"By-Pass" Turbojets and First-Generation Turbofans

The turbofan engine was a significant leap forward in the early jet era. Its design was the logical evolution of conventional jet engines, adding a larger propulsion fan to the basic core to provide substantially greater thrust and greatly reduced fuel burn that in turn allowed more range.

Rather than just settling for the turbine section of an engine powering one set of axial-flow compressors and producing anemic thrust levels, Rolls-Royce engineers added another low-pressure compressor section, independent of the first, and ducted the additional air around the core of the engine. This exhaust was routed around the combustion chamber and exited the engine along with the hot core exhaust through the same tailpipe. This helped cool the engine, all the while cooling the jet effluent and lowering the decibel level as well. The by-pass ratio of air in Rolls-Royce’s Conway, its first “by-pass” engine, was only a tiny 0.3. The later Spey model increased this to 0.6. It was a win-win compared to a straight turbojet, but obviously not the perfection of a true turbofan.

Rolls-Royce’s introduction of the 17,500-pound – thrust Conway as the world’s first commercial by-pass engine, spurred Pratt & Whitney to get with the program and take the ratio of their JT3C up to an amazing 1.5. They accomplished this by using a separate fan

|

section on the first compressor. This then became the JT3D, the worlds first true operational turbofan jet engine. By-pass turbojets, however, represented a significant bridge, or transition, from the turbojet to the turbofan, and played an integral part in aviation power – plant history.

Not to be left out, General Electric took its 11,200- pound-thrust CJ-805-3B turbojet (civil version of its military J79 engine as used on the Convair 880) and added a separate fan section on the aft end of the hot engine core, using a ducted “flow-through” nacelle that shrouded the entire engine. This proved to be a more aerodynamically streamlined engine structure than having a wider nacelle on the forward fan section only (Boeing 707) or a tapered nacelle with mid-section fan

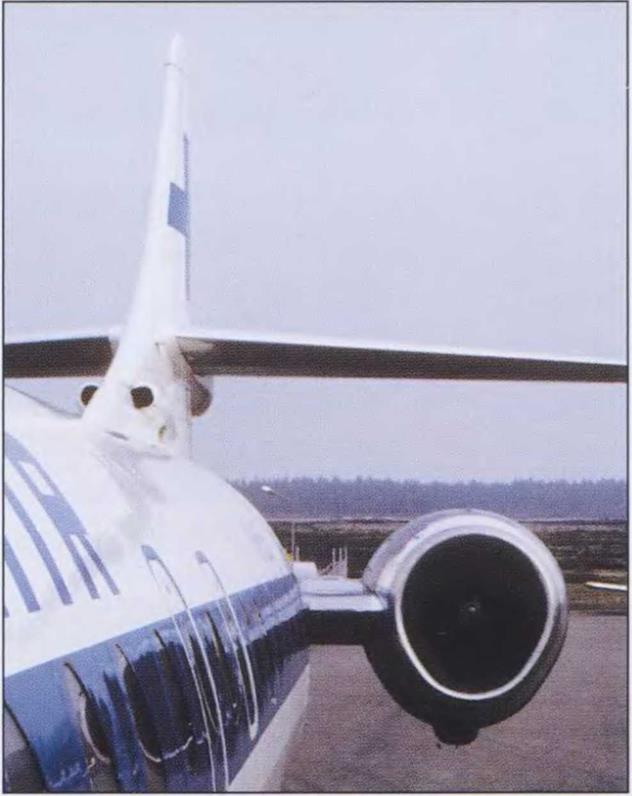

Boarding ramp view of the Caravelle 10B’s Pratt &

Whitney JT3D engine nacelle showing the unique ovaloid air intake shape. These new 18,000- pound-thrust fanjet engines gave the venerable Caravelle a new lease on life, and it soon found success with European charter carriers that used the aircraft to carry revenue passengers well into the 1980s. (Mike Machat)

exhaust (Douglas DC-8). Thus, the 16,100-pound – thrust GE CJ-805-23 turbofan was created, as was tested on the Sud Caravelle, and used operationally on the Convair 990. (Later models of the Caravelle used advanced versions of the Pratt & Whitney JT3D.)