HIGH RIDE

Amidst such euphoria, Conrad’s actual docking with Agena-XI at 11:16 am seemed anticlimatic, although both astronauts were able to practice the docking-and – undocking exercise which had eluded John Young two months earlier. Pulling loose from the target, then redocking, said Conrad, was much easier in space than on the ground and the astronauts managed it in daylight and darkness. It also gave Dick Gordon the distinction of becoming the first astronaut not in a command position to perform a docking manoeuvre.

This was followed by an ignition of the Agena’s main engine to boost their orbital altitude to the highest yet achieved by humans. Facing 90 degrees away from the flight path, Conrad fired the engine to add 33 m/sec to their velocity, as a test-run, and confirmed to Young that this was ‘‘the biggest thrill we’ve had all day’’. It was but the prelude for one of their main tasks on 14 September: increasing the high point of their orbit to no less than 1,370 km. For now, however, the astronauts rested, powering down Gemini XI, tucking into their first meal and bedding down for their first night’s sleep in space.

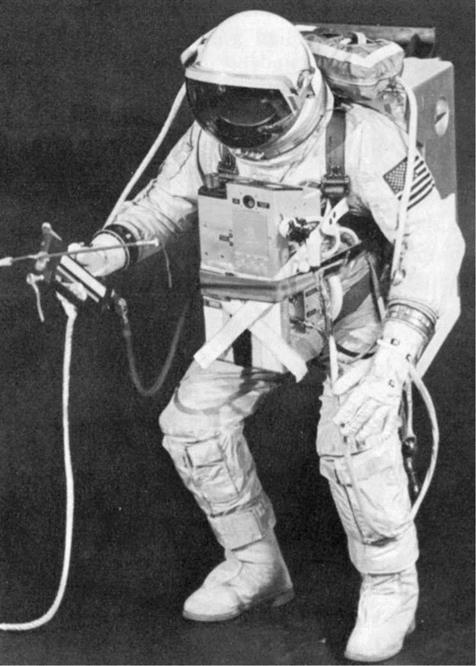

Despite its audacious nature, their only problem was a pair of dirty windows. This had, in fact, plagued each Gemini to date and even covers which could be jettisoned after launch had been little help. Capcom Al Bean told Gordon to rub half of Conrad’s window with a dry cloth during his spacewalk on 13 September. Four hours before they were scheduled to open Gemini XI’s hatch, they began preparing their suits and equipment; only to realise that, so thorough was their training, they actually needed barely 50 minutes to have all of their gear up and running.

By this point, Gordon could conceivably have gone outside, so Conrad called a halt, which left them sitting idly, fully kitted-out in their equipment. An hour later, they hooked up Gordon’s environmental support system and conducted several oxygen-flow checks, which proved a mistake because it dumped oxygen into the cabin and its excess was then vented into space. They could ill-afford this rate of oxygen loss and Conrad told Gordon to switch back to Gemini XI’s systems. Gordon, by this point uncomfortably warm, was relieved to get back onto the interior environmental control system. After all, the extravehicular system’s heat exchanger had been designed to operate in a vacuum, rather than inside a pressurised cabin.

The main problem, wrote astronaut Buzz Aldrin, actually lay in Conrad and Gordon’s impatience in skipping through the formal, six-page, hundred-plus-step sequence of donning and preparing their equipment. “As a result,’’ Aldrin related in 1989, “they upset cabin pressurisation when they checked out Gordon’s oxygen umbilical and he became overheated long before his EVA began.’’

The men considered asking Flight Director Cliff Charlesworth to let Gordon begin his EVA one orbit early, but due to issues with tracking and lighting, decided to stick with the pre-planned schedule, a decision that they would come to regret. As they prepared to fit Gordon’s sun visor onto his helmet, it proved a stubborn chore; Conrad eventually fastened one side, but could not reach over to snap the other side in place, leaving Gordon hot, bothered and in need of rest. After struggling for a few more minutes, Gordon eventually snapped the right side in place – cracking the sun visor in the process – and was thoroughly winded by the time he cranked open the hatch and stood on his seat at 9:44 am on 13 September, just two minutes past one full day into the mission. . . and precisely on time.

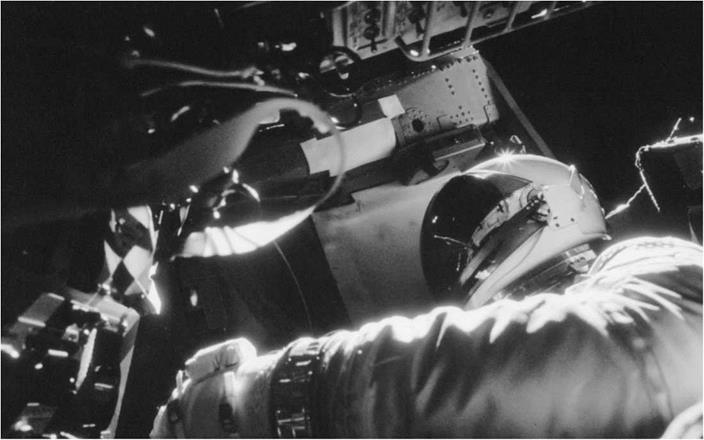

Instantly, Gordon’s exit into space was accompanied by everything else inside the cabin that was not tied down. Standing on his seat, his first activity was to deploy a handrail – a fairly easy task – after which he removed the S-9 nuclear emulsion package from outside the spacecraft and passed it in to Conrad, who stuffed it into his footwell. Next, Gordon tried to install a camera in a bracket to photograph his own movements, but this proved difficult. To resolve it, Conrad let enough of the umbilical slide through his gloved hand to let Gordon float above the camera, thump it with his fist and secure it in place.

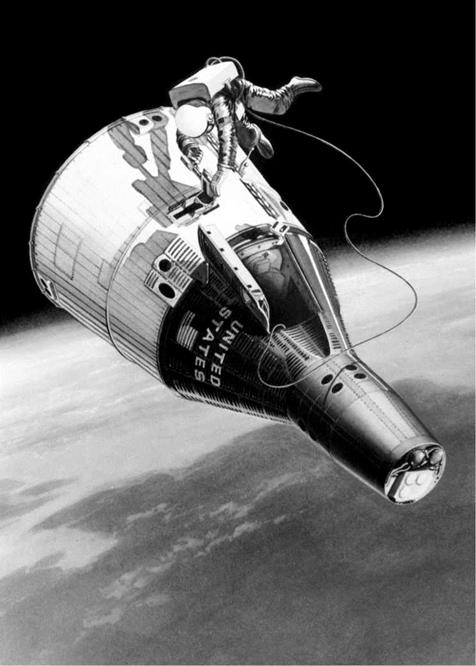

The spacewalker’s next task was to attach the 30 m Dacron tether, housed in Agena-XI’s docking collar, onto Gemini XI’s nose. As Gordon pushed himself forward, he missed his goal and drifted in an arcing path above the adaptor and around in a semi-circle, until he reached the back of the spacecraft. However, Conrad had released only a couple of metres of the 9 m umbilical, so he pulled Gordon back to the hatch to start his trek again.

At length, Gordon reached the target and grabbed some handrails to pull himself astride Gemini’s nose – prompting Conrad to yell “Ride ‘em, cowboy!” – but the exercise proved more difficult in space than it had in ground tests. Aboard the zero – G aircraft, Gordon had been able to push himself forward, straddle the Gemini’s reentry and recovery section and wedge his feet and legs between the docking adaptor and the spacecraft to hold himself in place, thus leaving his hands free to attach the tether and clamp it to the docking bar. However, in the vacuum of space, he found himself constantly fighting against his suit to keep himself from floating away; a situation rendered all the more difficult by the lack of any kind of ‘saddle’ or ‘stirrup’ to help him. All Gordon could do was hold on with one hand and try to operate the tether clamp with the other.

He struggled vigorously for six minutes, finally securing the line and setting the stage, at last, for the tethered flight experiment which would come later in the mission. Yet it was clear to Conrad that Gordon was encountering severe difficulties and the differences between EVA practice in terrestrial conditions and the real thing were profound: the spacewalker, soaked with sweat and eyes stinging, was reduced to groping his way blindly around. He tried to remove a mirror on Gemini XI’s docking adaptor, to help Conrad see him at the back of the spacecraft, but it would not move, and had no chance to wipe the windows either.

As Gordon neared the hatch, Conrad helped as much as he could, discussing procedures for getting to the spacecraft adaptor to store his zip-gun. It was obvious, though, that Gordon was exhausted: when they passed next over the Tananarive tracking station, Conrad told John Young that he had ‘‘brought Dick back in… he got so hot and sweaty, he couldn’t see’’. Unlike Gene Cernan, however, Gordon had no trouble whatsoever getting back inside Gemini XI or closing the hatch. Disappointingly, the spacewalk had lasted just 33 of its intended 107 minutes and one of its key tasks – experiment D-16, a power tool evaluation which had also evaded Dave Scott on Gemini VIII – was lost. Clearly, many of the complexities of EVA still remained to be resolved.

Having said that, Gordon’s exhaustion did not disrupt the remainder of the mission. Flight planners had learned to schedule periods of less-vigorous activity immediately after heavy workloads and Conrad and Gordon’s next task involved leisurely repacking equipment and restoring some semblance of order to the cabin. Additionally, communications with Mission Control dwindled to little more than short transmissions about spacecraft systems and medical checks, which gave them much-needed respite. Conrad test-fired a sluggish thruster, the men ate a meal and photographed the atmospheric airglow.

These moments of relatively quiet time would not last. Ahead of them lay the so – called ‘high ride’ – their Agena-assisted climb to a record-breaking altitude of 1,370 km. To prepare themselves, they donned their suits, closed their visors and secured as much cabin equipment as possible, as if in readiness for re-entry, and focused their attention on the Agena-XI. A problem quickly appeared. As they made a pre-firing

check of the target, it became clear that it was not properly accepting commands; instructions, in fact, had to be transmitted twice before they were acknowledged. Conrad expressed his concerns to Capcom Al Bean, who told them that, in fact, the Agena was responding correctly, but Gemini XI’s displays were at fault. “Heck of a time to have a… glitch like that show up,’’ Conrad grumbled, but was assured that everything remained ‘go’ for the burn.

Forty hours and 30 minutes after Gemini XI’s launch, at 2:12 am on 14 September, Conrad fired the Agena’s engine for 26 seconds, adding a blistering 279.6 m/sec to their speed. Both men were electrified by the burn. ‘‘Whoop-de-doo!’’ Conrad yelled. ‘‘[That’s] the biggest thrill of my life!’’ Like the experience of John Young and Mike Collins two months earlier, Conrad and Gordon were pushed ‘forward’ against their seat harnesses and, gradually, saw the Earth change from a vast expanse of blue and white beneath them. . . into something more planet-like, with a very distinct curvature. ‘‘I’ll tell you,’’ Conrad told the capcom in Carnarvon, Australia, ‘‘it’s go up here and the world’s round. . . you can’t believe it. . . I can see all the way from the end, around the top… about 150 degrees.’’

Beneath them, Conrad told Al Bean, the men beheld the intense and striking blues of the oceans, the sprinkling of clouds and the astonishing clarity of Africa, India and Australia. ‘‘Looking straight down,’’ he radioed, ‘‘you can see just as clearly. There’s no loss of colour and details are extremely good.’’ To cope with the adverse radiation effects of the Van Allen belts, Gemini XI’s high-apogee orbits were timed to take place over Australia, where levels were calculated to be relatively low. Over Carnarvon, indeed, Conrad reported that on-board dosimeters read barely 0.2 rads per hour. ‘‘Sounds like it’s safer up there than a chest X-ray,’’ replied Bean. In fact, Conrad added, Gemini XI experienced less radiation at 1,370 km than Young and Collins had endured in a longer period of time at 830 km.

It was at this altitude – 1,370 km high, the highest yet attained by humanity – that the flight’s imaging experiments, notably the synoptic terrain and weather photography objectives, produced some of their most stunning results. In total, Conrad and Gordon clicked more than 300 exposures and their descriptions of the sheer clarity of the eastern hemisphere filled principal investigators with excitement and anticipation.

Not until Apollo 8’s journey to the Moon in December 1968 would humans travel to higher altitudes and four decades later, Conrad and Gordon retain the record for the highest-ever Earth orbit attained by humans. ‘‘As the coupled craft soar toward their record apogee,’’ Time magazine told its readers a week after Gemini XI’s splashdown, following NASA’s release of the pictures, ‘‘the curvature of the Earth’s horizon becomes more pronounced and the Earth assumes an unmistakably globelike shape. Though the pictures are sharp and show geological features plainly, the Earth seems devoid of life; it offers no visible evidence of its teeming population, its great cities, its bridges or its dams.’’

Two orbits later, on their 26th revolution, as Gemini XI passed over the United States, Conrad again fired the Agena’s engine for 23 seconds to lower their apogee to 304 km and reduce their speed by 280 m/sec. After a bite to eat, at 8:49 am, Gordon opened his hatch, high above Madagascar, for his second EVA. This time, he stood

|

|

on the ‘floor’ of Gemini Xf, poked his helmeted head outside and watched the sunset. Secured by a short tether, he could at least use both hands to mount cameras easily in their brackets and remained ‘outside’ for no less than two full hours. ‘‘Most enjoyable’’ was his summary of the stand-up EVA and, indeed, flight surgeons commented that from the biosensor data, it was uneventful.

Whilst outside, Gordon experienced two nighttime passes, photographing several star fields with the S-13 ultraviolet camera and his view was so unimpaired that he was able to coach Conrad about which way to direct Gemini Xf. Although the Agena’s stabilisation proved somewhat erratic, the linked vehicles remained sufficiently stable to yield excellent results in about a third of Gordon’s photographs. fndeed, as the spacecraft passed over the United States, the skies were so clear that both men were able to marvel at the view of Houston. Drifting across Florida, then out over the Atlantic, Gordon suddenly broke the silence to tell Conrad that he had just fallen asleep outside. He was not the only one: Conrad, too, had dozed off inside the spacecraft.

‘‘That’s a first,’’ radioed John Young. ‘‘First time sleeping in a vacuum.’’

Returning inside after two hours and eight minutes, Gordon’s exhaustion was not, like that of Cernan, caused by over-exertion and battling against his rigid suit, but instead by sheer concentration on his tasks.

Their next step was the tethered vehicle exercise, which could be attempted by two different means. One of these assumed the position of a ‘pole’, always pointing towards Earth’s centre – a so-called ‘gravity gradient’ attitude – in which Conrad and Gordon would have backed their spacecraft out of the Agena’s docking cone slowly until the 30 m tether became taut. ff properly positioned, a slight thrust of just 3 cm/sec would have kept the tether taut and the joined ‘pole’ would have drifted serenely around the globe, each spacecraft maintaining the same relative position and attitude.

Should this have been unsuccessful, the men were tasked with trying a ‘spin-up’, or ‘rotating’, mode, a technique studied by McDonnell engineers. fn this case, after physical undocking, Conrad would fire Gemini Xf’s thrusters to induce a rotation of one degree per second and as the tethered pair circled Earth, their mutual centre-of – gravity would lie at a specific point on the tether, around which they would do a slow, continuous cartwheel. Centrifugal force would, it was theorised, keep the tether taut and the two spacecraft apart, with the tether itself providing centripetal force to keep them both in equilibrium.

Over Hawaii, Conrad and Gordon separated from the Agena and began the cautious attempt to start the gravity gradient demonstration. There was enough initial tension in the tether to upset the target and cause the Gemini to move to the ‘right’ – towards the Agena’s docking adaptor – and Conrad quickly adjusted his motion. Then, as he backed away, the tether stuck, probably in the stowage container, when just 15m had been released. Conrad pulsed the OAMS thrusters to free the tether, but it quickly became hung up on a patch of Velcro and he was forced to shift Gemini Xf out of vertical alignment to peel the tether off the Velcro pad. This disturbed the Agena again and there still remained about 3 m of tether to be pulled out.

On the ground, engineers began to worry. The Agena should have taken around seven minutes to stabilise itself; when it took longer, they began to suspect that something was wrong with its attitude-control system and opted to abandon the gravity gradient attempt and adopt the ‘spin-up’ mode instead. However, when Conrad tried to initiate the rotation, another problem arose when he could not get the tether taut; it seemed to rotate counter-clockwise. ‘‘This tether’s doing something I never thought it would do,’’ he told John Young. ‘‘It’s like the Agena and I have a skip rope between us and it’s rotating and making a big loop… Man, have we got a weird phenomenon going on here!’’

Although the spinning line was curved, it also had tension, and for several minutes Conrad and Gordon jockeyed Gemini XI’s thrusters to straighten the arc. Eventually, the tether straightened and became taut and Conrad rolled the spacecraft and fired the thrusters to begin the slow cartwheeling motion. At first, it seemed that he had ‘stretched’ the tether, which had a big loop in it, but steadily, as both astronauts gritted their teeth, centrifugal force took over and it smoothed out. A 38- degree-per-minute rotation rate was obtained and remained steady throughout a nightside orbital pass.

Moving into dawn, they were asked by the Hawaii capcom to accelerate their spin-up rate and, with some reluctance, Conrad agreed. Suddenly, Gordon shouted ‘‘Oh, look at the slack! It’s going to jerk this thing to heck!’’ When the added acceleration started, the tether tightened, then relaxed, causing a ‘slingshot’ effect which seesawed both astronauts up to 60 degrees in pitch. In response, Conrad steadied the spacecraft and, to his surprise, the Agena stabilised itself. Their rotation rate checked out at 55 degrees per minute and they were able to test for a tiny amount of artificial gravity: when they placed a camera against Gemini XI’s instrument panel and let go, it moved in a straight line to the rear of the cockpit and parallel to the direction of the tether. Neither of the astronauts, however, felt any physiological effect of gravity. After three hours of docked operations, they jettisoned Gemini XI’s docking bar and pulled away.

Despite understandable disappointment that the gravity gradient technique could not be fully demonstrated, the spin-up mode at least proved that station-keeping could be done economically. After undocking, Conrad originally intended to decrease his spacecraft’s speed, allowing him to pull ahead of the Agena, but was advised instead to prepare for a ‘coincident-orbit’ rendezvous, whereby he would follow the target by 28 km in its exact orbital path. This would demonstrate their ability to station-keep at very long range with little fuel usage.

As a result of the plan change, Gemini XI’s separation manoeuvre was adjusted; instead of a retrograde firing, Conrad and Gordon ‘added’ speed and height to their orbit, such that Agena-XI passed ‘beneath’ and in front of them. Next, they fired their OAMS to place themselves in the same (coincident) orbit as the Agena, trailing it. Three-quarters of a revolution around Earth, Conrad decreased his ‘forward’ speed and, as expected, Gemini XI dropped into the Agena’s orbital lane, 30 km behind it, with no relative velocity between the pair.

At the same time, the men set to work on another of their scientific tasks: the night-image intensification experiment (D-15), which sought to evaluate the usefulness of equipment which scanned ground-based objects onto the instrument panel. Conrad aimed Gemini XI at specific targets, including towns and cities, cloud formations, lightning flashes, horizons and stars, airglow, coastlines and peninsulas, while Gordon described his view on the monitor into a tape recorder. Unfortunately, Conrad’s dirty window prevented him from seeing much and, indeed, the glow from the monitor meant that he never became adequately dark-adapted. Nonetheless, the men returned with astonishing recollections, including the lights of Calcutta, whose shape almost exactly paralleled official maps of the city.

Turning their attention back to the Agena, they asked ground controllers on the Rose Knot Victor tracking ship how far they were from the target and were advised that their distance remained 30 km, closing very slowly. A second rendezvous, beginning at 3:09 am on 15 September, was near-perfect: Conrad tilted Gemini XI’s nose 53 degrees above level flight and fired the forward thrusters. This placed them in a lower orbit than the Agena, ready to catch up with it, and they took some time to tend to their experiments. An hour later, Conrad fired the aft thrusters to raise his spacecraft’s orbit, then began to brake Gemini XI until he finally reported that he was on-station and steady with the target once more. Twelve minutes later, they executed a separation burn from the Agena for the final time. By this stage, the success had been so great that they could afford to be jocular; Conrad even asking Flight Director Glynn Lunney to send up a tanker to refuel them for more rendezvous.

The ambitious mission came to a close with a fully-automatic re-entry; unlike previous returns, in which the command pilots had flown their spacecraft down from 120 km using the Gemini’s offset centre-of-gravity to generate lift for changes in direction, Conrad would not use his hand controller in conjunction with computer directions. Gemini XI would follow computer commands automatically, a technique derisively nicknamed ‘chimp mode’ by the astronauts. Seventy hours and 41 minutes after launch, at 8:24 am on 15 September, partway through their 44th orbit, the retrorockets fired. Conrad disengaged his hand controller and put the system onto autopilot. This performed admirably and Gemini XI splashed down safely, within 4.6 km of the helicopter carrier Guam, at 8:59 am.

Half an hour after hitting the Atlantic, Conrad and Gordon were aboard the Guam, almost exactly three days since leaving Cape Kennedy. Rendezvous, docking and their record-breaking altitude boost had been, all three, successfully achieved; yet EVA issues remained. Buzz Aldrin, in training to conduct his own excursion on Gemini XII in November, became one of the first astronauts to work underwater in ‘neutral buoyancy’ to prepare himself for working in space. His was supposed to be one of the most complex to date, completing what Gene Cernan had been unable to do in June: flying the Air Force’s AMU backpack. Ironically, had the AMU flown on Gemini XII, Aldrin would not, and almost certainly he would not have gone on to become the second man on the Moon.