Clear of White Knight, the pilot armed the rocket engine, flicked the ignition switch, put his head back against the seat, and grabbed the control stick with both hands.

“When you light that rocket motor off, everything literally starts with a bang. There is so much energy associated with that rocket motor. It is like a tsunami sweeps through the cabin and literally takes you away,” said Brian Binnie, the pilot who flew the first and last powered flights of SpaceShipOne.

“You really have nothing in your background or DNA to tell you that what is happening to you is good. You have no basis. Three or four seconds will go by, and you go, ‘Ah, I’m not dead. Therefore, it must be going as they told me it was going to go.’”

The roar from the rocket engine was extremely loud. “The noise is certainly worse right at ignition when you have little forward speed,” explained Binnie. “But as soon as you are supersonic, you are going faster then any sound that the rocket motor makes. It doesn’t really penetrate the cabin a lot. What you hear in the cabin is all the gurgling off the main oxidizer tank that’s right on the other side of the bulkhead from which you’re located. So, you hear that. There is a certain amount of wind noise over the vehicle. A good helmet with reasonable ear protection let the radio come across just fine.”

The force pinning the pilot to his seat just added to the flood of sensations. “The acceleration is fierce. It’s abrupt. It’s sudden. It’s a big slap in the back and whoosh off you go. It is a very dynamic environment, and you are very much holding on for dear life,” Binnie said.

“As it develops, your body readily adjusts to the g’s that you are experiencing. They are not that high during boost. They are between 3 or 4.” Having been a former navy fighter pilot, Binnie had some experience with some pretty fast starts. The initial kick from a catapult off the deck of an aircraft carrier had some similarity. After 2—2.5 seconds, the acceleration from the catapult was over, but after the same amount of time, SpaceShipOne would still be going and going.

“A catapult shot takes you from 0 to about 150 miles per hour [240 kilometers per hour] in 2 to 2.5 seconds. If you continue that acceleration rate, which is kind of what the spaceship is doing, you would then go from 150 to 300 miles per hour [480 kilometers per hour] in another 2.5 seconds or the 5-second mark. And at the 8-second mark, you’d be doing not 300 miles per hour but 600 miles per hour [970 kilometers per hour]. And by the 10-second mark, you’d be supersonic.”

The pilot held the control stick with both hands because, as SpaceShipOne moved faster and faster, the forces from the outside air pushed harder and harder against the vehicle and its controls. The pilot had to make sure the nose was coming up right away. Otherwise there was a danger of overspeeding SpaceShipOne and breaking it apart. The “never-exceed” speed was around 260 knots equivalent airspeed (KEAS). A knot is a nautical mile per hour, which is a little faster than a mile per hour. Equivalent airspeed is a measure of how fast a vehicle feels it’s going in terms of the air pressure pushing against it. So, this value may seem very low, but SpaceShipOne started out already operating above 85 percent of the atmosphere. The air density was very low to begin with and didn’t exert as much air pressure as if the vehicle were flying at a lower altitude where the air density was higher.

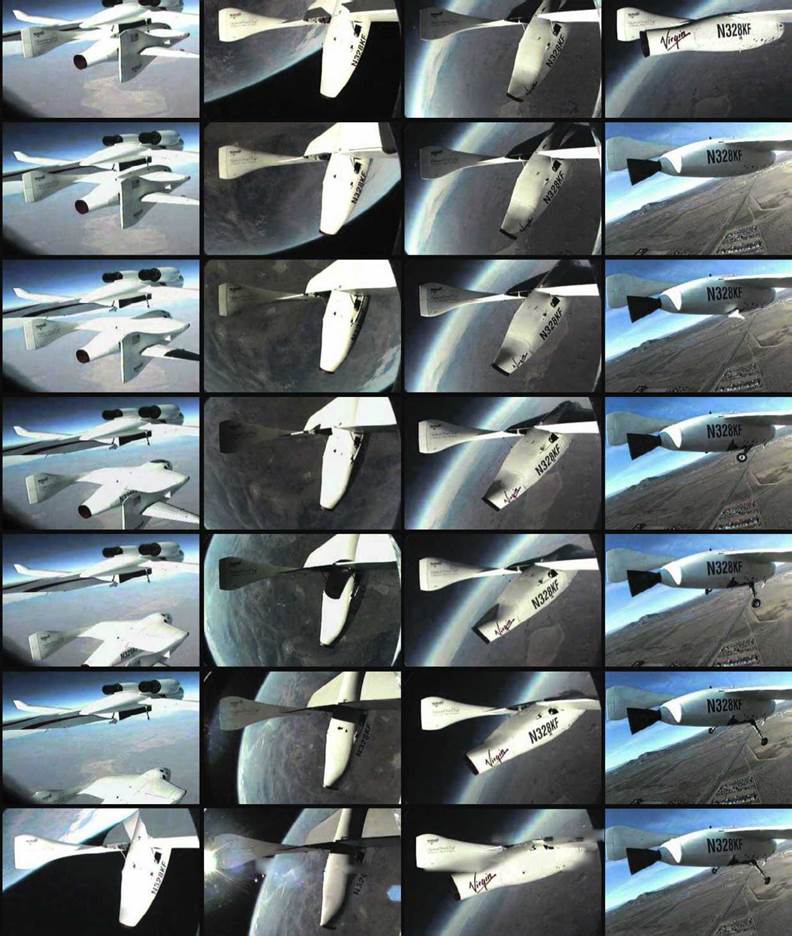

Figure 3.11 shows SpaceShipOne during the initial pull up, also called “turning the corner” or the “gamma turn.” With the feather locked down tight, it was critical for the pilot to keep the wings level during this phase.

“Because our wings are level, that turn results in pointing nose up,” Pete Siebold said. “So, if any portion of the time you roll to a

“Because our wings are level, that turn results in pointing nose up,” Pete Siebold said. “So, if any portion of the time you roll to a

ч

С “ ^

Fig. 3.11. Once the rocket engine ignited, the test pilot immediately had to begin to pull the nose of SpaceShipOne up in a maneuver called "turning the corner." By the time the turn upward was complete, SpaceShipOne was already traveling at supersonic speeds. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

V___________________________________________ )

non—wings level attitude, instead of going up, you are going to turn to a different heading and not go up. A significant amount of the energy is spent doing that initial turn.

“If there was any time spent non—wings level during this turn, you ran the risk of not making your ultimate goal of 100 kilometers [62.1 miles] at the end of the flight.”

A number of things caused the wing to wander back and forth. Asymmetries in the thrust from the rocket engine and asymmetries that resulted from supersonic shockwaves wanted to knock SpaceShipOne off course.

Melvill added, “And there are wind shears that exceed 100 miles per hour [160 kilometers per hour] going in different directions. So as you go up, it will blow you this way and then it blow you that way. You are not there for long, so you don’t get massive changes, but you are constantly correcting.”

By using an avionics system called the Tier One navigation unit (TONU), the pilot could ensure that SpaceShipOne was wings level and had the proper pitch rate, which was a measure of how fast the nose was rising. For the first 5 seconds, the pilot used the control stick and the rudder pedals to keep the wings level. “You can feel the forces start to build quite rapidly,” Binnie said. “And now your thinking is, ‘Okay, I’m going to keep fighting this thing physically until about 8 or 9 seconds, and then I’m going to transition over to controlling the vehicle with electric trims.’” To do this, the pilot took his left hand off the stick and reached for the rudder trim controller, a big black knob that looked liked a turtle shell.

Binnie explained, “As you are going through transonics, where the vehicle is shocking up asymmetrically, it is still rocking back and forth or more like whipping back and forth. Your job is to try to filter out the oscillatory motion and chase down with the turtle any longer-term disturbance that is driving the nose of the vehicle off trajectory.

“You have high-rate motions but you have a low-rate controller. So, things don’t happen as quickly as you’d like them to. You put in an

с ; ^

Fig. 3.12. Traveling close to vertical, SpaceShipOne’s hybrid rocket engine burned 76-84 seconds during a spaceflight. At rocket engine shutdown, SpaceShipOne was a little more than half the way up to apogee. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

V__________________ )

adjustment, and you’re going to have to be patient to sort of see it take effect. And that is not the easiest thing in the world to do because you just had your brains scrambled. And everything about you is on high alert, and now you have to be patient and wait for the thing to respond. If you don’t, it is easy to over-control it, and you can get yourself into even more trouble.”

As the pilot was finishing the initial pull up, SpaceShipOne passed the rough transonic transition from subsonic to supersonic.

“You settle in around the 10- to 15-second mark and look out the window. And appreciate that you are no longer horizontal. The nose will appear vertical, but it is not quite there yet,” Binnie said.

г-

г-

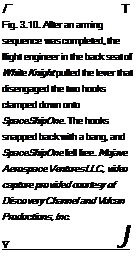

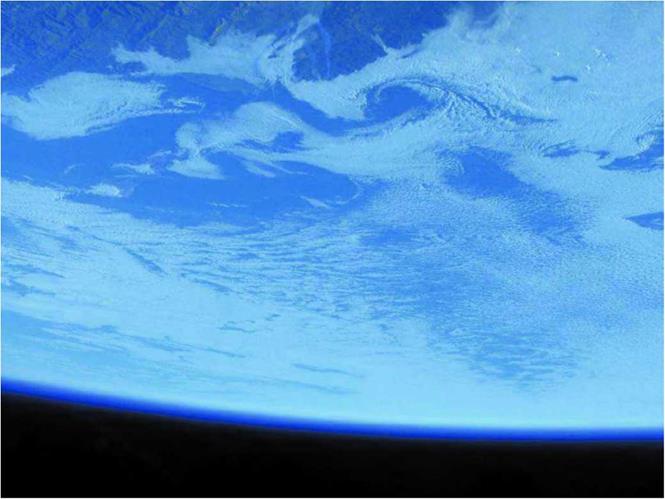

Fig. 3.13. Photographed from inside the cockpit of SpaceShipOne by Brian Binnie near the apogee of 367,500 feet (112,000 meters), the Channel Islands and the Pacific Coast peek through the cloud cover as black sky shrouds Earth. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

V__________________________________________________________________________________________

Figure 3.12 shows SpaceShipOne and its contrail during the ascent to space.

As SpaceShipOne continued to ascend and slowly move its nose closer to vertical, the use of the control stick came back. The pilot could again use the mechanical controls to fly, even though it traveled much faster than Mach 1 and was still gaining speed. The air density was too low to create much opposing force but still high enough for aerodynamics to work.

At about the 1-minute mark, the rocket engine went through a liquid-to-gas transition. “This is kind of a wake-up call that you are getting near the end of the boost phase of flight,” Binnie said. “The vehicle shakes and shudders some more. And then the rocket motor valve that you are sitting not too far from has some unusual acoustics

associated with it. It sounds like riding along with a possessed cat. It kind of screeches and howls and complains.”

SpaceShipOne reached a maximum speed of Mach 3.09, or 2,186 miles per hour (3,518 kilometers per hour).This occurred just before burnout while it was still accelerating. But the atmosphere was very thin at this point, so the airspeed was only about 40 knots equivalent airspeed.

The highest altitude for rocket-engine shutdown occurred at

213,0 feet (64,920 meters). The burn lasted 84 seconds. Unlike shutdown inside the thick atmosphere, where thrust no longer kept the pilot pinned to the seat and the deceleration force flung him forward in his seat, shutdown at high altitudes was tame because of the thin atmosphere and because the rocket engine’s thrust had tapered off due to the longer burn duration. SpaceShipOne now coasted upward.

г

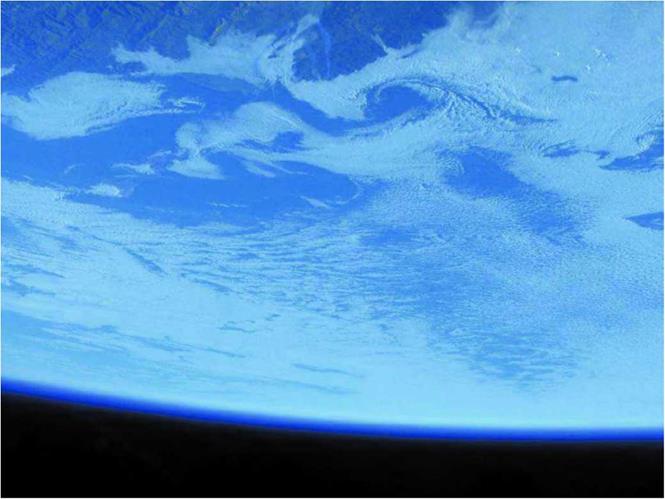

Fig. 3.14. During the 3.5 minutes of weightlessness, the test pilots were able to take photographs from inside SpaceShipOne’s cockpit. In this photograph, the red-colored thermal protection on the leading edge of the right wing can be seen through one of the porthole windows. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

Fig. 3.14. During the 3.5 minutes of weightlessness, the test pilots were able to take photographs from inside SpaceShipOne’s cockpit. In this photograph, the red-colored thermal protection on the leading edge of the right wing can be seen through one of the porthole windows. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

V__________________ У

“Three wonderful things happen/’recalled Binnie. “The noise goes away. The shaking, the shuddering, the vibration go away, and you become instantly weightless. And the weightlessness is just a profoundly exciting and pleasurable experience.”

“Then of course there is that view. You’ve seen it on the cover of magazines and things like that. But when you see it for yourself, it is really breathtaking. The eye is so much more dynamic than a video or a camera. It is yours for the enjoyment.”

As SpaceShipOne rocketed upward, light scattered less and less in the dwindling atmosphere. “You can already see the blue skies turning a much darker, deeper shade of blue and as you continue to watch that, it will deepen and darken and kind of go purplish and then to black,” said Binnie.

Figure 3.13 shows the black sky surrounding Earth in a photograph taken by Brian Binnie aboard SpaceShipOne. So where are the stars in the black sky? Above the atmosphere there should be stars galore. Well, they are there. However, a camera cannot catch the stars. Earth is much too bright. To see the stars in a photograph, a much longer exposure time is needed, but then the features of Earth would be totally washed out. This phenomenon can also be observed in the famous “Earthrise” photograph taken by the crew of Apollo 8 as they circled the Moon, where Earth is seen rising above the surface of the Moon and no stars can be seen in the background.

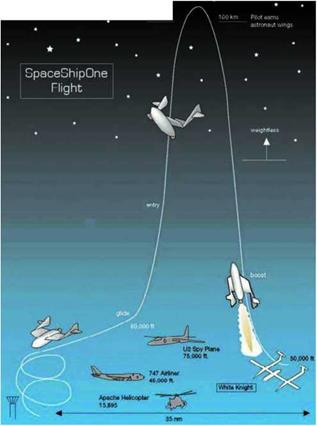

Following a ballistic arc, the unpowered spacecraft continued to climb, coasting up while the atmosphere dwindled away. To win the Ansari X Prize, it was necessary to reach an altitude of 328,000 feet (100,000 meters). So, as SpaceShipOne raced toward this height, the pilot enjoyed the effects of zero-g. Without the atmosphere, the drag

caused by the air resistance was no longer a factor causing SpaceShipOne to decelerate. Gravity still had a hold on SpaceShipOne, however, and the spacecraft was not traveling at a high enough velocity to escape the pull of Earth.

Having taken an hour to reach launch altitude and separation, the maximum altitude when SpaceShipOne reached the top of its climb, or its apogee, occurred about 3 minutes after the rocket engine initially fired off. SpaceShipOne stopped moving up at this point and began to free fall back to Earth. The pilot experienced weightless conditions for approximately 3.5 minutes, which he started to feel once the rocket engine shut down. For comparison, the Space Shuttle took 8.5 minutes to go from its launch pad to its orbital altitude of around 200 miles (320 kilometers).

Shot from space, the photograph in figure 3.14 gives a glimpse from SpaceShipOne’s window of the leading edge of its wing high above desert mountains.

While outside the atmosphere, SpaceShipOne could not use its rudders or elevons to control movement whether it was ascending or descending. Since space is a vacuum, there was no air to provide the lift that these control surfaces required to change the spacecraft’s course. This is the same problem faced by the Space Shuttle, as well as other spacecraft and satellites. Even astronauts during extravehicular activity (EVA), floating outside the International Space Station, need a way to steer themselves around. To maneuver in space, they accomplished this by shooting little jets of gas in a direction opposite to that of the intended motion. So, for example, if a spacecraft needed to move to the right, it shot a puff of gas to the left.

SpaceShipOne was no different. In the airless environment, the pilot had to use the reaction control system (RCS) to maneuver SpaceShipOne.

г

Fig. 3.15. In an interview with Ed Bradley for 60 Minutes after the Ansari X Prize spaceflights, Burt Rutan shows the feather configuration and describes how it allowed the safe return of SpaceShipOne to Earth’s atmosphere. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

After he switched the RCS on, he used the control stick and rudder pedals to control thrusters mounted on the fuselage and wings.

“We chose to put a microswitch on the end of the travel, so you had to get your knees out of the way just to do anything at all. You had to move the stick all the way to a stop until it closed the microswitch, opened up a valve, and then the jet worked,” Melvill said.

The rudder petals worked the same way, in that they had to be pushed all the way on the floor to activate the thrusters. So, the thrusters would fire as long as the pilot pressed against the microswitches.

r ; л

r ; л

Fig. 3.8. Carried to a height of

Fig. 3.8. Carried to a height of Fig. 1.1. Burt Rutan (top left), the SpaceShipOne and White Knight designer, and Doug Shane (top right), the test flight director, stand behind their test pilots, Pete Siebold, Brian Binnie, and Mike Melvill (left to right). Mojave Aerospace Ventures LLC, photograph by Scaled Composites

Fig. 1.1. Burt Rutan (top left), the SpaceShipOne and White Knight designer, and Doug Shane (top right), the test flight director, stand behind their test pilots, Pete Siebold, Brian Binnie, and Mike Melvill (left to right). Mojave Aerospace Ventures LLC, photograph by Scaled Composites

“Because our wings are level, that turn results in pointing nose up,” Pete Siebold said. “So, if any portion of the time you roll to a

“Because our wings are level, that turn results in pointing nose up,” Pete Siebold said. “So, if any portion of the time you roll to a

г-

г- Fig. 3.14. During the 3.5 minutes of weightlessness, the test pilots were able to take photographs from inside SpaceShipOne’s cockpit. In this photograph, the red-colored thermal protection on the leading edge of the right wing can be seen through one of the porthole windows. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

Fig. 3.14. During the 3.5 minutes of weightlessness, the test pilots were able to take photographs from inside SpaceShipOne’s cockpit. In this photograph, the red-colored thermal protection on the leading edge of the right wing can be seen through one of the porthole windows. Mojave Aerospace Ventures LLC, photograph by Scaled Composites

Starship, Pegasus, and the Pond Racer. Scaled Composites built some of these designs from start to finish, but for others the company only contributed to part of the construction.

Starship, Pegasus, and the Pond Racer. Scaled Composites built some of these designs from start to finish, but for others the company only contributed to part of the construction. Fig. 3.16. The feather extends and retracts by air-powered actuators, or pistons, that are attached on either side of the fuselage and connected to each side of the wing near their trailing edges. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

Fig. 3.16. The feather extends and retracts by air-powered actuators, or pistons, that are attached on either side of the fuselage and connected to each side of the wing near their trailing edges. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc. г >1

г >1 г л

г л Ґ

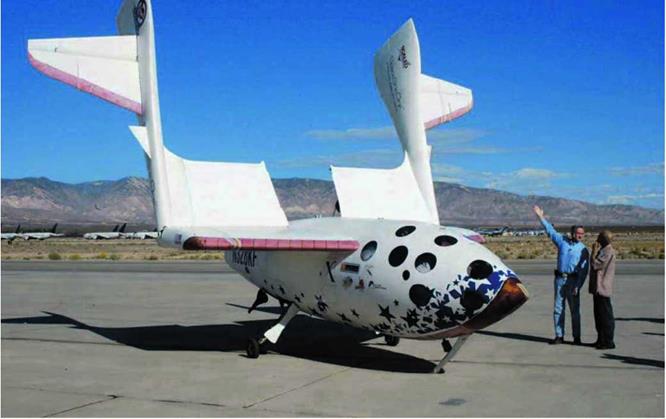

Ґ Fig. 3.19. Once SpaceShipOne touched down, steering was very limited. The nose skid and the rear landing gear’s brakes brought the craft to a quick stop, but since it was unpowered, it needed some help to get off the runway. This photograph shows Sir Richard Branson, Paul Allen, and Burt Rutan (left to right) sitting on the tailgate with SpaceShipOne under tow. Dan Linehan

Fig. 3.19. Once SpaceShipOne touched down, steering was very limited. The nose skid and the rear landing gear’s brakes brought the craft to a quick stop, but since it was unpowered, it needed some help to get off the runway. This photograph shows Sir Richard Branson, Paul Allen, and Burt Rutan (left to right) sitting on the tailgate with SpaceShipOne under tow. Dan Linehan