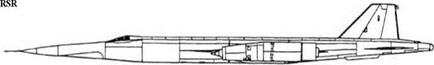

Tsybin 2RS

|

Purpose: To create a strategic reconnaissance aircraft.

Design Bureau: OKB-256, Podberez’ye, Director P V Tsybin.

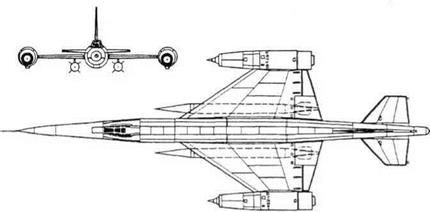

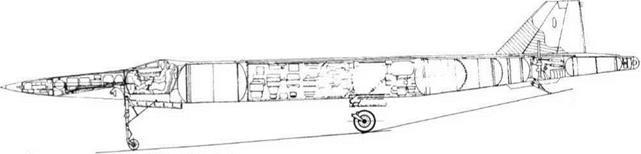

As noted previously, the 2RS was launched as a project in January 1956. It was to be a minimum-change derivative of the RS, carried to high altitude under the Tu-95N and subsequently powered by two RD-013 ramjets. However, it was decided that such an aircraft would be operationally cumbersome and inflexible, and that, despite a very substantial reduction in operational radius, it would be preferable to switch to conventional afterburning turbojets and take off from the ground. The revised project was called RSR (described later). The Ministry gave this the go-ahead on 31st August 1956, but work on

the 2RS continued until is was terminated in early 1957. As it was no longer needed, Tupolev then stopped the rebuild of the Tu – 95N carrier at Factory No 18 at Kuibyshev.

The 2RS would have differed from the RS principally in having the canard foreplanes replaced by slab tailplanes. Behind these was installed a braking parachute. Provision was made for large reconnaissance cameras in the fuselage ahead of the wing. Surviving drawings (below) also show provision for a 244N thermonuclear weapon, this time as a free-fall bomb recessed under the fuselage further aft. Carrying this would have moved the main landing gear unacceptably close to the tail.

Though there was much to be said for air launch, the basic concept looked increasingly unattractive.

|

Dimensions |

||

|

Span (over engine centrelines) 9.0 m |

29 ft 6% in |

|

|

Length |

27.4 m |

89 ft 1 13/ in |

|

Wing area |

64.0 m2 |

689ft2 |

|

Weight |

||

|

Empty |

9,030 kg |

19,907 Ib |

|

Fuel |

11,800kg |

26,014 Ib |

|

Loaded (cameras only) |

20,950 kg |

46,1 86 Ib |

|

Performance |

||

|

Max (also cruising) speed |

||

|

at 20 km (65,61 7 ft) |

2,700 km/h |

1,678 mph (Mach 2.54) |

|

Service ceiling |

27 km |

88,583 ft |

|

Range (high altitude) |

7,000 km |

4,350 miles |

|

Landing speed/ |

230 km/h |

143 mph |

|

run |

800 m |

2,625 ft |

Purpose: To create an improved reconnaissance aircraft.

Design Bureau: OKB-256, Podberez’ye, Director P V Tsybin.

The preliminary project for the revised aircraft, able to take off in the conventional manner, was dated 26th June 1957. Design proceeded rapidly, and in parallel OKB-256 created a simplified version, using well-tried engines, which could be got into the air quickly to provide data (see NM-1, next). These data became available from April 1959, and resulted in significant changes to the RSR (see R-020). The basic design, however, can be described here.

Though the RSR was derived directly from the 2RS, it differed in having augmented bypass turbojet engines (low-ratio turbofans) and strengthened landing gear for conventional full-load take-offs. A basic design choice was to make the structure as light as possible by selecting a design load factor of only 2.5 and avoiding thermal distortion despite local skin temperatures ofup to 220°C. By this means the use of steel and titanium was almost eliminat

ed, though some skins (ailerons, outer wing and tail torsion boxes) were to be in alumini – um/beryllium alloy. As before, the wing had a t/c ratio of 2.5 per cent, 58° leading-edge sweep and three main and two secondary spars. The tips, 86mm deep, carried Solov’yov D-21 bypass engines. These bore no direct relationship to today’s D-21A1 by the same design team. They were two-shaft engines with a bypass ratio of 0.6, and in cruising flight they were almost ramjets. Sea-level dry and augmented ratings were 2,200kg (4,850 Ib) and 4,750kg (10,472 Ib) respectively. Dry engine mass was 900kg (l,9841b) and nacelle diameter was 1.23m (4ft 1/2in). The fuselage had a fineness ratio of no less than 18.6, diameter being only 1.5m (4ft 1 lin). All tail surfaces had a t/c ratio of 3.5 per cent, and comprised a one- piece vertical fin with actuation limits of ±18° and one-piece tailplanes with limits of + 10°/-25°. All flight controls were fully powered, with rigid rod linkages from the cockpit and an artificial-feel system. The main and steerable nose landing gears now had twin wheels, and were supplemented by single

wheel gears under the engines, all four units hydraulically retracting to the rear. A braking parachute was housed in the tailcone. A total of 7,600kg (16,755 Ib) of kerosene fuel was housed in integral tanks behind the cockpit and behind the wing, plus 4,400kg (9,700 Ib) in two slender (650mm, 2ft 1 V-im diameter) drop tanks. An automatic trim control system pumped fuel to maintain the centre of gravity at 25 per cent on take-off, 45.0 in cruising flight and 26.4 on landing. In cruising flight the cockpit was kept at 460mm Hg, and the pilot’s pressure suit maintained 156mm after ejection. An APU and propane burner heated the instrument and camera pallets which filled the centre fuselage, a typical load comprising two AFA-200 cameras (200mm focal length) plus an AF A-1000 or AFA-1800 (drawings show four cameras), while other equipment included optical sights, panoramic radar, an autopilot, astro-inertial navigation plus a vertical gyro, a radar-warning receiver and both active and passive ECM (electronic countermeasures) During construction this aircraft was modified into the RSR R-020.

|

|

|