THE GENESIS OF THE X-15

The first hypersonic vehicles in flight were missiles, not airplanes. On February 24, 1949, a WAC Corporal rocket mounted on top of a captured German V-2 boost vehicle was fired from the White Sands Proving Ground in New Mexico, reaching an altitude of 244 miles and a velocity of 5,150 miles per hour. After nosing over, the WAC Corporal careened back into the atmosphere at over 5,000 miles per hour, becoming the first object of human origin to achieve hypersonic flight. In this same period, a hypersonic wind tunnel capable of Mach 7, with an 11- by 11-inch cross-section test section, went into operation on November 26, 1947, the brainchild of NACA Langley researcher John Becker. For three years following its first run, this wind tunnel was the only hypersonic wind tunnel in the United States. It later provided key data for the design of the X-15.

The real genesis of the X-15, however, was human thinking, not test facilities. On January 8, 1952, Robert Woods of Bell Aircraft sent a letter to the NACA Committee on Aerodynamics in which he proposed that the committee undertake the study of basic problems in hypersonic and space flight. At that time, several X-airplanes were already probing the mysteries of supersonic flight: the X-1, X-1A, and X-2. Accompanying Woods’s letter was a document from his colleague at Bell, Dr. Walter Dornberger, outlining the development of a hypersonic research airplane capable of Mach 6 and reaching an altitude of 75 miles. By June 1952, the NACA Committee on Aerodynamics recommended that the NACA expand its efforts to study the problems of hypersonic manned and unmanned flight, covering the Mach number range from 4 to 10.

After two more years of deliberation, the committee passed a resolution during its October 1954 meeting recommending the construction of a hypersonic research airplane. Among the members of this committee were Walter Williams and Scott Crossfield, who would later play strong roles in the X-15 program. Kelly Johnson, who not only was the Lockheed representative to the committee but was considered to be the country’s most famous airplane designer, opposed any extension of the manned research program, arguing that to date

the research airplane program was “generally unsatisfactory” and had not contributed to the practical design of tactical aircraft. Johnson was the only dissenter; he later appended a minority opinion to the majority report. The spectacular success of the X-15 program and the volumes of hypersonic data it contributed to the design of the Space Shuttle later proved Johnson wrong. The X-15 program was launched.

the research airplane program was “generally unsatisfactory” and had not contributed to the practical design of tactical aircraft. Johnson was the only dissenter; he later appended a minority opinion to the majority report. The spectacular success of the X-15 program and the volumes of hypersonic data it contributed to the design of the Space Shuttle later proved Johnson wrong. The X-15 program was launched.

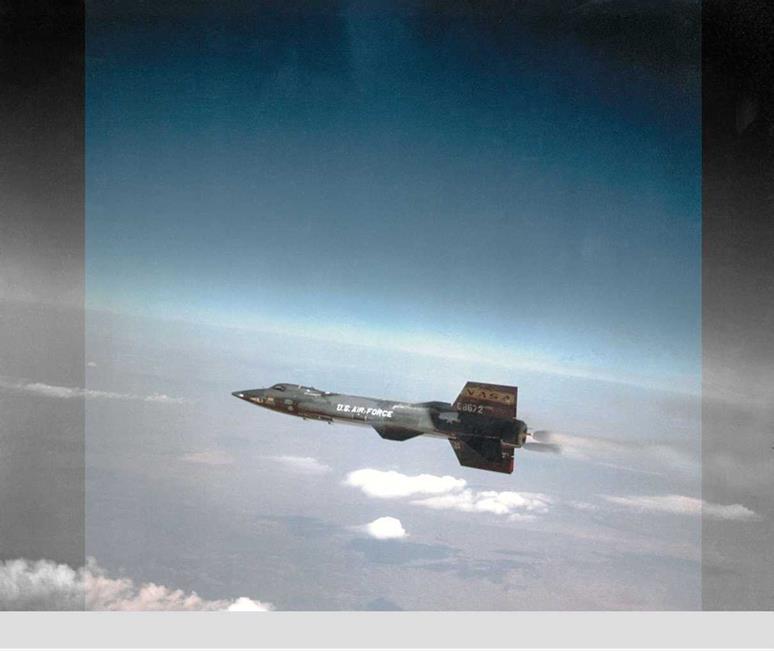

The X-15 was designed to be, purely and simply, a research vehicle to provide aerodynamic, flight dynamic, and structural response data

|

|

![]()

for use in the development of future manned hypersonic vehicles, such as the Space Shuttle.

No hypersonic wind tunnels, past or present, can provide accurate data for the design of a full – scale hypersonic airplane. The frontiers of flight today are the same as they were in the 1950s: the exploration of hypersonic flight. The X-15 will ultimately be viewed as the Wright Flyer of hypersonic airplanes.

The X-15 was the third of a series of research aircraft that were designed specifically to obtain aerodynamic data, beginning with the Bell X-1, the first piloted airplane to fly faster than the speed of sound. The X-1 investigated aircraft behavior primarily in the transonic flight regime. The transonic regime is generally considered to be flight between Mach 0.8 and about 1.3. It begins when air is accelerated to Mach 1 at any local location on the airplane, usually when the airplane is flying at the subsonic airspeed of about Mach 0.8 The second research airplane, the Bell X-1A, investigated supersonic flight to a Mach number of 2.44. This was followed by the Bell X-2, a swept-wing aircraft of stainless steel construction designed to investigate the effects of sweepback and aerodynamic heating to a Mach number of 3.2.

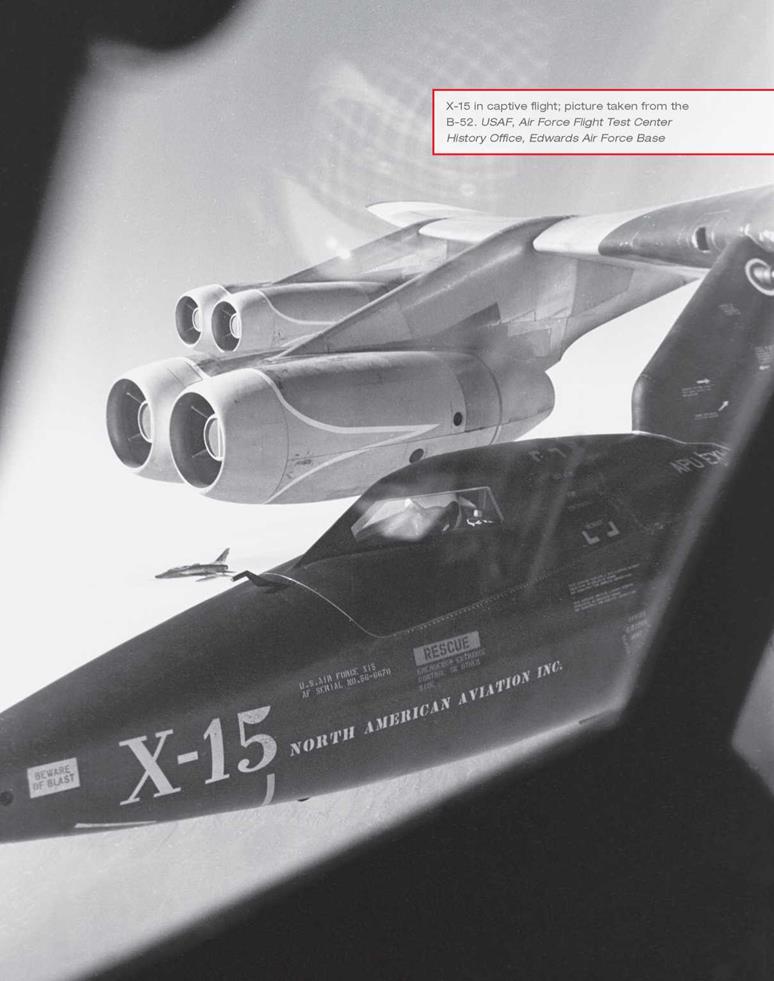

Each of these aircraft, like the later X-15, was rocket-powered and carried aloft to be dropped at an altitude of about 30,000 feet. At these high altitudes, where the air is less dense and the drag is therefore low, the rocket provides maximum acceleration to the airplane following launch. This acceleration is sufficient to allow the airplane to reach the desired speeds and altitudes that allow scientists to study the flight regions between where aerodynamic forces are still useful, and outer space, where they are not, and to study speeds of almost Mach 7, which are solidly in the hypersonic regime.

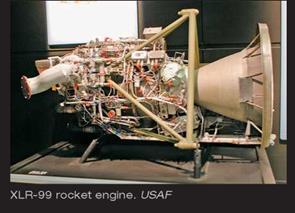

The X-15 was designed with a very high thrust, 57,000 pounds, provided by an RMI rocket engine with enough fuel for about a minute and a half

Inconel X is a high-temperature alloy of 72.5 percent nickel, 15 percent chromium, and 1 percent columbium, the rest being iron. It has excellent strength at high temperatures, and it was a natural choice for the X-15 because it could withstand the high surface temperatures expected for the hypersonic flight regime up to Mach 7. Inconel X is a registered trademark of the Huntington Alloy Products Division, International Nickel Company, Huntington, West Virginia.

at full thrust. Researchers wanted to know if the analytical calculations and the wind tunnel data accurately predicted the performance, stability, and control of an airplane flying at Mach 7 at very high altitudes (over 250,000 feet); whether the aerodynamic heating at the high Mach numbers is as high as predicted theoretically; and if the Inconel X structure could maintain its strength at high temperatures.

They also wanted to learn whether the directional stability of the aircraft, which decreases at faster supersonic speeds, could be made sufficient by the X-15’s design and by the addition of a stabilization augmentation system (SAS) installed in the airplane. The 199 X-15 test flights evaluated all of these questions.

The risks of flying an airplane designed for testing in an unexplored flight regime are many, both for the known uncertainties and for the unknown. Any research airplane will have a new

design, new subsystems, and new materials, none of which have yet been tested in flight. Conversely, a new airliner that is intended to fly in a familiar speed range and with a conventional design usually has two years of test flights to prove that it is safe for passengers.

The X-15, designed to investigate hypersonic flight, needed to also fly in the supersonic, transonic, and subsonic regimes, and to land safely on the desert lakebed at about 220 miles per hour. Moreover, on its first flight it had to land after being dropped at altitude without any practice, so that the pilot and research team could learn the response of the airplane to the controls.

A risk example is the X-15’s first flight. Launched at 33,550 feet and without an engine, which otherwise would allow the pilot to go around again

if his approach was not right, the pilot had less than five minutes to learn how to handle the airplane in pitch, roll, and yaw, and to practice a simulated landing at altitude before doing the real thing. On this first flight, a longitudinal instability that caused the airplane to cycle up and down uncontrollably made it dangerously difficult to land. By good piloting, Scott Crossfield was able to touch down on the bottom part of this cycle, avoiding a serious, life-threatening crash. The problem was corrected later by merely resetting a valve.

Each flight was an adventure, with the pilot enduring up to 5 g of acceleration at full thrust for about 90 seconds until the fuel was used up. After burnout, the pilot had to fly, while coasting, to reach the speed and altitude required to conduct the necessary tests. Then the pilot would

X-15 landing. USAF, Air Force Flight Test Center History Office, Edwards Air Force Base

return without fuel or power to the landing site at Edwards Air Force Base, which could be as far away as 300 miles from where the plane was originally dropped.

This history tells a single story, in two parts. The first details the goals and requirements of the X-15 program; the competition for the contract, eventually signed by North American Aviation (NAA) on December 5, 1955; NAA’s design and

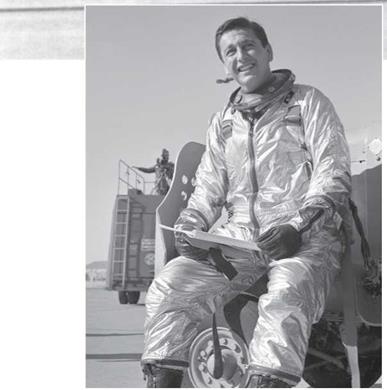

Scott Crossfield, suited up prior to a flight. USAF, Air Force Flight Test Center History Office, Edwards Air Force Base

![]()

|

The XLR-11 and XLR-99 are liquid-fueled rocket engines designed by Reaction Motors, Inc., specifically for use with high-speed airplanes. The fuel is anhydrous ammonia, and the oxidizer is liquid oxygen.

|

|

construction of the X-15; and NAA’s flight testing by Scott Crossfield, to show that the aircraft had met its contractual obligations. To demonstrate this achievement, Crossfield had to first fly the X-15 without an engine; then with two of the RMI-provided XLR11 rocket engines of the same type used in the X-1 flights (with 12,000 pounds thrust); and last, when it was ready, with the proposed RMI-provided XLR99 engine of 57,000 pounds thrust, all as specified in the contract.

The second part tells the thrilling story of the talented military pilots and NASA pilots who, under the direction of NASA’s Flight Research Center, were responsible for obtaining the data the X-15 was designed to provide. Eleven NASA and military pilots trained assiduously for each flight, flew each flight, managed the difficulties that arose with the aircraft or the engine in many of the flights, and dealt with crises that often placed them in mortal peril. They, along with the