. 2. AUTHORIZED FINISHES

a. DAY CAMOUFLAGE. – Standard day camouflage for liaison aircraft, helicopters, and gliders consists of upper surfaces olive drab, shade No, 41, Bulletin 41 or AN Bulletin 613; and lower surfaces neutral gray, shade No. 43, Bulletin 41 or Army-Navy sea gray, No. 603. (See AN Bulletin 157A.)

b. NIGHT CAMOUFLAGE.

(1) GENERAL. – Special black camouflage paints, color designation, “Jet No. 622,” have been developed for use in minimizing visibility of airplanes at night. The estimated quantities of materials required will be found in table 1.

(2) PREPARATION OF SURFACES.

(a) Metal surfaces which are painted with dull camouflage finish should preferably be stripped to bare metal in accordance with T. O. No. 07-1-7, and the metal cleaned and primed in order to save weight. However, if weight is not critical, Jet No. 622 camouflage enamel may be applied directly over the dull finish, after thorough cleaning and careful smoothing with No. 320 or finer waterproof sandpaper and water to minimize porosity and roughness.

NOTE Application of lacquer over enamel may cause lifting of the enamel. If, upon trial, trouble is encountered in application of lacquer over the old finish, the finish must be removed or Jet No. 622 enamel used. Prior to application of Jet No. 622 camouflaged enamel, unpaintcd metal surfaces will be cleaned in accordance with Specification No. 98-20007 (or phosphoric acid alcohol cleaner in accordance with T, O. No. 01-1-1) and then primed with one smooth coat of zinc chromate primer, Specification No. AN-TT-P-656.

(b) Wood surfaces painted with dull camouflage or aluminized finish will be cleaned and then smoothed out by sanding with No. 320 or finer waterproof sandpaper and water, prior to application of the Jet No. 622 camouflage enamel. Unfinished wood sur faces will be prepared in accordance with Specification No. AN-C – 83, to produce a surface as smooth and free from irregularities as possible, prior to application of the Jet No. 622 camouflage enamel. Surfacer, Specification No. 14116, may be used in direct-on-wood finishes, provided the film is sanded as thin as possible commensurate with the desired smoothness and “holdout” or fullness of gloss of the final finish.

TABLE 1

METAL SURFACES FABRIC SURFACES

|

Lacquer, Specification |

or Enamel, Specification |

Dope, Specification |

Total Approx. |

|

No. AN-TT-L-51 |

No. AN-E-3 |

No. AN-TT-D-554 |

Weight Increase |

|

Fighter (P-40) 10 gal |

or 6 gal |

2 gal |

15 lb |

|

Bomber (B-24) 30 gal |

or 15 gal |

7 gal |

46 lb |

|

Requirements for other airplanes may be estimated from the preceding table. |

|

|

North American P-51D-5-NA, 44-13550, aircraft A9-M of the 380th FS, 363rd FG, seen at strip A-8 on August 10,1944. Note how the invasion stripes have been painted out above the top of the fuselage and insignia, with dark olive drab. The same was dune to the stripes above the wings. Squadron color on the spinner is blue. (William L. Swisher)

(3) APPLICATION. – Application of Jet No. 622 camouflage will be by spraying, which presents no unusual problems. However, because of the need to produce a black finish having as near mirror-like an appearance as possible, it is necessary to take extra precautions to avoid dust during painting and drying. Dust which becomes adhered to the paint, especially on the bottom and side surfaces, will result in reduced effectiveness of the camouflage.

NOTE Lacquer, being faster drying, is preferred for Jet No. 622 finish for this reason.

|

|

Lockheed P-38H-5-LO, 42-66923; P-51A-10-NA, 43-6246: and P-47D-23-RA, 42-27798, From the AAF School of Applied Tactics, at Orlando Army Air Base, FI. Note the white ellipse markings of the school aircraft on the nose. The last three digits of the serial number were painted black on the ellipse. The school was under control of the AAF Board, who reported to the Dir. of Mil. Req. in Washington. (USAF via Gerry R. Markgraf)

|

Republic P-47D-21-RA, 43-25572, aircraft YJ-N “Smoocher”, of the 351st FS, 353rd FG, Eighth Air Force, with heavy wing damage sustained in a belly landing. Nose cowl is in black and yellow checks. Code letters are in white. Invasion stripes underneath only. August 13,1944, (USAF) |

Jet No. 622 lacquer will be applied to the properly prepared surfaces of metal {and wood) by spraying not less than two full coats; Jet No. 622 enamel, one mist coat and one hiding coat. Application of the camouflage material will be controlled so as to produce a finish of uniform hiding and blackness and very high gloss.

NOTE In the event that a rough finish is applied in the field, it may be smoothed by rubbing lightly with 320 or 400 waterproof abrasive paper after which a light, but wet, coat of camouflage material should be applied,

(4) FABRIC SURFACES. – Fabric doped with dull camouflage finish which has not become brittle, may be converted to jet camouflage by the following procedure: Remove all grease and dirt, then wash with soft soap and water, rinse with clean water, and allow the surfaces to dry. Apply two wet spray coats of thinner, Specification No, AN-TT-T-256, to soften up the old finish, and allow to dry not more than 30 minutes. Apply three spray coats of gloss black pigmented dope, the last of which is cut with an equal portion of clear dope, Specification No. AN-TT-D-514, before thinning to impart added gloss. If fabric is new, dope in accordance with Specification No. 98-24100, using a minimum of two brush and two spray coats of AN-TT-D-514 dope. Follow with one spray coat of sanding guide dope (3 ounce pigment, aluminum per gallon of AN-TT-D-514 dope). Sand (dry) moderately with No. 280 (or finer) sandpaper to minimize weave effects.

NOTE Ground parts when sanding.

Finish with three spray coats of gloss black pigmented dope, Specification No. AN-TT-D-554, the last coat of which is cut with an equal portion of (clear), Specification No. AN-TT-D-514 dope, before thinning, to impart added gloss.

(5) MAINTENANCE OF JET NO. 622 FINISH.

(a) The effectiveness of night camouflage is reduced by accumulations of mud, dust, oil, gun blast, or exhaust gas residues, and chalking of the paint film, particularly on sides and under surfaces, of aircraft. Excessively widespread scratches, and especially bare metal exposed by scratches, also have a deleterious effect. Therefore, cleaning and maintenance operations on the airplane should be so conducted as to avoid scratching the finish and to minimize exposure of bare metal. Before engaging in night operation, mud, dust, muzzle blast or exhaust gas residues and oil should be removed and all bare metal areas re-touched with Jet No. 622 camouflage material, especially on sides and under surfaces. At least once a week, and oftener, if necessitated by ground or atmospheric conditions, the airplane shall be washed and then polished with aircraft polish, stock No. 7300755000. The use of wax is discouraged because it will interfere, subsequently, with the drying of paint where retouching is necessary and because satisfactory results are obtainable through the use of polish. THE CLOSER THIS TYPE OF CAMOUFLAGE APPROACHES THE APPEARANCE OF A BLACK MIRROR, THE MORE EFFECTIVE IT BECOMES.

(6) REJUVENATION. – If, on extended exposure, a surface haze appears on the paint, which cannot be removed with polish, wash with soap and water and rinse with clean water then wipe surface thoroughly with clean cloths wet with naphtha or solvent, Specification No. P-S-661. The cloths should be wet by pouring solvent on them and should not be dipped into the solvent. Spray one light coat of Jet No. 622 camouflage enamel, Specification No. AN-E-3, or lacquer, Specification No. AN-TT-L-51. Clean doped surfaces in the same manner, but apply only glossblack dope, Specification No. AN-TT-D-554, cut with clear dope, Specification No. AN-TT-D-514.

C A U1′ 1 О N DO NOT APPLY LACQUER ON JET 622 ENAMEL, AS IT WILL INJURE ENAMEL FILM. CHECK THF STENCILED MARKING FOR APPLICABLE SPECIFICATION OR TEST WITH LACQUER SOLVENT.

|

|

Northrop P-61A-1U-NO, serial unknown, named “Lucky Lady” on the nose and “Doris” on the right hand engine cowl, seen at strip A-8 on August IS, 1944. (William L. Swisher)

|

|

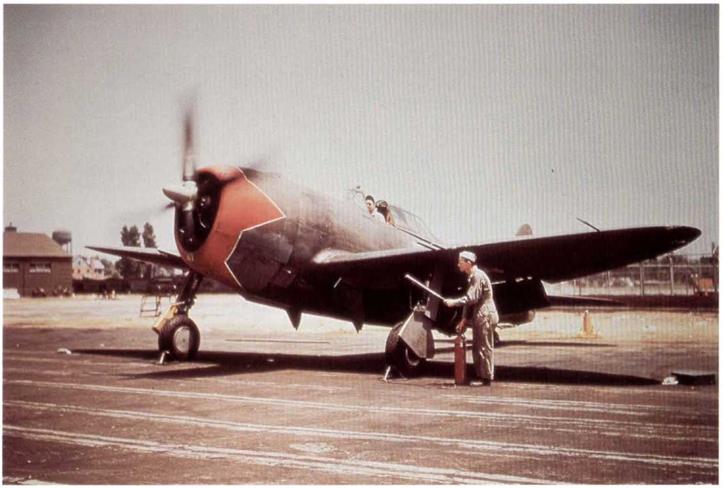

Republic P-47D, of the 375th FS, 361st FG, running up at Langley Field, Virginia, in the USA, prior to the unit embarking for Bottisham, England, in July 1943. This was the last P-47 Group to be assigned to the Eighth Air Force. Note the fancy nose cowl red marking with white trim; these markings were not used in England. Serial number not visible. (USAF via Gerry R. Markgraf)

Republic P-47D-25-RE, 42-26418, aircraft HV-A, flown by Lt. Col. Francis Gabreski, of the 61st FS, 56th FG, having its guns rearmed, Note the colors of the gun hay: zinc chromate primer and Dark Olive Drab on the wing rib top faces. Aircraft was painted in dark green and ocean gray, courtesy of the RAF, with front half of the cowl and the rudder in red. Full invasion stripes were above and below this aircraft. Col. Gabreski was shot down over Germany in this aircraft on July 20,1944. (USAF via Gerry R. Markgraf)

|

Douglas A-24B-DT, 42-54897, was the third from last A-24 huilt. Seen here in Air Transport Command service in the USA on August 21, 1944. (Nick Williams) |

c. METAL CORROSION PREVENTION. – The exterior of alclad metal fuselages and metal airfoils does not ordinarily require paint as a protection against corrosion. (Refer to T. O. No. 01- 1-2.) However, where it is necessary to provide additional protective finish on any parts not made from aluminum coated aluminum alloy, any such unprotected parts will be cleaned with phosphoric acid alcohol cleaner, finished with one coat of zinc chromate primer, Specification No. AN-TT-P-656, and two coats of aluminized lacquer. Aluminized lacquer consists of lacquer, cellulose nitrate, clear, Specification No. AN-TT-L-51, pigmented with 12 ounces per gallon of paste, aluminum pigment, Specification No. TT-A-468.

d. ANTIGLARE. – Antiglare camouflage olive drab or dull dark green paint is authorized where necessary, to be applied to top of the fuselage in front of the cockpit and on the inside upper one-fourth of the engine nacelle forward of the leading edge of the wing.

e. WOOD SURFACES. – Exterior plywood surfaces will be finished with two coats of sealer, Specification No, AN-S-17, or on open grained woods, one coat of sealer followed by one coal of surfacer, Specification No. 14115, sanded down, before the final two coats of aluminized varnish. Use 18 to 20 ounces of pigment, aluminum paste, Specification No. TT-A-468, in each gallon of varnish. Specification No. AN-TT-V-116.

f. WOOD – FABRIC. – Exterior wood surfaces (fabric covered) will have a minimum of one brush coat of sealer, Specification No, AN-S-17, and two brush or spray coats of clear tautening dope. Specification No, AN-TT-D-514, prior to attachment of fabric. The fabric may be cemented in place with the second coat of clear dope, or may be laid on the dried second coat

with cementing effected by wetting the fabric with thinner or thinned dope. The finish over the fabric shall consist of a minimum of one brushed (first) coat and two sprayed coats of clear tautening dope followed by the necessary spray coats of pigmented dope.

g. FABRIC.

(1) Exterior fabric parts will have a minimum of two brush and two spray coats of clear nitrate dope, Specification No. AN-TT – D-514 (aluminized dope vehicle, Specification No, AN-TT-D – 551, is not a suitable substitute, as it does not have the tautening qualities of Specification No. AN-TT-D-514). This will be followed by two or more coats of aluminized dope prepared by adding 8 ounces per gallon pigment, aluminum paste, Specification No. TT-A-468, to dope, cellulose nitrate, dear, Specification No. AN-TT-D-551, before thinning. Patching will be accomplished with clear dope, Specification No. AN-TT-D-614, applied in same manner as semipigmented dope previously used.

(2) For emergency rejuvenation of old fabric, add 1 fluid ounce each of tricresyl phosphate and castor oil to 1 gallon of two to one mix of clear dope, Specification No. AN-TT-D-514, and blush retarding thinner, Specification No. AN-TT-T-258. Apply one coat by brush to clean surface, followed by one spray coat. After several hours drying, spray one coat of aluminized dope, prepared as specified in paragraph 2.g.(l).

|

|

North American P-51B-15-NA, 42-106950, aircraft WR-P “Iowa Beaut” of the 354th FS, 355th FG, 65th FVV, 2nd Air Div, Eighth Air Force in summer 1944. Note how the invasion stripes have been painted out with smooth finish paint. This may be RAF Smooth Dark Green, rather than Dark Olive Drab, as it is slightly richer in color. Note white nose cowl and yellow tab, denoting the 354th FS. (LISAF)

|

|

North American P-51D – 5-NA, 44-13357, aircraft B7-R “T1KAIV” of the 374th FS, 361st FG, 65th FW, 2nd Air Div, with underneath invasion stripes only, after October 1944. Note 6 kills under canopy. Aircraft has the unit yellow spinner and nose. (USAF)

|

North American P-51B-10-NA, serial unknown, aircraft A9-? “Schubert’s Serenade” of the 380th FS, 363rd FG, photographed at strip A-8 on August 10,1944. Spinner and nose color were blue. (William L. Swisher) |

3. MARKINGS.

Only such markings and identifying insignia as outlined herein will be used on AAF aircraft except as specifically authorized by the Commanding General, AAF.

a. PARTS. – Each part and assembly will be permanently and legibly marked the same number as the drawing number in such location that it can be read after assembly in the unit. (See Specification No. 98-24105.)

b. DETAIL. – Various detail and code markings for the cockpit, fuselage, oil lines, etc., as required in Specification No. 9824105, will be maintained. In addition, Jet No. 622 finishes (on metal and wood) surfaces will be stenciled in yellow on an upper surface with the code number of the approved gloss black of the paint manufacturer under the two applicable specifications (Bulletin 102 for lacquer, and 148 for enamel), two dashes, followed by the symbol for the material as “L-51” or “E-3.” Example: 6005—L-51.

c. RADIO CALL NUMBERS

(1) Radio call numbers of not less than four numerals will be maintained on all AAF aircraft except as stated in paragraph 3.c.(3), utilizing both sides or each outboard side, as applicable, of the vertical stabilizer and rudder assembly. These call number^, or designators, will be of a size discernible at a distance of 150 yards. They will be derived by deletion of the first numeral of the serial number (4) and the hyphen (-), and the combination of the remaining four or more numerals. In case of serial numbers of type 41-7, use zero as necessary to make four numerals, as 1007. Decalcomauia may be used where available.

(2) On all airplanes operating solely within the continental limits of the United States, the radio call numbers will also be placed, with the top forward, on the lower surfaces of wings, except asstated in paragraph 3.c,(3). The size of the number to be painted on aircraft and the matter of whether the numbers will be painted on the left wing only or both wings will be determined by the local using agency in accordance with the space available and the desired usage,

(3) Radio call numbers in neither location are required, however, on primary trainers not equipped with radio and which bear field identifying numbers.

d. PROPELLER MARK1NGS. – American propeller blades, design Nos. A-272U07 and C-3821306, used in sets in Aeroproducts and Curtiss propellers, respectively, will be identified by a yellow stripe, 3/8 inch in width and 3/8 inch inboard of the yellow tip section. A. O. Smith propeller blades used in sets in Curtiss propellers will be identified by two 3/8-inch yellow stripes, one 3/8 inch inboard of the yellow tip section and the other stripe 3/8 inch inboard from the first. These stripes will extend completely around the blade section. The stenciled markings between the 18- and 24-inch stations on the cambered side of the propeller blades will be retained. When the exact location of the blade reference station is known, a stripe of yellow paint 1/8 inch wide, 2 inches long and spaced equally distant between the leading and trailing edge of the blade, will be placed on the thrust face at the reference station.

CAUTION Unless the exact location of the reference station on the blade is known no attempt will be made to identify this location by the afore-mentioned stripe.

|

Martin B-26B-25-MA, 41-31844, aircraft SS-S of the 451st BS, 322nd BG, at strip A-8 on August 10,1944, with stripes underneath only. Most of the aircraft that landed at these advanced strips in Normandy did so to refuel. (William L. Swisher) |