THE DOUGLAS MODEL 671

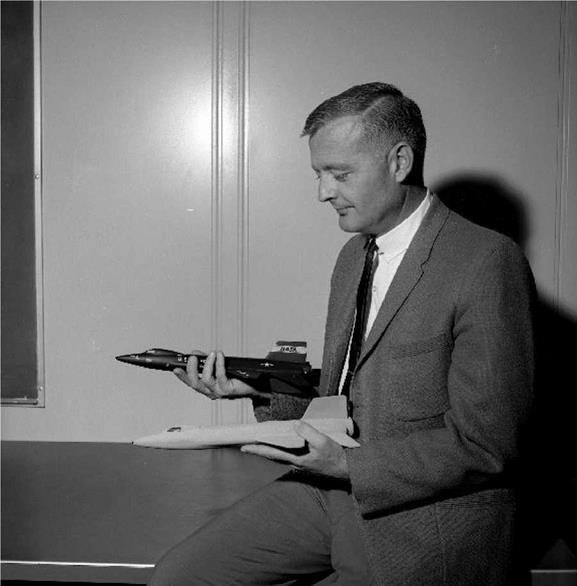

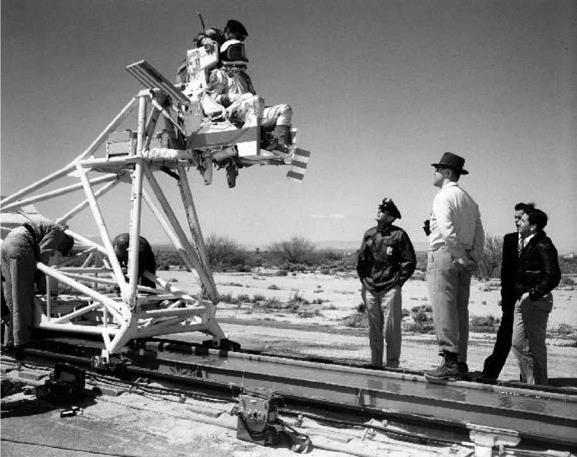

The "High Altitude and High Speed Study" by the El Segundo Division of the Douglas Aircraft Company had been funded by the ONR as a follow-on to the D-558 research aircraft that loosely competed with the Air Force X-1 series. Duane N. Morris led the study under the direction of the chief of the Aerodynamic Section, Kermit E. Van Every. Although the concept is generally mentioned—briefly—in most histories of the X-15, what is almost always overlooked is how insightful it was regarding many of the challenges that would be experienced by the X-15 a few years later.129

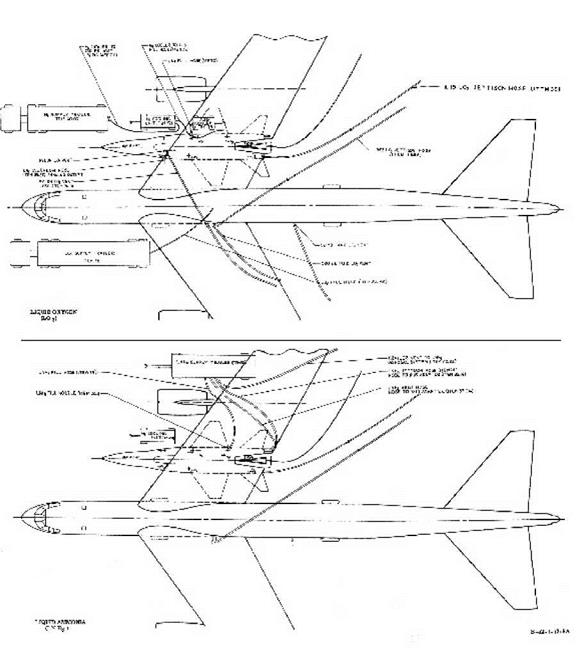

By the spring of 1954, when the X-15 approval process began, Douglas had not accomplished a detailed design for a new airplane, but recognized many of the same problems as John Becker and the researchers at Langley. The Douglas engineers also examined peripheral subjects—carrier aircraft, landing locations, etc.—that the initial Langley studies did not address in any detail.121

One interesting aspect of the Douglas Model 671 was that the contractor and the Navy had agreed that the aircraft was to have two mission profiles: high speed and high altitude (with the emphasis on the latter). This was in distinct contrast to the ongoing Langley studies that eventually led to the X-15. Although the Becker team at Langley was interested in research outside the sensible atmosphere, there was a great deal of skepticism on the part of others in the NACA and the Air Force. Douglas did not have this problem—the ONR strongly supported potential high-altitude research.

Excepting the Langley work, the Douglas study was probably the first serious attempt to define a hypersonic research airplane. Most of the other companies investigating hypersonics were oriented toward producing operational vehicles, such as the ICBMs and BoMi. Because of this, they usually concentrated on a different set of problems, frequently at the expense of a basic understanding of the challenges of hypersonic flight. The introduction from the Douglas study provides a good background:11221

The purpose of the high altitude study…is to establish the feasibility of extending human flight boundaries to extreme altitudes, and to investigate the problems connected with the design of an airplane for such flights.

The project is partially a result of man’s eternal desire to go higher, faster, or further than he did last year. Of far more importance, however, is the experience gained in the design of aircraft for high-speed, high-altitude flight, the collection of basic information on the upper atmosphere, and the evaluation of human tolerance and adaptation to the conditions of flight at extreme altitudes and speeds.

The design of an airplane for such a purpose cannot be based on standard procedures, nor necessarily even on extrapolation of present research airplane designs. Most of the major problems are entirely new, such as carrying a pilot into regions of the atmosphere where the physiological dangers are completely unknown, and providing him with a safe return to Earth. The type of flight resembles those of hypersonic, long-range, guided missiles currently under study, with all of their complications plus the additional problems of carrying a man and landing in a proper manner.

The study consists of a first approach to the design of a high-altitude airplane. It attempts to outline most of the major problems and to indicate some tentative solutions. As with any preliminary investigation into an unknown regime, it is doubtful that adequate solutions have been presented to every problem of high-altitude flight, or even that all of the problems have been considered. It would certainly appear, however, that the major difficulties are not insurmountable.

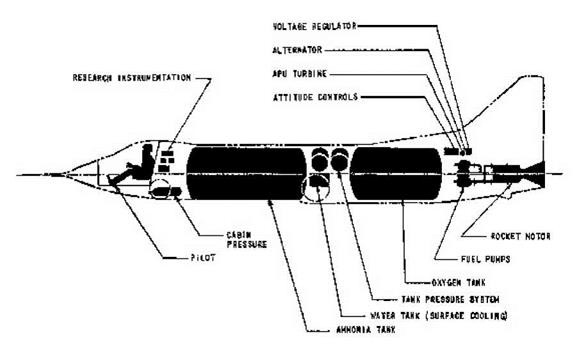

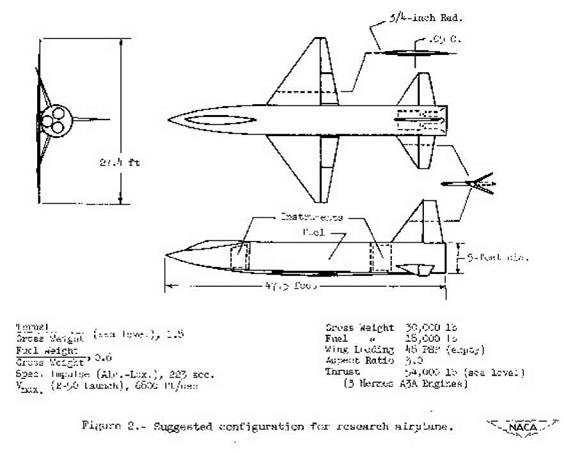

The Model 671 was 41.25 feet long (47.00 feet with the pitot boom), spanned only 18 feet with 81 square feet of area, and had an all-up weight of 22,200 pounds. In many respects, it showed an obvious family lineage to the previous D-558s. The fuselage consisted of a set of integral propellant tanks, and dive brakes were located on each side aft, as in most contemporary fighters.

A conventional configuration was deliberately chosen for the study, and no benefits have yet been discovered for any unconventional arrangement. Actually, for the prime objective of attaining very high altitudes, the general shape of the airplane is relatively unimportant. Stability and control must be provided, and it must be possible to create sufficient lift for the pullout and for landing; but, in contrast to the usual airplane design, the reduction of drag is not a critical problem and high drag is to some extent beneficial. The planform of the wing is unimportant from an aerodynamic standpoint at the higher supersonic Mach numbers. Therefore, it was possible to select the planform based on weight and structure and landing conditions. These considerations led to the choice of an essentially unswept wing of moderate taper and aspect ratio.11231

The empennage of the Model 671 was completely conventional and looked much like that of the Mach 2 D-558-2 that preceded it. However, Douglas realized that the design of the stabilizers was one of the greater unknowns of the design. "The tail surfaces are of proper size for stability at the lower supersonic Mach numbers, but there is some question of their adequacy at very high supersonic speeds. Further experimental data in this speed range are necessary before modifications are attempted. In addition, it may be possible to accept a certain amount of instability with the proper automatic servo controls." Unlike the Becker group, Douglas did not have access to a hypersonic wind tunnel.[124]

Nevertheless, preliminary investigations at Douglas indicated that "extremely large tail surfaces, approaching the wing area in size, are required to provide complete stability at the maximum Mach number of about 7." Engineers investigated several methods to improve stability, with the most obvious being to increase the size of the vertical stabilizer. However, placing additional area above the fuselage might introduce lateral directional dynamic stability problems "due to an unfavorable inclination in the principle axis of inertia and the large aerodynamic rolling moment due to sideslip (the dihedral effect)." The preferred arrangement was to add a ventral stabilizer and keep the ventral and dorsal units as symmetrical as possible. However, Douglas recognized that a large ventral stabilizer would present difficulties in ground handling and during landing. The engineers proposed that the fin should be folded on the ground, unfold after takeoff, and then be jettisoned just before touchdown. Alternately, Douglas believed that some sort of autopilot could be devised that would allow the use of more conventional-sized control surfaces.11251

Douglas conducted an evaluation of available power plants, and reached much the same conclusions the X-15 program would eventually come to. The desired engine should produce about 50,000 lbf with a propellant consumption of about 200 pounds per second. The only powerplant that met the requirements was the Reaction Motors XLR30-RM-2 rocket engine, which used liquid oxygen and anhydrous ammonia propellants. The high (245 lbf-sec/lbm) specific impulse (thrust per fuel consumption) was desirable since it provided "a maximum amount of energy for a given quantity of propellant." The high density of the propellants allowed a smaller tank size for a given propellant weight, allowing a smaller airframe. However, the researchers worried that since the original application was a missile, it would be difficult to make the engine safe enough for a manned aircraft.-11261

Douglas had some interesting observations about drag and power-to-weight ratios:11271

The function of drag in the overall performance must be reconsidered. The effect of drag is practically negligible in the power-on ascending phase of flight (for a high altitude launch), because of the very large thrust to weight ratio. Throughout the vacuum trajectory, the aerodynamic shape of the airplane is completely unimportant. During the descending phase of flight, a large drag is very beneficial in aiding in the pullout, and the highest possible drag is desired within the limits of the pilot and the structure. In fact, during the pullout it has been assumed that drag brakes would be extended in order to decelerate as soon as possible. However, because of excessive decelerative forces acting upon the pilot, it is necessary to gradually retract the brakes as denser air is entered, until they are fully retracted in the later stages of flight.

For a given propulsion unit (i. e., fixed thrust and fuel consumption), the overall performance of the present design [Model 671] is much more dependent upon the ratio of fuel weight to gross weight that it is upon the minimum drag or the optimum lift-drag ratio. Even though the fuel is expended in approximately the first 75 seconds of flight (a relatively small fraction of the total flight time), the ultimate performance as measured by the maximum altitude is affected to a great extent by small changes in the fuel to gross weight ratio. As an example, an increase in fuel weight/gross weight from 0.65 to 0.70 results in an increase in peak altitude of about 35% for a typical vertical flight trajectory, other parameters remaining

constant.

To better understand the nature of the various propellants then available for rocket engines, engineers reviewed numerous reports by the Caltech Jet Propulsion Laboratory, the NACA, and RAND. Only two oxidizers—oxygen and either red fuming or white fuming nitric acid-seemed to offer any increase in performance. Douglas was seeking better propellants than the liquid oxygen and alcohol used in the Reaction Motors LR8, effectively ruling out nitric acid since it was less dense than oxygen. The available fuels were alcohol (CH3OH or C2H5OH), anhydrous ammonia (NH3), hydrazine (N2H4), and gasoline. Alcohol offered no improvement, and hydrazine was too expensive and too difficult to handle safely, narrowing the choice to anhydrous ammonia and gasoline. Interestingly, Douglas ruled out liquid hydrogen because "on the basis of density, hydrogen is seen to be a very poor fuel." It would be 20 years before the Centaur upper stage would prove them wrong.-1128!

|

|

The Douglas Model D-671 was a proposed follow-on to the successful D-558 series of research airplanes developed under Navy auspices and flown at the High-Speed Flight Station. Preliminary investigation showed the concept was capable of roughly the same performance as the eventual X-15, but the Navy declined further development of the Douglas concept when it joined the X-15 program in late 1954. (Douglas Aircraft Company)

An auxiliary power unit (APU) rated at about 8 horsepower was necessary to support the electrical requirements of the instruments, controls, and radio. Investigation showed that the lightest alternative would be a small turbine generator using hydrogen peroxide or ethylene oxide monopropellant. The Walter Kidde Company and American Machine and Foundry Company were developing units that could satisfy the requirements. Both companies claimed they could develop a 10-horsepower hydrogen peroxide unit that weighed about 56 pounds, including propellants for 30-horsepower-minutes. Given the trouble of the future X-15 APUs, perhaps North American should have better reviewed this part of the Douglas report.-129!

to obtain reasonable estimates." They continued that "it is unfortunate that the largest contributing factor to the high temperatures of reentry, the convective heating from the boundary layer, is the one about which there is the least knowledge." Nevertheless, they took some educated guesses.[130]

The expected average heat level approached 1,400°F, with peak temperatures above 3,300°F on the wing leading edges and nose. Douglas believed "it would be impossible to design a structure for this temperature [1,400°F] which satisfies both the stress and weight requirements…." To overcome this, engineers recommended the use of some as-yet-undeveloped "good insulating material" with a density of 20 pounds per cubic foot and an insulating value of 0.20 British Thermal Units (Btu) per pound. For the purposes of the study, Douglas used a C – 110M titanium – alloy structure and skin protected by an unspecified ablative coating. Water sprayed into stainless-steel sections of the wing leading edges and nose area allowed superheated steam to remove unwanted heat, keeping these areas below their melting points. Alternately, Douglas investigated injecting cool gas (bottled oxygen) into the boundary layer to provide cooling. The study noted, however, that "none of these systems have yet been proven by practical application." The designers protected only a few areas, such as the cockpit, with batt insulation since the study assumed no heat transfer to the interior of the aircraft.-1131

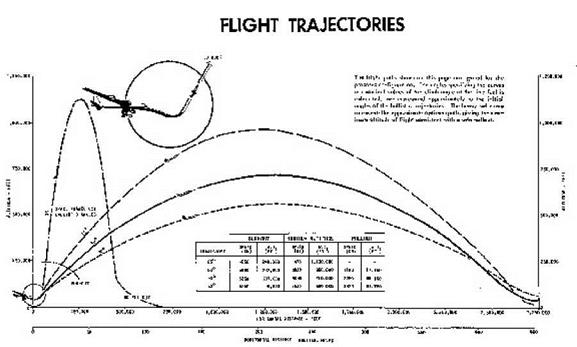

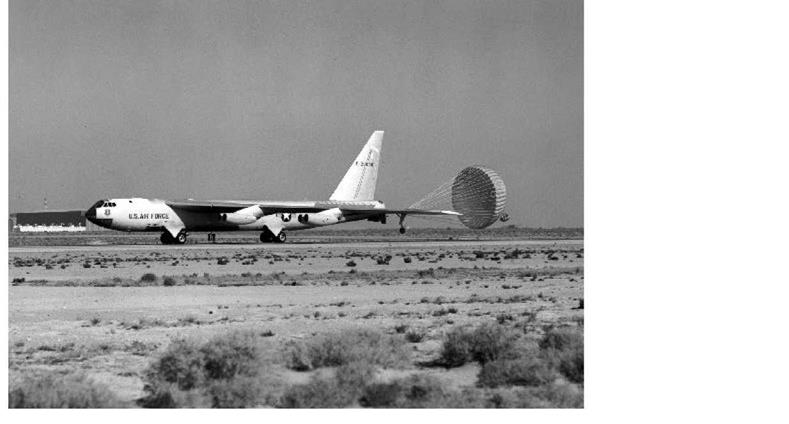

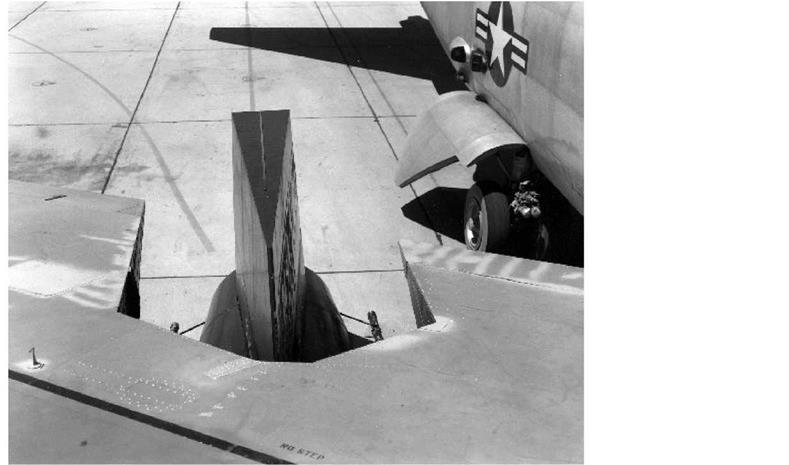

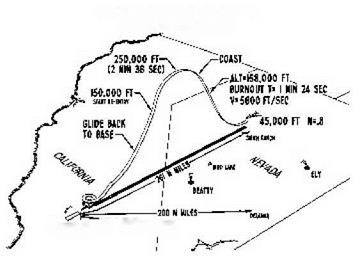

Not surprisingly, Douglas chose an air-launch configuration. What is interesting is that the launch parameters were Mach 0.75 at 40,000 feet—well beyond the capabilities of anything except the Boeing B-52, which was still in the early stages of testing. Douglas summarized the need for an air launch by noting that "[t]he performance is increased, but the prime reason for the high altitude launch is the added safety which 40,000 feet of altitude gives the pilot when he takes over under his own rocket power." Trade studies conducted by Douglas indicated that an increase in launch altitude from sea level to 40,000 feet would result in a 200,000-foot increment in maximum altitude on a typical high-altitude mission. Additional benefits of a higher launch altitude diminished rapidly above 40,000 feet since most of the initial improvement was due to decreasing air density.-132

|

|

interested in the high-altitude research and at one point estimated the D-671 could reach 1,000,000 feet altitude. Although Douglas only conducted a minimal amount of research into the concept before it was cancelled, they foresaw many of the issues that would ultimately confront the X-15 development effort. (Douglas Aircraft Company)

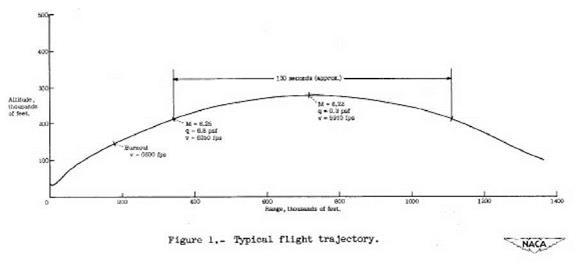

Engineers spent a great deal of time studying possible flight paths, but "no attempt has been made in the present study to determine an absolute optimum flight path, because of the large number of variables involved." The designers noted that the airframe and propulsion systems could theoretically support a maximum altitude in excess of 1,130,000 feet; however, based on a conservative pullout altitude of 30,000 feet, the vehicle was more realistically limited to 770,000 feet. The pullout altitude (and the limiting decelerations, which were really the issue) was "directly traceable to the single limiting factor of the presence of a human pilot." The 770,000-foot, 84- degree profile resulted in a 10-g pullout maneuver, about the then-known limit of human tolerance.-1133!

Some thought was given to using a "braking thrust," which would allow a small amount of propellant to be saved and used during reentry. Either a mechanical thrust reverser would be installed on the rocket engine, or the airplane would reenter tail-first. This technique would have allowed slightly higher flights by reducing the stresses imposed by the pullout maneuver, although less propellant would be available for the ascent. The designers did not pursue this concept since entering tail-first involved undesirable risks, and the mechanical complexity of a thrust reverser seemed unnecessary, at least initially.!134!

The theoretical maximum performance was 6,150 mph and 190,000 feet for the speed profile, and 5,200 mph and 1,130,000 feet for the altitude profile (but limited, as discussed above). Landings would be made at Edwards AFB because of its "long runways and considerable latitude in the choice of direction and position of touchdown." The study noted that there would be little opportunity to control either the range or the heading by any appreciable amount after engine burnout. "Since the airplane must land without power at a specified landing site, it is obvious that it must be aimed toward the landing site at launch." Douglas estimated that a misalignment of 5 degrees in azimuth at burnout would result in a lateral miss of over 45 miles.!133!

One of the concerns expressed by Douglas was that "rocket thrust will not be sufficiently reproducible from flight to flight, either in magnitude or in alignment." Engineers estimated a thrust misalignment of less than one-half of a degree could impart 500 pounds of side force on the aircraft, causing it to go significantly off course. Researchers investigated several possible solutions to thrust misalignment, including using a larger rudder, using the auxiliary reaction control system, installing movable vanes in the exhaust,!136! performing gas separation in the nozzle,-!137! and mounting the rocket engine on a gimbal. All of these methods contained various problems or unknowns that caused the engineers to reject them. Further consideration showed that thrust misalignment was largely a non-issue since early low-speed flights would uncover any deficiencies, allowing engineers to correct them prior to beginning high-speed flights.!138!

The estimated landing speed was 213 mph, with a stall speed of 177 mph. Engineers accepted this relatively high speed "given the experimental nature of the aircraft and the high skill level of the pilots that will be flying it." The study noted that the slower speeds were possible if high-lift leading-edge devices were used or the area of the wing was increased. However, the increased weight and/or the resulting complications in the leading-edge cooling system appeared to make these changes undesirable.!139!

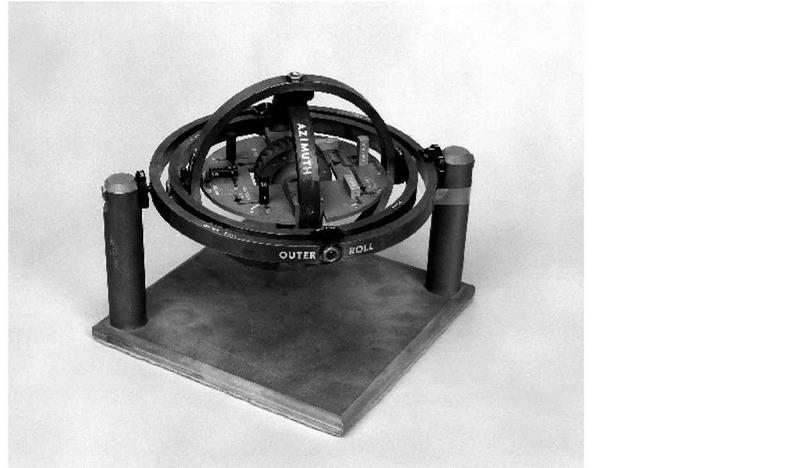

The high-altitude profile would use "flywheels, gyroscopes, or small auxiliary jets" for directional control outside the atmosphere, with Douglas favoring hydrogen peroxide jets in the wing tips and at the rear of the fuselage. Flywheels were rejected because they were too complex (for a three- axis system), and gyroscopes were too heavy. Each of the hydrogen peroxide thrusters would generate about 100 lbf and use 1 pound of propellant per second of operation. The engineers arbitrarily assumed that a 25-pound supply of propellant was required since no data existed on potential usage during flight. A catalyst turned the liquid hydrogen peroxide to steam at 400-psi pressure.-114^

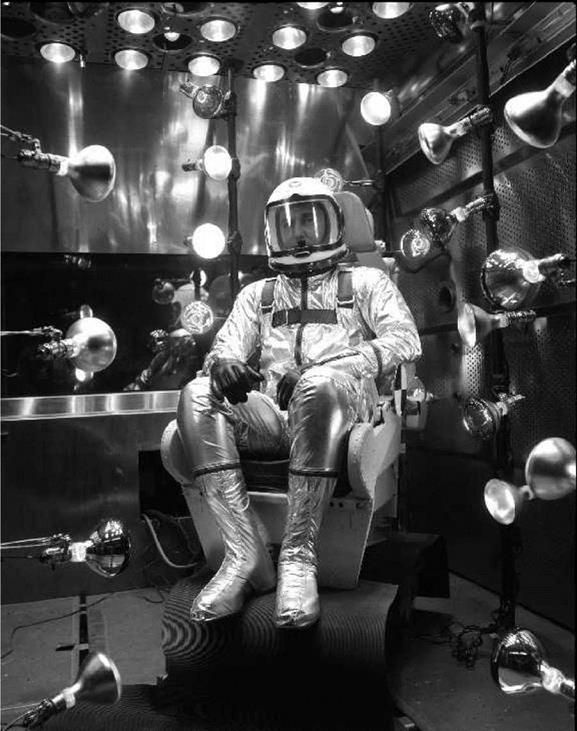

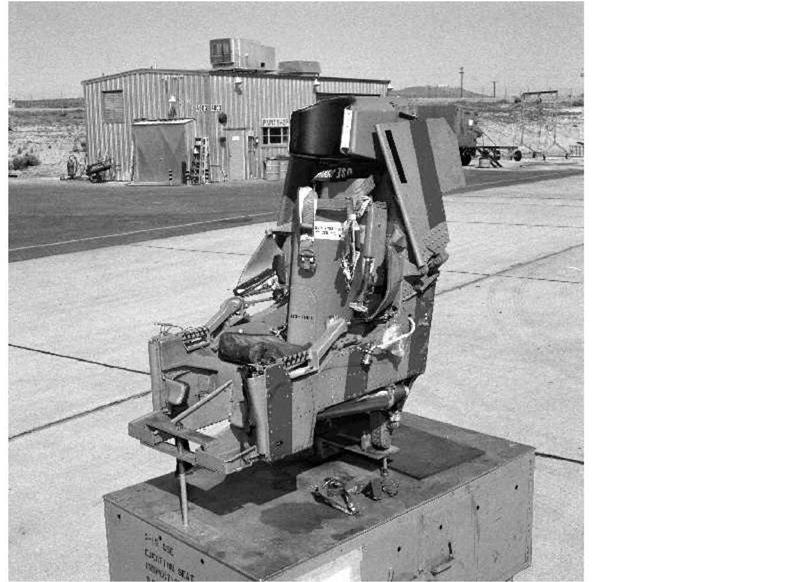

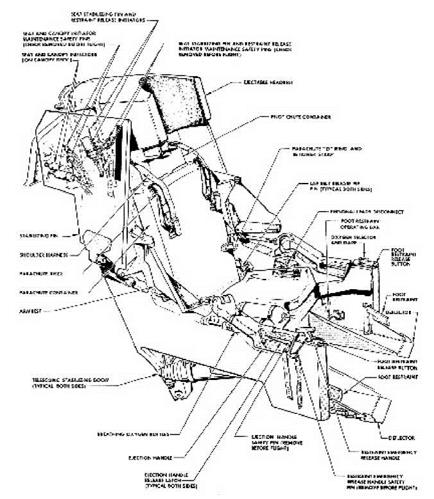

The projected performance of the airplane caused Douglas engineers to investigate escape capsules for the pilot: "Because of the high altitude and high speed performance of the aircraft, it is believed that all ordinary bailout procedures, such as escape chutes and ejection seats, are of no value to the pilot." At the time, Douglas believed that ejection seats were only "suitable up to a Mach number of approximately one at sea level, with somewhat higher speeds being safe at higher altitudes." Instead, the engineers decided to jettison the entire forward section of the fuselage, including the pilot’s compartment, much like the Bell X-2. The total weight penalty for the capsule was about 150 pounds. The study dismissed pressure suits, stating that "it is very doubtful that sufficient pressurization equipment could be carried by the pilot during…ejection… to sustain suit pressurization from the maximum altitude to a safety zone within the earth’s lower atmosphere." Douglas stated flatly that "an ejection seat or other ordinary bailout techniques will be inadequate in view of the problem of high speeds and high altitudes." Scott Crossfield would later disagree.-1141!

In order to withstand the reentry temperatures, the cockpit windscreen used two 0.5-inch layers of quartz with a 0.25-inch vented air gap between them. This would keep the inner windscreen below 200°F. A thin sheet of treated glass placed inside the inner quartz layer reduced ultraviolet and other harmful radiation. Although the potential dangers of radiation above the atmosphere were largely unknown, Douglas predicted that little harm would come from the short flights (a few minutes) envisioned for the D-558-3. However, "proper precautions to prevent any one pilot from making too many successive flights in a weeks or months time interval should be taken….’,[142]

One of the technical innovations of the eventual X-15 program was the "ball nose" that sensed the angle of attack and angle of sideslip during high-speed and high-altitude flight. The Douglas study foresaw the need for a new pitch and yaw sensor "capable of sensing exceedingly low forces or pressures, but capable of withstanding the maximum dynamic pressures encountered during the complete pullout." However, Douglas thought that "the instrument need not be precise, for it is only to serve as a guide for pointing the nose into the wind at heights where a pilot might otherwise lose all sense of orientation." Four possible solutions emerged:[143]

and a set of pilot displays. This system was even smaller and required less power and cooling than the redesigned FRC-66 analog system. In addition, the X-20 IFDS could automatically erect itself and perform an alignment cycle on the ground while the NB-52 was taxiing, and completely eliminated the need for information from the N-1 compass and APN-81 Doppler radar on the NB – 52. This made it somewhat easier to pilot the carrier aircraft as the X-15 approached the launch position; the APN-81 took 90 seconds to stabilize after even a gentle turn, requiring the NB-52 pilot to think well ahead of the drop time. To improve accuracy, however, the IFDS altitude loop was synched to the NB-52 pressure altimeter until 1 minute before launch.-1167

and a set of pilot displays. This system was even smaller and required less power and cooling than the redesigned FRC-66 analog system. In addition, the X-20 IFDS could automatically erect itself and perform an alignment cycle on the ground while the NB-52 was taxiing, and completely eliminated the need for information from the N-1 compass and APN-81 Doppler radar on the NB – 52. This made it somewhat easier to pilot the carrier aircraft as the X-15 approached the launch position; the APN-81 took 90 seconds to stabilize after even a gentle turn, requiring the NB-52 pilot to think well ahead of the drop time. To improve accuracy, however, the IFDS altitude loop was synched to the NB-52 pressure altimeter until 1 minute before launch.-1167