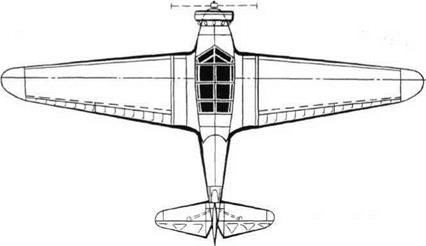

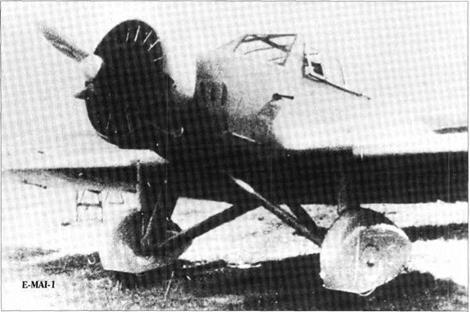

MAI EMAI-1

|

||||||||||||||||||||||||

|

Purpose: To see whether a safe aeroplane could be constructed from magnesium. Design Bureau: Moscow Aviation Institute.

As magnesium has a density of 1.74, compared with 2.7 for aluminium and almost 8 for typical steels, it seemed reasonable to the MAI management to investigate its use as a primary structural material. In 1932 such a project was authorised by Director A M Be- lenkovich and the GUAP (civil aviation ministry), and a year later a design team was assembled under Professors S I Zonshain and A L Gimmelfarb, with construction led by N F Chekhonin. A neat four-seat low-wing monoplane was quickly designed, and flown about 600 times in 1934-39. It was also statically tested at (CAHI) TsAGI.

The EMAI was also known as the E-MAI, Elektron MAI, EMAI-1, E-l, EMAI-I-34 and Sergo Ordzhonikidze. Elektron is the name of the alloy with Al, Mn and Zn, considerably stronger than pure Mg, which was used for most of the airframe. The straight-tapered wings were based on Steiger’s Monospar principles, with the ribs and single spar built up from square and tubular sections. The entire trailing edge was hinged, forming ailerons and plain flaps. The well-profiled fuselage was largely skinned in Elektron, the wings and tail being covered in fabric. On the nose

was the Salmson seven-cylinder radial engine, rated at 175hp, in a ring cowl and driving a two-blade propeller. The strut-braced tailplane was mounted high on the fin, and the rubber-sprung main landing gears had spats. The cockpit was covered by one sliding and one hinged canopy. Most of the structure was welded, but many joints were bolted so that they could be dismantled.

The EMAI-1 was judged to be a comple success, with a structure weight ’42 per cent lower than using aluminium, steel tube or wood’. The fire risk was not considered a serious hazard, and according to MAI the main reason for not taking the use of Elektron further was because in the USSR there was not enough spare electric power available to produce the magnesium.

MAI-62 AND MAI-63