, the vast majority of it is not under our control, and it is the lifeblood of our economy. Only when we truly come to terms with this will we be ready to acknowledge the need and establish the long-term support and vision for a new “Apollo of Aeronautics” to help us escape from a predictable and lasting threat.

|

|

ark D. Bowles is associate professor of history at American Public University and founder of Belle History, a public history company (www. beUehistory. com). He has authored or coauthored eight books on the history of aeronautics, education, and medicine. His most recent. Chains of Opportunity (University of Akron Press. 2(X)8), is a history of the emergence of the “polymer age" from the institutional perspective of one of the leading polymer universities in the world. His Science in Flux (NASA, 2006) won the American Institute of Aeronautics and Astronautics’ 2005 History Manuscript Award, which is presented each year for the best historical manuscript dealing with the impact of aeronautics and astronautics on society. The “Apollo" of Aeronautics won the same award for 2010. He received his B. A. in psychology (1991) and M. A. in history (1993) from the University of Akron. He earned his Ph. D. in the history of technology (1999) from Case Western Reserve University and his MBA in technology management from the University of Phoenix (2005). He has been married to his wife, Nancy, for 19 years, and they are raising their 9-year-old daughter, Isabelle, and newborn twin girls, Emma and Sarah, in northeast Ohio. He can be reached at mark@bellehistory. com.

[1] Statement by various participants to the Senate Committee on Aeronautical and Space Sciences, Nov. 4. 1975. Box 179. Division 8000, NASA Glenn archives.

[2] “Airlines to Furlough 25.000 by January Due to Fuel Crisis; Pan Am Seeks Cutbacks.” Wall Street Journal. Dec. 11. 1973. p. 12.

[3] Statement by Charles F. McErlean to the Senate Committee on Aeronautical and Space Sciences. Nov. 4. 1975, Box 179. Division 8000. NASA Glenn archives.

[4] “Aircraft Fuel Efficiency Program,” Report of the Committee on Aeronautical and Space Sciences of the United States Senate. Feb. 17. 1976.

[5] LAV. Reilhmaier, Much I and licutml: The Illustrated Guide to High-Speed Flight (New York: TAB Books. 1995), p. 189. Jeffrey L. Ethell. Fuel Economy in Aviation (Washington. DC: NASASP-462.1983).p. I. Stephen L. McFarland.“Higher. Faster. and Farther: Fueling the Aeronautical Revolution. 1919-45." Innovation and the Development of Flight. Roger D. Launius, ed. (Texas: Texas A&M University Press. 1999), pp. 100-131.

[6] After advances in speed, as well as airfoils, composite structures, and onboard computers in the 1960s and 1970s. the "era of higher, faster, and farther in flight records was largely over.” Donald M. Pattilo. Pushing the Envelope: The American Aircraft Industry (Michigan: University of Michigan Press. 1998). p. 267.

[7] Brian И. Rowe with Martin Ducheny. The Power to Fly: An Engineer’s Life (Reston. VA: American Institute of Aeronautics and Astronautics. 2005), p. v.

[8] Joseph R. Chambers. Innovation in Flight: Research of the NASA Langley Research Center on Revolutionary Advanced Concepts for Aeronautics (Washington. DC: NASA History Division. 2005). p. 6. Erik Conway in has masterfully told this story. Conway. High-Speed Dreams: NASA and the Technopolitics of Supersonic Transportation. I945-I999(Baltimore: Johns Hopkins University Press. 2005).

[9] Chambers, correspondence with Mark D. Bowles, Mar. 28.2009.

[10] Interview with Donald Nored. by Virginia P. Dawson and Bowles, Aug. 15. 1995.

[11] Examples include: Roger E. Bilstein. Testing Aircraft. Exploring Space: An Illustrated History ofNACA and NASA (Baltimore: Johns Hopkins University Press. 2003), pp. 122-123; James R. Hansen. The Bird Is on the Wing: Aerodynamics and the Progress of the American Airplane. Centennial of Flight Series. No. 6. (College Station: Texas A&M University Press. 2004). p. 204: Louis J. Williams. Small Transport Aircraft Technology (The Minerva Group. 2001). p. 37: William D. Siuru and John D. Busiek. Future Flight: The Next Generation of Aircraft Technology. (Blue Ridge Summit. PA: TAB/AERO. 1994). p. 5: Conway. High-Speed Dreams, p. 265: Ahmed Khairy Noor. Structures Technology: Historical Perspective and Evolution (Reston. VA: AIAA, 1998). p. 298.

[12] Bowles and Dawson. “The Advanced Turboprop Project: Radical Innovation in a Conservative Environment.” Front Engineering Science to Big Science: The NACA and NASA Collier Trophy Research Project Winners. Pamela E. Mack. ed. (Washington. DC: NASA SP-4219, 1998). pp. 321-343.

[13] Roy D. Hager and Deborah Vrabel. Advanced Turboprop Project (Washington. DC: NASA SP-495. 1988). Carl C. Ciepluch. Donald Y. Davis, and David E. Gray, “Results of NASA’s Energy Efficient Engine Program." Journal of Propulsion, vol. 3. No. 6 (Nov.- Dee. 1987). pp. 560-568.

[14] Marvin B. Dow. "The ACEE Program and Basic Composites Research at Langley Research Center (1975 to 1986)." (Washington, DC: NASA RP-1177. 1987). David B. Middleton. Dennis W. Bartlett, and Ray V. Hood. Energy Efficient Transport Technology (Washington. DC: NASA RP-1135. Sept. 1985). Albert L. Braslow. A History of Suction- Type Laminar Flow Control with Emphasis on Flight Research (Washington. DC: NASA Monographs in Aerospace History No. 13. 1999).

[15] Jeffrey L. Ethell. Fuel Economy in Aviation (Washington. DC: NASA SP-462. 1983).

[16] Lisa Mastny. “World Air Traffic Soaring." Vital Signs 1999: The Environmental Trends that arc Shaping Our Future. Lester Russell Brown. Michael Renner, and Linda Starke, eds. (New York: Norton, 1999), p. 86.

[17] Thomas Hughes, American Genesis, p. 54.

[18] David A. Hounshell. “Hughesian History of Technology and Chandlerian Business History: Parallels. Departures, and Critics." History and Technology, vol. 12 (1995). p. 217.

[19] Ibid. See also Hounshell and John Kenly Smith. Jr.. Science and Corporate Strategy: Du Pont R&D. 1902-1980 (Cambridge: Cambridge University Press. 1988).

[20] Robert W. Leonard. “Fuel Efficiency Through New Airframe Technology.” NASA TM-84548. Aug. 1982.

[21] Robert K. Schaeffer. Understanding Globalization: The Social Consequences of Political. Economic, and Environmental Change (Lanham, MD: Row man & Littlefield Publishers. 2009). pp. 9-10.

[22] John Newhouse, Hoeing Versus Airbus: The Inside Story of the Greatest International Competition in Business (New York: A. A. Knopf. 2007).

23 Janies J. Kramer. “Aeronautical Component Research." Advisory Group for Aerospace Research and Development (Report No. 782. 1990).

24. “Survey Finds Little Impact of Election on Aerospace.” Aviation Week <& Space Technology. Nov. 3. 1980. p. 34.

[25] Raymond Colladay. interview with Bowles. July 21.2008.

[26] Other examples besides the Supersonic Transport were SCAR and HSR. Chambers, correspondence with Bowles, Mar. 28.2009.

[27] Abe Silverstein to George Low. Nov. 16, 1973. Box 181. Division 8000, NASA Glenn archives.

[28] Wolfgang Saxon. “Abe Silverstein. 92. Engineer Who Named Apollo Program,” New York Times. June 5. 2001.

[29] Ethell. Fuel Economy in Aviation (Washington. DC: NASA SP-462. 1983). p. 2.

[30] General Accounting Office. “Preliminary Draft of a Proposed Report, Review of NASA’s Aircraft Energy Efficiency Project.” Box 182. Division 8000. NASA Glenn archives.

[31] Bowles and Dawson. "The Advanced Turboprop Project," pp. 321-343.

[32] ."Terrorist’s Bomb Opens Yom Kippur.” Las Angeles Times. Oct. 6. 1973. p. 13. 2.“Sirens Break Solemnity of Israel’s Yom Kippur." Los Angeles Times. Oct. 7. 1973, p. 8.

[33] Glenn Blackburn. Western Civilization: From Early Societies to the Present (New York: St. Martin’s Press. 1991). p. 238.

[34] John Noble Wilford. “Nation’s Energy Crisis: It Won’t Go Away Soon,” New York Times. July 6. 1971. p. 1.

[35] Wilford. “Nation’s Energy Crisis: Nuclear Future Looms.” New York Times. July 7. 1971.p.1.

[36] Earl Cook. Man, Energy, Society (San Francisco. CA: W. H. Freeman. 1976). p. 208.

[37] Clyde 11. Farnsworth. “Oil as an Arab Weapon,” New York Times. Oct. 18. 1973. p. 97.

8 “Saudis Threaten U. S. Oil Embargo.” Washington Post. Oct. 19. 1973. p. Л1.

[39] Don Peretz, The Middle East Today. 5th ed. (New York: Praeger. 1988). p. 254.

[40] Victor Israelyan, Inside the Kremlin During the Yom Kippur (University Park. PA: Pennsylvania Stale University Press, 1995). p. x.

[41] “Nixon Sees ‘Possibility’ of Arabs Lifting Oil Embargo: Signs Alaska Pipeline Bill." Los Angeles Times. Nov. 16. 1973.

[42] Joseph Alsop. “Oil Blackmail Threatens U. S. Independence." Washington Post. Nov. 21,1973. p. A19.

[43] Soma Golden. “Impact of Embargo Lingers On.” New York Times. Mar. 17. 1974. p. 155.

[44] Thomas Rees, quoted in Martha L. Willman."Oil Embargo End May Be Ruinous,” Ims Angeles Times. Feb. 10. 1974. p. SF_C2.

[45] “Saudis Threaten U. S. Oil Embargo.” Washington Post, Oct. 19. 1973. p. AI.

[46] “The Arab Oil Threat.” New York Times. Nov. 23.1973. p. 34.

[47] Robert C. Cowen, "Fiddling While the Energy Runs Out.” Christian Science Monitor. Jan. 29.1975. p. 11.

[48] Victor K. McElheny, “Hans Bethe Urges U. S. Drive for Atom Power and Coal.” New York Times. Dec. 14. 1974. p. 58.

[49] Cowen, “Fiddling While the Energy Runs Out." p. 11.

[50] Tom Wicker. “Mr. Foid Acts Like a President.” New York Times. Jan. 31.1975.

[51] Eugene Kozicharow. “New NASA Aeronautics Stress Sought," Aviation Week <& Space Technology. Oct. 4. 1976, p. 23.

[52] “Aircraft Fuel Conservation Technology Task Force Report." Office of Aeronautics and Space Technology, Sept. 10.1975. p. 7.

[53] Statement by Clifton F. von Kann to the Senate Committee on Aeronautical and Space Sciences. Sept. 10. 1975. Box 179. Division 8000, NASA Glenn archives.

[54] John Klineberg. interview with Bowles. July 28.2008.

[55] Barry Goldwater and Frank E. Moss to James C. Fletcher, as quoted in “Aircraft Fuel Conservation Technology Task Force Report." Office of Aeronautics and Space Technology. Sept. 10. 1975.

[56] Bill Siuru and John D. Busick, Future Flight: The Next Generation of Aircraft Technology (Blue Ridge Summit. PA: ТЛВ/AERO. 1994). p. 37.

[57] Gerald G. Kay ten. NASA Headquarters Director of Study and Analysis, to Lewis Research Center director. Dec. 7. 1973. Box 181. Division 80(H). NASA Glenn archives.

[58] Ethell. Fuel Economy in Aviation, p. 7.

[59] The task force included: Jim Kramer (director), John Klineberg. Bill McGowan, Fred Povinelli. and Bill Roudebush. OAST: Darrell Wilcox and Lou Williams. Ames Research Center; Del Nagel. Joe Alford, and Dal Maddalon. Langley Research Center; Milt Beheim and Dick Weber. Lewis Research Center: Dick Baird, the Department of Defense: Bill Devereaux. the Department of Transportation: and Herm Rediess and Joe Tymczyszyn. Federal Aviation Administration.

[60] The advisory board included: Raymond L. Bisplinghoff, University of Missouri: Jack L. Kerrebrock. the Massachusetts Institute of Technology; Franklin W. Kolk. American Airlines: John G. Borger. Pan American World Airways; Ronald Smelt. Lockheed Aircraft Corporation; Charles S. Glasgow. Jr.. Douglas Aircraft Company: Abe Silverstein. a former NASA Center Director: Michael I. Yarymovych. the Energy Research and Development Administration: William E. Stoney. the Department of Transportation: Robert N. Parker, the Department of Defense: Richard Coar. Pratt & Whitney Aircraft Division: H. W. Withington, Boeing Commercial Airplane Company; and Edward Woll. General Electric.

[61] Klineberg, interview with Bowles, July 28.2008.

[62] Statement by Kramer to the House of Representatives Subcommittee on Aviation and Transportation R&D Committee on Science and Technology, Sept. 1975. Box 179. Division H(MX). NASA Glenn archives.

[63] Hans Mark to Alan Lovelace. June 4. 1975. Box 181. Division 8000. NASA Glenn archives.

[64] Bisplinghoff to Lovelace, July 30.1975. as found in, “Aircraft Fuel Conservation Technology Task Force Report," Office of Aeronautics and Space Technology. Sept. 10. 1975.

[65] “Advisory Board Report of the Third Meeting on Aircraft Fuel Conservation Technology." Box 179. Division 8000. NASA Glenn archives.

[66] “Examination of the Costs. Benefits and Energy Conservation of the NASA Aircraft Fuel Conservation Technology Program." Report No. 8291-01. Nov. 15. 1975, pp. 12.18. and 32. as found in. Box 948. Division 2700. NASA Glenn archives.

[67] The Senate Committee on Aeronautical and Space Sciences included: Chairman Frank E. Moss (D-UT). Stuart Symington (D-MO), Barry Goldwater (D-AZ). John C. Stennis (D-MS). Pete V. Domenici (R-NM), Howard W. Cannon (D-NV). Paul Laxalt (R-NV). Wendell 11. Ford <D-KY). Jake Gant (R-IJT). and Dale Bumpers (D-AR).

[68] Statement by Clifton F. von Kann to the Senate Committee on Aeronautical and Space Sciences. Sept. 10. 1975. Box 179. Division 8000. NASA Glenn archives.

[69] Statement by W alter B. LaBerge to the Senate Committee on Aeronautical and Space Sciences. Sept. 10. 1975. Box 179. Division 8000, NASA Glenn archives.

[70] Statement by George M. Low to the Senate Committee on Aeronautical and Space Sciences. Sept. 10. 1975. Box 179. Division 8000. NASA Glenn archives.

[71] Statement by Alan M. Lovelace to the Senate Committee on Aeronautical and Space Sciences. Sept. 10. 1975. Box 179. Division 8000. NASA Glenn archives.

[72] Statement by Raymond L. Bisplinghoff to the Senate Committee on Aeronautical and Space Sciences. Sept. 10. 1975, Box 179. Division 8000. NASA Glenn archives.

[73] Statement by George H. Pedersen to the Senate Committee on Aeronautical and Space Sciences. Oct. 23. 1975. Box 179. Division 8000, NASA Glenn archives.

[74] Statement by Karl G. Harr. Jr., to the Senate Committee on Aeronautical and Space Sciences. Oct. 23. 1975. Box 179. Division 8000. NASA Glenn archives.

[75] Statement by John E. Steiner to the Senate Committee on Aeronautical and Space Sciences. Oct. 23. 1975, Box 179. Division 8000. NASA Glenn archives.

[76] Statement by Bruce N. Torell to the Senate Committee on Aeronautical and Space Sciences. Oct. 23. 1975. Box 179. Division 8000. NASA Glenn archives.

[77] Letter from Gerhard Neuman to the United States Senate Committee on Aeronautical and Space Sciences. Oct. 22.1975. Box 179, Division 8000. NASA Glenn archives.

[78] Statement by Yuji Sawa to the Senate Committee on Aeronautical and Space Sciences. Nov. 4. 1975. Box 179. Division 8000. NASA Glenn archives.

[79] Statement by Charles F. McErlean to the Senate Committee on Aeronautical and Space Sciences. Nov. 4. 1975. Box 179. Division 8000. NASA Glenn archives.

[80] Statement by Roger W. Sant to the Senate Committee on Aeronautical and Space Sciences. Nov. 4. 1975. Box 179. Division 8000. NASA Glenn archives.

[81] Statement by James S. Kane to the Senate Committee on Aeronautical and Space Sciences, Nov. 4. 1975. Box 179. Division SOW. NASA Glenn archives.

[82] Statement by Klaus P. 1 leiss. president of ECON, Inc., to the Senate Committee on Aeronautical and Space Sciences. Nov. 4.1975. Box 179. Division 8000. NASA Glenn archives.

[83] Letter from James F. Dugan to the Director of Aeronautics. Sept. 15. 1975. as found in Box 179. Division 8000. NASA Glenn archives.

[84] “Aircraft Fuel Efficiency Program.” Report of the Committee on Aeronautical and Space Sciences of the United States Senate. Feb. 17. 1976. p. 6.

[85] Ibid., p. 7.

[86] Ibid., p. 9.

[87] Ibid., p. 10

[88] Roger E. Bilstein. Testing Aircraft. Exploring Space (Baltimore: The Johns Hopkins University Press, 2003). p. 123.

[89] Charles Hillinger. “Jet Fighter Made of Thread.” Los Angeles Times. Nov. 6. 1978.

[90] Anthony Ramirez. “Advanced Composite Construction.” Los Angeles Times. Sept. 4. 1984.

[91] James J. Haggerty. “Winglets for the Airlines.” Spinoff 1994. (Washington. DC: NASA, 1994). pp. 90-91.

[92] Richard Whitcomb, quoted in Tom D. Crouch. Wings: A History of Aviation from Kites to the Space Age (New York: WAV. Norton & Co.. 2003), p. 462.

[93] Robert W. Leonard and Richard D. Wagner, “Airframe Technology for Energy Efficient Transport Aircraft." Aerospace Engineering and Manufacturing Meeting of the Society of Automotive Engineers. Nov. 29-Dec. 2. 1976.

[94] James Schultz. Winds of Change: Ex/Kinding the Frontiers of Flight: Langley Research Center’s 75 Years of Accomplishment 1917-1992 (Washington. DC: NASA, 1992). Roger D. Launius and Janet R. Daly Bednarek. eds.. Reconsidering a Century of Flight. (Chapel Hill: University of North Carolina Press. 2003). Tom D. Crouch. Wings: A History of Aviation from Kites to the Space Age (Washington. DC: Smithsonian National Air and Space Museum. 2003).

[95] Thomas Wolfe. Look Homeward. Angel: A Story of the Buried Life (New York: Charles Scribner. 1957), p. 121.

[96] “Poor Old Langley." Los Angeles Times. May 27. 1918.

[97] “Langley Research Center. Research Highlights. 1917-1967." Unit 4A. Cabinet 4. Shelf 3. Langley History Box 1. NASA Langley archives.

[98] Alex Roland. Model Research: The National Advisory Committee for Aeronautics, 1915-1958. vol. 1 (Washington. DC: NASA SP-4103. 1985). p. 83. Hansen, Engineer in Charge, pp. xxxi-xxxii.

[99] Roland. Model Research, p. 225.

[100] Dawson, correspondence with Bowles. May 3. 2009. Dawson. Engines and Innovation: Lewis Laboratory and American Propulsion Technology (Washington. DC: NASA SP-4306. 1991). pp. 163-166.

[101] Hansen, Engineer in Charge, p. 396.

[102] Roland. Model Research, p. 283.

[103] Chambers. Innovation in Flight.

[104] Robert W. Leonard. “Fuel Efficiency Through New Airframe Technology." NASA TM-84548. Aug. 1982.

[105] Albert L. Braslow and Ralph J. Muraca, “A Perspective of Laminar-Flow Control,” ЛІАА Conference on Air Transportation. Aug. 21-24. 1978, p. 2.

[106] Hearth, quoted in Craig Covault, “Langley Aiding Transport Competition.” Aviation Week & Space Technology, Aug. 21. 1978. p. 14.

[107] Leonard. “Fuel Efficiency Through New Airframe Technology.” NASA TM-84548, Aug. 1982.

[108] Chambers. Concept to Reality: Contributions of the NASA Langley Research Center to U. S. Civil Aircraft of the 1990s (Washington. DC: NASA SP-2003-4529. 2003).

[109] Tom Crouch. The Bishop’s Hoys: A Life of Wilbur and Orville Wright (New York: W. W. Norton & Co.. 1989).

[110] “Aeronautics—A Century of Progress.” Presented at the 50th Anniversary Celebration and Inspection of Langley Research Center. Oct. 2-6. 1967. Unit 4A. Cabinet 4. Shelf 3. Langley History Box I. NASA Langley archives.

[111] Ethell. Fuel Economy in Aviation, p. 59.

[112] John Cutler and Jeremy Liber. Understanding Aircraft Design, 4th ed. (Oxford: Black – well Publishing. 2005), p. 159.

[113] Charles llillinger. "Jet Fighter Made of Thread.” Los Angeles Times. Nov. 6.1978.

[114] Marvin B. Dow, "The ACEE Program and Basic Composites Research at Langley Research Center < 1975 to 1986)" (Washington. DC: NASA RP-1177,1987). p. 1.

[115] "ACEE Program Overview," NASA RP-79-3246(l). July 31.1979. Box 239. Division 8000. NASA Glenn archives.

[116] L. F. Vosteen, Composite Structures for Commercial Transport Aircraft (Washington. DC: NASA TM-78730, June 1978).

[117] A. Cominsky, Manufacturing Development of DC-Ю Advanced Rudder (Washington, DC: NASACR-159060, Aug. 1979).

[118] D. V. Chovil, S. T. Harvey. J. E. McCarty, O. E. Desper, E. S. Jamison, and H. Snyder. Advanced Composite Elevator for Boeing 727 Aircraft, vol. I (Washington. DC: NASA CR-3290, Nov. 1981).

[119] C. F. Griffin. L. D. Fogg, and E. G. Dunning, Advanced Composite Aileron for L-I01I Transport Ain raft: Design and Analysis (Washington. DC: NASA CR-165635, Apr. 1981).

[120] “Composite Ailerons Readied for L-101 Is." Aviation Week <& Space Technology, Oct. 13.1980.p.27.

[121] “ACEE Program Overview," July 31. 1979. Box 239. Division 8000. NASA Glenn archives.

[122] T. Alva. J. Henkel. R. Johnson. B. Carll. A. Jackson. B. Mosesian. R. Brozovic. R. O’Brien, and R. Eudaily. Advanced Manufacturing Development of a Composite Empennage Component for L-I01I Aircraft (Washington. DC: NASA CR-165885. May 1982).

[123] “Boeing 737 with New Stabilizer Makes First Flight.” Aviation Week <i Space Technology. Oct. 13, 1980. p. 37.

[124] R. B. Aniversario, S. T. Harvey. J. E. McCarty. J. T. Parsons. D. C. Peterson, L. D. Pritchett. D. R. Wilson, and E. R. Wogulis, Design. Ancillary Testing. Analysis ami Fabrication Data for the Advanced Composite Stabilizer for Boeing 737 Aircraft, vol. 2 (Washington, DC?: NASA CR-1660II. Dec. 1982).

[125] C. O. Stephens, Advanced Composite Vertical Stabilizer for DC-10 Transport Aircraft (Washington. DC: NASA CR-173985, July 1978).

[126] “New Tests of DC-10 Composite Stabilizer Set.” Aviation Week <& Space Technology. May 6. 1985. p. 94. Dow. “The ACEE Program and Basic Composites Research at Langley Research Center (1975 to 1986)” (Washington. DC: NASA RP-1177.1987). p. 1. L. F. Vosteen. Composite Structures for Commercial Transport Aircraft (Washington. DC: NASA TM-78730, June 1978).

[127] M. S. Anderson. WJ. Stroud. В J. Durling. and K. W. Hennessy, PASCO: Structural Panel Analysis and Sizing Code (Washington, DC: NASA TM-80182. Nov. 1982).

[128] S. B. Diggers and J. N. Dickson. POSTOP: PoStbuckledOpen-Stiffener Optimum Panels (Washington. DC: NASA CR-172260. Jan. 1984).

[129] C. D. Babcock and A. M. Waas. Effect of Stress Concentrations in Composite Structures (Washington. DC: NASA CR-176410, Nov. 1985).

[130] J. W. Deaton. A Repair Technology Program at NASA on Composite Materials (Washington. DC: NASA T. M-84505. Aug. 1982).

[131] D. J. Hoffman. Environmental Exposure Effects on Composite Materials for Commercial Aircraft (Washington. DC: NASA CR-165649, Aug. 1980).

[132] R. A. Pride. “Interim Results of Long Term Environmental Exposures of Advanced Composites for Aircraft Applications." Proceedings of the llth Congress of the International Council of the Aeronautical Sciences, vol. 1. Sept. 1978. pp. 234-241.

[133] R. L. Coggeshall, Environmental Exposure Effects on Composite Materials for Commercial Aircraft (Washington, DC?: NASA CR-177929. Nov. 1985).

[134] “Composites Programs Pushed by NASA,” Aviation Week c£- Space Technology. Nov. 12.1979.p.203.

[135] “Carbon Fiber Hazard Concerns NASA." Aviation Week <& Space Technology. Mar. 5. 1979,p.47.

[136] Risk Analysis Program Office. Risk to the Public From Carbon Fibers Released in Civil Aircraft Accidents ( Washington. DC: NASA SP-448. 1980).

[137] Ibid.

[138] “Composite Wing,” Aviation Week & Space Technology, Dee. 28. 1981. p. 12.

[139] C. F. Griffin. Fuel Containment and Damage Tolerance in Large Composite Primary Aircraft Structures (Washington. DC: NASA CR-166083, Mar. 1983).

[140] J. Lameris. S. Stevenson, and B. Streeter, Study of Noise Reduction Characteristics of Composite Fiber-Reinforced Panels (Washington. DC: NASA CR-168745. Mar. 1982).

[141] PJ. Smith. L. W. Thomson, and R. D. Wilson. Development of Pressure Containment and Damage Tolerance Technology for Composite Fuselage Structures in Large Transport Aircraft (Washington. DC: NASA CR-178246. 1986). A. C. Jackson. F. J. Balena. W. L. La – Barge. G. Pei, W. A. Pitman, and G. Wittlin. Transport Composite Fuselage Technology— Impact Dynamics and Acoustic Transmission. (Washington. DC: NASACR-4035. 1986).

[142] Dow. “The ACEE Program and Basie Composites Research at Langley Research Center (1975 to 1986)." NASA RP-1177. 1987. p. 5.

[143] Richard G. O’Lone, "Industry Tackles Composites Challenge,” Aviation Week & Space Technology, Sepl. 15. 1980. p. 80.

[144] Interview with Herman Rediess by Bowles. June 6,2008.

[145] Mark A. Chambers. From Research to Relevance: Significant Achievements in Aeronautical Research at Langley Research Center {1917-2002) (Washington. DC: NASA NP-2003-01 -28-LaRC. 2003). p. 15.

[146] R. C. Madan and M J. Shu art. “Impact Damage and Residual Strength Analysis of Composite Panels with Bonded Stiffeners.” Composite Materials: Testing anti Design, vol. 9. S. P. Garbo, ed. (Philadelphia: American Society for Testing and Materials. 1990). p. 64.

[147] Alan Baker. Stuart Dutton, and Donald Kelly, eds.. Composite Materials for Aircraft Structures. 2nd ed. (Reston. VA: American Institute of Aeronautics and Astronautics. 2004). p. I.

[148] Chambers, Concept to Reality.

[149] See "Boeing Dreamliner Will Provide New Solutions for Airlines, Passengers." as found at h4p:llvww. boeing£omlcommerci(il!787family/backgrotmd. hinil. accessed Sept. 2. 2(X)9.

[150] Ethell. Fuel Economy in Aviation, p. 74.

[151] Chambers, Concept to Reality.

[152] Leonard and Wagner, “Airframe Technology for Energy Efficient Transport Aircraft.” Aerospace Engineering and Manufacturing Meeting of the Society of Automotive Engineers. Nov. 29-Dec. 2. /976.

[153] David B. Middleton. Dennis W. Bartlett, and Ray V. Hood. Energy Efficient Transport Technology (Washington, DC: NASA RP-1135. Sept. 1985). This is an excellent concluding summary to the EET program and includes a comprehensive bibliography.

[154] Bilstein. Testing Aircraft. Exploring Space, pp. 106-107.

[155] Elhell. Fuel Economy in Aviation, p. 78.

[156] Bill Siuru and John D. Busiek. Future Flight: The Next Generation of Aircraft Technology. 2nd ed. (Blue Ridge Summit, PA: TAB/AERO. 1994), p. 36.

[157] Richard Whitcomb, quoted in Richard Witkin. “NASA Says the Supercritical Wing is Passing Tests.” New York Timex. Mar. 5. 1972.

[158] Hausen. The Bird is On the Wing, p. 196.

[159] Whitcomb, quoted in Warren C. Wetmore. “Langley Presses Fuel Efficiency Programs.” .Aviation Week A Space Technology. Nov. 10. 1975. p. 68.

[160] James J. Haggerty. "Winglets for the Airlines.” Spinoff 1994. pp. 90-91.

[161] Hansen. The Bird Is on the Wing. p. 200.

[162] R. V. Hood. Jr.. "The Aircraft Energy Efficiency Active Controls Technology Program." Guidance and Control Conference, Aug. 8-Ю. 1977. Hollywood. T’L. АІЛЛ Paper 77-1076. p.279.

[163] Jerry Mayfield. “Energy Efficiency Research Growing ” Aviation Week & Space Technology. Nov. 12. 1979. p. 119.

[164] Jeffrey M. Lenorovitz. “L-1011 Active Control System Tested ” Aviation Week & Space Technology, Sept. 19. 1977. p. 26.

[165] Ethell. Fuel Economy in Aviation, p. 96.

[166] Nacelle Aerodynamic and Inertial Louds (NAIL) Project-Summary Report (Washington. DC: NASA CR-3S85. 1982).

[167] Aircraft Surface Coatings—Summary Report (Washington. DC: NASA CR-3661. 1983).

[168] Natural Laminar Flow Airfoil Analysis and Trade Studies—Final Report (Washington. DC: NASA CR-159029. 1979).

[169] Middleton. Bartlett, and Hood. Energy Efficient Transport Technology, p. 16.

[170] James J. Kramer. “Aeronautical Component Research." Advisory Group for Aerospace Research and Development (Report No. 782. 1990). p. 5-4.

[171] Interview with Wagner by Bowles. June 30, 2008.

[172] Leonard, “Fuel Efficiency Through New Airframe Technology.” NASA TM-84548. Aug. 1982.

[173] Asra Q. Nomani, "Pan Am Seeks Chapter 11 Shield. Fuel Costs are Cited.” Wall Street Journal, Jan. 9. 1991. p. A3.

[174] Jack Egan. "Pan Am Warns Survival in Fuel Crisis May Depend on JJS. Aid,” Los Angeles Times. Dec. 5. 1973. p. BIO. “Pan Am Loss Jumps More Than 4 Times to SSI Million,” Los Angeles Times. Feb. 6. 1975. p. EI4.

[175] N. B. Andersen and L. H. Allen, Engine Component Improvement Program. Airline Evaluation. Dec. 19. 1980. Report of Meeting No. 10. Box 208. Division 8000. NASA Glenn archives.

[176] Donald L. Nored to director of aeronautics, Feb. 8. 1979. Box 244. Division 80(X>. NASA Glenn archives.

[177] Interview with Nored by Dawson and Bowles, Aug. 15. 1995.

[178] William M. Leary, "Sharing a Vision: Juan Trippe, Charles Lindbergh, and the Development of International Air Transport,” Realizing the Dream of Flight: Biographical Essays in Honor of the Centennial of Flight. 1903-2003, Dawson and Bowles, eds. (Washington. DC: NASA SP-4112. 2005), p. 76. Likewise. Robert Gandt. a pilot who (lew with Pan Am for 26 years, said the company’s failure was due to the "complex life and times” caused by the energy crisis of the 1970s, rather than a failure of leadership. Robert Gandt. Skygods: The Fall of Pan Am (New York: William Morrow and Company. 1995).

[179] Harold M. Schmeck. Jr.. “NASA Cuts Programs to Save $200-Million in Current Budget.” New York Times. Jan. 6. 1973.

[180] Dawson, Engines and Innovation, p. 204.

[181] “Pollution Course Taught at Lewis." Lewis News. Dec. 31. 1970.

[182] Bowles. Science in Flux: NASA’s Nuclear Program at Plum Brook Station. 1955- 2005 (Washington. DC: NASA SP-4317.2006). p. 144.

[183] Dawson. Engines шиї Innovation, p. 204.

[184] David Brand. “It’s an 111 Wind. Etc.: Energy Crisis May Be Good For Windmills,” Wall Street Journal. Jan. 11. 1974.

[185] “NASA Sells World’s Largest Wind Turbine to Hawaiian Electric,” Lewis News. vol. 25. No. 3 (Feb. 5. 1988). p. 1.

[186] “Ohio to Seek Solar Institute: NASA’s Plum Brook Facility Could be Considered as Site,” Sandusky Register. Dec. 10. 1975.

[187] “Village to Get Its Power from Sun.” Los Angeles Times. May 17. 1978.

[188] Howard W. Douglass, chief of the Lewis chemical energy division, to Robert E. English. regarding “Hybrid Vehicle Planning Exercise." June 24. 1975. Box 214. Division 8000. NASA Glenn archives.

[189] “Battery Power." Washington Post. Feb. 16. 1978.

[190] “I low Should NASA Conduct Research and Technology in Aeronautical Propulsion. Should the Agency Continue an Aeronautical Propulsion Program at LeRC?" draft report. Box 260. Division 8000. NASA Glenn archives.

[191] Dawson. Engines шиї Innovation.

[192] Nored. “ACEE Propulsion Background,” Jan. 14. 1980. unpublished report. Box 277. Division 8000. NASA Glenn archives.

[193] Ibid.

[194] Interview with Colladay by Bowles. July 21.2008.

[195] ACEE Engine Component Improvement Statement of Work. Dec. 7. 1976. Box 208. Division 8000. NASA Glenn archives.

[196] Joseph A. Ziemianski. “Project Plan. Engine Component Improvement Program,” Feb. 1976. Box 244. Division 8000. NASA Glenn archives.

[197] R. V. Garvin. Starting Something Big: The Commercial Emergence of GE Aircraft Engines (Reston, VA: American Institute of Aeronautics and Astronautics. 1998), p. 126.

[198] Klaus HUnecke, Jet Engines: Fundamentals of Theory. Design, and Operation (London: Zenith Press. 2005), p. 15.

[199] General Electric. “A Proposal for CF6 Jet Engine Component Improvement Program." Sept. 8. 1976. Box 251. Division 8000. NASA Glenn archives. Pratt & Whitney Aircraft, “Technical Proposal for the JT8D and JT9D Jet Engine Component Improvement Program." Sept. 8. 1976. Box 251. Division 8000. NASA Glenn archives.

[200] Interview with Colladay by Bowles. July 21.2008.

[201] Robert J. Anti to manager of the Engine Component Improvement Project Office, regarding negotiations of airline support contracts with Eastern Airlines and Pan American World Airways. Mar. 2. 1977. Box 208. Division 8000. NASA Glenn archives.

[202] Colladay, ‘‘Suggested Response to Congressional Inquiry on Cost Recoupment on the Engine Component Improvement Program." Box 244. Division 8000. NASA Glenn archives.

[203] Robert W. Drewes. The Ліг Force and the Great Engine War (Washington. DC: National Defense University Press. 1987). p. 79.

[204] Nored to director of aeronautics, Feb. 8. 1979. Box 244. Division 8000, NASA Glenn archives.

[205] Pan American World Airways contract with NASA Lewis Research Center. Feb. 28. 1977. Box 208. Division 8000. NASA Glenn archives.

[206] Etbell, Fuel Economy in Aviation (Washington. DC: NASA SP-462. 1983). p. 20.

[207] Engine Component Improvement Program, Monthly Project Management Report. Sept. 30. 1977. Box 206. Division 8000. NASA Glenn archives.

[208] “NASA JT9d Engine Diagnostics Program.” Sept. 14.1977. Box 225. Division 8000. NASA Glenn archives.

[209] N. B. Andersen and L. li. Allen. Engine Component Improvement Program. Airline Evaluation. Dec. 19.1980. Report of Meeting No. 10, Box 208. Division 8000. NASA Glenn archives.

[210] ACEE Engine Component Improvement Statement of Work. Dee. 7. 1976. Box 208. Division 8000. NASA Glenn archives.

[211] Pratt & Whitney Aircraft. “Summary of the Proposal for the JT8D and JT9D Engine Component Improvement Program,” Sept. 8. 1976. Box 251. Division 8000, NASA Glenn archives.

[212] Robert M. Gaines. Assistant Counsel for Pratt & Whitney, Feb. 13, 1979. Box 244. Division 8000. NASA Glenn archives.

[213] Nored. response to Pratt & Whitney on reporting marketing-sensitive data on NASA ECI program. Feb. 8. 1979. Box 244. Division 8000. NASA Glenn archives.

[214] N. B. Andersen and J. G. Borger. Engine Component Improvement Program. Airline Evaluation, Mar. 22. 1977. Report of Meeting No. I. Box 208. Division 8000. NASA Glenn archives.

[215] Andersen and Burger. Engine Component Improvement Program. Airline Evaluation.

Oct. 31, 1978. Report of Meeting No. 6. Box 208. Division 8000. NASA Glenn archives. 44.Ibid.

[217] John E. McAulay. "Engine Component Improvement Program—Performance Improvement." Jan. 1980. Aerospace Sciences Meeting. AIAA Paper 80-0223.

[218] "Engine Component Improvement Report Status.” Mar. 1980. Box 224. Division 8000. NASA Glenn archives.

[219] Harry C. Stonecipher to John McCarthy. May 5.1980. Box 260. Division 8000. NASA Glenn archives.

[220] David J. Poferl. manager of the Advanced Propulsion Systems Office, memorandum for the record regarding a teleconference with Boeing’s Dick Martin. Feb. 25. 1980. Box 244. Division 8000. NASA Glenn archives.

[221] Roger Bilstein. Orders of Magnitude: A History of the NACA and NASA. 1915-1990 (Washington. DC: NASA SP-4406. 1989). p. 117.

[222] Howard Banks, “A Job Well Done." Forbes (Oct. 10.1983). p. 146.

[223] Skip Derra. “Joint R&D Program Improves Aircraft Engine Performance,” Industrial Research A Development (Nov. 1983). p. 79.

[224] Banks, "A Job Well Done.” p. 146.

[225] General Electric, “Original Work Plan for Energy Efficient Engine Component Development & Integration Program.” Apr. 28. 1978. Box 239. Division 8000. NASA Glenn archives.

[226] R. W. Bucy. “Progress in the Development of Energy Efficient Engine Components," ASME paper 82-GT-275. Box 181, Division 8000. NASA Glenn archives.

[227] W. B. Gardner. W. I lannah. and D. E. Gray. “Interim Review of the Energy Efficient Engine E’ Program." ASME paper 82-GT-27I. Box 181. Division 8000. NASA Glenn archives.

[228] For more on the "turbojet revolution." see: Edward W. Constant. The Origins of the Turbojet Revolution (Baltimore: Johns Hopkins University Press, 1980).

[229] Jack L. Kerrebrock, “Aircraft Energy Efficiency Program Status." Subcommittee on Transportation. Aviation and Materials. Feb. 17. 1982. Box 234. Division 8000. NASA Glenn archives.

[230] American Airlines and Pratt & Whitney. "Technology of Fuel Consumption Performance Retention." unpublished report. Feb. 1974. Box 181. Division 8000. NASA Glenn archives.

[231] Colladay and Neil Saunders. “Project Plan. Energy Efficient Engine Program." June 1977. Box 272. Division 8000. NASA Glenn archives.

[232] R. V. Garvin. Starting Something Big: The Commercial Emergence of CE Aircraft Engines (Reston, VA: ЛІЛА. 1998), p. 167.

[233] Ethell. Fuel Economy in Aviation, p. 30.

[234] Colladay and Neil Saunders. "Project Plan. Energy Efficient Engine Program.” June 1977. Box 272. Division 8000. NASA Glenn archives.

[235] Kramer to Nored. Apr. 20. 1976. Box 181. Division 8000. NASA Glenn archives.

[236] Nored to Kramer. June 1. 1976. Box 181. Division 8000. NASA Glenn archives.

[237] Derra. "Joint R&D Program Improves Aircraft Engine Performance," Industrial Research A Development (Nov. 1983). p. 80.

[238] Cecil C. Rosen. III. to Lewis chief of transport propulsion, Feb. 22. 1982. Box 181, Division 8000. NASA Glenn archives.

[239] “E’ Considered World Leader in Fuel Efficiency." Design News (Dec. 5, 1983).

[240] Bucy. quoted in "E1 Considered World Leader in Fuel Efficiency." Design News (Dec. 5. 1983).

[241] Garvin, Starting Something Big: The Commercial Emergence of GE Aircraft Engines (Reston. VA: AIAA, 1998). p. 167.

[242] Christopher D. Clayton, as quoted in Dick Rave,“GE90: Future Power Plant.” The Cincinnati Tost. Dec. 17. 1991.

[243] Pratt & Whitney. “Advancement in Turbofan Technology… NASA’s Role in the Future." 1988. Box 121. Division 8000. NASA Glenn archives.

[244] Rob Spiegel. “Pratt-Whitney Builds Energy-Efficient Engine for Mitsubishi." Design News. Dec. 10. 2007.

[245] Colladay. “Engine Component Improvement Program." Sept. 24. 1979. Box 244. Division 8000. NASA Glenn archives.

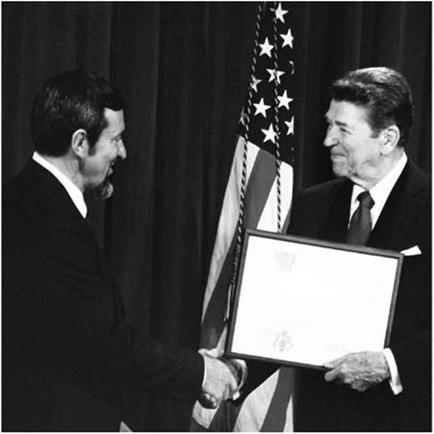

[246] Ronald Reagan to Gen. Clifton von Kann. Sept. 11. 1980. Box 234. Division 8000. NASA Glenn archives.

[247] Italics in original. Eugene J. McAllister, ed.. Agenda for Progress: Examining Federal Spending (Washington. DC: Heritage Foundation. 1981). pp. 171-172.

[248] “NASA Aircraft Energy Efficiency Program Marked for Elimination.” Aerospace Daily, vol. 113. No. 3 (Jan. 6. 1982). p. 17.

[249] General Accounting Office. “Preliminary Draft of a Proposed Report. Review of NASA’s Aircraft Energy Efficiency Project.” Aug. 1979. Box 182. Division 8000. NASA Glenn archives, p. 9.

[250] Ibid., p. 16.

[251] Ibid., pp. 18.26,34,42,44. and 52.

[252] Robert A. Frosch to J. H. Stolarow. Jan. 24. 1980. Box 182. Division 8000. NASA Glenn archives.

[253] NASA response reprinted in. “A Look at NASA’s Aircraft Energy Efficiency Program,” by the Comptroller General of the United States. July 28. 1980. Box 182. Division 8000. NASA Glenn archives, p. 65.

[254] Ibid., p. iv.

[255] General Accounting Office. "Preliminary Draft of a Proposed Report, Review of NASA’s Aircraft Energy Efficiency Project.” p. 11.

[256] “A Look at NASA’s Aircraft Energy Efficiency Program,” by the Comptroller General of the United States. July 28. 1980. Box 182. Division 8000. NASA Glenn archives, p. 5.

[257] Klineberg to NASA Headquarters, Dec. 21. 1979. Box 182. Division 8000. NASA Glenn archives.

[258] General Accounting Office, “Preliminary Draft of a Proposed Report. Review of NASA’s Aircraft Energy Efficiency Project,” p. 37.

[259] “A Look at NASA’s Aircraft Energy Efficiency Program," by the Comptroller General of the United States. July 28. 1980. Box 182. Division 8000. NASA Glenn archives, p. 45.

[260] Walter B. Olstad to Office of Inspector General. Aug. 28. 1980. Box 182. Division 8000. NASA Glenn archives.

[261] Lyn Ragsdale. "The U. S. Space Program in the Reagan and Bush Years." Spaceflight and the Myth of Presidential Leadership. Roger D. Launius and Howard E. McCurdy, eds. (Urbana: University of Illinois Press. 1997), p. 140.

[262] H. Guyford Stever. Chairman of the Aeronautics and Space Engineering Board Workshop. to Robert W. Rummel. Chairman of the Aeronautics and Space Engineering Board. Jan. 16. 1981. NASA’s Rale in Aeronautics: A Workshop, vol. 1. Box 260. Division 8000. NASA Glenn archives, p. vii.

[263] Ibid., pp. v-vi and 4-5.

[264] Adam Clymer. “Staff Quietly Plans for a Reagan Presidency," New York Times. Sept. 14. 1980.

[265] William Endicott, ’“Think Tank’ Drawing Up Plans to Achieve Conservative Goals in Reagan Presidency,” Los Angeles Times. Oct. 4. 1980.

[266] John Noble Wilford. "Others Tread on NASA’s Piece of Sky." New York Times. Sept.

14.1980.

23 “NASA Chief Intends to Resign His Post on Inauguration Day.” Wall Street Journal. Oct. 7. 1980.

[268] “Conservative Think Tank Moves Into Capitol Spotlight.” Los Angeles Times. Dec.

21.1980.

[269] Joanne Omang,“The Heritage Report: Getting the Government Right with Reagan,” Washington Post. Nov. 16. 1980.

[270] Donald E. Abelson, A Capitol Idea: Think Tanks and US Foreign Policy (Montreal: McGil 1-Queen’s University Press, 2006). p. 34.

[271] Charles L. Heatherly. ed.. Mandate for Leadership: Policy Management in a Conservative Administration (Washington. DC: Heritage Foundation. 1981). p. 235.

[272] George A. Key worth. II. “The Federal Role of R&D." Research Management (Jan. 1987). pp. 7-9.

[273] Emphasis in original. Eugene J. McAllister, ed.. Agenda for Progress: Examining Federal Spending (Washington. DC: Heritage Foundation, 1981). pp. 171-172.

[274] Lynn Anderson to Nored. Feb. 23. 1981. Box 260. Division 8000. NASA Glenn archives.

[275] Lovelace to Edwin "Jake" Gam. Chairman of the Subcommittee on HUD – Independent Agencies. Feb. 9. 1981. Box 260. Division 8000. NASA Glenn archives.

[276] Olstad to center directors. Feb. 17. 1981. Box 260. Division 8000. NASA Glenn archives.

[277] "Planet Exploration Dwindles in ‘Hit List’on NASA’s Budget,” Washington Post. Feb. 5.1981.

[278] Nored. “Guidelines for Advocacy of New Programs in the Aeronautics Directorate.” Jan. 1981. Box 121. Division 8000. NASA Glenn archives.

[279] Walter L. Stewart to R. J. Weber. Feb. 2. 1981. Box 238. Division 8000. NASA Glenn archives.

[280] Lovelace, hearings before the Subcommittee on Science. Technology, and Space. Serial No. 97-29. Part I. Mar. 10. 1981.

[281] Lovelace, statement before the Subcommittee on Space Science and Applications. Mar. 31. 1980. Box 234. Division 8000. NASA Glenn archives.

[282] Casper Weinberger to David Stockman. Nov. 1981. Box 234. Division 8000. NASA Glenn archives.

[283] Weinberger. In the Arena: A Memoir of the 20th Century (Washington. DC: Regnery. 2001). p. 191.

[284] Richard D. DeLaurer to Janies Beggs. Nov. 30. 1981. Box 234. Division 8000. NASA Glenn archives.

[285] Chambers, correspondence with Bowles. Mar. 28.2009.

[286] J. R. Sculley to Beggs. Dec. 1. 1981. NASA Glenn archives.

[287] Dan Glickman to Thomas Donohue, general manager. Aircraft Engine Group. General Electric. Box 234. Division 8000. NASA Glenn archives.

[288] Statement of Mary Rose Oakar. Dec. 8.1981. Box 234. Division 8(K)(). NASA Glenn archives.

[289] Statement of Donohue. Dee. 8. 1981. Box 234. Division 8000. NASA Glenn archives

[290] Dan Glickman to John F. Welch. Jr.. Dec. 8. 1981. NASA Glenn archives.

[291] Brian U. Rowe to Victor H. Reis, assistant director. Office of Science & Technology Policy. Apr. 23. 1982. Box 234. Division 8000. NASA Glenn archives.

[292] Glickman. hearing before the Subcommittee on Transportation Aviation and Materials. Feb. 17. 1982. Box 234. Division 8000. NASA Glenn archives.

[293] “Budget Cuts Forcing NASA to Close Lewis Research Center,” Defense Daily, vol.

119. No. 25 (Dec. 9. 1981). Dawson. Engines and Innovation, p. 217.

[294] “NASA Aircraft Energy Efficiency Program Marked for Elimination,” Aerospace Daily, vol. 113. No. 3 (Jan. 6. 1982). p. 17.

[295] Jack Kerrebrock to directors of Ames. Langley, and Lewis Research Centers. Feb. 19. 1982. Box 215. Division 8000. NASA Glenn archives.

[296] “Strategic Plan for Aeronautics." Mar. 1982. Box 234. Division 8000. NASA Glenn archives.

[297] Andrew Stofan. interview by Bowles. Apr. 13. 2000.

[298] Red Robbins, as found in Dawson. Engines and Innovation, pp. 213-214.

[299] Martha M. Hamilton.“Firms Give Propellers a New Spin." Washington Post. Feb. 8.1987.

[300] Robert J. Serling. "Back to the Future with Propfans ” USAIR (June 1987).

[301] R. S. Stahr. “Oral Report on the RECAT Study Contract at NASA." Apr. 22. 1976. Nored paper. Box 224. NASA Glenn Archives.

[302] Hugh Vickery. "Turboprops are Back!" Washington Times. Nov. 1. 1984. p. 5B.

ill

[303] Statement by Clifton F. von Kami to the Senate Committee on Aeronautical and Space Sciences, Sept. 10. 1975, Box 179. Division 8000. NASA Glenn archives.

[304] John C. Waugh. “Wings ‘Breathe’ in Laminar Plane.” Christian Science Monitor. May 21,1963.

[305] Marvin Miles. "Plane Passes Revolutionary Air Flow Test.” Los Angeles Times. Aug. 16. 1963. William L. Laurence. “Aviation Landmark: New Design May Permit Aircraft to Stay Aloft for Days.” New York Times. May 26. 1963.

[306] Hansen. The Bird Is On the Wing, p. 203.

[307] Interview with Wagner by Bowles. June 30. 2008.

[308] Braslow. A History of Suction-Type Laminar Flow Control with Emphasis on Flight Research (Washington. DC: NASA Monographs in Aerospace History No. 13. 1999), p. I.

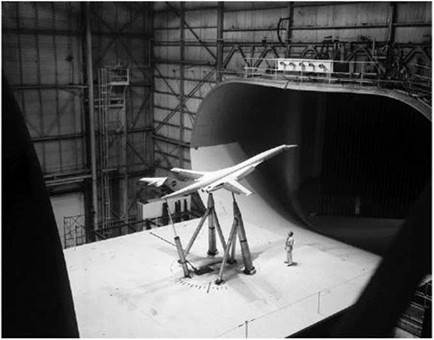

[309] Bill Siuru and John D. Busick. Future Flight: The Next Generation of Aircraft Technology. 2nd ed. (Blue Ridge Summit. PA: TAB,•AERO. 1994). p. 45.

[310] Braslow. Dale L. Burrows. Neal Tetervin. and Fioravante Visconte. Experimental and Theoretical Studies of Area Suction for the Control of the Laminar Flow Boundary on an NACA 64A010 (Washington. DC: NACA Report 1025. Mar. 30. 1951).

[311] William L. Laurence, “Aviation Landmark: New Design May Permit Aircraft to Stay Aloft for Days," New York Times. May 26. 1963.

[312] Walter J. Boyne, Beyond the Wild Blue: A History of the United Stales Ліг Force (New York: St. Martin’s Griffin. 1998), p. 194.

[313] Braslow and Allen H. Whitehead. Jr.. Aeronautical Fuel Conservation Possibilities for Advanced Subsonic Transports (Washington. DC: NASA TM-X-71927. Dec. 20. 1973). Braslow. A History of Suction-Type Laminar Flow Control, p. 13.

[314] Edgar Cortright. “Establishment of Laminar Flow Control Working Group.” Sept. 12. 1975. as found in Braslow. Л History of Suction-Type Laminar How Control, p. 61.

[315] “ACEE Program Overview,” NASA RP-79-3246(l), July 31.1979. Box 239.

Division 8000. NASA Glenn archives.

[316] Mark to Lovelace. June 4. 1975. Box 181. Division 8000. NASA Glenn archives.

[317] Braslow and Muraca. “A Perspective of Laminar-Flow Control," АІЛЛ Conference on Ліг Transportation. Aug. 21-24. 197S. p. 14.

[318] Emphasis in original. Braslow. A History of Suction-Type Laminar Flow Control, p. 15.

[319] Braslow, quoted in Wetmore. “Langley Presses Fuel Efficiency Programs.” Aviation Week & Space Technology. Nov. 10. 1975. p. 68.

[320] David F. Fisher and John B. Peterson. Jr.. "Flight Experience on the Need and Use of Inllight Leading Edge Washing for a Laminar Flow Airfoil.” A! A A Aircraft Systems and Technology Conference (A1AA Paper 78-1512. Aug. 21-23. 1978).

[321] “Laminar Flow Research Enters Tunnel. Flight Test.” Aviation Week <& Space Technology. Sept. 25. 1978. p. 49.

[322] Dal V. Maddalon and Braslow. Simulated-Airline-Service Flight Tests of Laminar – Flow Control with Perforated-Surface Suction System ( Washington. DC: NASA TP-2966, Mar. 1990).

[323] Roy Lange, quoted in Keith F. Mordoff, “NASA C-140 with Laminar Flow Wing Simulating Airline Service Flights.” Aviation Week & Space Technology, Apr. 15. 1985. p. 58.

[324] Chambers. Innovation in Flight.

[325] Braslow. A History of Suction-Type Laminar Flow Control, p. 32.

[326] II. Keith Henry. “Flight Tests Prove Concept for Jetliner Fuel Economy,” Aug. 23.

1990. as found at hltp://wwiv„sciencehlog. comfcommunitylolderiunhivesIDiarchnas/334. him I. accessed June 1,2009.

[327] William S. Sarie and Helen L. Reed.’Toward Practical Laminar Flow Control —Remaining Challenges." AIAA Fluid Dynamics Conference, June 28—July 1.2004. Portland. OR. as found at. hup:UfiightJamtunluipubslpaperslaiaa-2004-23I/ jxlf. accessed June 1.2009.

[328] Interview with Wagner by Bowles. June 30. 2008.

[329] Hansen. The Bird lx on the Wing. pp. 204-205.

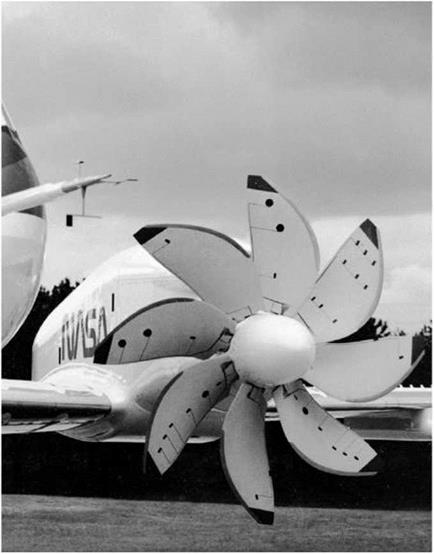

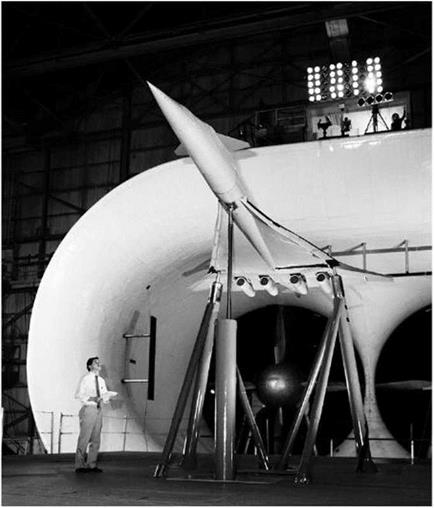

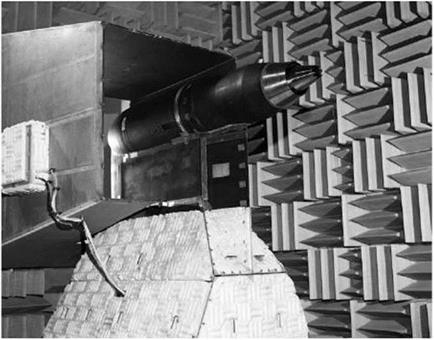

[330] Much of this section appeared in Bowles and Dawson. "The Advanced Turboprop Project: Radical Innovation in a Conservative Environment.’’ From Engineering Science to Піц Science: The NACA and NASA Collier Trophy Research Project Winners. Pamela E. Mack. ed.. (Washington. DC: NASA SP-4219. 1998). pp. 321-343.

[331] Interview with Dan Mikkelson by Dawson and Bowles. Sept. 6. 1995.

[332] James H. Capshew and Karen A. Rader. “Big Science: Price to the Present," Osiris. 2nd ser.. vol. 7 (1992). pp. 3-25.

[333] Roy D. Hagar and Deborah Vrabel, Advanced Turboprop Project (Washington. DC: NASA SP-495, 1988). p. 5.

[334] “Aircraft Fuel Conservation Technology Task Force Report,” Office of Aeronautics and Space Technology. Sept. 10. 1975. p. 44.

[335] Hagar and Vrabel. Advanced Turboprop Project, pp. 6-10.

[336] Klineberg. quoted in “How the ATP Project Originated.” Lewis News. July 22. 1988.

[337] Howard Banks. “The Next Step." Forbes. May 7. 1984. p. 31.

[338] Nored to G. Keith Sievers. Jan. 9. 1981. Box 260. Division 8000. NASA Glenn archives.

[339] Interview with Nored by Dawson and Bowles. Aug. 15. 1995.

[340] Interview with Mikkelson by Dawson and Bowles. Sept. 6. 1995.

[341] “Aircraft Fuel Conservation Technology Task Force Report” Office of Aeronautics and Space Technology. Sept. 10.1975. p. 48. These Soviet long-range turboprops included the Tupolev TU-95 “Bear" {which weighed 340.000 pounds, had a maximum range of 7.800 miles and a propeller diameter of 18.4 feet, and operated at a 0.75 Mach cruise speed) and the Antonov AN-22 “Cock" (which weighed 550.000 pounds, had a maximum range of 6.800 miles and a propeller diameter of 20.3 feet, and operated at a 0.69 Mach cruise speed).

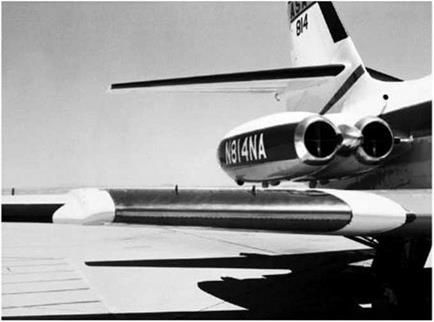

[342] “Aircraft Fuel Conservation Technology Task Force Report.” Office of Aeronautics and Space Technology. Sept. 10. 1975. pp. 18.46.

[343] C. R. Copper to Kramer. Mar. 5. 1979. Box 179. Division 8000. NASA Glenn archives.

[344] Lloyd E. Frisbee to Howard Cannon. Chairman of the Commerce. Science and Transportation Senate Committee. Feb. 23.1979. Box 179. Division 8000. NASA Glenn archives.

[345] Robert C. Collins to Robert A. Frosch. Dec. 1. 1978. Box 179. Division 8000. NASA Glenn archives.

[346] Percy A. Wood to Frosch. Sept. 14. 1979. Box 179. Division 8000. NASA Glenn archives.

[347] “Large-Scale Advanced Prop-Fan Program (LAP)," technical proposal by Lewis Research Center. Jan. 11. 1982. NASA, Nored papers. Box 229. NASA Glenn archives.

[348] Interview with Nored by Dawson and Bowles. Aug. 15. 1995.

[349] “United Airlines Passenger Survey." Box 224. Division 8000. NASA Glenn archives.

[350] Quoted by Hamilton. “Firms Give Propellers a New Spin: GE leads high-stakes competition for aircraft engineers with its ‘fan.’" Washington Post. Feb. 8. 1987.

[351] “Prop-Fan survey results." Dec. 1978. Box 231. Division 8000, NASA Glenn archives.

[352] Interview with Sieversby Dawson and Bowles. Aug. 17.1995.

[353] Interview with Mikkelson by Dawson and Bowles, Sept. 6. 1995.

[354] Robert C. Collins, statement submitted to the Subcommittee on Transportation. Aviation, and Materials. House of Representatives Committee on Science and Technology. Feb.26.1981.

[355] Interview with Nored by Dawson and Bowles, Aug. 15.1995.

[356] llagar and Vrabel, Advanced Turboprop Project, pp. 49-74. This stage was called the Propfan Test Assessment (PTA) project.

[357] Mary Sandy and Linda S. Ellis. "NASA Final Propfan Program Flight Tests Conducted." NASA News. May I, 1989.

[358] Andrew Pollack. "The Return of Propellers," New York Times. Oct. 10. 1985. p. D2. Hugh Vickery,“Turboprops are back!” Washington Tones. Nov. 1. 1984. p. 5B.

[359] Sandy and Ellis. “NASA Final Propfan Program Flight Tests Conducted," NASA News. May 1. 1989.

[360] Historical inflation adjusted price data as found at http:!> www. inflatiomlata. com! inflation! lnflativn_Rate! Historical _Oil_Prices_Tablejusp, accessed Sept. 2. 2009.

[361] John R. Facey, "Return Of the Turboprops,” Aerospace American (Oct. 1988). p. 15.

[362] Citation for the Collier Trophy in Roy D. Hager and Deborah Vrabel. p. vi.

[363] Interview with Sievers by Dawson and Bowles, Aug. 17.1995.

[364] Interview with Nored by Bowles. Aug. 15. 1995.

[365] Greg Knill. “This is Not Our First Energy Crisis." The News. July 30. 2008.

[366] Alexandra Marks, “Aviation Leaders Urge Congress to Act on Eneigy Policy—Now.’ The Christian Science Monitor. July 30, 2008.

[367] Defense and Aerospace Weekly. June 23. 2008.

[368] James May from the Ліг Transport Association, as found in Jamie Orchard. “Oil Crisis." Globed News Transcripts. July 11.2008.

[369] “Air Transport Association Leads Coalition in Call for Bi-Partisan Near-Term Solutions to Energy Crisis." Energy Weekly News. June 23. 2008.

[370] Wagner interview by Bowles. June 30.2008.

[371] Historical inflation adjusted price data as found at http:Hwww. inflationdata. coinf inflation/Inflation _RatefHistorical_Oil_Prices_Tablextsp, accessed Sept. 2. 2009.

[372] Conway. High-Speed Dreams, pp. 1-2.

[373] Annual Meeting of the Transportation Research Board. Transportation Demand Management and Ridesharing: [Papers Contained in This Volume Were Among Those Presented at the 76th TRB Annual Meeting in January 1997J, Transportation research record. 1598 (Washington. DC: National Academy Press. 1997). p. 18.

[374] Wesley 1 larris. quoted in Philip K. Lawrence and David Weldon Thornton. Deep Stall: The Turbulent Story of Boeing Commercial Airplane (Aldershot. England: Ashgate. 2005). p. 95.

[375] “Impact of the Termination of NASA’s High Speed Research Program and the Redirection of NASA’s Advanced Subsonic Technology Program." Report to the Congress, pp. 6-77. as found at http:/lwwwj>stp£Ovlpdflhsrpdf, accessed June 1.2009.

[376] National Research Council (U. S.), For Greener Skies: Reducing Environmental Impacts of Aviation. (Washington. DC: National Academy Press. 2002). pp. 2. 31.

[377] Robert J. Shaw. “UEET Overview,” Tech Forum. Sept. 5-6.2001. NASA Glenn archives.

[378] John E. Green. "Laminar Flow Control —Back to the Future?” ЛІАЛ Fluid Dynamics Conference. June 23-26. 2008. Seattle. WA. AIAA 2008-3738. as found at hnp://adg. stanford. edu/aa24l/supplemeni/Lam-Flow-Conirol-AIAA-200S-3738.pdf. accessed June 1.2009.

[379] Dennis Huff, interview w ith Bowles, July 29. 2008.

[380] Jan Roskam. Roskam л Airplane War Stories: An Account of the Professional Life and Work of Dr. Jan Roskam. Airplane Designer and Teacher (Lawrence, KS: DARcorporation, 2002). p. 134.

[381] Colladay. interview with Bowles. July 21.2008.

[382] Andrew Revkin. “Obama on the ‘Shock to Trance’ Energy Pattern." Nov. 17.2008. as found at. hltp://iIoiearlh. blogs. nylimesx-tm/200S/Jl/I7/obtimei-on-shock-lo-ir(ince- energy-pattern, accessed Sept. 2. 2009.

[383] Chambers, correspondence to Bowles, Mar. 18.2009.

[384] Richard Mial. “If Energy Crisis Eases. Will We Stay Focused on Energy Issues?” McClaichy-Tribune Business News. May 29. 2008.