T. O. 07- 1-1A corrects incorrect insignia data, May 29,1944

About one month after the release of T. O. 07-1-1 on April 25, 1944, a correction had to be made to the basic instructions for the construction of the bars on either side of the insignia. The original issue had stated:

The straight line formed on the top edges of the two-star points that are located to the left and right of the upper star point will be extended outward from the blue circle a distance equal to one half the radius of the circle.

(the error has been underlined – author). The correct dimension was, of course, one radius (one-half of the diameter) of the circle.

Lack of dope code markings on fabric-covered parts for B-17 questioned, June – July, 1944.

On June 13, 1944, the Office of the Base Inspector, AAF Pilot School (Specialized 4 Engine), Lockbourne Army Air Base, Columbus, OH (phew!), wrote to the CG, Eastern Training Command, stating that they had received 78 ailerons, 50 elevators and 35 rudders installed on B-17 aircraft delivered to them from 21 different stations, including Air Depots and manufacturers. These surfaces did not have any identifying code markings, as required by Spec. 98-24105-Q. They requested instructions on how to correct the situation. The Eastern Flying Training Command in turn wrote to the CG., Air Service Command, Patterson Field, Ohio, requesting a decision on how to handle the situation.

|

|

The aircraft in this photo belong to the fighter group commanders of the fighter wings of the Eighth Air Force in summer 1944. They are: (I) P-51D. aircraft MC-R “Gentle Annie” of the 79th FS, 20th FG; (2) P-51D-10-NA, 44-14111, aircraft PE-X “Straw Boss” of the 328th FS, 352nd FG; (3) P-47D-20-RE, 42-76541, aircraft LM-S of the 62nd FS, 56th FG; (4) P-51D-10-NA, 44-14291, aircraft CL-P“Da Cowie” of the 338th FS, 55th FG; and (5) P-47D-20-RE, 42-76415, aircraft Pl-1 of 360th FS, 356th FG. The last aircraft in the front row is a T-6 and in the second row are a P-47D and a P-38H.

|

The resulting correspondence became somewhat acrimonious as the original complainant was asked for paper work pertaining to contract numbers, item numbers, packing sheet number, bill lading number, shipping date, quantity and part numbers! They replied that their complaint concerned parts installed on aircraft, not delivered as spare parts. They also raised the problems that arose during periodic inspections if the code markings were not on the parts; these included the difficulty of determining if deterioration of the surfaces was due to age or poorly manufactured paints, dopes or fabrics. If surfaces required refinishing it was difficult to determine if the maximum number of allowable coatings would be exceeded. They recommended that higher authorities take steps to correct the situation.

CG., Eastern Flying Training Command wrote to Air Service Comand on July 6,1944, requesting clarification and that any communications to any of the stations in their command should be addressed to them.

|

On July 29,1944, ASC replied that T. 0.00-25-34 gave the reason for not dating aircraft and parts, and stated that Spec. 98-24105 had not been revised to conform to the T, O. and to Material Command Regulation 151-6. This was because the markings were still applicable to training aircraft already in service within the Continental United States. Therefore, T. 0. 07-1-1 required that these detail markings be accomplished by all repair activities. No action could be taken to have new control surfaces or new fabric aircraft dated until non-dating was no longer considered necessary.

|

Stinson L-5 42-14974 of the 415th Field Artillery Group HQ, in summer of 1944 in the US. It is unusual in carrying the aircraft radio call number under the right wing, facing forward. Pilot was Capt. Paul T. Talbott, father of one of our photograph suppliers. (Paul Talbott) |

This shows that conditions in the AAF had changed so much that they did not expect to be operating their aircraft for long lives; it is pertinent to point out that the average life of combat aircraft at that time had been calculated to be only twenty five hours!

Aircraft aati-corrosion protection raised to the JAC, May 15,1944, as a separate matter to use of camouflage finishes.

The Material Command reported that it had been found impractical in production to produce aircraft with their surfaces suitably protected, and at the same time, build aircraft that were to be delivered with unpainted and uncamouflaged surfaces to meet the requirements of the AAF. They pointed out that the B-17, B-25, and P-51 all had excellent service records, and that none of them had any protective coatings applied to their faying and internal surfaces.

|

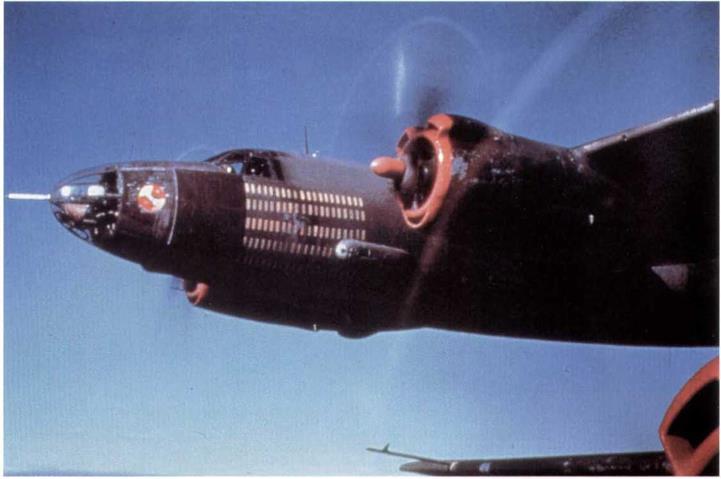

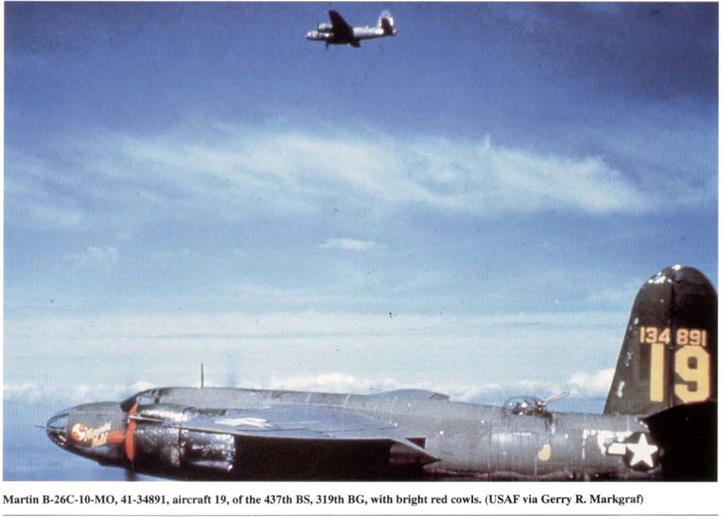

Martin B-26C-10-MO, of the 319th BG, Twelfth Air Force, Italy, with bright red cowls. (USAF via Gerry it. Markgraf) |

|

Three Northrop P-61A’s over France in summer of 1944. They are: P-61A-5-NO, 42-5536; P-61A-10-NO, 42-5573 and P-61A-10-NO, 42-5564. The nearest one is still in the dark olive drab and neutral gray finish, while the other two are in the Jet 622 gloss black finish. They are from either the 422nd or 425th NFS. (USAF) |

They therefore requested that the JAC reconsider their recommendations and report, dated January 19, 1944, and make it applicable to camouflage only. They believed that the subject of protective finishes could be resolved by agreement between the Army and Navy, through the working committee of the Aeronautical Board.

The JAC met on July 18, 1944, and agreed to delete the earlier recommendation, which had read as follows;

(2) That protective finishes be not eliminated in connection with any elimination of camouflage, but that surfaces be suitably protected, and that the committee be directed to expedite a spec, to accomplish this.

|

|

|

North American F-6C-NA, 43-12365, aircraft ZM-L “Puff”, of the 12th TRS, 10th PG, Ninth Air Force, at strip A-64 St. Dizier, France, on September 22,1944. Note the camera port beneath the star insignia. (William L. Swisher) |

They also recommended that the AAF be required to apply protective coatings to the interior and faying surfaces of aircraft on dissimilar metal contacts such as aluminum alloy with magnesium, unclad aluminum alloy, steel, etc.. The finish of magnesium and steel parts were to continue to meet current specs.. The AAF were requested to make special and immediate check on their contractors to assure that the interior and faying surfaces of magnesium, unclad aluminum alloy and dissimilar metal contacts were properly protected in all cases. The Working Committee of the Aeronautical Board were requested to discontinue any action on the earlier recommendation and the Material Command, AAF, make a study regarding the use of protective coatings on helicopters.