Curing Sick Engines—Engine Component Improvement

It was Raymond Colladay’s responsibility to establish the three ACEE propulsion projects at Lewis Research Center. Having started his career at Lewis in 1969. he moved to NASA Headquarters in 1979 to become the Deputy Associate Administrator of the Office of Aeronautics and Space Technology, and then head of DARPA in 1985. Colladay recalled that, at the time he was helping to develop the ACEE program, it was an easy sell to Congress. “The general tenor of Congress and the country as a whole was focused on energy efficiency.” and “therefore the Congress was pretty receptive to NASA trying to do what it could in research for energy efficiency." The biggest hurdle was the Office of Management and Budget (OMB). Ideologically, its concern was the proper role of Government in a research and development enterprise. The OMB did not want NASA developing applications for the aircraft industry. While this was not a problem for the majority of the ACEE programs, Colladay said, “the area that caused them the greatest concern was the ECI program because it was component improvements in existing engines, existing aircraft engines.”[193] [194]

|

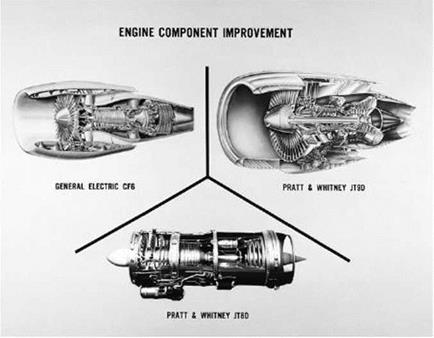

Three of the engines studied in the Engine Component Improvement (ECI) project. The EC1 engineers’ mission was to improve various components on existing engines that were most likely to wear and decrease fuel efficiency. (NASA Glenn Research Center [NASA GRC].) |

The Engine Component Improvement project was unique among all the ACEE programs in that it was expected to return quick results. While other projects looked to incorporate fuel savings advances over 10 to 15 years, ECI aimed to incorporate new technologies within 5 years. The project did not call for revolutionary advances or fundamental changes to existing airplanes. Instead, the mission of the ECI engineers was to improve the components on existing engines that were most likely to wear and decrease fuel efficiency. Pratt & Whitney Aircraft and General Electric manufactured most of the commercial aircraft engines in the United States in the 1970s, and both of these companies collaborated closely with Lewis Research Center on the ACEE project. According to the ECI statement of work, written in December 1976. the main objectives of the program were to “(1) develop performance improvement and retention concepts which will be incorporated into new production of the existing engines by the 1980-1982 time period and which would have a fuel savings goal of 5 percent over the life of these engines, and (2) to provide additional technology which can be used to minimize the performance degradation of current and future engines."25

In 1976, four jet engines that were responsible for powering all commercial aviation in the United States. These engines consumed 10-billion gallons of fuel per year.-4 The ECI project focused specifically on developing fuel-saving techniques for the JT9D, JT8D, and CF6 engines. It ignored the JT3D. the fourth major engine, because most industry analysts believed it would not be produced in the future. Introduced in 1964, the Pratt & Whitney JT8D engine was a “phenomenal success” and at its height of popularity flew 12.000 aircraft of different types.25 Two years later, Pratt & Whitney introduced the JT9D engine, often referred to as opening a “new era in commercial aviation ” because it was the first high-bypass engine to power a wide-body aircraft. It was first installed on the Boeing 747 Jumbo Jet. and Pan American placed the first order for this new jet in April 1966.26 The CF6, a General Electric engine first introduced in 1971, was used on the DC-10 and became the cornerstone of its wide-body engine business for more than 30 years.

The organizations involved in the ECI program read like a who’s who of the airlines industry in America at the time. Beginning in February 1977, NASA awarded the two major contracts to General Electric and Pratt & Whitney.27 Because these companies stood to increase their sales significantly thanks to these NASA advances, a cost recoupment clause was included in their contracts. They were to pay to the U. S. Treasury a 10-percent return on every sale of one of these improved engine components. which was how the ACEE administrators persuaded the OMB to let [195] [196] [197] [198] [199]

|

Pan Am-Boeing 747 flying in 1975. It was one of the main types of aircraft used to test and incorporate ACEE fuel-saving technology. (NASA Glenn Research Center [NASA GRC).) |

them go ahead with the ECI project. Every engine that went into active service and had a component traceable to ECI triggered this recoupment. Colladay recalled, ‘’It was a bigger headache than any money it derived, and NASA never saw the money anyway, it went into the Treasury."211

General Electric and Pratt & Whitney then established subcontracts with American Airlines. Trans World Airlines, United Airlines. Douglas Aircraft, and Boeing. In addition. Lew is Research Center also contracted with Pan American (for an international route analysis) and Eastern Airlines (for domestic analysis of the technology ) to review’ the program independently and provide ongoing assessments for 30 months.[200] [201] All of these contracts called for three specific tasks: feasibility analysis, development and evaluation in ground test facilities, and in-service and flight-testing. According to Colladay, the reason for the inclusion of essentially all the major airlines

in the United States was to “generate a broad base of support” and ensure the highest probability that the ECI technology would be rapidly retrolitted into existing engines or incorporated into new engine builds.10

Although getting this broad base of support was important, it did generate some problems—most notably in the relationship between General Electric and Pratt & Whitney. Though within the ECI program they worked together with NASA, in the real world. General Electric and Pratt & Whitney were fierce competitors. Theirs was a historic rivalry. After World War II. Pratt & Whitney dominated in the commercial aircraft engine market, while General Electric was more closely aligned with the military. However, their spheres of influence shifted over time, and by 1977, Pratt & Whitney began losing ground to General Electric in the commercial market. This set the stage, in the early 1980s, for what some have called the "great engine war” between the two companies.4

Because of this, the collaboration was sometimes difficult. Pratt & Whitney thought there were “major problem areas” with their relationship. Nored. head of the NASA Energy Conservative Engines Office, admitted that the office was having “extreme difficulty" with Pratt & Whitney and said. “I think they are suffering a corporate reaction to the increasing competition by GE (JT9D vs. CF6).” Both of these engines were scheduled to be improved within ECI. Nored thought the company was nervous about the Freedom of Information Act and as a result wanted to classify all of its research as proprietary. Pratt & Whitney also, in his opinion, sought more and more governmental support to “augment their technology in ways that can influence immediate sales.” In accepting this assistance, the company had to learn how to work in the much more open governmental research atmosphere, and sometimes this included being bedmates with chief rivals. For example, General Electric had expressed no concerns about sharing proprietary information, and Nored concluded that Pratt & Whitney needed to “bite the bullet.”’- The program continued despite its often-stated concerns. [202] [203] [204]

There were two main thrusts to EC1 —Performance Improvement and Engine Diagnostics. The Performance Improvement section began with a feasibility study to examine a variety of concepts and to prove which one might offer the highest fuel-savings results for the airlines industry. The study looked at the development of an analytical procedure to determine possible concepts, the identification and categorization of concepts, preliminary concept screening, and detailed concept screening. Engineers evaluated 95 concepts for the Pratt & Whitney engines and another 58 concepts for the General Electric engine. The job of the airline industry was to "assess the desirability and practicality of each concept."3′ The concepts were evaluated on two main criteria—technical and economic factors. Technical factors included performance, weight, maintenance, fuel – savings potential, material compatibility, development time, and technical risk, while economic factors included fuel prices, engine cost, production levels, operating costs, return on investment, and life expectancy. Using these criteria, the 153 initial concepts were quickly reduced to 18 and 29, respectively. They were then reviewed in greater detail by NASA and the airlines, which identified 16 concepts that could meet their goals.

The content of these projects can be broken into several important areas. The first was leak reduction. An aircraft engine is similar to an air pump in that it moves air from in front of it to the back. By adding energy to it, the speed of the air moving through the exhaust is faster than what originally came through the inlet. Any air leak in this system caused it to be inefficient, just like an air pump leak. ECI engineers looked for areas in which engine seals could be improved to reduce this leakage. A second major area for improvement was in aerodynamics: ECI engineers developed improved designs of the compressor and turbines. A third area was ceramic coatings on components, which was important because it reduced the necessity of cooling holes and both increased efficiency and reduced manufacturing costs.

Specifically, the 16 projects, and their related engine types, were as follows. For the JT8D. they included an improved high-pressure turbine air seal, high-pressure turbine blade, and a trenched tip high-pressure compressor. JT9D improvements for the high-pressure turbine included a [205] ceramic outer seal, a thermal barrier coating, active clearance control, and new fan technology. CF6 improvements were a new fan, a front mount for the engine, a short core exhaust nozzle, improved aerodynamics for the high-pressure turbine, a roundness control for the turbine, and active clearance controls for the turbine. There were two other aircraft-related projects: a nacelle drag reduction for the DC-9 and compressor bleed reduction for the DC-10. The ECI Performance Improvement program was significant thanks to its success after only a few’ years of research, testing, and development. According to Jeffrey Ethell,“By 1982 most of the improved components were flying and saving fuel, giving the companies involved a firm leg up in the commercial aircraft marketplace, w here they were being challenged by foreign competition."14

The Engine Diagnostics program focused on analyzing and testing the JT9D and CF6 engines.[206] [207] [208] Pan Am engineers considered this to be the “most significant work” of the ECI program. An often-used logo for the Engine Diagnostics program was an engine with a human face, frowning, tongue sticking out. and arms clasped over its midsection. A country doctor hunched over it, tools sticking out of his pockets, examining an x-ray machine, diagnosing a w ay to “cure the sick engine.” While just a caricature, it did simplistically convey the fundamental goals of this program. The engine “illnesses” were the performance losses they experienced as their flight hours increased. The “doctors” were the Lewis engineers, whose job was to determine the mechanical sources of these problems and recommend ways to “cure" the sick machines. Their recommendations could keep existing engines healthy and help to prevent the deterioration of future engines.3*

One known problem with these or any type of engines wfas that over time, various components begin to deteriorate because of operational stresses, which included combustors that w’arped because of continual fluctuation in temperatures from hot to cold, compressor blades whose tips w’ore down over time, seals that began to leak hot gases, and turbine blades eroding from high temperatures. Other types of damage could occur when foreign objects such as stones or dust entered the engines on the runway and caused dents, breaks, or scratches to the fan blades. The engines were durable and could typically tty for 10.000 hours before they needed major maintenance, but during that time, the engine slowly became less and less fuel efficient because of small degradations that did not compromise the safety of the aircraft. Furthermore, the major maintenance sessions never restored the engines to their original levels of fuel efficiency. Pan American engineers said that prior to the ECI Engine Diagnostics program, “engine deterioration had been largely a matter of educated guessing, speculation, and hand-waving.”” This deterioration became the focus of the Engine Diagnostics program, and engineers estimated that by preventing these wear-and-tear issues, aircraft would become more fuel efficient.

Engine Diagnostics engineers from NASA, General Electric, and Pratt & Whitney began their work by evaluating the existing data on performance deterioration from the airline industry and engine manufacturers. The data included in-flight recordings, ground-test data, and information on how frequently various parts were repaired and replaced. Additional data, needed on the JT9D and CF6. were obtained though special monitoring devices, as well as analysis gained from a complete teardown and evaluation of the engines. Special ground tests were developed to experiment with short – and long-term performance deterioration. These ground tests helped engineers simulate operating conditions to determine the sources of component deterioration. From the data they collected, they identified certain components whose failure rates could be improved upon/1*

One concern, raised by Pratt & Whitney, was that the deterioration information on its engines was being used by its competitors. Its company slogan was “Dependable Engines," and extensive publications as to how they deteriorated over time was. in its opinion, damaging to its reputation; [209] [210] [211]

Specifically, the company had evidence that Rolls-Royce, a British engine competitor, used the ECI deterioration data from the JT9D and CF6 engines in its then-current marketing campaign, demonstrating the superiority of Rolls-Royce engines. A 1979 letter from Pratt & Whitney’s legal team to NASA expressed concerns that the ECI program would “adversely affect" its marketing and future sales potential. The team wanted NASA to change its dissemination policy for technical reports to protect the Pratt & Whitney “marketing position" for its engines.[212] NASA responded that this was an unintended consequence of the ECI program and the effort to improve engines for the United States airlines industry. Furthermore, according to NASA, Pratt & Whitney’s role in the program had been voluntary and had the “full backing and support of P&W management.” NASA officials had informed the companies at the outset that comparisons between the engines would be made, and both Pratt & Whitney and General Electric “realized the consequences of entering into the program and accepted them.”[213]

The independent outside evaluations by Pan American and Eastern Airlines were an important part of the ECI project. The independent reports by Pan American World Airways are especially revealing. The reports were based upon 10 meetings held during the project in which NASA, General Electric, and Pratt & Whitney representatives summarized their work for the Pan America review committee. The first meeting, held at John F. Kennedy Airport in March 1977, was a get-acquainted session for the various participants to discuss early concepts, directions, and goals for the project.[214] By the sixth meeting, in September 1978, Pan American was expressing serious concerns, characterizing the program as “disappointing" and criticizing the ECI engineers for taking a “very conservative approach," rather than a “considerably more aggressive" one. “We are also greatly concerned that the manufacturers appear to be losing sight of the basic objective of this program," Pan American concluded at the time.[215] By the end of the program. Pan American engineers saw significant areas of improvement and at one of the final reviews offered substantial praise to the program, saying, “In spite of what may have been interpreted as high critical comments during various review presentations”the program has resulted in “important knowledge” and was “quite successful.”[216] In fact, the ECI project was one of the more successful of the ACEE programs, for several reasons. The first reason was the speed with which improvements were incorporated onto commercial aircraft —many of the projects findings found their way into commercial aircraft engines before other ACEE programs even had their first test flights. John E. McAulay, the head of the ECI Performance Improvement project, presented the positive results of the project’s work at the January 1980 Aerospace Sciences Meeting, just 3 years after the program began. While it “has already provided significant potential for reductions in the fuel consumed by the commercial air transport fleet,” he said he was optimistic that even greater savings were possible through their ongoing studies.[217] By March 1980. the ECI engineers had produced 20 technical papers, 21 contractor reports. 4 technical memorandums, 6 conference publications, and 8 journal and magazine articles.[218]* Second, the organizations that benefited most from the project were very enthusiastic about the results when ECI ended. In 1980. Harry C. Stonecipher (General Electric vice president and general manger) wrote to John McCarthy (Director of Lewis Research Center) to highlight the program’s value to his company, writing that it generated a “wealth of knowledge” and that its main beneficiaries were the airline industry. He estimated the savings of this “invaluable” research at a reduction of 10 gallons of fuel for the CF6 engine for each hour of flight. Stonecipher concluded, “We at General Electric want you to be aware of the benefits this program has provided, and the tremendous potential for the years ahead.”[219]

Third, the ECI program helped to maintain the competitive advantage of the entire commercial aircraft industry. For example, in February 1980, Boeing executives approached NASA to ask if they could disclose results of the ECI program to foreign airlines, because in order to sell new American aircraft in the international marketplace, the company needed to show its more advanced understanding of engine deterioration and how to improve engine performance. NASA agreed with Boeing’s request and stated. “In order to meet the challenge presented by international competition, it is appropriate that the U. S. aircraft industry use the technology generated in the ECI program to maintain its dominant position in the marketplace.”4*As Roger Bilstein wrote, “Research results were so positive and so rapidly adaptable that new airliners in the early 1980s like the Boeing 767 and McDonnell Douglas MD-80 series used engines that incorporated many such innovations.”[220] [221] [222] Though the fuel-efficiency rewards were never intended to be as high as in other ACEE programs (including the Energy Efficient Engine), ECI was successful in achieving a significant fuel reduction of roughly 5 percent, exactly what its engineers projected at the onset of the program.