THE TERMINAL OF TOMORROW

|

By Mike Machat

|

A |

s a young airliner enthusiast growing up on Long Island during the 1950s, a trip to New York International Airport (then called Idlewild, and now JFK) was even better than going to Disneyland because real jet airliners were making their proud debut here by the end of that decade, turning the airport into a virtual fantasyland of its own. A new, ultimate “Airport of the Future” was being built to accommodate the needs of air travel in the burgeoning Jet Age, and the revolutionary concept of each major airline having its very own distinctive terminal building was utilized in the creation of “terminal city,” a two-mile circle of individual buildings creating a veritable skyline of airport architecture.

Located on either end of Idlewild’s new International Arrivals Building (IAB) on the airport’s southern flank were the brand-new terminals of both U. S. international flag carriers, with Pan American World Airways’ open-air umbrella-style building on the west side, and Trans World Airlines’ swooping “concrete bird” terminal on the east. These strategic locations allowed both airlines to disembark international passengers at the IAB for U. S. Customs processing, and then after towing the aircraft over to their respective terminals next door, they would service the aircraft and board passengers for new departing flights.

TWA’s magnificent terminal was designed by the renowned Finnish architect Eero Saarinen as a “living sculpture” to look like a giant bird poised for takeoff. Days after its official opening ceremonies on May 28, 1962, I visited the airport as a young teenager, full of anticipation at seeing what was, at that time, probably the world’s most futuristic and revolutionary piece of

industrial architecture. I stood there, staring up in awe at the brand-new building —a bit more diminutive in size than I’d originally expected, but visually stunning, none the less, in all its gleaming white concrete and deeply tinted glass.

Walking inside that terminal for the first time was like entering a space station. Vast expanses of white hand-laid miniature circular tiles complemented by fire-engine-red upholstered furnishings led to large, airy waiting areas, curving ticket counters, posh restaurants, and a space-age information desk with flight information displayed in a pod seemingly hovering overhead. Most intriguing to me, however, was the tubular entryway to the satellite gate area. In the pre-security age of the early 1960s I simply strolled out to see the airplanes through this softly lit, Muzak – filled, red-carpeted passageway that looked as if it could have very possibly led to a waiting Martian spaceship.

I gazed longingly at the upstairs Lisbon Lounge Bar where such legendary personalities as Frank Sinatra and Ava Gardner sat waiting to board their flights to exotic locales all over TWA’s route system. Pope Pius IV was also there during his October 1965 visit to New York, and one can only imagine the colorful stories of celebrities, movie stars, show-business legends, and heads of state, all of whom traveled through this terminal when it was new. And as if all this wasn’t futuristic enough, New York Airways Sikorsky S—61 helicopters shuttled TWA passengers from this terminal to yet another bustling fantasy – land—the New York World’s Fair in 1964 and 1965.

In retrospect, the future turned out a bit differently than we’d expected back then. Those atom-powered supersonic flying cars and helicopter jetpacks never quite materialized, but gave way instead to personal

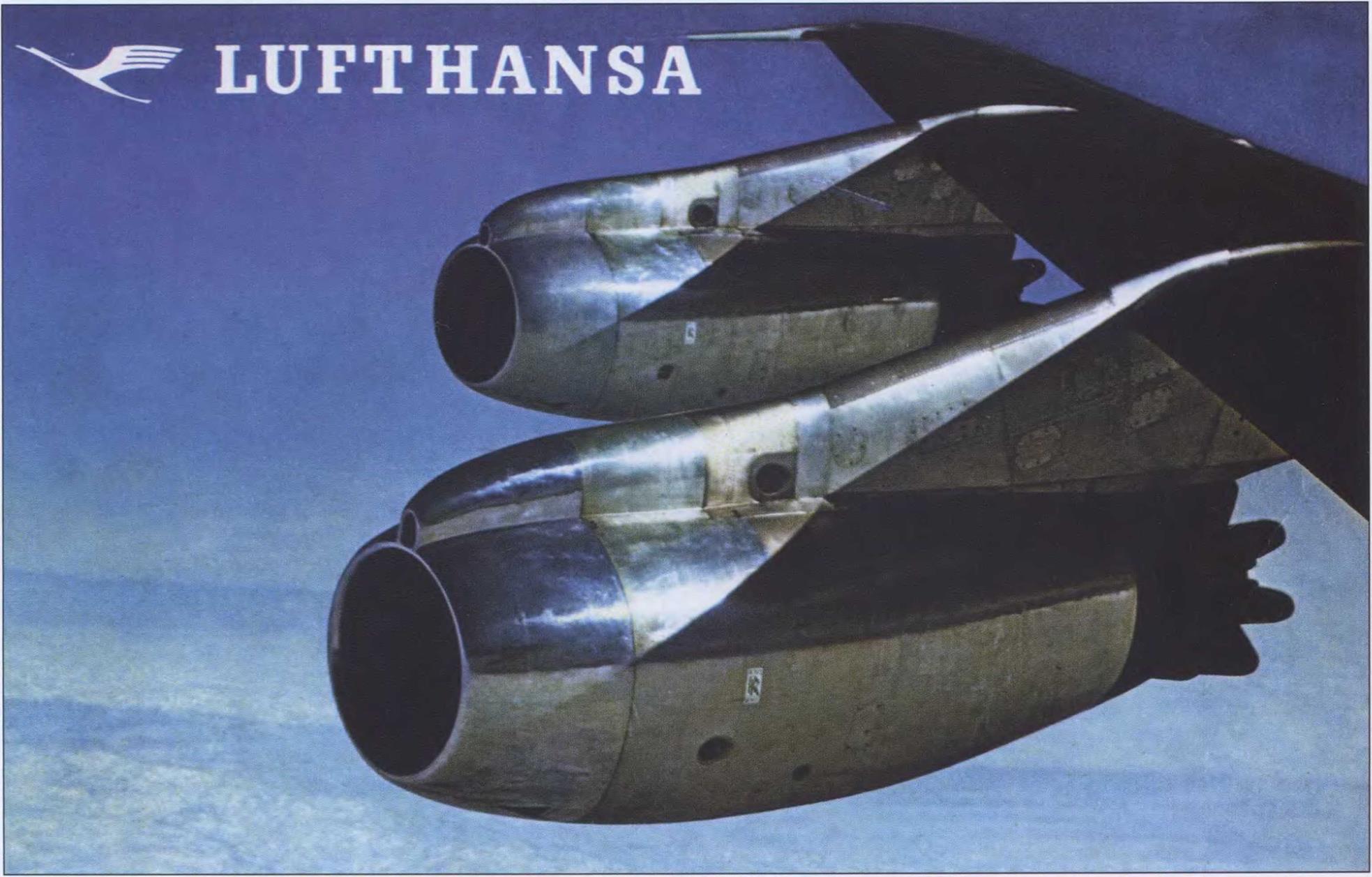

computers, cell phones, BlackBerry Smartphones, and GPS. More amazingly, TWA’s first 707-131s carried only 111 passengers, yet were flown by a crew of four. They were powered by four turbojet engines that sported a voracious appetite for JP-4, and were deafening to boot. By comparison, the last Boeing 757 to depart this terminal in 2001 flew on two turbofan powerplants that each produced more than twice the 707 engine’s thrust. That airplane carried 178 passengers flown by two pilots, and was far more quiet, fuel-efficient, and ecologically friendly than anything ever dreamed of during the 707’s inaugural era.

With air travel being such an entirely different experience today, we will simply have to remember the glory days of DynaFan-powered StarStream 707s pulling up to the jetways, with passengers dining in the Paris Cafe and celebrities having one last drink at the Lisbon Lounge before jetting off to Europe, Africa, or the Far East. Now, as an integral part of JetBlue’s stunning new JFK terminal, the former TWA “Terminal of Tomorrow” still stands silently in solemn tribute to the dawning of the Jet Age.

With air travel being such an entirely different experience today, we will simply have to remember the glory days of DynaFan-powered StarStream 707s pulling up to the jetways, with passengers dining in the Paris Cafe and celebrities having one last drink at the Lisbon Lounge before jetting off to Europe, Africa, or the Far East. Now, as an integral part of JetBlue’s stunning new JFK terminal, the former TWA “Terminal of Tomorrow” still stands silently in solemn tribute to the dawning of the Jet Age.

![]()

![]()

Larger ramp areas with a variety of different gate configurations were being built for the first time, and the grand interiors of these new terminals bore more than a casual resemblance to the large spacious shopping malls also making their first appearance in America. Depending on the size of the airport, these impressive new structures either housed many airlines collectively, or individual carriers by themselves in a cluster of separate new buildings. These grand assemblages were linked together by sweeping circular roadways, and were envisioned as being great new “terminal cities.”

The aforementioned blast fences were more than just a convenience, as jet exhaust waves would prove to be a formidable hazard for unprotected vehicles and personnel in close proximity. Also, before enclosed and elevated jet bridges protected people boarding or deplaning jetliners, unsuspecting passengers could be blown over or lose their carry-on luggage crossing an unprotected ramp while walking out to board their jet.

By the mid-1950s, airport studies performed in conjunction with aircraft manufacturers were conducted to measure and extrapolate data for new jetliner flight – and ground-operation manuals. These studies revealed the need to cope with surprisingly strong amounts of jet exhaust blast. For instance, the four turbojets of a parked Boeing 707 spooled up to 80-percent power to move the aircraft off its tires’ flat spots and begin forward turning motion on the ramp would produce an

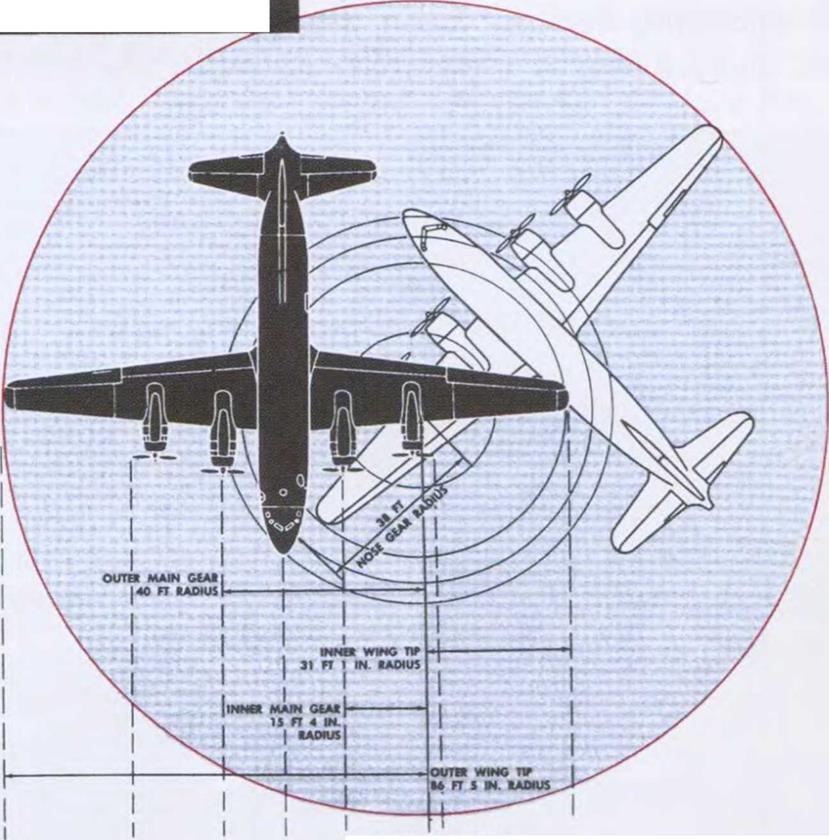

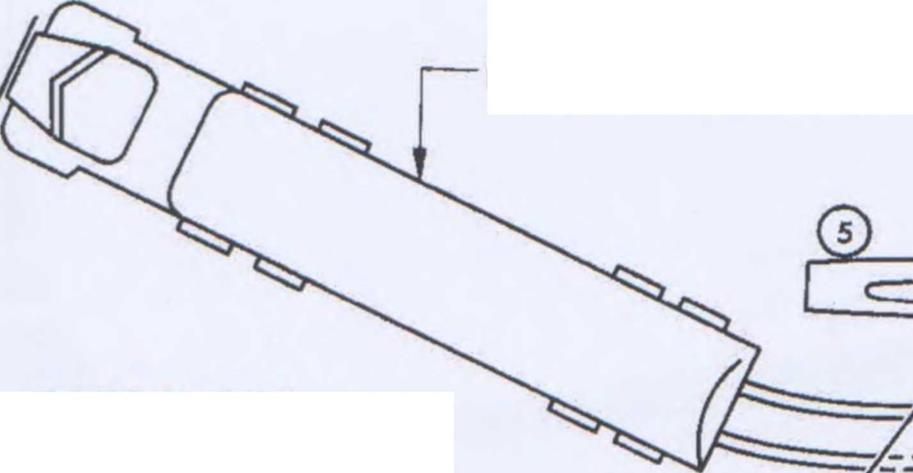

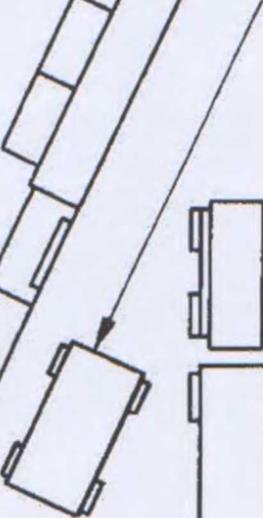

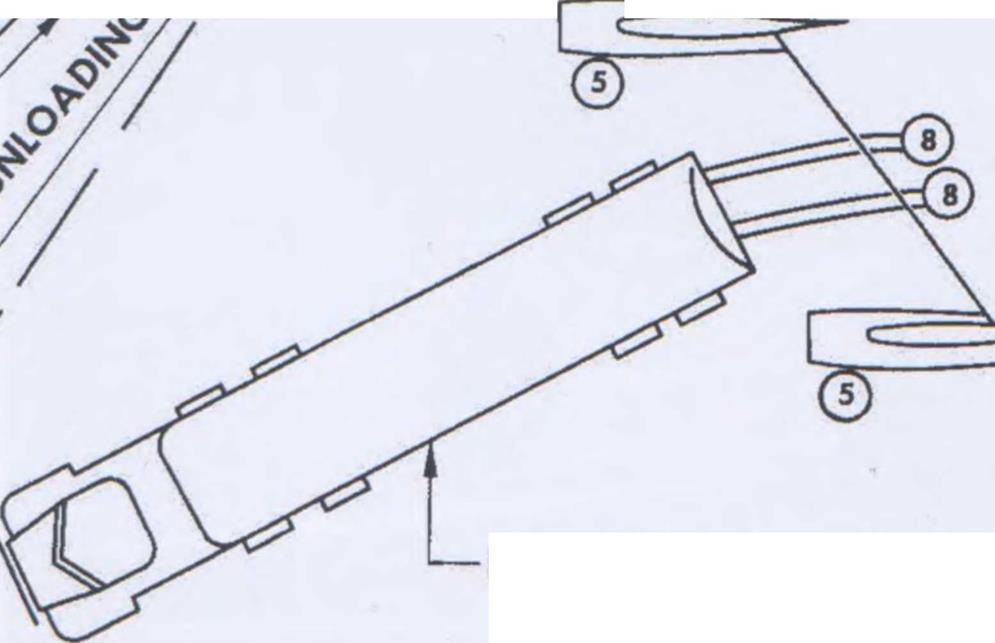

Manufacturer’s operating manual shows the turning radius and ramp clearances necessary for safe ground operations with the Douglas DC-4/C-54 aircraft. Clearances for wingtips, tail, and propeller discs were critical in avoiding potentially dangerous situations for both the aircraft and ground crew. (Courtesy of John K. Lewis via Mike Machat Collection)

exhaust velocity of nearly 30 mph at a distance of more than 100 feet behind the airplane.

exhaust velocity of nearly 30 mph at a distance of more than 100 feet behind the airplane.

Exhaust temperature was another dangerous factor, with heat of as much as 700 degrees F emanating from the engine exhaust aperture, diminishing to 150 degrees F at the tail of the airplane. Jet exhaust velocity at full takeoff power was measured at a formidable 1,000 feet per second at the exhaust cone of the engine nacelle. At that velocity, unprotected cars driving on a perimeter road behind a jet

at full takeoff thrust would be blown over like a child’s toy. The front of the jet engine also posed a potentially fatal hazard to ramp personnel with overpowering suction from the air intake replacing spinning propeller blades as the number-one ground safety threat.

Fueling the new jetliners would also be a different experience for ground handlers. The days of placing ladders against wing leading edges, then climbing up and walking out on top of the wing while trailing a fuel hose and nozzle would soon be ending. The first big advance for fueling the big jets was underwing fueling capability, meaning that two men, each operating a 6,000-gallon F-6 fuel tanker truck, could hook up underwing hoses and fuel the entire airplane in one continuous operation. This was a welcome change for ground crewmen having to walk around on top of the wings, opening fuel-tank caps and then filling one tank at a time on a Constellation or DC-7.

Further advances would eliminate the fuel truck altogether, as underground pipes fed fuel stored in large airport fuel-tank “farms” to valves and hose hook-ups located in the ramp itself just below the parked airplane’s wings. This way, ramp fueling personnel could plug hoses from these outlets into small mobile pumping units and then connect those directly to the underwing attach points of the jetliners, thus reducing the amount of large vehicles needed to service the airliner.

Speaking of vehicles, new types of ground equipment would also supplement, and in some cases eliminate

|

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

|||||||

|

![]()

![]()

![]()

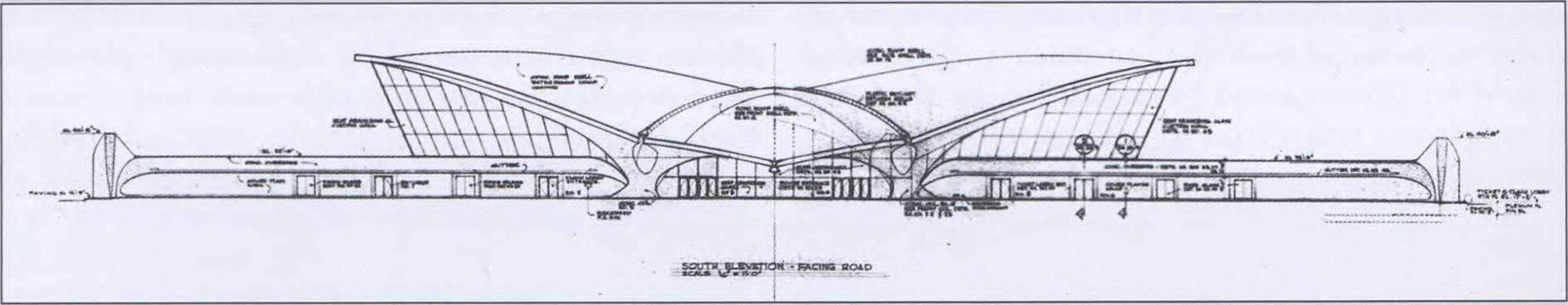

This schematic shows the proper location relative to the airplane of all the ground equipment necessary for the new 707. Compare this layout to the photograph (on page 98) of an actual TWA 707 being serviced at O’Hare Airport in Chicago. (Mike Machat Collection)

altogether, standard prop-era ramp vehicles such as electrical power carts, lavatory trucks, and baggage-handling tugs. Engine-water trucks would be required to pump aboard the alcohol and distilled water mix for water – injected takeoffs. Galley delivery trucks the size of small moving vans would back up to the airplane, their aft sections rising to the height of the cabin floor, to deliver meals and other galley provisions directly into the cabin. Large galley loading doors designed into the airframe would define how differently the new jets would be operated from all the other airliners that had come before.

These new galley doors were located fore and aft on the right-hand side of the airplane at main cabin floor height. Also on the right-hand side but below the cabin floor were large forward and aft baggage doors that allowed baggage and freight to be loaded aboard conveyer belts angled up to the open baggage bay. Ground power connections were also located on the right side of the jetliner’s nose to facilitate ramp personnel operating safely away from passengers loading on the left side of the airplane.

As originally intended before the jets entered service, each airplane would be surrounded by an armada

of ground vehicles upon arrival at the gate and while being turned around for its next flight. A typical fleet of ground vehicles and service apparatus required for handling the new jets parked at a terminal was expected to include:

• External power cart

• Forward lavatory service truck

• Aft lavatory service truck

• Forward baggage bay cargo and baggage conveyer truck

• Aft baggage bay cargo and baggage conveyer truck

• Engine-oil and generator-drive filler service

• Ground tug for towing or pushing on the ramp

• Potable-water service truck

• Right wing F-6 tanker truck

• Left wing F-6 tanker truck

• Forward door passenger-loading ramp truck

• Aft door passenger-loading ramp truck

• Ground air-conditioning truck

• Water-injection service truck

• Truck for engine “air-starts”

Commercial Avation’s Transition to the Jet Age 1952-1962

Commercial Avation’s Transition to the Jet Age 1952-1962

A large part of aviation’s popularity in the 1950s was due to the convenience offered for even inner-city travel. Los Angeles Airways began 10-passenger Sikorsky S-55 helicopter service from Los Angeles International Airport (LAX) on November 22, 1954. Having replaced the smaller Sikorsky S-51 carrying mail and passengers around the vast L. A. basin, the S-55s proved to be a boon to local commuting and were later upgraded to turbine-powered 28- passenger Sikorsky S-61s in 1962. (Los Angeles World Airports)

The East Coast counterpart of L. A. Airways was New York Airways (NYA), linking that metropolis’ three major airports with downtown Manhattan. Commuter service was provided using twin-rotor 15-passenger Vertol 44s. NYA also upgraded to jet-powered helicopters in the early-1960s using 25-passenger Boeing-Vertol 107s. Note flotation gear mounted on the big Vertol’s landing struts to ensure passenger safety when flying over the open waterways of New York City. (Mike Machat Collection)

|

![THE TERMINAL OF TOMORROW Подпись: Unlike on the BOAC Stratocruisers and DC-7Cs that preceded it, the Comet 4's interior was virtually noise and vibration free. According to BOAC ad copy in 1958, the Comet 4 offered passengers a "fusion of speed and rock-like stability [yielding] an impression of being suspended comfortably in space." Interior configuration shown here featured 16 first-class sleeper-seats in the forward cabin and 43 tourist seats aft. (Craig Kodera Collection)](/img/1246/image184_0.gif)

By the mid-1950s, airport management staffs and their in-house planners and designers had begun to look at the special needs of the new breed of jet-powered airliners. At this stage, however, the very first seedlings of these new ideas were just beginning to sprout. As we will see, by the time the new jets actually entered commercial service several years later, more refined and effective advancements would be incorporated into airline operations and modern airport design.

The work of one of the true masters of modern American^illustration, this

The work of one of the true masters of modern American^illustration, this

m-m –

m-m –

South African Airways (Suid-Afrikaanse Lugdiens), was known for luxurious in-flight services on its three 707-344s. ZS-CKC is seen here on push-back at London-Heathrow. Like other carriers, SAA later took advantage of Pratt & Whitney turbofan-powered Boeings, which were better suited to the airline’s high-altitude destinations. The 707- 300B series offered maximum gross takeoff weights of 330,000 pounds. (Jon Proctor Collection)

South African Airways (Suid-Afrikaanse Lugdiens), was known for luxurious in-flight services on its three 707-344s. ZS-CKC is seen here on push-back at London-Heathrow. Like other carriers, SAA later took advantage of Pratt & Whitney turbofan-powered Boeings, which were better suited to the airline’s high-altitude destinations. The 707- 300B series offered maximum gross takeoff weights of 330,000 pounds. (Jon Proctor Collection)

5AUDI ARABIAN AIRLINES

5AUDI ARABIAN AIRLINES

r І///1 * f-‘sl /7111

r І///1 * f-‘sl /7111

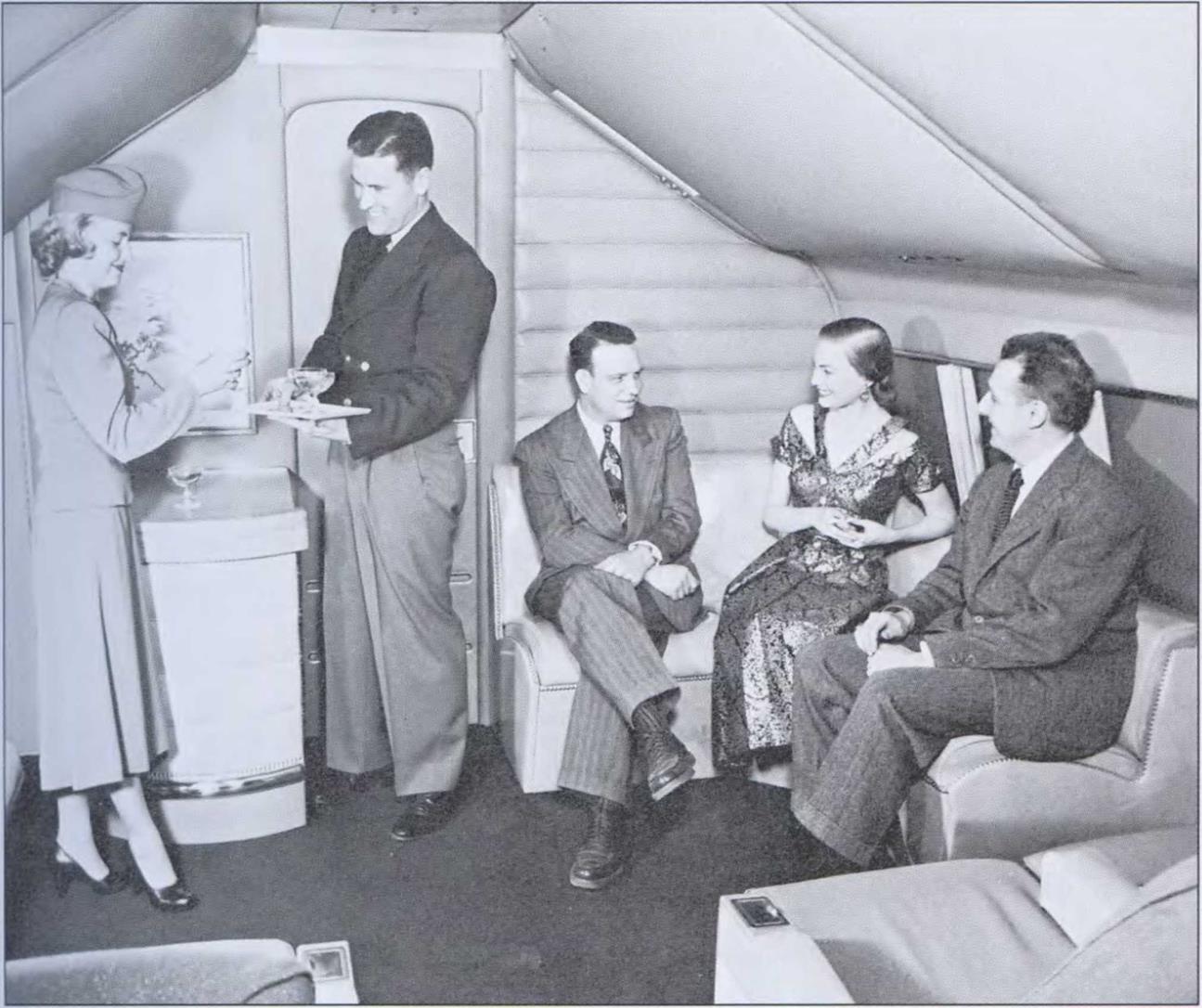

A cocktail lounge located at the front of the 749A Constellation passenger cabin provided a casual atmosphere for passengers awaiting dinner, or makeup of their sleeping berths, on TWA’s nonstop Ambassador Service from New York to London.

A cocktail lounge located at the front of the 749A Constellation passenger cabin provided a casual atmosphere for passengers awaiting dinner, or makeup of their sleeping berths, on TWA’s nonstop Ambassador Service from New York to London.

This extra power was used to lift an additional 1,100 gallons of fuel, which boosted the range of the Electra beyond its originally planned 2,500 miles, all the way to 3,460. The В designation was an unofficial tag used internally by Lockheed to denote the Electra with navigator stations and extra lavatories destined for use by the international airlines.

This extra power was used to lift an additional 1,100 gallons of fuel, which boosted the range of the Electra beyond its originally planned 2,500 miles, all the way to 3,460. The В designation was an unofficial tag used internally by Lockheed to denote the Electra with navigator stations and extra lavatories destined for use by the international airlines.

Unlike Pan American, TWA held off overseas jet service until its intercontinental 707-300s arrived, eliminating the need for fuel stops on flights to Europe. An example is seen at New York-ldlewild’s International Arrivals Building (IAB), wearing the twin- globe logo scheme adopted two years after entering service. (Jon Proctor)

Unlike Pan American, TWA held off overseas jet service until its intercontinental 707-300s arrived, eliminating the need for fuel stops on flights to Europe. An example is seen at New York-ldlewild’s International Arrivals Building (IAB), wearing the twin- globe logo scheme adopted two years after entering service. (Jon Proctor)

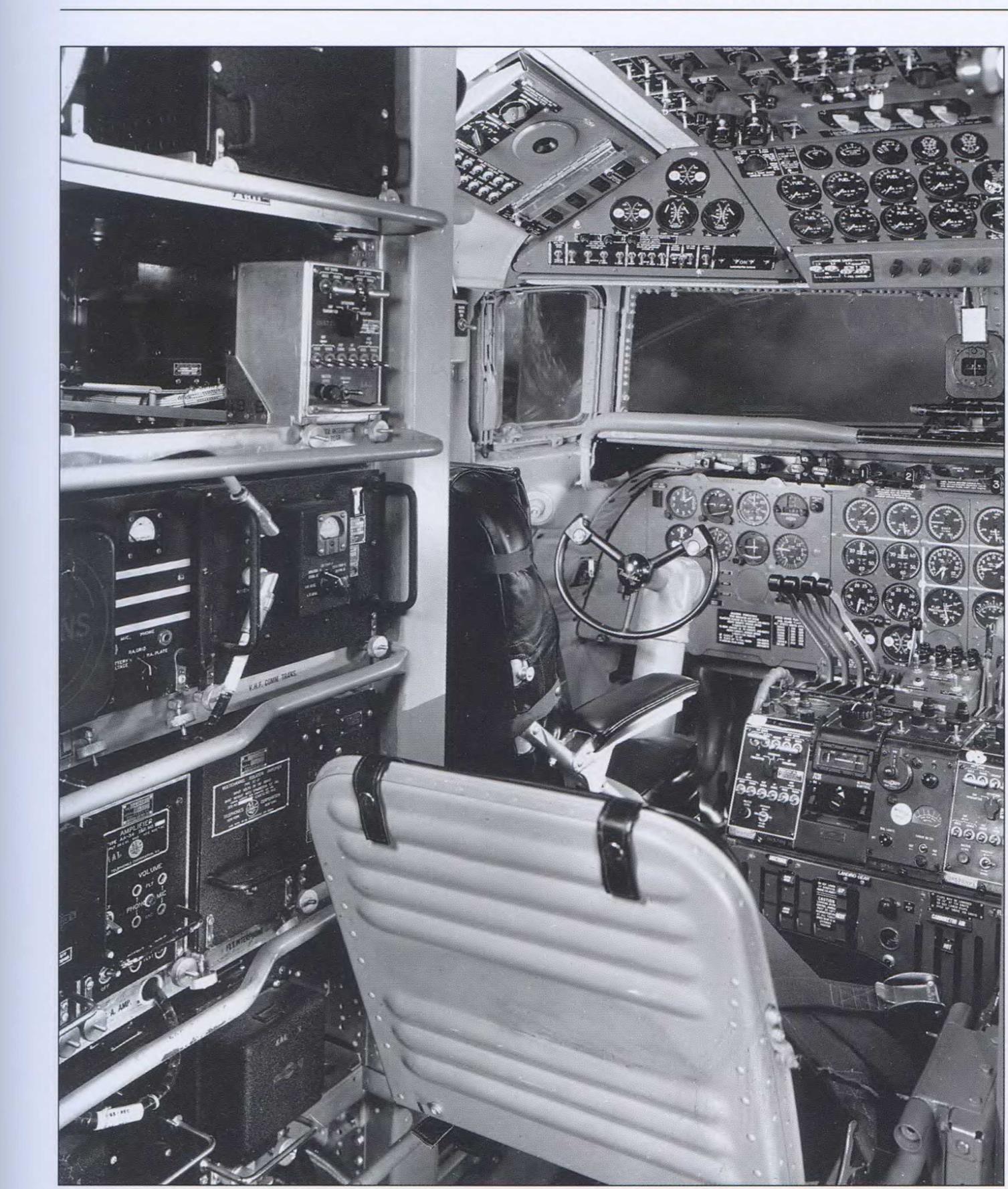

Cockpit of the DC-7 shows a well-laid-out instrument panel and control pedestal with the throttles, radio consoles, and trim wheel readily at hand. Flight Engineer’s seat is facing forward in this photo giving him access to the control pedestal and the overhead panel controlling the aircraft’s many onboard systems. Radio rack at left provided easy access for avionics maintenance personnel who may have had to change an entire radio unit or repair one of the many vacuum tubes contained therein. (Mike Machat Collection)

Cockpit of the DC-7 shows a well-laid-out instrument panel and control pedestal with the throttles, radio consoles, and trim wheel readily at hand. Flight Engineer’s seat is facing forward in this photo giving him access to the control pedestal and the overhead panel controlling the aircraft’s many onboard systems. Radio rack at left provided easy access for avionics maintenance personnel who may have had to change an entire radio unit or repair one of the many vacuum tubes contained therein. (Mike Machat Collection)

This work by famed artist Ren Wicks depicts the dome lighting of TWA’s 707s, designed to look like portholes in the aircraft ceiling. At night, pinholes of light against a dark background gave the impression of a night sky filled with a galaxy of stars. (TWA/Jon Proctor Collection)

This work by famed artist Ren Wicks depicts the dome lighting of TWA’s 707s, designed to look like portholes in the aircraft ceiling. At night, pinholes of light against a dark background gave the impression of a night sky filled with a galaxy of stars. (TWA/Jon Proctor Collection)

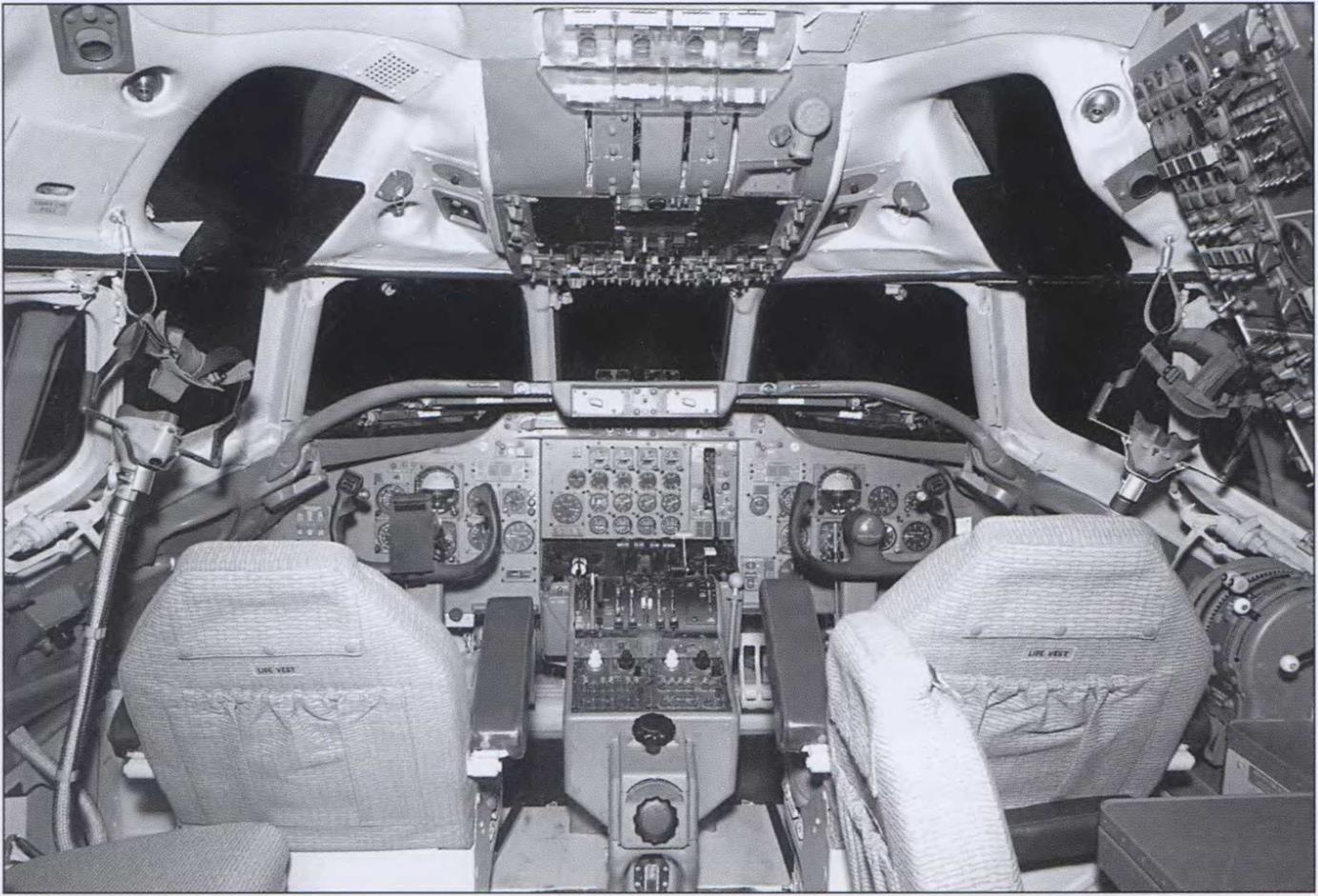

The DC-8’s cockpit was much roomier and offered much greater outward visibility than that of its piston-powered predecessors. Flight Engineer’s station is visible to the right with an observer’s jump seat at extreme left. Note move – able sunshades mounted on a circular track to ensure placement anywhere they were needed, a unique Douglas feature. Emergency quick – donning oxygen masks seen hanging next to each seat were a new addition for the flight crew. (Mike Machat Collection)

The DC-8’s cockpit was much roomier and offered much greater outward visibility than that of its piston-powered predecessors. Flight Engineer’s station is visible to the right with an observer’s jump seat at extreme left. Note move – able sunshades mounted on a circular track to ensure placement anywhere they were needed, a unique Douglas feature. Emergency quick – donning oxygen masks seen hanging next to each seat were a new addition for the flight crew. (Mike Machat Collection)