It’s interesting when you stop and think about it,

how you get thrust very unexpectedly into an environment that

a few years later is the apex of your career.

You were doing stuff that had never been done before,

and you were successful.

Jim Splawn

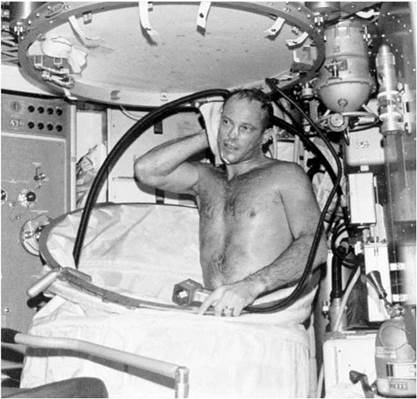

“Eighteen days before launch—let’s see, that would be April 26—the Sky – lab 2 crew entered quarantine and started eating our carefully measured flight-type diets,” Joe Kerwin recalled. “That meant saying goodbye to our wives and families and moving into a couple of trailers on jsc property. Yes, we missed our families, but the arrangement was efficient, and we were in peak concentration mode. Nobody could come near us without a brief physical exam and a surgical mask. Launch readiness was everything. One of us recalled Coach Vince Lombardi’s famous and often misinterpreted quote about football: ‘Winning isn’t everything. It’s the only thing.’ He did not mean that football was more important than God, country, or family, just that on Sunday afternoon, you should not be thinking of that other stuff. That’s where we were. It was a good, team feeling; I remember all six of us [the prime crew of Conrad, Kerwin, and Weitz and their backups, Rusty Schweikart, Story Musgrave, and Bruce McCandless] standing outside the trailer each evening at bedtime, joking as we filled our urine specimen bottles for science.”

By launch morning the uncertainties of the Skylab program had practically vanished. All the battles that had been fought to improve the hardware and

procedures were over. Chris Kraft, jsc director, had called the first crew in to his office about a month earlier to tell them to knock off trying to change the medical experiments and start working to accomplish them; and Commander Pete Conrad had been able to say that they were already there. Training was over. They felt confident of their abilities and trusted the team. The crew and NASA were ready to fly and had no premonition of disaster. “You could say Fate had us right where she wanted us,” Kerwin said.

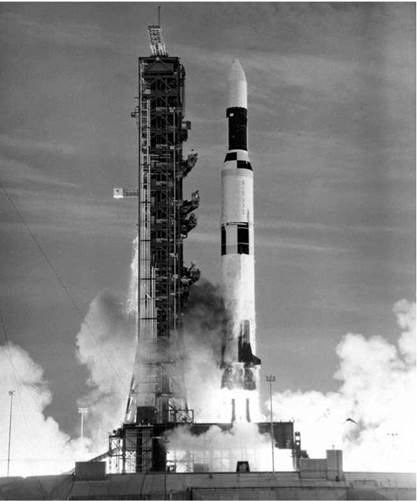

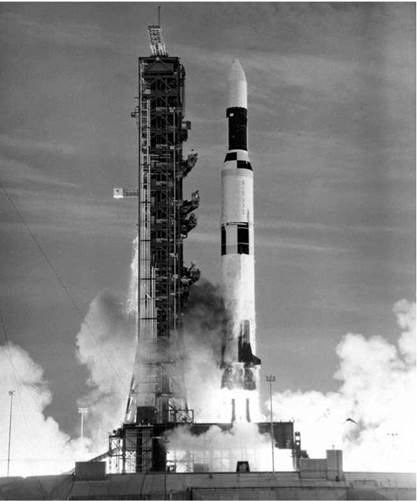

With only one day left on the countdown for their own launch, the crew watched from the roof of the Manned Spaceflight Operations Building the Skylab station launch on a beautiful May morning. The Saturn v rose slowly and majestically from the pad and disappeared into the eastern sky. The launch looked good. They went back down the stairs to the crew quarters conference room, where the flight director voice loop from Houston’s Mission Control was set up so that they could listen to the activation activities as they lunched and did a last-minute review of the next day—their launch day.

According to Owen Garriott, “May 14, 1973, was a beautiful day at the Cape. All of the three planned Skylab crews, along with tens of thousands of space enthusiasts, were in attendance to watch what would be the final launch of NASA’s most powerful launch vehicle. It all appeared from the ground to go perfectly with a long, smoky trail headed into the blue sky.

“Jack [Lousma] and I headed back to our usual motel—Holiday Inn, Cocoa Beach—to change into flight suits and head for Patrick Air Force Base where our NASA T-38 was ready for a quick flight back to Ellington Air Force Base, near the Manned Spacecraft Center. We wanted to be home as soon as possible to observe the Skylab telemetry and verify that our home to be was in good shape for human visitation and also to watch the launch of Pete, Joe, and Paul scheduled for the next morning from Mission Control.

“As we were walking out to our rental car for the short drive to Patrick, we noticed the recently appointed director of the Marshall Space Flight Center, Dr. Rocco Petrone, walking along the porch in front of his second story room. ‘Looked like a great launch,’ we shouted. ‘Yes, but don’t get your expectations too high. There were some telemetry glitches observed.’

“With no more time for discussion, we headed for our aircraft, hoping that the telemetry issues would be resolved by the time of our arrival in Houston. We could only speculate about what these ‘glitches’ were, never imagining

|

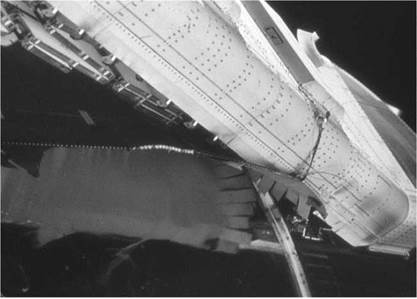

16. Skylab was launched as the third stage of a modified Saturn v rocket.

|

the problems to be encountered and then solved in the next ten days.” That apparently beautiful launch was when things started to fall apart. The problems didn’t surface all at once. There had been a “g spike” — a sudden, brief shock to the vehicle—about forty-five seconds after launch as the Saturn booster was accelerating through the speed of sound. Around a minute after liftoff, and very near the time of “max-Q” when the atmospheric pressure on the speeding vehicle is at the maximum, telemetry received in Houston indicated the micrometeoroid shield had deployed prematurely,

an anomaly not fully appreciated as the Saturn kept going and deposited Skylab in the correct orbit.

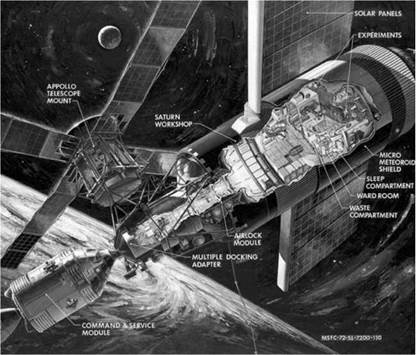

Once the s-ivb stage was in orbit, a planned sequence began to reconfigure it from its launch mode to its operational arrangement. The first deployment action was to jettison the “sla Panels,” four large panels that protected the docking adapter and atm during launch. That action went well. The next sign that something was wrong began to surface as workshop temperatures started to climb above normal, but the full extent of the problem was still not apparent, and the deployment appeared to be going well. Mission Control proceeded with the next scheduled step: rotating the atm ninety degrees to face the sun and opening its four solar panels into their “windmill” configuration. That too went smoothly.

Then it was the turn of the Solar Array System, the main solar panels on the workshop itself. First the Solar Array System beams, the solar panel housings, would be deployed to ninety-degree angles from the workshop; then the panels themselves would unfold accordion-style. Fully open they would provide two-thirds of Skylab’s electrical power. And after they were open, the thermal/meteoroid shield over which they’d been folded (the “heat shield”) could itself be popped up away from the workshop’s exterior surface to assume its function of reflecting the sun’s heat and breaking up small meteoroids. The beams did not deploy. And the workshop surface and internal temperatures continued to climb. Something was wrong with the heat shield, which should have kept the workshop cool even before deployment. Mission Control went into troubleshooting mode.

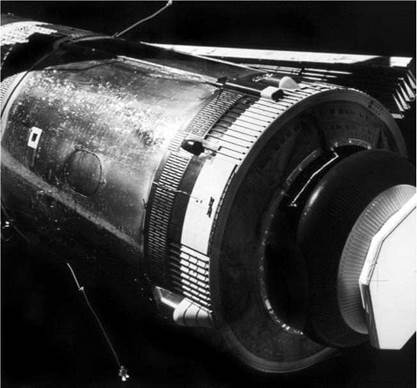

By late afternoon they finally realized the truth: the heat shield was gone. That G spike during launch had been the shield departing the vehicle. The anomalous telemetry had been completely accurate. Further there was no response at all from Solar Panel 2, indicating that it was probably gone as well. Solar Panel 1 was showing just a trickle of current, leading controllers to believe it was still present but stuck shut. NASA was soliciting high-resolution photography from other satellites and ground-based telescopes.

While the full import of what had taken place would take some time to pin down exactly, it became very apparent very quickly that something very bad had happened. For those involved in the program, 14 May would be an unforgettable day; many can still recall what they were doing when they learned that what had looked like a perfect launch had in fact been anything but and that years’ worth of work was in real danger of being lost. Marshall Skylab program director Lee Belew remembers that he was at Kennedy Space Center that day, having traveled down there to watch the launch. One particular memory that has stuck with him over the years since was being grilled by the national media for answers that were still unknown. “I was interviewed by Walter Cronkite at the Cape, and of course, he asked pretty tough questions.”

Phil Shaffer was in Mission Control at Johnson Space Center. He was not actually on duty; he was scheduled for a shift as flight director for launch and rendezvous the following day, overseeing the launch of the first crew. “Don Puddy was the flight director for the workshop launch,” he said. “Because I was going to sit down to launch sl-2 [with the first crew] the next day, I was there, more than willing to be a ‘gofer’ for him. When the telemetry just went nuts and those pieces started coming off, we didn’t know what had happened except that a lot of things we were seeing from telemetry didn’t make any sense. We certainly hadn’t seen anything like that in any of the simulations. We got to orbit, and Don started trying to get the post-insertion sequence to work. Many of the actions he was trying to get done involved equipment that was missing now. It wasn’t working, and the instrumentation was so screwed up we really couldn’t tell what was going on. Then additional unexpected things began to happen on orbit, began to not work. Probably the best thing I did for anybody that day was start a malfunction list. Puddy didn’t have time for it. Two or three hours into the business, Gene Kranz leaned over the console and said, ‘You guys better start a malfunction list.’ I told him, ‘Here it is; it’s got forty-seven items on it, or some number like that, things that need to be pursued.’ So at that point we were stalled out on the post-insertion activation sequence. And stuff just kept failing, and we could see it was beginning to get hot inside Skylab.”

Though things looked grim, Shaffer had a moment that night of being able to view the Skylab in a more positive light. “I remember distinctly, the night of the day of Skylab i launch, I knew it was going to come over Houston,” he said. “And I went out to look for the ‘string of pearls’ as it had been advertised—the [booster’s second stage] stage, the sla panels, the refrigerator cover, and the Skylab itself. There it was, a big ol’ string of pearls, going across the sky. Outstanding. Beautiful. It was really spectacular. It was a crystal-clear night in Houston, and I watched it for a very long time, almost from horizon to horizon.”

As controllers began to determine what the problems meant for the workshop, the first crew realized what it meant for them: they weren’t going to Skylab the next morning. Instead they were going back to Houston. Ken – win recalls that his family and friends were having a prelaunch party at the Patrick Air Force Base Officers’ Club in Melbourne. “I called my wife and told her the news. ‘No launch tomorrow. But might as well keep partying!’” The next morning the crew manned their T-38 jets at Patrick and flew back to Houston. They joined a full-scale battle in progress: the NASA/contrac – tor engineering workforce versus Skylab’s problems.

As it happened, the high atmospheric forces near “max-Q” had caused the shield to be torn off the Workshop and drop into the Atlantic Ocean, all unseen from the ground. “Max-Q is a very dangerous, peculiar place, and the pressures are really peculiar at that point and shock waves all over the place,” Shaffer said. “If something is going to come undone, that’s where everybody says it’s going to come undone.” And to make matters worse the meteoroid shield also tore one of the workshop solar arrays completely off, dropping it into the ocean as well. The second workshop solar array had a different story. In this case the departing shield caused a metal strap to wrap across the array, which turned out to likely have been a blessing in disguise. On the one hand the strap caught the array and prevented it from deploying properly, leading to severe power limitations after launch. On the other hand, the strap held the array in place during the launch so that it couldn’t be ripped off too, a life-saving event for the Skylab science program, which needed the power the array would later be able to generate.

“We knew quickly something was wrong, that’s for sure,” said Marshall’s George Hardy, who had gone down to Houston to monitor the launch and ended up staying there for much of the time before the first crew launched, serving essentially as a liaison between the operations team in Houston and the engineering team at msfc. “We knew there’d been a failure of the heat shield to deploy, or to properly deploy. We weren’t quite sure about that. Because there weren’t any extensive strain gauges and instrumentation and things like that on it that, we couldn’t pinpoint a structural problem of some kind exactly. But we knew that it wasn’t functioning properly. We weren’t getting thermal protection. It was a battle for the first days.”

That battle was fought on several fronts. First was keeping the vehicle in shape for the crew’s arrival, whenever that would be. (The orbit of Skylab

|

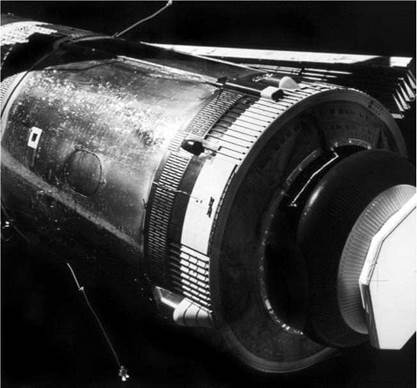

yj. The exterior of the Orbital Workshop, stripped of its heat shield, began to bake in the solar radiation.

|

passed directly over the Kennedy Space Center every five days, so launch opportunities would be at five-day intervals after the original 15 May launch date.)

Skylab’s only source of power was the atm solar panels, and every watt was needed, which meant keeping the atm pointed straight at the sun. But with the heat shield gone, pointing at the sun was the worst direction for workshop temperatures. It was 130 degrees Fahrenheit inside the workshop. The results of the high temperature could be disastrous: food might spoil; noxious chemicals might outgas from the walls; batteries and other equipment might be degraded. The materials lab at Marshall had conducted a temperature overtest on the substances used inside the workshop to make sure there wouldn’t be an outgassing problem if temperature exceeded nominal levels but had only run the test up to over 100 degrees. After the loss of the heat shield, they resumed their testing, this time at higher temperatures.

The flight controllers battled this dilemma for ten days. With no panacea for the conflicting problems of heat and attitude available, those days were filled with constant compromise between the dual concerns. They’d roll Skylab away from the sun, to keep the temperatures from increasing. Power would drop, battery charge decrease, and a roll back toward the sun would have to happen.

The question of controlling the station’s attitude was further complicated by its means of attitude control. Skylab had the three large momentum wheels, like large gyroscopes, called “Control Moment Gyros.” By ordering the cmg’s electrical system to push against the gimbals of one or more of these cmg momentum wheels, it was possible to move the direction in space in which Skylab was pointed, thanks to the principle of conservation of angular momentum. So it was easy enough to change the station’s direction. But when this was done, other small forces were encountered (technically called “gravity gradient forces”) that tended to drive Skylab’s attitude in another direction, perhaps opposite of the one desired. This problem was not so easily solved and required firing the cold gas jets in space to hold the desired attitude. Further complicating the matter, the amount of cold nitrogen gas was strictly limited, and if this procedure were to continue for too many days, perhaps twenty or thirty, all the gas would be expended and attitude control would be lost. So a fix was needed in rather short order to save the Skylab missions.

For ten days mission controllers worked constantly to preserve the delicate balances needed to keep the station fit for when its first crew arrived. Over half the supply of the nitrogen gas for the entire mission was used in these ten days. “It was ironic,” Hardy said. “There was a preferred orientation for generating electric power. However, it turns out that most of the time that was the most adverse orientation for the workshop overheating and for drag.

“It was management of the orientation of the workshop on a continual basis, going to one particular attitude knowing that it was penalizing you in some areas. But you had to do that, and you figure out how long you have to stay there and then get back in the other attitude. It was a real balancing act between those three things. The operations people did a fantastic job in that, and of course we loved the great engineering team. There were real questions about whether the batteries would actually survive that kind of cycling. We just started cycling, and I guess we learned a lot of things.” But they kept Skylab alive.

The second front of the battle to save Skylab was finding a way to erect a substitute for the heat shield. The spacecraft, its contents, and any crew just could not tolerate those temperatures. And whatever NASA came up with, they had to be quick about it. The longer launch was postponed, the less likely it was that Skylab would remain salvageable.

Engineering teams were formed at NASA centers across the country and told to forget the paperwork for a while. “It was an opportunity for some imagination,” Shaffer said. “It was an environment where if you had a good idea, it was really easy to get it executed, ’cause all of the energy was there to do that.” The astronauts from the later Skylab missions and the backup crews were sent out to the centers to provide an operations viewpoint for the efforts.

“I remember leaving the launch site and coming back to the Holiday Inn,” Jack Lousma said. “I met Ed Gibson and Julie, and they had more word than I did. They were somewhat disappointed and discouraged. I was thinking, at least the Skylab is up there, and even though it’s not perfect, there’s probably something we can do about it; at least it’s up there. I had no other knowledge, and no one else did either. I didn’t know what the extent of the damage was, or if I should feel confident that something could be salvaged. But I knew at least it was up there. And that was somewhat heartening.

“I went on to Houston because they hadn’t figured out what the problem was for a short period of time. I wasn’t there long, because we had to find out what was wrong with the Skylab and figure out what to do about it. I remember coming to work one morning, and Al Shepard said ‘I want you to go to Langley and help them develop one of the fixes for the thermal shield.’ I didn’t go home, I didn’t get any clothes, I didn’t do anything, I just got in a T-38 and flew there directly. I spent about three days there and worked all day and all night with those guys at Langley to develop one of the concepts that was being proposed. This was an inflatable structure [inspired by an earlier communications satellite design], where it was a very lightweight material that would be shaped in the form of a covering, and it would be inflated when it got up there. It was all this silvery material.

“I think we [would have] extended it out the airlock, but I could be corrected on that. I don’t remember there being any external tie downs, or anything like that, that we developed. But anyway they had fabricated one of those very quickly, and started the inflation, and tried to deal with those engineering difficulties, and finally made it work. I introduced my crew comments on it as we went along on how to make sure the crew could actually do it and be able to get it to operate.

“But my conclusion after being there for two or three days was that it was not going to be a satisfactory fix. It was too vulnerable to losing its inflation; the dynamics of its inflation and spreading over the workshop were marginal in my estimation. So all of us rendezvoused down at the Cape directly after that. All of us went to the Cape and met with Pete’s crew. I sat and listened to all of the presentations of the fixes that were available, and then I told them that I didn’t think that the one I was working on had top priority. They could make up their own minds, but here’s what I thought about it. It wasn’t one of the ones that went through.”

After all the work was done and all the ideas were brought together and reviewed, three solutions seemed feasible. All three ended up being launched, and two were used.

From the Manned Spacecraft Center in Houston, a cloth sunshade that would be deployed by flying the Command and Service Module from point to point around the workshop, while the crew would unfold it and secure it to structure. Installation would be feasible but tricky. This one was not used.

From the Marshall Space Flight Center in Huntsville, the “Marshall Sail” (also known as the Twin-Pole Sunshade), designed to be deployed by a pair of astronauts during a spacewalk after docking with and activating Skylab, using the Skylab airlock. A solid and elegant solution, it was deployed over the original parasol a few months later by the second crew to extend the life of the parasol’s delicate aluminized Mylar reflective covering material.

From Houston, a “Solar Parasol” (or “jsc Parasol” or just “the parasol”) — a large square of thin nylon cloth attached to four spring-loaded fishing poles and packed in a long metal canister. As luck would have it, there was the Scientific Airlock built into the wall of the workshop on the sunpointing side. It was designed to allow astronomy and materials experiments in pressure-tight canisters to be pushed right out into vacuum to take their observations. The parasol made some investigators unhappy by monopolizing that airlock for the entire mission. But it played an essential role in saving Skylab, being a quick, safe solution to the heat problem. It was invented by Jack Kinzler.

|

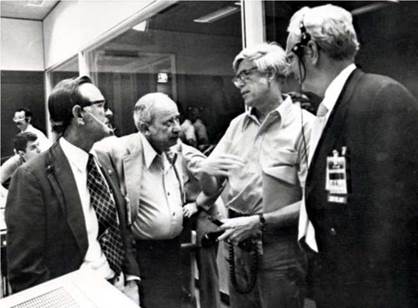

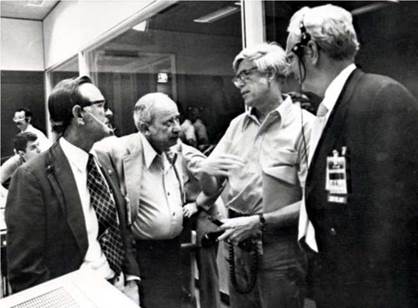

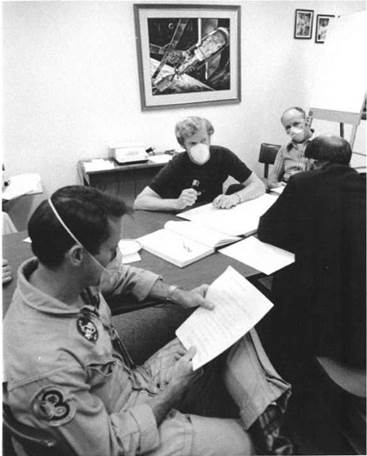

i8. Jack Kinzier (secondfrom right) explains his parasol concept.

|

Jack Kinzier graduated from South Hills High School in Pittsburgh in 1938. He was hired at the National Advisory Committee for Aeronautics’ Langley Research Center in 1941 as a journeyman toolmaker. His skills earned him multiple promotions, and in 1961 he was assigned to the Manned Spacecraft Center in Houston as chief of the Technical Services Division. He never got a college degree, but his “equivalent in experience” was worth at least a master’s in mechanical engineering.

“Different groups were working on sun shields deployed on spacewalks,” Kinzler recalled. “When I realized nobody thought about going inside and doing it the simple way, I thought, ‘Well, I’m going to look around some.’”

He found the experiment airlock on the sunny side of the station—he called it a “Sally Port”—in the trainer in Building 8. “So I had one of my techs go down to Houston and buy four fiberglass extendable fishing poles,” he said. “I drew up a hub with springs attached to the bottom of each pole. Then I had the sheet-metal shop roll up a tube about eight inches in diameter. I called up my parachute shop and said, ‘Get me a twenty-four-foot section of parachute cloth.’

“The machine shop fastened the four fishing rods to my base. I fastened

that base to the floor of our big high-bay shop area. We fastened the cloth to the rods and long lines to the tips of each rod. I lowered the big overhead crane to floor level and swung my four lines over the crane hook. Then I called Gilruth, and everybody came over for a demonstration. I said, ‘I think I’ve got something you’ll like.’

“So they were standing around thinking, ‘What’s Kinzler up to now?’ I raised the crane back up, letting out excess line ’til I had enough clearance, then let the crane pull all four lines simultaneously. It looked like a magician’s act because out came these fishing rods, getting longer and longer. They’re dragging with them fabric. They get all the way to where they’re fully out, and all I did was let go and it went ‘sshum!’ So the springs were on each corner (and each spring pulled a pole outward and downward), and they came down and laid out right on the floor just perfectly. And everybody was impressed, I’ll tell you. They were impressed! So that concept—my concept —was chosen for the real thing.”

Kinzler and his techs gladly paid the price for success, working day and night for six days building the flight version (substituting thin nylon for the parachute cloth) and testing it. Afterward he got a lot of fan letters — and from NASA its highest decoration, the Distinguished Service Medal.

Many others were working on the problem at jsc. Ed Smylie, then chief of the Crew Systems Division, remembered: “We constructed an umbrella that would deploy like a flower petal, rather than like a traditional umbrella. We covered the assembly with a test canopy filled with holes to reduce air resistance during our deployment tests. On the initial test it worked perfectly. I invited NASA management to review our design. Most of senior management from Johnson, Marshall, and headquarters joined us. Upon deployment the frame twisted itself out of shape and failed completely. The managers shook their heads and went away. When I asked my crew what happened, they said they thought the spring was too weak and installed a stronger spring.

“Shortly after, I had a call; I should abandon our design and support Max Faget [director of engineering at Johnson] in the design of the chosen approach. As I recall, the frame was constructed in the jsc fabrication shop under the direction of Jack Kinzler and Dr. Faget. I can remember working with Max laying out the frame on the floor of the shop in the middle of the night. Max turned to me and said, “Isn’t this fun?” I had not thought of it that way, but he was right. There was intense pressure, but it was a fun kind of pressure.”

Ed shared the fun and the pressure with his key engineers — Jim Correale, Larry Bell, Harley Stutesman, Joe McMann, and others. He set up a clearinghouse called “Action Central.” All elements of the center used it for getting things done quickly. One of his branch chiefs took it upon himself to charter a Learjet to move supplies as needed around the country.

“Everybody was working horrendous hours, and towards the end of those ten days one of my branch chiefs was leaving Building 7A one evening, and as he walked out the back door he simply collapsed,” Smylie recalls. “He was not injured, but his system had simply shut down.

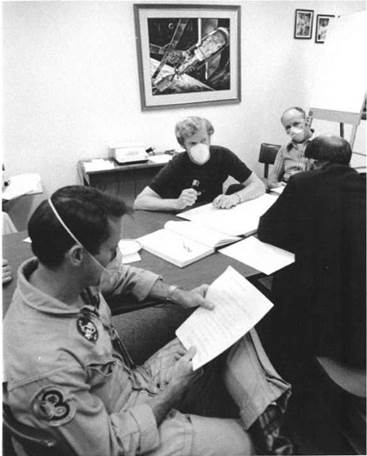

“The briefing of the Skylab 1 crew was held in the ninth-floor conference room [of the main building at Johnson, then called Building 2] after the crew had been quarantined. Everybody had to wear those little painter’s masks over their mouths and noses. It was quite a sight to see the astronauts, senior management, engineers, and industry types—over a hundred of them—crowded together in that room around the huge table, all wearing those little white masks. After an hour or so everyone’s masks were getting damp and hard to breathe through, so people started moving the masks a little bit and sneaking breaths. Then Pete Conrad stuck a cigar out the side of his mouth and commenced to smoke it—still keeping the mask on his face. Soon everyone was moving the masks away from their mouths so they could breathe. They started wearing them over their ears, on top of their heads, anywhere—but no one took off their mask!”

While the Houston-designed parasol had the advantage of being easy to deploy and thus providing a quick fix to the heating problem, Bob Schwing – hamer, who was the head of the Marshall materials lab, had concerns about its long-term durability. “I was afraid of that because I had run these tests about building the flag, and I knew the nylon wouldn’t stand up very long.” Schwinghamer was also concerned that the station’s TACS thrusters would damage the thin material when they fired. “What if it rips or comes apart totally?”

“For the Marshall Sail, I had used that same rip-stock nylon material, and I had a material called S-13G, which was a thermal-control material, real nice white stuff, very highly reflective,” he said. “When you sprayed it on that sail parachute material, it still had high flexibility. It wouldn’t flake

|

19. Seamstresses prepare the Marshall Sail sunshade.

|

off or anything. So we sprayed it with that, and I ran some ten-sun tests in the lab to see how long it would stand up, and we knew it would last for the Skylab mission.

“Then we had some Navy seals in; they packed it. We didn’t have a parachute packer; they packed it. That thing was pretty big, it was like thirty by forty, I think. We got some seamstresses in from New Jersey to do the sewing. I remember that stuff was laying all over the floor, and they were just sewing away, and pulling that big sail through there. And we got that stuff all done in ten days, in time to fly.”

The failure of the micrometeoroid shield had come as a complete surprise to the Skylab engineering team, which had not foreseen even the possibility of its failure. “The meteoroid shield went through design reviews like all the other hardware did,” Hardy said. “There were known design requirements; there were some tests that were done. You couldn’t do a test that exposed it

directly to aerial loading and things like that, obviously. Nobody predicting a failure or anything like that. But like a lot of other things, after it happened, you go back and look and see where you were deficient in your analysis and some of your designs, but not prior to launch.

“McDonnell Douglas Huntington Beach was the prime contractor for the Orbital Workshop, which included the heat shield. But other contractors were involved in design reviews and things like that. I don’t know, there could have been somebody out there that was expressing some concern that wasn’t taken into account. But if there was, it was almost after the fact, because I had no knowledge of that.”

While the rescue effort was underway, an investigation was started into the causes of the failure. The board of investigation was chaired by Bruce T. Lundin, director of NASA’s Lewis (now Glenn) Research Center and presented its findings on 30 July. The board determined that the most probable cause of the failure was pressurized air under the shield forcing the forward end of the shield away from the workshop and into the supersonic air stream, which tore the meteoroid shield from the workshop. The report stated that this was likely due to flaws in the way the shield was attached to the workshop, which allowed in air.

The failure to recognize these issues during six years of development was attributed to a decision to treat the shield as a subsystem of the s-ivb, based on the presumption that it would be structurally integral to the tank. As a result, the shield was not assigned its own project engineer, who could have provided greater project leadership. In addition, testing focused on deployment, rather than performance during launch. The board found no evidence that limitation of funds or schedule pressure were factors and that engineering and management personnel on Skylab, both contractor and government, were highly experienced and adequate in number.

Resolving one final issue was absolutely essential to Skylab’s long-term success. It was to answer the questions “Is one of the solar array wings still there; what’s wrong with it; and how can we get it deployed?” Related to these were the further questions of how much the crew could do with atm power alone and how they would do it. Even if it were possible to deploy the remaining solar array wing, living off the atm power would be necessary when they arrived and until (and if) they got the solar panel open. The crew spent a lot of time with the flight planners, going through all the checklists, and marking them up for low-power operations. General conclusions were:

With care and frugality, the crew could live in the workshop and do some of the experiments.

They should use lights sparingly and turn them off when they moved and not make coffee or heat food.

The solar physics and Earth resources work should be minimized. (The medical experiments were pretty low power users and ok.)

And so forth.

There was serious doubt that Skylab could go three missions like that or that it would be worth doing. One or two failures would put it out of business. The science return would be badly hurt. They had to get that solar panel out to save Skylab.

Some images had been obtained. They were blurry but showed that the solar panel was there. What was holding it shut would have to await inspection after crew arrival. But the holdup must have to do with the ripped – off heat shield. Freeing the array would require a spacewalk. And the team had to select a suite of tools for the job right then without waiting for the inspection. Engineering did a superb job of outlining possible situations they might meet and finding a collection of tubes, ropes, and cutters to make up their tool kit.

And soon the decision was made that NASA couldn’t possibly be ready to launch on 20 May. The flight controllers said they could hold on another five days. So they aimed for 25 May, the next fifth-day opportunity to launch.

“I was in the flight operations management room at jsc at the launch on May 14 and spent about the first week down there,” George Hardy remembered. “After the first ten-twelve hours of meetings and looking at data, everybody was walking around with their heads down. I’d just come out of a meeting with Gene Kranz. I felt we’d bought the farm; we’d lost the mission. And Kranz said, ‘No, no, we’ll figure it out. We’ll figure out some way to get this thing done.’ That’s the sort of guy he was, still optimistic.

“The next seven to ten days was remarkable. I stayed down there with the first-line Marshall engineering support group. And, of course, we stayed in touch with what was going on at Marshall. But I got to see firsthand what the jsc folks were doing too. It was quite remarkable.

“We were getting all kinds of suggestions from the public. I still have, tucked away somewhere in shoeboxes or somewhere, letters that I got from people all over the world that had suggestions about what we might do.

“The other thing I remember, Chris Kraft had a meeting every morning in his conference room, and he accepted me in that conference room just like I was one of the jsc guys. We had the best working relationship you can imagine. There was no ‘invented here or there.’ Both centers worked aggressively to get their sun shield out, and both of them worked; both of them served their purpose. Those were good days, great days.

“That was something, the first seven days. It was actually ten days, but there was a movie about that time called ‘Seven Days in May,’ and Jim Kingsley and I joked later about that. It turns out at that point in time we’d worked on Skylab about seven years, and we almost lost it, so we decided we were going to write a book called Seven Years in May.”

About a week after the launch, Hardy left jsc to return to Marshall and oversee his team there. He recalled that Rocco Petrone, who in January of that year had been brought to the center to serve as its new director, was very involved in the discussions about the status of Skylab. “Dr. Petrone would come by every morning and get a briefing on what was going on,” Hardy said. “He’d usually call sometime during the day. And he’d come by every afternoon. And every afternoon we’d have a briefing for him on every problem, all the plans for the next day and everything. He’d come by like six o’clock in the afternoon, and sometimes those briefings would last until midnight. You had to stay on top of it. At that particular time, initially, he hadn’t been [at msfc] but a very short time, and his wife wasn’t here, and he was living in an apartment, so he had a lot of time. He’d come over there and eat Kentucky Fried Chicken, or whatever it was we’d ordered for that night, and stay with us. A lot of times he’d stay five or six hours.”

Lee Belew had a similar recollection: “We worked day and night. I mean, absolutely day and night. With Rocco whipping us all the time. He was something else.”

Bob Schwinghamer was also at Kennedy Space Center for the launch. “I was down there on the fourteenth,” he said. “I had the family along for that launch. That was a big deal, Skylab. Right away we started hearing that the temperature was not the way it should be; and they concluded that something had happened with the micrometeoroid shield and everything.

“I hung around the control room as long as I could down there. I finally went back to the motel and told everybody, ‘We’ve got to get out of here, and we’re going to leave very early, about three o’clock in the morning,’ and it was about nine or ten then. We drove all the way back, nonstop. And I got in sometime the next day—I don’t know exactly when—went over to Hose, which is where our control center was, and for the most part stayed around there. We started trying to figure out what might have happened, and what should we do.”

Like most at NASA’s manned spaceflight program at that time, Schwing- hamer has memories of long hours of hard work, and as with most at Marshall then, Rocco Petrone features prominently in those memories. “It was ten days and ten nights,” Schwinghamer said. “I didn’t go home the first three days. And then after that, Rocco would come in about ten o’clock at night all the time, eleven o’clock, ‘What kind of progress are we making?’ After we started building the sail, I had three teams for around-the-clock coverage on the sail, and I had a big chart in my office, and I had a guy that his responsibility was to log in the results: When did you paint? Have you inspected? All the steps were there, and they were logging them in as they occurred.

“And Rocco would come in at ten or eleven o’clock at night, and he’d say, ‘I’ll be back later.’ Well, hell, you didn’t know if later was in an hour, or two hours, or tomorrow morning. So the first three days, my deputy Gene Allen and I stayed all night. Finally on the third day, we looked at each other, with dark circles under our eyes, and I said, ‘Gene, I can’t keep this up.’ He said, ‘I can’t either.’ I said, ‘I’ll tell you what let’s do, let’s go on two twelves, and a little bit extra if it takes it, fifteen, maybe, or whatever. But nominally two twelve-hour shifts.’ Well, we did that after the first three days, and it worked out pretty good. Somebody was always there when Rocco showed up. Oh, he was tough on us. Oh, he was tough. But that’s what it took.”

Schwinghamer recalled that during the preparation of the sail, the process laboratory at Marshall insisted that they should be responsible for spraying the protective coat on it. He warned them that it would probably be more difficult to apply than they were anticipating and said that his materials lab could do it. “They said, ‘Ah, we can do anything,’ And I said, ‘All right go ahead, spray it.’ So I went over there, and it was about six o’clock, seven o’clock in the evening, and I was standing there, and it was the damnedest mess you ever saw. All of a sudden, somebody behind me says, ‘Did you guys ever make any flight hardware in this place?!’ It was Rocco, and he was madder than a hornet. It was a mess. He said, ‘Bob, you get everybody that has anything to do with this sail into your office; at eight o’clock tonight we’re going to decide how this gets done.’

“So I called Matt Sebile, the lab director in the process engineering department. I call him on the phone and he said, ‘Well, I’m cutting the grass, I’d like to get finished.’ I said, ‘I tell you what, I can’t tell you what to do; I’m just a division chief. But if I were you, I’d get my butt over here just as fast as I could.’ And he did, and he had ratty old Bermuda shorts on and dirty tennis shoes. At that eight o’clock meeting, Rocco says, ‘All right Schwingham – er, the sail’s your responsibility. J. R. [Thompson, head of crew systems at Marshall], you’re responsible for the deployment and how it gets used. Now get out of here, and get it done.’ Of all things, my dad came down to visit us from Indiana right in the middle of that. I said, ‘Dad, no fishing this time.’ He always used to come down, and I’d take him fishing one time.”

Despite the busy schedule, Schwinghamer did get to talk to his father, once, during the visit, while he “was home shaving one morning, and taking a shower.” His father questioned why his son was spending so much time at work. “He said, ‘Are just you doing that?’ And I said, ‘No, everybody’s doing that.’ He said, ‘I can’t understand that.’ He was the superintendent of a chair factory up there in Indiana. He said ‘You know what, I couldn’t get my people to do that.’ I said, ‘Everybody’s doing that, not just me.’”

While Petrone loomed large in Marshall’s efforts during those ten days, he made at least one contribution of which he was utterly unaware. One evening Schwinghamer found himself in need of some material used in the sail, which was only produced at the Illinois Institute of Technology in Chicago. Obviously simply ordering the material would have taken far too long; he had to have it right away. As happened often during the around-the-clock work, it was already into the evening when Schwinghamer discovered he needed the material.

“I wanted to get [the center’s] Gulfstream to go up and get that stuff so we’d be there at seven o’clock the next morning and could bring it home by noon the next day,” he said. “Of course, everybody was gone, and you couldn’t get the normal approvals. I tried to call some people at home to get approval to use the Gulfstream. I finally conned somebody — I don’t remember who,

I don’t wanna know—who would give me enough paper that I could go out there and say I need to take the Gulfstream. And we did that.

“And I kept thinking, ‘Rocco Petrone’s the director, if I get caught doing this, I’m done for.’ That would have been a little too far. But since it was at night, there was no call or request or requirement for the airplane, and we got by with it all right. Boy oh boy, that would have been very bad. I can tell you some center directors we had that I could have talked my way out of it, but I couldn’t have done it with him.”

The only-semi-authorized use of the center’s Gulfstream was practically by the book though, compared to another vehicle use Schwinghamer was involved in during that ten-day period. When he ran out of another material he needed one evening, Schwinghamer called Tom McElmurry in Houston for more at around 9:00 or 10:00 p. m. “I called him; I said, ‘Tom, I’ve got to have some of that damn material. Can you bring me some?’ And he said, ‘I think I can.’ He got here at midnight, I’ll never forget. He said, ‘Bob, I’m not flying back to Houston tonight. I’m going to get a hotel room. Can you get me a car?’

“I thought, ‘How am I going to get a car now?’ And then I thought, ‘Oh, the lab director’s got a car, and I know where they keep the key.’ The secretary always left the key under the desk. I said, ‘I’ll get you the lab director’s car.’ My thought was, he’s going to take off at six in the morning, and Heinberg wouldn’t come in until seven thirty, and I could get that car back, and he’d never know it was gone. But I worked all night, and I was getting pretty woozy. By that time in the morning, I didn’t think about the damn car any more. The car was sitting out at the Redstone strip.

“Heinberg comes in—the secretary told me this story—he looked through the Venetian blinds, and said, ‘Where the hell is my car?’ She said, ‘Mr. Heinberg, it’s in your parking place.’ He said, ‘You just come over here and look, and the car was gone.’

“So then they called all around, and they had the mps running around looking for the car with the license number and all that crap. And they finally found the car out there at the Redstone airstrip, and somebody out there, said ‘Yeah, Schwinghamer did that.’ So he called me up about ten o’clock that morning, I’ll never forget. And he said, ‘Schwinghamer, you know what, you’re totally irresponsible.” And he hung up. And I thought, ‘Oh, I’m fired.’”

There were several other occasions when the exigencies of the situation meant that protocol was waived in favor of expediency. “We had very strict rules about handling flight hardware,” Schwinghamer said. “You couldn’t just put that in the trunk of your car and drive off. This guy that worked for me had this big Ford van with just two seats in the front. I got so tired calling transportation and then having them show up four or five hours, or the next day, later. And I thought, ‘The hell with it.’ So every time we had to move [something], I’d get him and we’d put it all in the back of that big Ford van and move it.”

On one occasion, though, he had “unofficially” transported some flight hardware for a qualification check, and someone came back and told him it wasn’t working. “And I said, ‘What are you talking about? We checked that thing out ourselves here and it was working fine.’ So I went up there and said, ‘Nothing happened here, did it? I mean, when we moved it?’

“I looked around real carefully, and one corner of that cube was scrunched, and it had green tile in it. And they had green tile on the floor up there. I said, All right, this metal got yielded. I suspect it fell on that corner.’ Finally one guy broke down, and he started crying. He said, ‘I did it, I didn’t mean to.’ I’ll never forget, he was one of the best techs we had. I really hated that. I said, ‘Just forget about it. You get this thing going again, fix it, and I won’t say anything.’ I felt so bad, ’cause he was one of the best techs we had and that would have gotten him in a lot of trouble. And I had a little personal interest too: I thought, next thing you know, they’re going to start inquiring about how this stuff gets moved around. We were in it together, I do believe. He fixed everything up, and it worked fine.

“One night I needed something in that same building, and I got in before they closed everything, but I stayed too long, and then I couldn’t get out,” Schwinghamer recalled. “I had what I needed; it was two small parts. And I couldn’t get out. I thought, ‘If I call these damn security guys, they’ll be here in two hours or something. I’ll climb the fence.’ It was one of these fences with that overhanging barbwire. I didn’t think about what the hell I’m going to do when I get up to the barbwire. I cut a big gash in my butt, and I fell off the fence and fell on the ground. It was about eight feet high. And just when I hit the ground, two headlights came on. These darned security guys drove up and slammed up the brakes and jumped out. One of their names was Miller; I knew him well, ’cause he had nailed me for speeding four or five times. He walked up there, and I’m lying on the ground, saying ‘Oh, my. . And he said, ‘Hell, I should have known it’d be you, Schwing – hamer.’ He didn’t do anything; he let me go. Boogered my butt too.”

“We didn’t let anything deter us in those days,” Schwinghamer said of the construction of the sail. “A lot of funny stuff happened on our way to the Skylab. We did all kinds of stuff in those days. I can remember I was getting in hot water all the time. And it was day and night, I’m telling you what. It was really something. Oh, we did all kinds of stuff like that at that time, but we got her built. And they got it deployed, and the temperature came down real nice.”

A total of seven of the sails were built; two of which were set aside as flight hardware, and the others were designated for testing. “I even had one left and gave it to the Space and Rocket Center out here,” he said.

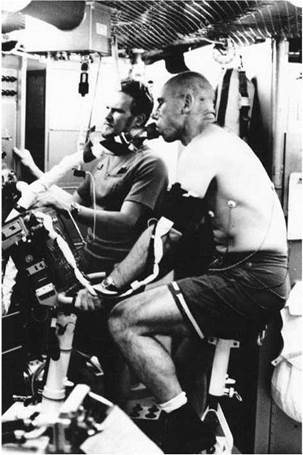

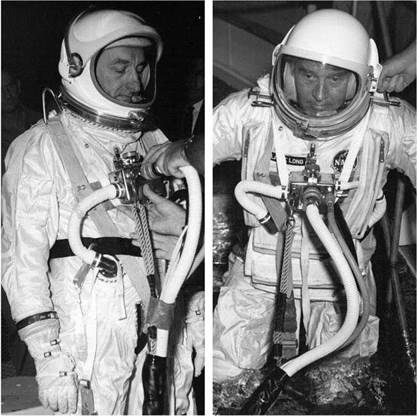

During the ten days they were grounded, the astronauts of the first crew were still under quarantine and continued to eat their flight diet so as not to ruin the metabolic balance experiment regardless of when they launched. But a trip to Huntsville was necessary, to inspect hardware and discuss repairs with Skylab engineers and to try out the Marshall Sail twin-pole sunshade in their water tank.

“That spacesuited water tank run was a memorable experience,” Joe Ker – win said. “There was an air of quiet intensity. We were all old hands at this, donning the suits, checkout, entry into the water were quick and easy. A preliminary version of the sail was ready, and tools were available. We worked our way through the deployment process, noting omissions and improvements. We liked what we saw. It was late in the evening when we emerged, and we didn’t know that reporters had gotten wind of the exercise and were clamoring to get in and take pictures. Word came to us, we’d done enough, go back to the motel and home tomorrow; let the backup crew take over. So we returned to the motel, and who should show up but Deke Slayton, carrying a couple of large pizzas and a bottle of wine. Best pizza and wine I ever tasted. Morale was good. Deke knew how to lead. And the metabolic balance experiment didn’t suffer. That was the only time we broke the meal regimen.”

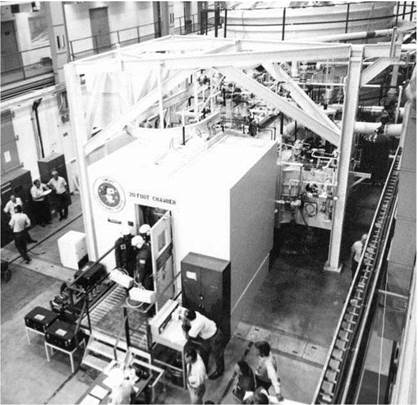

Marshall’s Neutral Buoyancy Simulator, large enough to hold full-scale replicas of space hardware underwater, had already played a vital role in the Skylab program in the wet workshop versus dry workshop decision. Now it would make yet another key contribution. “It really proved out to be very,

|

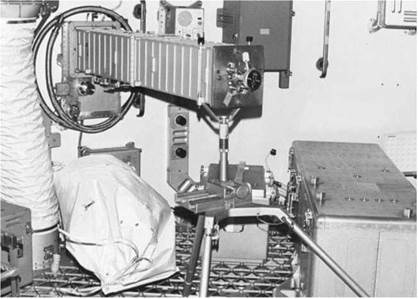

20. Jim Splawn (left) shows Rocco Petrone (center) and Bill Lucas the mount of the sunshade poles.

|

very beneficial,” said Jim Splawn, who was the neutral-buoyancy tank manager at Marshall at the time. “Because once we had the difficulty at the launch of the Skylab itself heading toward orbit, it really proved its worth because of all the hardware we had to assemble underwater.”

Like so many others involved in the effort to save Skylab, Splawn had been at the sl-i launch and was already putting plans in motion even before boarding the NASA plane for the return flight to Marshall. “Once we knew we had a problem, I got on the phone with the crew back here in Huntsville and said, ‘Hey guys, we’ve got to start thinking about how we may help with the repair — design of tools, the mechanics of the procedures we go through. We need to start thinking about that, not tomorrow, but right now. And just ‘think outside the box,’ as we say today.”

The two biggest tasks were to contribute any ideas as to how the problems with the orbital facility could be fixed and to begin thinking about how they would train the flight crews on the procedures and the tools that would be needed to make the repairs. “And that started within probably an hour or so of knowing we had a problem,” he said.

Once development of the Marshall twin-pole sunshade began, the water

tank played an important role in qualifying the design. Test hardware would be fabricated and tested in the tank, problems would be identified and corrected, and the cycle would begin again. “With us being there right next door to the shop areas, we had the run of the entire shop to make whatever we needed,” Splawn said. “There were times when the shop would make a welded piece, and we’d grab it and run to the water, and when we would put it in the water, it would sizzle because, luckily, with the close proximity we were just working that fast.”

During that period the tank essentially operated as a twenty-four-hour – a-day facility. “Our wives, our families brought changes of clothes to us; they brought hot meals to us. I have no idea how many hours we went without sleep. I think at one point I personally went about thirty-four, thirty-six hours. But it was simply because the adrenaline was flowing; you had a mission, and you felt that it was just absolutely your job to do everything you could to make it happen. And we were no different from dozens and dozens of other people at Marshall that were pursuing an answer to the problem that we had. So it was very rewarding to see it all come together eventually and put us in business.” Other key members of the msfc neutral-buoyancy team included Charlie Cooper and Dick Heckman, and astronaut Rusty Schweickart spent a large amount of time working with the team to provide crew operations input.

For Splawn his work on Skylab, and particularly the effort to save the station, was the highlight of his career. “When we were doing flight crew training, we never dreamed that we would end up doing an exercise like this, to have a salvaging kind of ‘Let’s fix the Skylab for the crew so that they can go and spend their days on orbit and do the things they had been trained to do.’ We never dreamed we’d end up in that kind of posture. But the way it worked out, that really is a highlight of my career, even beyond the flight crew training, which for us was probably what we thought would be the apex of our careers. But that ten days, obviously, topped it.

“For the launch of the last crew, we took all of our staff— all the divers, secretary, everybody—to the Cape and got to see the last launch,” he said.

At the same time that the work was going on to figure out how to erect some sort of sunshade on Skylab, another effort was underway to work out how to free the station’s remaining solar array so that it could deploy and provide power. With an attitude that was typical of people involved in the

|

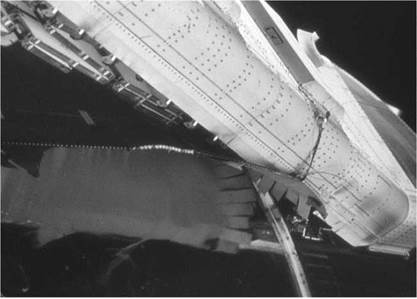

2i. When the first crew arrived at Skylab, they discovered that debris had prevented the solar array (white beam at top) from deploying from the workshop (black cylinder at bottom).

|

project, the engineers took a task that was considered impossible and promptly began working to figure out how to make it happen.

“Six weeks or so prior to that, maybe it was a little longer, we had done a failure modes and effects analysis, which is kind of typical,” said Chuck Lewis, a man-systems engineer at Marshall at the time (not the same as the Chuck Lewis at Mission Control in Houston). “And one of the things that we and jsc did together was a study of what sort of contingency plans were feasible. One of the issues, believe it or not, was if one of the solar arrays malfunctioned. And the answer to that was, ‘It’s not possible [to do anything]. Can’t get there. Don’t even need to worry about doing any analysis on that.’ The message was, ‘You’re not going down the side of the s-ivb. It’s not possible to get down there, because there are no handrails.’ That was the killer in the notion of whether you could do anything about this.”

Just weeks after the task had been deemed impossible, J. R. Thompson, who went on to become the director of the Marshall center, and later nasa’s associate administrator, called in Lewis and others after the Skylab had arrived in orbit and controllers had learned that the unfixable problem had occurred. “J. R. Thompson called three or four of us up to the conference room up there,” Lewis said. “He had the whole vehicle on one drawing spread out on a table. And he said, ‘ok, guys, I know we’ve said we aren’t going to do this. But we’re going to do it. We’re going to figure out how to get down there and see what’s going on.’”

Work on solving the task began even before the initial imagery revealed what exactly had happened. “J. R. was jumping the gun a little bit, not knowing what the details were. Essentially telling us, ‘Start thinking hard about this. We don’t know what’s going on yet, but start thinking about it.’” A “war room” was set up to deal with the situation, with communication lines established with other NASA centers and with the contractors who would be able to provide expertise on the equipment either involved in the problem or needed to fix it.

“We were sitting in that office,” Chuck Lewis said, “and at that point we were basically going on a thirty-hours-on and eight-hours-off schedule; you worked till you dropped—which was about thirty hours—and then went home. I spent the first or second night under the conference table in the room under the one-G mock-up in 4619. My wife brought up a sleeping bag, and I sacked out the first night under the conference table, and J. R. Thompson went and slept in that advanced concepts module, which later turned out to be the precursor to Spacelab. And we were all growing beards and had sunken eyeballs and everything else.

“We were all in contact with an awful lot of people. Because at this point the environment had changed from ‘Who are you, what’s your need to know, who do you work for, and why should I give you this information?’ to ‘What can I get for you?’ Managers were walking around asking what we needed — money, people, airplanes, whatever—which was a 180-degree reversal from the typical NASA mindset.

“It seemed like everybody in the world had ideas for solutions. And everybody was working on something. So we had the MacDac [McDonnell Douglas] contractors and our NASA guys sitting in the same room across the aisle from one another. Everybody was keeping track of what was going on. It was the day after launch because everybody was working—Boeing and MacDac and Martin and a bunch of people were working overnight to put concepts together.

“We were being called constantly. The phone was ringing off the wall; everybody had an idea. Every now and then Thompson would come in, and he’d have some reporter calling him on the line, and the typical question was, ‘What are you guys doing?’ And Bob’s answer typically was, ‘It’s what we’re not doing that’s easier to answer. Ask us what we’re not doing, and that’s an easy answer. We’re doing everything.”

Relatively early in the discussions, the idea had arisen of conducting a “stand-up eva,” in which the first crew would fly their Command Module around to the stuck solar wing, open the spacecraft’s hatch, and one crewmember would stand up through the open hatch and attempt to free the array. They got in touch with their counterparts at Johnson Space Center, who said they had been thinking the same thing. “We’d been sitting there with a mock-up on the table, playing around with toothpicks and strings,” Lewis said. “We kinda brainstormed that together and thought what we need to do is figure out something to take up there that will let you poke and prod and maybe pull on something.”

By the morning after the sl-i launch, someone had found a lead on just such a tool. “About nine o’clock in the morning, one of the MacDac guys poked me on the shoulder and said, ‘Chuck, we just learned about a company in Centralia, Missouri, called A. B. Chance Company,’” Lewis said. “They made what they called hot poles for linemen to use from the ground to reach up and activate breakers and stuff like that. They were fiberglass collapsing poles.

“[The Mcdonnell Douglas engineer] said, ‘We found out they also have a number of detachable tools that go on the end of these poles. It might be that if you call these guys, there might be something useful there.’ Anyway, the MacDac guy gave me the phone number for this A. B. Chance Company, and I said, ‘Sure, I’ll give them a call.’

“So I gave the guys a call, and I talked to the first person who answered and kind of explained the situation. I said, ‘This is Chuck Lewis, and I work for Marshall, and you probably know that we’re having a little trouble with the last launch, and we think you guys might have a tool with some end effectors on the end that we might be able to use.’ The answer I got back was, ‘Well yes, we do, we have a lot of those, and I can send you a catalog right out.’”

Of course, with the crew launch at that point scheduled just days later on 20 May, a mail-order catalog wasn’t going to be anywhere near fast enough. Lewis explained the situation and was directed to the next person up the ladder at the company, who told him that the same – or next-day delivery he needed just wouldn’t be possible because of an airline strike.

“I said, ‘That’s ok, no problem, no problem. Let me talk to the next guy up,’” Lewis said. “He said, ‘ok, I’ll let you speak to the product manager.’ So a guy came on the phone, and his name was Cliff Bosch.”

Bosch told him that A. B. Chance did carry the sort of tools that it sounded like NASA needed, took his phone number, and promised to call back in fifteen minutes with an inventory of possible solutions.

“So I let him go, and about that time, the same guy that had originally clued me about the A. B. Chance company bumped me on the shoulder again and said MacDac had been working on an automatic, pneumatically operated nibbling tool that you could pull the trigger, and it would nibble through,” Lewis said. “They’d been working on that all night, and [the president of McDonnell Douglas] wanted to bring it out, and he was headed to Huntsville, flying his Aerocommander, and if the guy from A. B. Chance really came up with anything, he’d land at the airport in Cen – tralia and pick it up.

“So when Cliff called back, I asked him how things went, and he said, ‘Oh I haven’t had so much fun in a long time. It’s the first time I’ve ever done this; I walked through the stock room with a box in my hands, and I just picked up stuff off the shelves—now how do I get it to you?’

“And I said, ‘Well, do you have a little airport there in Centralia?’ And he said, ‘Yeah.’ I said, ‘Well, the president of MacDac is going to pick it up in his Aerocommander and bring it to Huntsville.’ And he said, ‘Hell no, you guys don’t know how to use this stuff; you need somebody there to tell you how to use it. Has he got an extra seat?’ So we negotiated back and forth, but the upshot was that Cliff came to Huntsville.”

By the time Bosch arrived at Marshall, first-crew backup astronauts Story Musgrave and Rusty Schweickart had joined Lewis’s team in working on the solution to the stuck solar array. When Bosch arrived in the high-bay room with the full-size Skylab mock-up, he and the team all sat in a circle on the concrete floor, and he began showing them everything he had brought in his box. “We all sat down cross-legged on the floor, and it was kinda like opening presents at Christmas time,” Lewis said. “He had all kinds of stuff. He must have had thirty or forty pounds worth of end effectors, and two of the extendable poles.”

One of Bosch’s tools, in particular, struck the team at Marshall as having potential. “The one thing they had that was really neat was this scissorslike

|

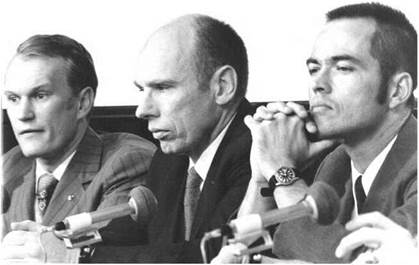

22. Ed Gibson (from left), Rusty Schweickart, and Pete Conrad participate in discussions about saving Skylab.

|

cutter that they used to clip electrical cables, that was kinda like the tree trimmer,” Lewis said. “The guys at Marshall re-engineered that in about a day and a half to provide some extra mechanical advantage because they did the analysis on the strap—we’d figured out the material by that time—and we knew what sort of load it was going to take for those jaws to get through that and whether they were going to be able to pull on it. So they put a double-pulley arrangement in there that was not there originally.”

Of course modifying a tool for spaceflight and actually being able to fly it are two different things. “They had to get that through stress test and everything else,” Lewis said. “And how it usually goes is it takes forever. Well, in

this case what they had done was to set up stations, just like college registration. Station one, there was a desk out in front of the office, and somebody would be there with a rubber stamp. Put your drawing down, stamp it, take it over to station two, stamp it. And of course, while all of this was going on, we still had managers going through, saying, ‘What can we do to help? What do you need, money?’ So we had a lot of support.”

(That support wasn’t just limited to people within NASA, either, as Steve Marks, who was working at the time as a NASA aerospace education specialist, recalls. Marks was involved in an effort to explore the untapped potential of television for NASA education and was transporting some equipment for that project to Marshall. Driving late at night, he was pulled over by a police officer for speeding. However, when the officer saw the NASA logo on the van, and Marks explained that he was delivering equipment to Marshall, the officer promptly sent him on his way—without a ticket.)

While the team at Marshall was going through the goodies that Bosch brought, another team took the poles to look into how they could be stored in the equipment bay of the Command Module. (Ultimately, the collapsible A. B. Chance poles would not be used, and NASA would instead re-create a modified version consisting of segments that could be assembled.) By that afternoon, the group working that issue at Kennedy said that they believed they had figured out how to store poles in the Command Module, but they wanted to actually see what they were working with to be sure.

“And J. R. came striding in; he strode into our meeting circle on the floor,” Lewis said. “We were still sitting cross-legged on the floor of the high-bay area, and he said, ‘Where’s this guy from Centralia, the guy with the tools? ’ Cliff raised his hand. J. R. said, ‘Your plane leaves for the Cape in forty-five minutes, can you be ready?’ And he said, ‘Yeah, give me a chance to call my wife.’ He hadn’t talked to her since he left that morning for work. He’d had a glass of orange juice, that was it. So he called his wife, and he said—at least, this is what he reported back—he said, ‘I asked her to pack me a bag, and send it on a plane to Florida. I tried to explain what was going on, and I promised I’d explain it when I had a chance.’ I think it was the Gulfstream that he got on and took his tools, with the exception of the flight items that our guys were still running through the machine shops.

“My recollection is, it was about a week and a half before he got home,” he said. “To me, that’s just a wonderful story, and it’s such a wonderful example of what was going on around the world.”

During the ten-day period between the troubled launch of the Skylab on 14 May 1973, and the launch of the first crew on 25 May, three completely independent repair methods had been conceived and built by the NASA team and tested and practiced by the flight crews who would deploy them.

“I consider these ten days the crowning achievement of NASA’s real-time performance in their near half-century of existence—only matched in the recovery of the Apollo 13 crew a few years before,” Owen Garriott said. “With Skylab, however, all NASA centers and thousands of civil servants and space contractors were involved in saving the program.