SELECTIONS BY LII

An initial group of civilian test pilots from the Flight Research Institute were selected as candidates for the Buran program on 12 July 1977 by an order of the head of the institute. They were:

• Igor Petrovich Volk;

• Rimantas Antanas-Antano Stankyavichus [6];

• Anatoliy Semyonovich Levchenko;

• Aleksandr Vladimirovich Shchukin;

• Oleg Grigorevich Kononenko;

• Nikolay Fyodorovich Sadovnikov.

A seventh pilot, Aleksandr Ivanovich Lysenko, had been pre-selected to become a member of the group, but while the necessary documents were still being prepared, Lysenko was killed when his MiG-23UB fighter crashed on 3 June 1977.

Selecting the group had been more problematic than anticipated. There was little willingness among LII’s pilots to enter the program because of the stringent medical examinations. In fact, initially only Volk and Levchenko had volunteered. Many feared that if anything was found that would disqualify them for Buran, they would also lose flight status for their test pilot work. Because this proved a serious problem in selecting candidates, Igor Volk managed to strike a deal with Oleg Gazenko, who was in charge of the medical screenings. The deal implied that as soon as it would become clear that a pilot was deemed medically unfit for the cosmonaut program, the selection process would be halted, both the pilot and Volk would be informed, and the pilot could return to test flying in LII, no questions asked [7].

Igor Volk can probably be called a logical choice as member of the group. In May 1976 he had already test-flown the 105.11 (nicknamed “Lapot”), an atmospheric test bed of the Spiral spaceplane. However, Volk himself has stressed that he made only one flight on “Lapot” at the invitation of the Mikoyan design bureau and was not involved in the program as such [8].

Late in 1977 the group lost a member when Sadovnikov decided to move from LII to the Sukhoy design bureau and become a test pilot there. Between April and June 1980 he would fly 15 combat missions in Afghanistan on Su-25 fighter jets. After returning to Sukhoy, he went on to become their lead test pilot and a Hero of the Soviet Union before passing away on 22 July 1994, only 47 years old.

|

Nikolay Sadovnikov (left) and Aleksandr Lysenko (B. Vis files). |

Sometime in 1978 Igor Volk became the commander of the group [9]. Eventually, the group would become known as the “Wolf Pack”, a tongue-in-cheek reference to Volk, whose name is Russian for “wolf”. The cosmonauts from later LII selections would become known as the “Wolf Cubs”.

On 3 August 1978 Volk, Stankyavichus, Levchenko, Shchukin, and Kononenko passed the so-called Chief Medical Commission (GMK), which cleared them for preliminary space-related training such as centrifuge tests and parabolic flights on aircraft to simulate zero-g [10]. Almost five months later, on 30 December 1978, the five went through the next phase in the selection process, appearing before the State Interdepartmental Commission (GMVK), the top government commission for cosmonaut selection. Its main task was to select cosmonauts on the basis of their political reliability and both moral and human qualities [11]. Headed by Leonid Smirnov, the chairman of the Military Industrial Commission, it consisted of representatives of the appropriate ministries and the KGB and also included Kerim Kerimov, the chairman of the State Commission for manned spaceflight [12]. All five were given the go-ahead to begin their OKP at the Gagarin Cosmonaut Training Center the following April, thereby receiving the official status of “cosmonaut candidates”. Unlike Air Force cosmonaut candidates that were selected for flights on Soyuz, they went through their OKP in periodic sessions, continuing their regular test pilot work at LII at the same time.

In December 1980 the Wolf Pack members finished OKP training and passed their final exams. Sadly, Oleg Kononenko was not among them. He had died on 8 September 1980 while testing a naval version of the Yakovlev Yak-38 vertical takeoff and landing plane in the South China Sea. Shortly after take-off from the aircraft carrier Minsk, the aircraft developed engine trouble and crashed into the ocean before Kononenko had a chance to eject. He was posthumously awarded a second Order of Lenin. One LII pilot has stated that before his death, Oleg Kononenko had been slated to become commander of the LII cosmonaut group [13]. This has not been confirmed by other sources and it should be noted that throughout their careers Volk had been senior to Kononenko.

At this point, the LII test pilots were not yet on an equal footing with the “career cosmonauts” of TsPK and NPO Energiya. The Wolf Pack was considered a specialized group, temporarily assigned to one particular task—namely, to fly Buran’s atmospheric and orbital test flights. Their status was somewhat comparable with that of “payload specialists’’ in the US Space Shuttle program, individuals not employed by NASA who are assigned to particular missions to operate one or more payloads and then return to their usual line of work.

All that changed on 23 June 1981, when MAP issued an order to set up its own cosmonaut team, something which became official on 10 August 1981 with a corresponding order from the chief of LII. This is considered the official date of the formation of the LII Buran cosmonaut team, which now consisted of Volk, Levchenko, Stankyavichus, and Shchukin. The move may have been linked to the success of the first US Space Shuttle mission in April 1981, which in many ways was an eye-opening event for officials in charge of the Energiya-Buran program. It should be noted though that the members of the LII team continued their usual work as test

|

Oleg Kononenko’s remains arrive in Vladivostok on the aircraft carrier Minsk on 26 November 1980 (B. Vis files). |

pilots throughout their Buran careers [14]. At this point they also received the official title of “cosmonaut-testers”, the same title given to the career cosmonauts of TsPK and NPO Energiya after their OKP. Before that they had been named “cosmonaut – researchers”, just like scientists of the Academy of Sciences and doctors of the Institute of Medical and Biological Problems. The official formation of the LII cosmonaut team was apparently also related to a new “Statute for Cosmonauts” approved by the Central Committee of the Communist Party and the Council of Ministers on 30 April 1981.

Meanwhile, LII was looking for more pilots to expand its ranks. In November 1979 deputy MAP minister Ivan Silayev had already called for expanding the LII group, but it was not until February 1982 that four more candidatures were presented to MAP:

• Pyotr Vasilyevich Gladkov;

• Ural Nazibovich Sultanov;

• Vladimir Yevgenyevich Turovets;

• Viktor Vasilyevich Zabolotskiy.

Reportedly, the four had already undergone initial screening in 1979. In June 1982 two more names were added to the list of candidates:

• Magomed Omarovich Tolboyev;

• Vladimir Viktorovich Biryukov.

Sadly, Vladimir Turovets had to be dropped very early on in the process, when he was killed in the crash of a Mil Mi-8 helicopter on 8 February 1982. Turovets, born on 20 February 1949 in the Ukraine, had been an LII pilot since June 1977 and a Test Pilot 3rd Class since 1980. His assignment to the Buran team would probably have been problematic anyway because of an incident in which, as a salute to his fellow LII test pilots, he had made a low-altitude pass over the site where Aleksandr Lysenko and fellow pilot Gennadiy Mamontov had crashed in June 1977 [15]. The fact that Turovets was not liked by many people could also have had a negative impact on his selection, even though colleagues have described him as a gifted man and an excellent pilot.

Pyotr Gladkov and Vladimir Biryukov were not selected and returned to test flying. Gladkov, born on 22 July 1949 in Krasnodar, mainly flew state-of-the-art fighter aircraft like the MiG-29, MiG-31, and Su-27, but also heavy transport planes such as the Ilyushin Il-76 and Tupolev Tu-154. For this work he would be awarded the title of Merited Test Pilot of the Russian Federation in December 1997. Vladimir Biryukov, born on 9 June 1950 in the Sverdlovsk region, had become a test pilot at the Flight Research Institute in 1981, upon graduation from test pilot school. In October 1996, he too was awarded the title of Merited Test Pilot of the Russian Federation.

Left over were Tolboyev, Zabolotskiy, and Sultanov. When still in the military, Tolboyev had already tried to become a cosmonaut in the TsPK Buran selection group of 1976, but he hadn’t managed to pass the medical commission at the time [16]. Both Zabolotskiy and Sultanov had already been involved in Buran-related research since 1978. This included a series of experiments called “Immersion” (1978-1980), in which they spent some time in simulated zero-g in a water tank at

Pyotr Gladkov (left), Vladimir Turovets (center), and Vladimir Biryukov (B. Vis files).

the Institute of Medical and Biological Problems and then performed landings with a Buran-type steep glideslope on Il-18 and Su-7 aircraft [17].

In September 1982 MAP decided that Zabolotskiy, Sultanov, and Tolboyev would undergo medical screening for possible inclusion in the LII cosmonaut team. While Zabolotskiy failed the initial medical, Sultanov and Tolboyev were accepted by the GMK on 25 January 1983, passed the GMVK on 9 March 1983, and were officially included in the LII team as cosmonaut candidates by a MAP order on 25 April 1983. Zabolotskiy was finally declared fit by the GMK on 4 April 1983, but it took almost another year for him to be accepted by the GMVK (15 February 1984) and be included in the team by MAP (12 April 1984).

In spite of the selection of these three new candidates, LII still felt that it needed more cosmonauts. In September 1983 two more pilots were recommended to MAP:

• Sergey Nikolayevich Tresvyatskiy;

• Yuriy Petrovich Sheffer.

Sheffer and Tresvyatskiy passed the GMK on 8 July 1984 and 17 April 1985, respectively, and were both accepted as cosmonaut candidates by the GMVK on 2 September 1985. They were officially included in the team by a MAP order on 21 November 1985. That same month they began their OKP training at Star City together with Tolboyev, Zabolotskiy, and Sultanov, finishing it in May 1987. On 5 June 1987 they were awarded their certificates of cosmonaut-testers.

In the meantime, there had been another organizational change at LII in May 1987, when MAP decided to create the so-called Departmental Training Complex for Cosmonaut-Testers (OKPKI for Otraslevoy Kompleks Podgotovki Kosmonavtov – Ispytateley). In a sense this was LII’s own cosmonaut training center. Volk was named head of OKPKI, with Levchenko being assigned as his deputy. Stankyavichus

|

Ural Sultanov climbs out of a Soyuz descent module during a survival training session (B. Vis files). |

in turn became the commander of the LII cosmonaut team, with Shchukin acting as his deputy.

OKPKI numbered around 60 people. Apart from the cosmonaut team itself, it consisted of medical, engineering, administrative, and various support departments. One of these support departments had three cameramen, whose job was to film and photograph every test flight that was conducted with the BTS-002 atmospheric test bed and the Tu-154LL and MiG-25 training aircraft.

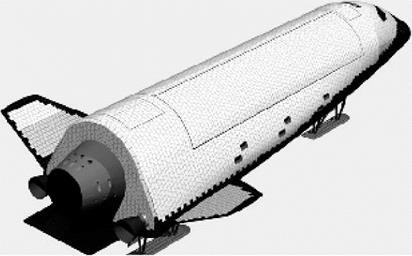

The LII cosmonaut team spent the next years performing Buran-related test flights. Volk, Levchenko, Stankyavichus, and Shchukin performed take-off runs and approach and landing tests on the BTS-002 between December 1984 and April 1988. Stankyavichus and Zabolotskiy would conduct one additional ground run in December 1989. The others flew flight profiles on the Tupolev Tu-154LL flying laboratory, MiG-25, Su-27, and other types of aircraft.

|

OKPKI organization chart, showing the situation in 1989 (E. Vaskevich archives). |

|

The Wolf Pack. Sitting are, from left, Sheffer, Sultanov, Yolk, and Tolboyev. Standing behind them are Prikhodko, Tresvyatskiy, Stankyavichus, and Zabolotskiy. This photo was taken in 1989 or 1990 (B. Yis files). |

The team suffered a major blow in August 1988, when two of its members died only two weeks apart. Levchenko passed away from a brain tumor on 6 August and Shchukin perished in the crash of a Su-26M sports plane on 18 August. This necessitated more organizational changes. Stankyavichus became deputy head of OKPKI, Zabolotskiy took Stankyavichus’ place as commander of the cosmonaut team, and Tolboyev was named his deputy, replacing Shchukin.

The deaths of Levchenko and Shchukin reduced the LII cosmonaut team to just seven men and it was decided to select a new candidate. Yuriy Yiktorovich Prikhodko passed the GMK on 21 October 1988 and got the nod from the GMYK on 25 January 1989, officially becoming a member of the team by a MAP order on 22 March 1989. He finished his OKP training in 1990.

It almost seemed as if OKPKI was under a curse when the team suffered yet another loss on 9 September 1990. Rimantas Stankyavichus was killed during a demonstration flight at an air show in Italy. His Su-27 didn’t pull out of a loop in time and crashed. Stankyavichus was buried in Kaunas in his native Lithuania.

After the break-up of the Soviet Union in late 1991, it became increasingly clear that there simply wasn’t enough room in the space budget to keep Buran alive. When the program was officially terminated in 1993, the fate of the pilot teams looked sealed. In 1995 the GMYK recommended both LII and GKNII to either reassign their Buran pilots to other programs or disband the teams. While the GKNII team was officially disbanded in late 1996, the LII team officially continued to exist, reportedly at the insistence of Igor Volk, who held out hope that the Buran program would one day be resurrected. Although the LII team was never officially disbanded, it eventually simply dissolved itself as cosmonauts began to leave OKPKI and move on in their careers. The last one to depart LII was Vladimir Tresvyatskiy in late 2004 (for further careers of the LII pilots see Appendix B).

LII’s Buran cosmonaut team can probably be regarded as the most diverse group ever selected. No fewer than six nationalities from the former Soviet Union were represented among the eleven men that made up the group. Kononenko, Prikhodko, Sheffer, Tresvyatskiy, and Zabolotskiy were Russians, while Levchenko and Volk were Ukrainians. Shchukin was a Belorussian, Stankyavichus was Lithuanian, Sultanov was a Bashkir, and Tolboyev was an Avar (a people of about 300,000 in Daghestan).