Ld and New. Engines at Lewis

|

P |

an American World Airways was for a time the most influential airline organization and known quite simply as the airline that “taught the world to fly”1 Begun in the late 1920s through a legendary partnership between Juan Trippe and Charles Lindbergh, it sought to promote international commercial air transport in the United States. It was widely successful and through the early 1970s led the world in the commercial transport industry. Because of the increasing price of oil, however, the United State’s largest airline suffered a major setback in 1973, and the company was driven to the edge of bankruptcy in 19743 L. H. Allen, its vice president and chief engineer, said that when “fuel prices for Pan Am. .. reached a staggering 40 cents per gallon,” fuel efficiency then ranked as the “single most important factor in aircraft operations today.”[173] [174] [175] Allen tried to offset these devastating forces by working with NASA’s Lewis Research Center and its Aircraft Energy Efficiency (ACEE) program to devise new ways to make aircraft engines more efficient.

Like the Langley Research Center, NASA’s Lewis Research Center in Cleveland, OH. operated its own specialty fuel-efficiency research programs under ACEE. The first of these propulsion projects. Engine Component Improvement (ECI)—with Pan Am serving as one of its chief

Lewie Research Center NASA

ENERGY EFFICIENT PROPULSION TECHNOLOGY

|

|

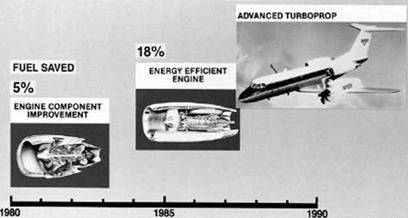

The three ACEE projects at Lewis Research Center. (NASA Glenn Research Center [NASA GRCJ.)

independent evaluators and main program supporter—focused on improving existing turbofan engines through the redesign of selected engine components that were most prone to wear.[176] An attempt to “cure sick engines,” it was the least technically challenging of the three Lewis ACEE projects and aimed for a 5-percent improvement in fuel efficiency. The second project, the Energy Efficient Engine (E3), involved building “a brand new engine from scratch” and offered a far greater payoff—a 10- to 15-percent increase in fuel efficiency.[177] These two engine projects became Lewis’s most significant contribution to improving fuel efficiency for the Nation’s commercial aircraft. (A third Lewis project, the Advanced Turboprop, the most controversial of all, will be addressed in a later chapter.)

While Pan Am’s collaboration on ACEE was successful, it was not enough to save the company, which declared bankruptcy in January 1991.

|

|

Langley engineers ai the Structural Research Laboratory designing the NACA’s new engine lab in Cleveland. Among those pictured are: Addison Rothrock. George Darchuck, Harold Friedman (at the front and center with his back to the camera), and Nick Nahigyan (across table from Friedman) (April 21.1941). (NASA Glenn Research Center [NASAGRC].)

The reason most often cited for its demise, according to historian William Leary, is that it was never able to recover from the ‘’the world oil crisis.”[178]