Breaking the Sound Barrier (11P)

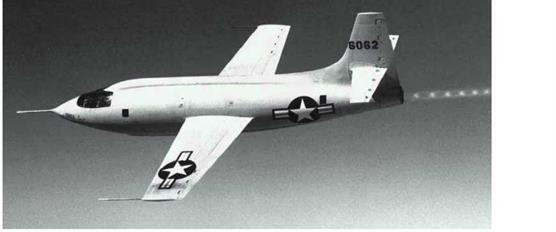

On December 17, a flimsy aircraft that no one thought would fly prepared to launch from sand-swept dunes. This wasn’t the Mojave Desert, though. It was 1903 in Kitty Hawk, North Carolina. The Wright brothers proved that a couple of bicycle makers could accomplish the unbelievable—powered, controlled, and sustained flight. Their famous flight is shown in figure 8.1.

One hundred years later, to the day, Scaled Composites also looked to make the unbelievable believable. SpaceShipOne was ready for its first rocket-powered test flight.

The sound barrier posed the greatest challenge the team had yet to face. The choice of pilots was not a straightforward one. Mike Melvill, the most experienced test pilot with Rutan designs, had already piloted SpaceShipOne seven times. Pete Siebold and Brian Binnie had each only flown SpaceShipOne once. During such a critical juncture, the test pilot with the greatest stick tim SpaceShipOne would seem like the most likel candidate. But Binnie was selected. The entire fate of Rutan’s space program now rested in his hands.

Flight Test Log Excerpt for 11P

Date: 17 December 2003

Flight Number Pilot/Flight Engineer

SpaceShipOne 11P Brian Binnie

White Knight 43L Pete Siebold/Cory Bird

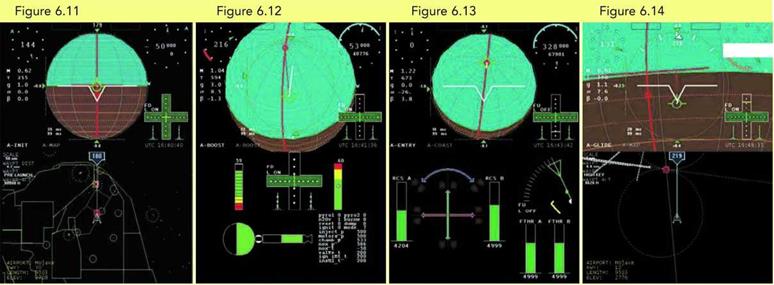

Objective: The eighth flight of SpaceShipOne and first powered flight, fifteen-second burn of the rocket motor and supersonic flight. Motor light-off at altitude and inflight engine performance. Vehicle handling qualities through transonics and feather performance from altitude.

One of the most obvious reasons for the selection was Binnie’s experience flying supersonic jets for the U. S. Navy. “I would suspect that certainly was part of the thinking that went into it,” Binnie said. “I was also kind of the anointed test director for the rocket motor. So, I was very familiar with all the ins and outs with the motor and its performance. I was comfortable with its design and robustness and performance, more so than perhaps anybody else. And perhaps I had, right from the first time I saw it fire, this image in my mind of how it would play out when put into a vehicle. I was very motivated to fly that flight.”

Binnie also had flown Roton, a spaceship prototype produced by Rotary Rocket, Inc., that was half rocket and half helicopter. “That vehicle was decidedly scary to fly,” Binnie said. “I flew it three times. I thought, ‘You know, if I have to do this one or two more times, I’m pretty sure I’m going to kill myself.’ I was honestly sort of fearful that I’d climb into this thing and not climb out. I never felt that way with the spaceship. There were certainly things that could go wrong that could cause an accident, but I never felt that the accident was going to be life threatening.”

With Pete Siebold flying White Knight, Cory Bird released SpaceShipOne at 47,900 feet (14,600 meters). Dropping down, Binnie stabilized SpaceShipOne and started to pull the nose up.

“We knew very little about it. It was all about risk. Our standard for success was, literally, if the rocket motor lit off even for just a few seconds and we shut it down, we were going to call that a success,” Binnie said.

How would the rocket engine function? Would SpaceShipOne hold together during the enormous acceleration? What about the messy transonic region? How about the cockpit? Would it shake too much or be too loud to operate the vehicle? How would the untested controls work at supersonic? Would SpaceShipOne climb quickly enough so that an overspeed didn’t rip it to pieces?

“This was the riskiest flight of our whole program, probably times five or ten,” Doug Shane said.

At 44,400 feet (13,530 meters) and flying Mach 0.55, Binnie lit the rocket engine. “It’s a real rush to kind of ride something that powerful. Like I said, it is like a tsunami comes through the cabin. You are just taken away. So, it is very exhilarating,” Binnie said.

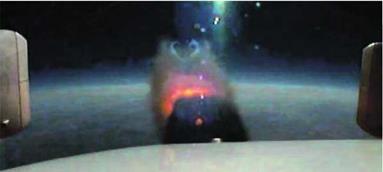

As SpaceShipOne rocketed upward, it broke the sound barrier after only 9 seconds. Figure 8.2 shows SpaceShipOne’s rocket engine firing.

Binnie shut down the rocket engine after a burn duration of 15 seconds as SpaceShipOne hit a maximum speed of Mach 1.2 (800 miles per hour or 1,290 kilometer per hour) while having pulled more than 3 g’s. As SpaceShipOne became the first manned vehicle to have ever used a hybrid rocket engine, it pointed up at 60 degrees and still climbed. SpaceShipOne continued to coast upward and was upside down by the time it reached near-weightlessness at an apogee of 67,800 feet (20,670 meters). Binnie then descended for about a minute with the feather deployed and retracted it at 35,000 feet (10,670 meters).

“It was manageable,” Binnie said. “It wasn’t the most graceful flight. If you looked at it from inside the cockpit, there were a lot of snakes being killed. The boost part of it went extremely well, all things considered, and gave us a lot of confidence that we had a design that was capable. It was only the landing that marred an otherwise wonderful day.”

|

|

Г ^

Fig. 8.2. Brian Binnie took the controls of SpaceShipOne for test flight number 11P, one hundred years after the flight of the first successful airplane, in which the 1903 Wright Flyer had flown for 12 seconds. Even though Binnie burned the rocket engine for only 15 seconds,

SpaceShipOne broke the sound barrier after only 9 seconds. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

ч___________________ ;______________________ J

|

|

c ^

Fig. 8.3. A crash landing blemished an otherwise successful first rocket – powered test flight. SpaceShipOne touched down harder than the landing gear could handle, causing the left rear main landing gear to collapse and SpaceShipOne to skid off the runway. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

v__________________________________________ J

On the landing, which had proved to be a surprising and persistent source of trouble for Scaled Composites, SpaceShipOne hit very hard. The left main landing gear collapsed, and SpaceShipOne skidded to the left and off the runway into the dirt, as shown in figure 8.3 and figure 8.4.

Burt Rutan gave some clarification about the cause of the crash landing during a press conference late in 2004. He said, “We were testing at that time, a flight control modification that would give us a better margin on flutter in the transonic area. And that damper in the flight controls had gotten so cold that the controls were extremely sticky. That landing wasn’t Brian’s fault. It was the fault of us not doing the proper thing, and that is putting a heater on the damper so that it didn’t freeze up on him on the landing approach.”

As Binnie was flaring up for the landing, the damper unfroze. The controls buffeted like SpaceShipOne was going to stall. It was actually just the control linkages responding differently, but there was no way that Binnie could have known this. So, he dropped the nose to prevent the stall that he thought was about to occur. As a result, SpaceShipOne came in too fast and too hard for the fragile landing gear.

Г"

Г"

in one respect what we would call a functional check flight after any major modifications to the airplane. We wanted to go fly it in a semi – benign environment and try and shake down any of the problems that we may have overlooked or additional problems that had been created due to the modifications.

in one respect what we would call a functional check flight after any major modifications to the airplane. We wanted to go fly it in a semi – benign environment and try and shake down any of the problems that we may have overlooked or additional problems that had been created due to the modifications. ( ■ >1 Fig. 6.8. In Gemini 4, astronaut Ed White made the first U. S.

( ■ >1 Fig. 6.8. In Gemini 4, astronaut Ed White made the first U. S.

Fig. 8.5. Nearly four months after the first rocket-powered flight test, Pete Siebold ignited the rocket engine of SpaceShipOne for 40 seconds and reached an apogee of 105,000 feet (32,000 meters). He hit a top speed of Mach 1.6 on the boost and Mach 0.9 on the way down. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

Fig. 8.5. Nearly four months after the first rocket-powered flight test, Pete Siebold ignited the rocket engine of SpaceShipOne for 40 seconds and reached an apogee of 105,000 feet (32,000 meters). He hit a top speed of Mach 1.6 on the boost and Mach 0.9 on the way down. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

Fig. 8.9. SpaceShipOne reached an apogee of 211,400 feet (64,430 meters), and the video camera in the tail boom recorded the feather in the extended position. While high above Los Angeles, SpaceShipOne was technically not in space, even though the curvature of Earth can be clearly seen. However, the curvature is somewhat exaggerated due to the auto focus lens used. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

Fig. 8.9. SpaceShipOne reached an apogee of 211,400 feet (64,430 meters), and the video camera in the tail boom recorded the feather in the extended position. While high above Los Angeles, SpaceShipOne was technically not in space, even though the curvature of Earth can be clearly seen. However, the curvature is somewhat exaggerated due to the auto focus lens used. Mojave Aerospace Ventures LLC, video capture provided courtesy of Discovery Channel and Vulcan Productions, Inc.

r ; л

r ; л

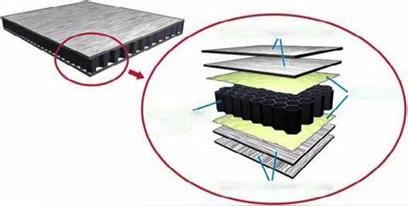

Honeycomb Sandwich Structure

Honeycomb Sandwich Structure