Even before the X-15 took to the air the Air Force, NACA and North American were making plans for an orbital version. This X-15B would be launched using a multi-stage rocket derived from the launch booster of the SM-64 Navaho missile; a project that had just been canceled and had left North American with a warehouse of rocket boosters. But the X-15B was canceled when Project Mercury was approved, a much simpler capsule concept that promised early results in the developing space race with the Soviets. Then the national goal of being first to land a man on the Moon gave rise to the Gemini and Apollo capsule-style spacecraft.

However, the Air Force, regarding a capsule as merely a step on the way to more routine access to space, saw the benefit of a reusable shuttle-type vehicle for manned missions. During the 1950s Werner von Braun had proposed a reusable canard space glider to be launched atop a rocket using two expendable stages. This was explained in Collier’s magazine in 1952, in one of a series of articles on future spaceflight that von Braun wrote with Willy Ley between 1952 and 1954. Collier’s printed 4 milhon copies per issue, so these articles did much to spur enthusiasm for spaceflight in the US. The articles were enlivened by beautifully detailed illustrations by leading space artists, including Chesley Bonestell, that effectively dramatized von Braun’s manned spaceflight development blueprint for the general public. Further publicity came soon afterwards with von Braun presenting a hugely popular three-part Disney television show on the future of space travel, which also featured his designs. At one point von Braun presents his winged spacecraft design: “Now here is my design for a four-stage orbital rocketship. First we would design and build the fourth stage and then tow it into the air to test it as glider. This is the section that must ultimately return the men to the Earth safely.” His ‘Ferry Rocket’ is basically an upper rocket stage with multiple engines and long, slightly swept-back wings, each with an elongated vertical stabilizer mid-way. Large horizontal stabilizers were fitted to the nose, resulting in a canard design. The launcher’s first stage had huge fins as well, not for flying but for counteracting the imbalance caused by the rocket glider’s wings on top of the rocket, as otherwise a slight wind during take-off or buffeting while ascending through the atmosphere would easily blow the whole assembly off course.

By 1959 the Air Force was promoting a new program as the means of performing military manned space missions. Like von Braun’s concept, this ‘Dyna-Soar’ would not be a real rocket plane but a reusable space glider (its name was a contraction of Dynamic Soaring) bolted to the nose of a conventional launch rocket. It would only use its wings during the unpowered descent back through the atmosphere and make a controlled landing near its launch site. There it would be quickly readied for its next launch on a new expendable rocket. In its operational form Dyna-Soar would be able to perform all kinds of missions and even put things into orbit because it would have a cargo bay; it was basically to be a small, early version of the Space Shuttle.

In contrast, Mercury and the later Gemini and Apollo spacecraft were completely single-use; very Uttle of what was launched would come back, and with their ablative heat shields that burned away during re-entry the capsules were not reusable. They also had very little means of maneuvering once they started their ballistic fall back to Earth and at best could be expected to land within a radius of several kilometers of a specific point. Because of this uncertainty in the landing spot, as well as to ensure a soft landing, they had to come down in the ocean, which meant a fleet of search and recovery ships was required. The X-20 pilot would fly his craft back to its airbase, making the return much more economical. Of course a controllable, winged machine was also much more appealing to the Air Force than a ‘spam-in-a-can’ capsule using parachutes. It facilitated a dignified landing on a runway, rather than an inglorious splash into the ocean.

The Air Force forecast numerous versions and missions for the X-20, involving payloads for gathering aerodynamic flight data, satellite inspection, electronic and photographic intelligence, and even dropping nuclear bombs with greater precision than was possible using a balhstic missile! Dyna-Soar was to be a research aircraft, spy plane, orbital bomber and transportation shuttle all in one.

In June 1959 Boeing was awarded the development contract. Boeing’s design was a 5,200 kg (11,400 pounds) delta-winged vehicle with large vertical winglets instead of a more conventional tail for lateral (yaw) control. Most of the internal structure as well as the upper surface was to be made from Rene 41, a ‘super alloy’ that was able to withstand extreme temperatures. However this material would not suffice for the areas that would see the highest temperatures during re-entry, when slamming into the atmosphere at some 28,000 km per hour (17,000 miles per hour), or Mach 28. Capsule spacecraft solved this issue by using expendable ablative heat shields, but as the X-20 was to be a completely reusable space glider its underside would require to be made by placing molybdenum sheets over insulated Rene 41, while its nose-cone was to be made from pure graphite incorporating zirconia rods.

The X-20 would be controlled by a single pilot. Behind him was an equipment bay that could contain either data-collection equipment, reconnaissance equipment, weapons, or seats for up to another four astronauts. The X-20 would be connected to a small rocket stage to enable the craft to shoot itself away from the Titan III booster during launch in case of an abort or, once in space, to change its orbit. At the end of a mission this ‘transition stage’ would fire its main rocket engines against the velocity vector so that the X-20 would fall back to Earth. It would then be jettisoned and the aircraft would descend through the atmosphere and use aerodynamic drag to further slow down (‘aerobraking’). During the initial, high-temperature re-entry, the pilot’s windows would be protected by an opaque heat shield that could be jettisoned once the aerothermodynamic onslaught was over. Because rubber tires would burn during re-entry, the X-20 would land using wire-brush skids made of Rene 41. The Titan III

|

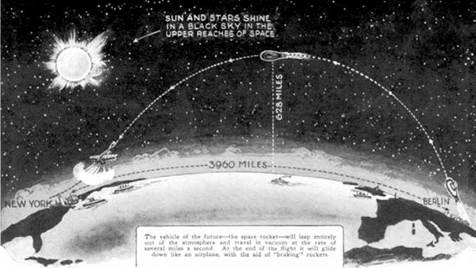

Diagram of the X20 Dyna-Soar [US Air Force].

|

launcher would be based on the Titan intercontinental ballistic missile and be fitted with exceptionally large stabilizing fins to compensate for the disturbances caused by the X-20’s wings on top of the assembly during ascent through the atmosphere.

In April 1960 seven astronauts were secretly chosen to fly the X-20, among them (future) X-15 pilots Neil Armstrong, Bill Dana, Pete Knight and Milt Thompson.

But the X-20 Dyna-Soar never made it out of the factory, let alone into orbit. In the early 1960s it was already becoming evident that many of its foreseen missions could be performed sooner and more cheaply by unmanned spacecraft or manned capsules. The high cost and questionable military utility led to the cancellation of the program in December 1963. This made sense at the time in terms of immediate technological and military priorities, but in hindsight it is definitely a pity. Although the X-20 was a vertically-launched reusable glider with some orbital maneuvering capabihty rather than a real rocket plane, it was a logical next step in the evolution of rocket aircraft. The X-15 was a true rocket plane, but suborbital. It could reach orbital altitudes but lacked the propellant to accelerate to orbital speed. With the X – 20 the Air Force was developing the technology needed to fly a plane from orbit back to Earth, with all the aerodynamic and thermodynamic complications, and some new materials capable of withstanding extreme temperatures. Had the X-20 continued, it would have delivered valuable experience that could have made the later Space Shuttle a more economical launch vehicle and perhaps opened the way to fully reusable spaceplanes.

Conceptually, a follow-on to the X-20 could have been to replace the expendable launching rocket with a reusable rocket powered carrier aircraft to create a two-stage rocket plane (similar to the X-15B/Valkyrie combination but with the carrier aircraft able to fly higher and faster than the Valkyrie, and with the secondary vehicle able to

|

The X-20 Dyna-Soar launched on a Titan III booster [US Air Force].

|

boost itself into orbit). That would have been considerably simpler than developing a single-stage rocket spaceplane, whilst retaining the benefits of an all-reusable system with (hopefully) aircraft-like operations. Prior to the cancellation of the X-20 there were many outline designs for orbital rocket plane and shuttle-type vehicles, most of them involving multiple stages. There were all kinds of combinations: orbital gliders with or without integrated rocket stages; with expendable or reusable, winged or non-winged stages using either liquid or solid propellants; and with horizontal or vertical take-offs.

Martin offered the very ambitious ‘Astroplane’, a horizontal-take-off, horizontallanding, single stage spaceplane which, powered by “nuclear magnetohydrodynamic engines”, sounds like something straight out of Star Trek. This intriguing propulsion system would extract nitrogen from the atmosphere, rapidly cool it, then accelerate the resulting liquid using powerful electromagnetic forces generated by an onboard nuclear reactor. The vehicle had a long, slim shape that would have been perfect for low drag at high speed but unsuitable for horizontal runway landings at reasonable speeds. The designers therefore envisaged deployable wings that would be extended at low speeds to provide additional lift. The bat-like airfoils would be composed of rigid ribs with a flexible membrane stretched between them. What would happen if a wing failed to deploy properly and this flying radiation hazard fell out of the sky was obviously something that would have to be worked on a bit.

In general, however, it was understood that without resorting to exotic, farfetched propulsion systems, a reusable launcher would have to be a multi-stage vehicle. For conventional multi-stage expendable launchers the useful payload that can be placed into orbit typically represents only 3% of the total weight of the rocket that leaves the pad, and around 18% in terms of hardware (i. e. without propellant). A single-stage vehicle cannot shed the weight of empty tanks and no-longer-needed rocket engines on the way up, so its payload is necessarily considerably less than for a multi-stage launcher. The wings, heat shields and control systems that are required to enable a single-stage vehicle to return to Earth can all too easily reduce its payload to zero, or even to negative values implying the vehicle will not even be able to reach orbit. To compensate, Single Stage To Orbit (SSTO) vehicles must carry more propellant per unit of hardware, which leads to larger vehicles. All this makes the development of a single-stage spaceplane with a reasonable payload extremely challenging, expensive and risky, and certainly beyond the technology of the 1960s and 1970s (and indeed beyond today’s technical capabilities; more on this later in this book).

The Martin ‘Astrorocket’ concept studied in the early 1960s therefore consisted of two vertically launched, winged rocket stages mated belly to belly. The task of the larger vehicle was to get its smaller sibling to high altitude and high speed, release it and then glide back to Earth while the second stage continued into orbit. The orbital vehicle would later make a gliding return (very much like the Space Shuttle) and be reunited with the first stage and prepared for another mission. This VTHL (Vertical Take-off and Horizontal Landing) concept would be proposed many times in various forms and by several different companies.

Douglas offered the ‘Astro’ design. This was based on the same idea but with the orbital vehicle mounted on the nose of the carrier booster rather than attached to its belly, and with both vehicles having lifting body configurations.

Lockheed’s ‘Reusable Orbital Carrier’, which was studied at about the same time, also involved two winged rockets but this combination would take off horizontally using an accelerated sled. The orbital vehicle of this HTHL (Horizontal Take-off and Horizontal Landing) launcher would ride on the back of its large carrier stage, which would use jet engines to return to its launch base. Interestingly NASA had stated in the specifications for this carrier stage that it “should offer a potential commercial application in the late 1970s, such as operating the vehicle over global distances for surface-to-surface transport of cargo and personnel”. In other words, it must be able to be converted into a hypersonic, rocket propelled airliner; a kind of super – Concorde similar to that proposed by Max Valier in the 1930s.

Lockheed and North American both had similar concepts for three instead of two winged stages, which meant more complicated operations but less stringent vehicle mass-minimization requirements. A proposed further development of Lockheed’s ‘System ІІГ would involve a giant first stage booster aircraft with ramjet propulsion and was called ‘System IV’ (System I was the Apollo Saturn IB combination as later used on the Apollo 7 mission, while System II would consist of a Saturn IB rocket with a reusable 10-man spaceplane that would also form the basis for the System III and System IV orbital stages).

In the mid-1960s NASA, along with the Department of Defense, adopted a similar phased approach involving a ‘Class ІІГ vehicle based on the Lockheed’s System IV design but with a hypersonic booster aircraft powered by combined turbofan-ramjet-scramjet engines. Such engines would run as regular turbojets at subsonic and low supersonic speeds, and as ramjets at supersonic velocities where the airstream could still be slowed down to subsonic speeds; at hypersonic flying velocities the airflow through the engine would be supersonic and so the engines would go into scramjet mode. A scramjet (meaning ‘supersonic combustion ramjet’) is a ramjet in which the combustion takes place in a supersonic airflow so that the air coming into the engine does not need to be slowed down to subsonic speeds (as is required for ramjets). The big benefit is that the incoming air does not lose useful energy due to deceleration, energy that would otherwise be converted into heat that would require the engine to be actively cooled. The combined engine system NASA envisaged represented an enormous technological challenge: at the time the only existing hybrid jet engine was the J58 of the SR-71 Blackbird, whose turbojet and ramjet modes enabled the aircraft to reach about Mach 3.2. The hypersonic stage of the Class III vehicle would require to fly much faster and its engine would be considerably more complicated. The joint Aeronautics and Astronautics Coordinating Board Subpanel on Reusable Launch Vehicle Technology, formed by NASA and the Department of Defense, concluded that the required technology could not be expected to be operational before 1982. (In fact, it still does not exist today.) Preliminary calculations for the Class III carrier vehicle indicated it would weigh

306,0 kg (675,000 pounds) at liftoff, if required to carry a 132,000 kg (290,000 pound) orbiter plane with a 16,000 kg (35,000 pound) low-Earth-orbit payload. This meant the total liftoff weight would have been about a quarter of that of the Space Shuttle for a payload only about one-third less. Of course the Space Shuttle actually flew whereas this Class III vehicle remained a paper study so we must be wary of such comparisons. Nevertheless, the numbers do indicate the potential mass benefits to be gained by using airbreathing engines.

A concept called ‘Mustard’ (Multi-Unit Space Transport And Recovery Device) was studied by the British Aircraft Corporation (ВАС) in the mid-1960s. It involved three similar winged vehicles that would be launched vertically as a single stack. A number of configurations were examined: a belly-to-belly-to-back sandwich, triangular belly-to-belly, two belly-to-belly and the third inline on top. Two of the vehicles would serve as boosters to put the third one into orbit, with the boosters pumping their remaining propellant into the orbital vehicle to top up its tanks prior to separation. In this way all of the engines could fire simultaneously for the first phase of the flight, yet the orbital shuttle would still initiate its solo flight with a full propellant load. The concept would potentially have enabled the orbiter to reach the Moon, which is a unique capability for a winged reusable design. All three stages

would have flown back to base after their mission, landing horizontally to be readied for the next launch. Around this same time the Warton Division of ВАС also studied several launch vehicle concepts in which a very large hypersonic aircraft carried on its back a small shuttle mounted on top of an expendable rocket. The ‘European Space Transporter’, which originated as the Nord Aviation Mistral and was studied by French and West German aerospace companies, was rather similar; it looked like a giant airbreathing fighter with enormous ramjet intakes and a rocket propelled lifting-body shuttle strapped onto its belly. Dassault’s ‘Aerospace Transporter’ was also based on essentially the same idea, involving an orbital ‘space taxi’ shuttle carried under a turboramjet Mach 4 aircraft that resembled the Concorde. Dropping a rocket vehicle rather than (as envisaged for the X-15A-3) launching it from the back of a carrier aircraft reduces the risk of the shuttle striking its motherplane, but the downside is a longer and more complex undercarriage on the carrier in order to give the shuttle enough clearance above the ground during take-off and aborted landings of the aircraft combination.

In 1967-1968, the US Air Force awarded several study contracts for an ‘Integral Launch and Re-entry Vehicle’ (ILRV) which would consist of a reusable single-stage VTHL that would jettison relatively inexpensive propellant tanks. This represented a compromise between a fully reusable single-stage launch vehicle (which would be large, heavy and extremely challenging and expensive to create) and a fully reusable two-stage vehicle (that would require the development and operation of two separate vehicles). The McDonnell-Douglas ILRV design featured a VTHL lifting body that resembled a steam iron, mated to four jettisonable tanks: two large ones for liquid hydrogen and two smaller ones for liquid oxygen. It would fold out small wings to increase its lift over drag ratio in the final descent and landing. Lockheed’s proposed ‘Starclipper’ was a VTHL lifting body design in which a single integrated A-shaped propellant tank would ‘wrap around’ the reusable lifting body. General Dynamics proposed a ‘Triamese’ solution with three reusable rocket stages which had fold-out wings and jet engines to land using a standard airport runway. The concept did partly satisfy the ILRV concept of a single vehicle design because the three winged stages would have been virtually identical.

The primary mission of all these reusable spaceplane concepts dreamed up in the 1960s was to transport crews to a large Earth orbiting space station. However, other missions such as the launching, inspection, repair and retrieval of satellites were also envisaged. The reusability was expected to translate into very low operating costs: for instance Lockheed claimed that their Starclipper would have a turn-around time (the time necessary to prepare the vehicle for its next mission) of only 24 hours and would reduce the costs of launching cargo into space to less then $100 per kg in 2011 terms. In fact, launching satellites into low orbit currently still costs $10,000 per kg for expendable launchers (and double this for the Space Shuttle when it was retired that year).

By mid-1969 NASA was planning an extremely ambitious and financially rather unrealistic, manned space exploration program to follow up on Apollo. The wish list included space stations, interplanetary ‘space tugs’ and eventually bases on the Moon and Mars. The first task was to build a 12-person space station in orbit by 1975 and to expand this into a 50-person ‘space base’ by 1980. Smaller ‘way-stations’ would then be deployed in geostationary Earth orbit and around the Moon and Mars. Naturally all this infrastructure would require an efficient, dependable and inexpensive means of transportation in the form of a space shuttle.

In a meeting in April 1969 Maxime Faget, the renowned designer of the Mercury capsule and by then director of engineering and development at NASA’s Manned Spacecraft Center, presented a balsa-framed, paper-skinned airplane model that had short, straight wings and a shark-style nose. It looked remarkably similar to Sanger’s Silbervogel concept of the Second World War. When introducing the design, Faget explained, “We’re going to build America’s next spacecraft. It’s going to launch like a spacecraft; it’s going to land like a plane.”

Back in January NASA had awarded four Phase-А study contracts to McDonnell-Douglas, North American Rockwell, Lockheed and General Dynamics to begin the development of the shuttle launch system. Martin Marietta, whose bid had been rejected, decided to participate using its own funds in order not to be left out of what promised to be a very lucrative project. The NASA requirements called for a vehicle able to launch 12 people as well as some 11,300 kg (25,000 pounds) of supplies to a space station in low orbit. Soon these became even more demanding and complex when it was decided that the vehicle must also be capable of launching satellites and interplanetary probes. Then the Air Force demanded that the stated payload capacity be doubled.

NASA had by then decided that the shuttle was going to be a fully reusable YTHL Two Stage To Orbit (TSTO) vehicle, since that was expected to produce the lowest cost per flight and highest payload capability in combination with good operability and mission flexibility. This meant the next generation launch vehicle was not going to be a real single-stage spaceplane but rather a combination of vertically launched winged rocket stages, each capable of gliding back to Earth and making a horizontal, unpowered landing. In an article optimistically titled ‘The Spaceplane That Can Put YOU in Orbit’ in the July 1970 issue of Popular Science, Wernher von Braun (at the time NASA Deputy Associate Administrator) commented on the decision: “It would be ideal, of course, if we could build a single-stage-to-orbit shuttle, which, without shedding any boost rockets or tanks, could fly directly up to orbit and return in one piece to the take-off site for another flight. Although we may well know how to build such a vehicle some day, most studies unfortunately show that with the present state of propulsion and structural technology this objective would be just a shade too ambitious.”

Out of the 120 different concepts studied, five emerged as the most promising. ‘Concept A’ of North American as well as ‘Concept C’ of Lockheed involved a huge winged, vertically launched booster stage carrying a smaller orbital shuttle stage on its back. ‘Concept B’ of McDonnell-Douglas and ‘Concept D’ of General Dynamics both had a winged booster stage and a shuttle fitted belly-to-belly. Martin Marietta’s ‘Concept E’ involved a shuttle vehicle mated to a twin-body winged booster stage. For the orbital elements, North American, General Dynamics and Martin Marietta favored conventional, fuselage-with-wings shapes, whereas McDonnell-Douglas and Lockheed proposed lifting bodies. However, McDonnell-Douglas soon changed their shuttle design to a more conventional shape which would re-enter with folded wings. General Dynamics’ shuttle was based on a similar idea but with retractable switch-blade wings. Not having the wings extended during re-entry would save on thermal protection weight, but of course the extension system would be complicated, heavy, and involve a fair amount of risk (for example if they did not open).

For the ensuing Phase-В step of the project Lockheed teamed up with Boeing to further develop their concept, but did not win a contract. North American Rockwell and General Dynamics did, and joined forces to work on the concept of a North American shuttle stage to be launched on the back of a large winged booster designed by General Dynamics. McDonnell-Douglas and Martin Marietta, the other winning team, jointly studied a concept that was very similar but employed re-entry thermal protection based on metal alloys rather than the sihca tiles favored by North American Rockwell and General Dynamics. Both teams considered two basic orbiter designs (NASA having not expressed a preference either way): one involved Maxime Faget’s design with straight wings and lower re-entry heating but a relatively small cargo capability and a limited cross-range, and the other a delta-winged design with a greater cross-range and a larger cargo bay but higher heat loads. All Phase-B concepts were for a fully reusable launch system.

In addition to the primary Phase-В study contracts, in June 1970 NASA also let three contracts to Grumman/Boeing, Chrysler, and Lockheed to study an ‘Alternate Space Shuttle Concept’ (ASSC). This was intended as a backup plan in case the fully reusable concepts turned out to be too expensive to develop (as would soon prove to be so). The Grumman/Boeing team received the most important contract (which was later upgraded into a full Phase-В contract) for studies of a shuttle with expendable propellant tanks and of a reusable orbiter boosted by existing liquid propellant rocket engines and expendable solid rocket motors. For its ASSC contract, Lockheed further refined its Starclipper concept, which already envisaged drop tanks. The ASSC study results showed that the use of expendable tanks greatly reduced the size and weight of the orbital vehicle as well as the booster vehicle, whilst also significantly lowering the total system’s development costs.

While Phase-В was underway, NASA’s original grand plan involving large space stations, lunar bases and manned missions to Mars evaporated. This left the Space Shuttle “a project searching for a mission”, as critics in the US Congress derided it. NASA and the Air Force then began to focus on the shuttle as a stand-alone project, as a low-cost ‘space truck’ for launching, repairing and retrieving satellites, and for flying all kinds of onboard experiments. Based on what we now know to have been wildly optimistic assumptions, NASA’s plan was for a total of 445 flights during the 10 year period 1979 through 1988 (the Space Shuttle as we know it actually flew only 135 missions during its 30 year lifetime).

In May 1971 it also became clear that the government was not going to allocate sufficient funding to enable NASA to develop a fully reusable Space Shuttle. NASA and its contactors then spent the next 6 months frantically revising their concepts by incorporating expendable propellant tanks, solid propellant rocket boosters, and even modified forms of the first stage of the Saturn Y moonrocket. At the end of 1971 the manned, winged flyback booster options were discarded on the basis of the expected development cost and system complexity (both for development as well as in-service operations). By mid-1972 NASA had finally decided on the general concept for the Space Shuttle as a reusable, winged orbiter with a single expendable propellant tank and two huge solid propellant rocket boosters which would be retrieved by parachute and refurbished for reuse. Based on the expected sizes of future military spy satellites and the orbits they would require, the Orbiter had to have a huge payload bay as well as the ability to put large satellites into polar orbit from Vandenberg Air Force Base in California (from which no Shuttle ever launched, even although a nearly complete launch facility was created there). The Orbiter also required a fairly large cross-range during its descent to Earth, since its landing site in California would be rotating away from under it when returning from a reconnaissance mission involving flying a single polar orbit. Consequently the Orbiter had to be equipped with large delta-wings, and Faget’s straight-wing concept was discarded. In mid-1972 the Phase-C/D contract for the design and construction of the Orbiter was awarded to North American Rockwell. Its Rocketdyne subsidiary would supply the main engines that would burn hydrogen and oxygen, Martin Marietta would supply the external propellant tank and Thiokol would supply the sohd rocket boosters. The concept illustrations of the time show a vehicle very similar to the Space Shuttle we are familiar with. Early in 1974 NASA also decided that the Orbiter would not require jet engines, because the X-24 and other lifting bodies had proven that ‘dead-stick’ glide landings would be sufficiently safe. Discarding the (deployable) jet engines further simplified the design and resulted in considerable weight and volume savings. It did mean that Shuttle pilots had only one chance to land, but the decision was correct because not a single Orbiter ever crashed during landing.

The selected configuration had a major impact on the test flight philosophy. Up to then all crewed launch systems had been unmanned on their maiden flights. For the early Shuttle concept, when it involved a reusable winged booster stage, von Braun said in his aforementioned article that the first stage and the orbiter would each be tested separately. Although the system as a whole would be launched vertically when operational, both winged stages would initially make a series of horizontal take-offs and subsonic flights using their own jet engines. In the next step, each vehicle would make individual vertical take-offs and supersonic flights using their rocket engines. Only after these test flights had been satisfactorily concluded would the orbiter be strapped to the booster and the combination launched into space. This logic could not be applied to the Space Shuttle. The Orbiter was able to make unpowered, subsonic glide tests from the back of a Boeing 747 but the first powered flight simply had to be an all-out launch with two pilots on board because it was not designed to fly in an unmanned role. The Orbiter was not able to take off horizontally since it lacked jet engines. There was no way to flight test the large External Tank and the two Sohd Rocket Boosters separately because the Orbiter’s computers provided the commands. When astronauts John Young and Bob Crippen first flew the Space Shuttle in April 1981 NASA took an enormous risk with a new system that was so radically different from the previous manned capsules (for their later Buran shuttle the Soviets actually flew their orbiter with jet engines installed for flight tests, launched the large Energia carrier rocket separately to verify its performance, and only then launched and landed the entire Buran system unmanned).

The chosen Space Shuttle design was an awkward compromise between mission requirements, technology, costs, schedule, the need for the project to provide jobs all across the US, and the political wish for something ambitious to reassert the nation’s technological leadership. Nevertheless, NASA still believed its partial reusability and great payload capabilities would revolutionize spaceflight. Access to space would be relatively cheap, opening Earth orbit and beyond for all manner of exciting scientific, industrial and even commercial activities. In a speech to the National Space Club on 17 February 1972 NASA Deputy Administrator George Low said that now the great challenge was to develop a “productive Space Shuttle, one that performs as required, can be developed at a reasonable cost, and is economical to operate. If we meet the first two of these objectives, but not the third, we will have developed a white elephant.”

During its 30 year life the Space Shuttle performed an amazing array of missions but it never fulfilled its promise of regular, safe, economic flights into space. Instead of weekly launches NASA managed to fly an average of fewer than five missions per annum. Two of the Shuttle flights have ended in disaster; an accident rate of 1 in 68, which is rather dismal compared to the fewer than two crashes per million flights for commercial airliners in the US. Instead of costing around $40 million per flight as predicted in 1975 (equivalent to about $160 million in 2011), actual costs were closer to $500 million per launch. When also taking into account the development costs and the production costs for the five Orbiters, the actual average cost per flight was well over $1 billion!

During the 1970s NASA claimed the Orbiter’s spacious cargo bay would relax the constraints on the size and weight for its payloads, resulting in lower costs. However in reality the stringent safety constraints imposed on spacecraft and equipment meant to be transported on crewed space vehicles generally resulted in higher development and production costs than when launching on an unmanned expendable rocket.

There are several reasons why the Space Shuttle cost far more to operate and took much longer to ‘turn around’ than expected. An important reason is the maintenance of the Orbiter. For a start it had 35,000 brittle thermal protection tiles, and these had to be individually inspected after every flight and often replaced. Structural elements, instrumentation, and electrical wiring all had to be thoroughly inspected after every flight; a task that is only done periodically for normal aircraft. The Orbiter required a team of some 90 people working more than 1,030 hours in total on maintenance and refurbishment after each mission, costing about $8 million per flight in 2011 prices. Not included in this was the heavy maintenance work on the three very complicated Space Shuttle Main Engines that was done separately from the vehicle. Even though the engines only operated for 8 minutes per flight they were not nearly as reliable as airliner jet engines; they suffered more rapid wear and required a lot of checking and maintenance after each mission. In contrast, jet engines run for hundreds of hours before preventive maintenance is needed. In addition the two Solid Rocket Boosters, which landed in the ocean by parachute and were retrieved by specialized ships, had to be completely disassembled, cleaned and repaired before they could be filled with solid propellant and reassembled for reuse. Most of the things that on a conventional rocket are thrown away, with the Shuttle had to be retrieved, refurbished and than put together again. Only the large External Tank was discarded once the Shuttle had almost reached orbit and left to burn up upon falling back into the atmosphere. But that meant a new one was needed for each flight.

The idea that the Space Shuttle would launch any and all US payloads, whether from NASA, the military or commercial users, never materialized. It was simply too expensive, and it was deemed too risky to have the nation’s access to space depend on a single launch system. To stimulate the diversity of launch systems following the loss of Challenger, President Reagan even decided that commercial satellites would no longer be launched using the Shuttle. This meant a dramatic decline of the number of Shuttle launches relative to the rate advertised in the 1970s (although on the other hand that rate was unattainable). Another important reason for the reduced number of launches required was the increased lifetime of satellites, yielding lower replacement rates than were assumed during the development of the Shuttle. Another mission that was claimed for the Shuttle, retrieving satellites, was undermined by the fact that the Shuttle could not fly high enough to retrieve geostationary communications satellites (potentially the biggest market); it could only reach satellites in low orbit. In any case the retrieval of a malfunctioning satellite was usually more expensive than building a replacement. The relatively low flight rate in itself also increased the cost per flight, because the so-called fixed costs for facilities and personnel had to be shared across fewer missions. This was foreseen by several people even before the Shuttle started flying, as by, for instance, Gregg Easterbrook in the very insightful article ‘Beam Me Out Of This Death Trap, Scotty’ published by the Washington Monthly in 1979.

Roger Launius, former Chief Historian for NASA and now Senior Curator at the Smithsonian Air and Space Museum, has perfectly summarized the Shuttle program: “In 135 missions, with two catastrophic failures, the US Space Shuttle proved itself a vehicle filled with contradictions and inconsistencies. It demonstrated on many occasions remarkable capabilities, but always the cost and complexity of flying the world’s first reusable space transportation system ensured controversy and difference of opinion.”

The Soviets also investigated the development of reusable spaceplanes in the early 1960s. In 1962 the Mikoyan Design Bureau presented its ‘50-50’ concept, so-named since it would have comprised a reusable, air-breathing, hypersonic aircraft carrying a two-stage expendable rocket with a small orbital space glider. A first version of the carrier aircraft, using kerosene as fuel, would have accelerated to Mach 4 prior to releasing the rocket/spaceplane combination at an altitude of about 23 km (14 miles). A variant for the longer term would have reached Mach 6 at 30 km (19 miles) using hydrogen fuel. The orbital spaceplane was to be a lifting body with extendable wings for use during the subsonic part of the return flight. It was officially named the MiG

|

The 50-50 spaceplane system [NASA].

|

105 ‘Spiral’ but unofficially was the ‘Lapot’ (meaning ‘flat shoe’) for its somewhat awkward appearance. The MiG 105 would only have been able to accommodate a single cosmonaut-pilot, housed in an emergency escape capsule that could return to Earth independently even after being ejected in orbit.

The first flight of the complete 50-50 system was planned for 1977, and a group of cosmonaut-pilots started training in 1965 to fly test models and eventually the real spaceplane. But it proved difficult to maintain financial and political support because it was expensive, the technology was difficult to master and the lengthy development did not promise the quick results the Kremlin preferred. In 1973 the

|

The Buran shuttle landing after its only mission in space.

|

cosmonaut team was disbanded and in 1976 the seriously underfunded project was finally halted. The large 50-50 carrier aircraft was never built, but a turbojet-powered prototype of the MiG 105 for subsonic tests flew eight times between 1976 and 1979, both taking off under its own power and being dropped from a Tupolev Tu-95 bomber. Today this MiG 105-11 test vehicle languishes in a muddy field at the Monino Soviet Air Force Museum outside Moscow.

Despite the 50-50 project’s demise the flight test program of the MiG 105 was continued to collect data for the new but less ambitious ‘Buran’ project. The Buran (Russian for ‘Snowstorm’) was the Soviet equivalent of the US Space Shuttle. It was developed purely to keep up with the US in technology and capability, and the Buran orbiter ended up looking remarkably similar to its American competitor. But unlike the Space Shuttle it did not use its own rocket engines for launch, it was mounted on the side of a giant Energia rocket. The Buran made only one, completely automatic, orbital flight without crew in 1988 and then the financial problems of the crumbling Soviet Union killed both the Buran and Energia projects.

The only Buran vehicle flown in space was destroyed in 2002 when the roof of its hangar collapsed due to poor maintenance, but a decrepit ground-test prototype is an attraction in a Moscow park. The atmospheric flight and landing test prototype with jet engines for a runway take-off found a more dignified home in the Technical Museum Speyer in Germany.

Being similar to the Space Shuttle, it is very unlikely that the Buran could have lowered launch costs relative to those of reliable expendable Russian launchers like Soyuz and Proton. In fact, the Russians regarded the optimistic Space Shuttle flight cost figures that NASA published during the 1970s as misinformation to disguise the Shuttle’s real purpose as an orbital bomber and “space pirate ship” for destroying or abducting Soviet satellites.

In the 1979 James Bond movie Moonraker, highjackers steal a Space Shuttle Orbiter during a transfer flight on top of its Boeing 747 carrier. They ignite its main engines and fly off, with the rocket exhaust blowing up the 747 (in reality the Orbiter was of course only transported with empty tanks for its maneuvering thrusters, and could not carry propellant for its main engines). From 1988 until 1991 the Russians briefly worked on a shuttle that would do something similar, without the destruction of its carrier. A concept called MAKS (Russian abbreviation for ‘Multipurpose Aerospace System’) involved launching a fairly small shuttle mated to a large expendable propellant tank from atop a giant, subsonic Antonov An-225 airplane (which had already been built for transporting the Buran orbiter). The standard version of the MAKS shuttle would have had a crew of two and a payload of 6,600

|

Artistic impression of the MAKS system and mission.

|

|

Full-scale mockup of the MAKS shuttle [NPO Molniya].

|

kg (14,500 pound) to low orbit. It was supposed to reduce the cost of transporting materials into orbit by a factor of ten. But the collapse of the Soviet Union and the ensuing poor Russian economy killed this project as well. In June 2010 Russia nevertheless announced that it was considering reviving the MAKS program.

In the early 1980s the US Air Force studied a very similar concept. It was initially called the ‘Space Sortie Vehicle’, then the ‘Air Launched Sortie Vehicle’, and finally the ‘Air Force Sortie Space System’ (AFSSS). The carrier was to be a souped-up version of the modified Boeing 747 used to transport Space Shuttle Orbiters. Several companies came up with designs based on the initial specification which involved a lifting-body mini-shuttle about 15 meters (50 feet) in length, either unmanned or with a single pilot, and powered by RL-10 rocket engines whose liquid oxygen and liquid hydrogen propellants would be in large external tanks that would be discarded when empty. Some consideration was given to wrapping these expendable tanks around the shuttle in order to create an aerodynamic assembly that would be capable of a lifting ascent, meaning generating lift to help it attain altitude after release from its carrier (in which case it would have been a real rocket plane). Rather than having its shuttle take off gently from a horizontal flying carrier (as was envisaged for MAKS) the Air Force Rocket Propulsion Laboratory had something more spectacular and effective in mind: the 747, normally not an aerobatic aircraft, would have the thrust of its jet engines augmented by the installation of afterburners: liquid hydrogen from tanks on the Boeing (also used for topping up the propellant tanks of the minishuttle shortly prior to launch) would be injected into the hot exhaust of the four otherwise standard turbojet engines to produce a massive increase in power of up to 400%. This would enable the giant airliner to zoom up at a 60 degree angle to reach a launch altitude of 15 to 17 km (50,000 to 55,000 feet). An alternative idea was to install a single Space Shuttle Main Engine or a cluster of RL-10 rocket engines in the tail of the 747. When standing on ‘alert status’, this rapid response system was to facilitate a flyover of any point on Earth within 75 minutes of the moment the 747 started to taxi. The shuttle was also to deliver small payloads into orbit, rendezvous with satellites or space stations, and fly “low altitude penetration of target area” missions to drop bombs before reigniting the engines to regain altitude and return to its base. As the cryogenic propellants would boil off whilst standing on alert, constant replenishment from tanks on the ground would have been required to keep the system ready for take off at a moment’s notice. This project never progressed beyond the preliminary design stage, in part because it was judged too expensive but primarily because there was no urgent need for it.

The French space agency (CNES) and the European Space Agency worked on a small, manned space shuttle named Hermes. The concept was similar to that of the X-20 Dyna-Soar, with a small space glider launched on top of a European Ariane 5 rocket. The project was approved in November 1987 but canceled in 1992 when it became apparent that neither the cost nor performance goals could be achieved. The Ariane 5 development continued as a conventional, expendable launch vehicle and is now very successful in the geostationary satellite market.

|

The canceled Hermes shuttle with its expendable Resource Module attached [ESA],

|

|

X-34 on the tarmac [NASA].

|

In the US, work on a successor for the Space Shuttle has not been very successful. During the 1990s NASA and prime contractor Orbital Sciences worked on the X-34, an unpiloted, experimental rocket plane powered by an inexpensive, non-reusable ‘Fastrac’ engine running on RP-1 kerosene and liquid oxygen. The X-34 was to test reusable launch vehicle technology. Like the X-15 it would have been dropped from a carrier airplane, but would have been able to reach Mach 8. But NASA canceled it in 2001 after the company refused to incorporate significant design changes without additional funding.

The most ambitious reusable launcher test project, NASA’s X-33 developed by Lockheed Martin, involved a suborbital, single-stage, unpiloted VTHL vehicle with a wedge-shaped lifting-body. It was to lift off vertically without making use of the lift generated by its shape, fly at Mach 15 and then land horizontally Uke an airplane. It was to be powered by a ‘linear aerospike’ engine that consisted of a series of small rocket motors along the outside edge of a wedge-shaped protrusion. The aerospike is essentially an inside-out bell-shaped rocket nozzle in which the ‘unwrapped’ bell (or ramp) serves as the inner wall of a virtual nozzle along which the expanding hot gas flow produces thrust. The other side of the nozzle is effectively being formed by the outside air. The advantage is that the expansion of the rocket exhaust automatically adjusts itself to the ambient pressure of the atmosphere, preventing thrust losses due to underexpansion or overexpansion. While a conventional rocket nozzle can only be optimized for a single altitude, and hence only one point in a rocket’s trajectory, an aerospike engine runs efficiently at all altitudes as well as in the vacuum of space.

|

Normal Bell-Nozzle Linear Aerospike

Rocket Engine Rocket Engine

Comparison of a conventional rocket nozzle and a linear aerospike [NASA],

|

Sadly the X-33 project was scrubbed in 2001 owing to major problems with the development of this aerospike engine and with the lightweight composite-material hydrogen tanks (which required complex shapes to fit the lifting-body curves). The cost of the project exceeded the $1.2 billion budget limit even before any test flights could be made. The X-33 was to have led to the development by Lockheed Martin of the operational single-stage reusable launch vehicle named ‘Venture Star’. However, it would probably have been very difficult to scale up the X-33 test vehicle without putting on too much weight, which (as explained earlier) is a frequent problem in the design of reusable single-stage launchers.

NASA’s Orbital Space Plane program to develop a crew transportation vehicle for the International Space Station was initiated in 2002. Four competing concepts from different industries emerged, three of which involved mini-shuttle designs and one a capsule spacecraft, all of which were to be launched on top of an expendable rocket. But by 2004 they had been superseded by the Orion Multi-Purpose Crew Vehicle, an Apollo-style capsule that is still under development.

In April 2010 the Air Force finally launched a small robotic demonstrator shuttle on top of an Atlas V rocket. The payload and operations of this X-37 ‘Orbital Test Vehicle’ were classified, but after 7 months in low orbit it made a gliding return. A second X-37 was launched in March 2011. The X-37 was intended to be carried into orbit inside the Space Shuttle cargo bay, but once it was realized that a Shuttle flight

|

Artist impression of the X-33 [NASA],

|

would be uneconomic and moreover that the Shuttle would be retired in 2011, it was redesigned for an expendable launcher and in order to prevent its wings steering the rocket off course the mini-shuttle was covered by an aerodynamic shroud. The X-37, which was developed by Boeing, would appear to be a test vehicle for an operational military, reusable, robotic spacecraft rather than a sub-scale precursor for a crewed shuttle system.

The Space Shuttle taught us that to really lower the price of transporting people and cargo into space, we require a fully reusable launcher that is easy to maintain. Ideally, it would be a single integrated vehicle without expendable tanks or boosters that require retrieval and refurbishment. It should return to its launch site to preclude complicated and expensive transportation; if the Orbiter landed anywhere other than at Kennedy Space Center it had to be mated with a specially equipped Boeing 747, flown to Florida, then de-mated from its carrier. Instead of thousands of fragile heat resistant tiles, a limited number of readily replaceable metallic shingles ought to be employed. The propellants should be non-toxic, safe and relatively easy to handle to avoid complicated tanking and propulsion system maintenance procedures (although the various rocket planes have yielded a lot of experience in handling dangerous liquids such as hydrogen peroxide). Future reusable rocket planes may carry computers and sensors that constantly check the health of all subsystems and components in flight, both to warn the crew/flight operators of any problems during a mission and to make it easier for the turn-around team to determine when and what kind of maintenance is required. The reusable rocket engines should last longer than the Space Shuttle Main Engines, require less maintenance, and be easier to repair. The RS-25 engines of the Space Shuttle can only be operated for about 10 minutes before major maintenance, which involves time-consuming (and hence expensive) tasks and the replacement of a lot of equipment. In contrast, jet engines as used in modern airliners can operate for months of accumulated flight time with only very limited checking and maintenance. Ideally, a future space plane would have some kind of combined rocket/jet engine that can use oxygen from the atmosphere while flying at relatively low altitudes. This would mean less onboard propellant, smaller tanks, and therefore a smaller, Ughter vehicle. However, such engines tend to be complex, which potentially makes them hard to maintain.