ACCEPTANCE TESTING

Finished work undergoes functional checkout to insure it meets operational requirements. Tests range from continuity and compatibility of wiring to all-systems ground testing. Fluid-carrying components are subjected to pressures beyond normal operating requirements, and structural components receive visual and X-ray inspections. Instruments simulate flight conditions to evaluate total performance of electrical and mechanical equipment.

Rocket engines are static-fired before delivery to the stage contractor. Such tests demonstrate per-

9- 1

|

|

|

ASSEMBLY AND CHECKOUT

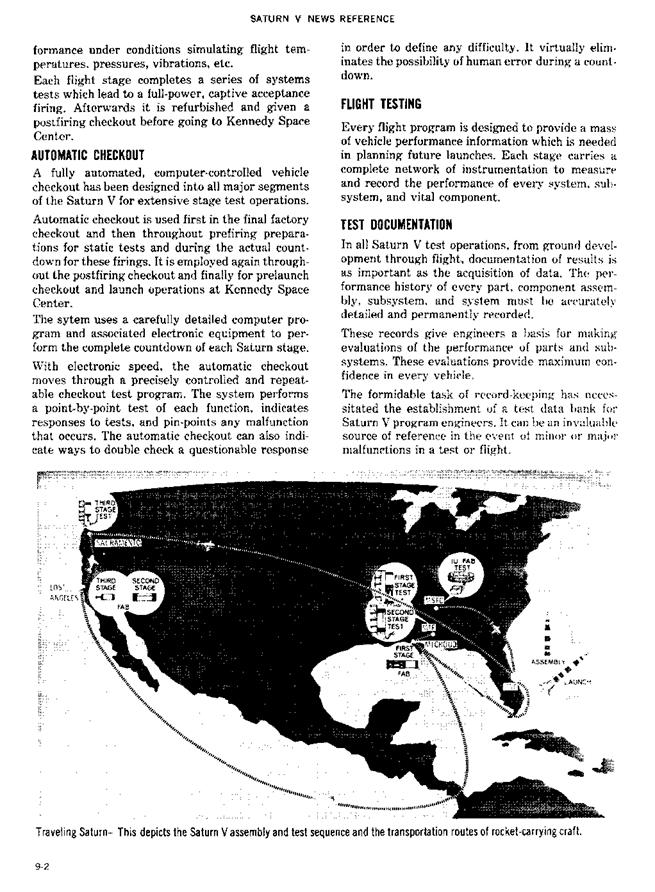

Saturn V stages are shipped to the Kennedy Space Center by ocean-going vessels or by specially designed aircraft. Apollo spacecraft modules are transported by air and delivered to the Manned Spacecraft Operations Building at Kennedy Space Center for servicing and checkout before mating with the Saturn V.

Saturn V stages go into the Vehicle Assembly Building low bay area where preparation and checkout begins. Receiving inspection and the low bay checkout operations are first performed before stages are erected within a high bay.

After being towed into the high bay area and positioned under the 250-ton overhead bridge crane, slings are attached to the first stage and hooked to the crane. The stage is positioned above the launch platform of the mobile launcher and lowered into place. Then it is secured to four holddown/support arms. These support the entire space vehicle during launch preparation and provide holddown during thrust buildup prior to launch.

Next, engine fairings are installed on the stage and fins are moved into position and installed in line with the four outboard engines.

Mobile launcher electrical ground support equipment is connected to the ‘launch control center (LCC) via the high speed data link, and the test program is started with the actual launch control equipment.

Prior to and during this time, all low bay testing is completed and the upper stages are prepared for mating. The mating operation consists of stacking the stages. Umbilical connection begins immediately and continues during the mating operation on a noninterference basis. The vertical alignment of the vehicle is performed after each stage is mated.

When the launch vehicle is ready, the Apollo spacecraft is brought to the VAB and mated.

Checkout of all systems is performed concurrently in the high bay. The first tests provide power and cooling capability to the vehicle, validate the connections, and establish instrumentation. When this is completed, systems testing begins. The systems tests are controlled and monitored from the LCC wherever practical and “break-in” tests are held to a minimum. Following the validation of each stage, a data review7 is held and the vehicle is prepared for combined systems tests.

Illustration of Vehicle Assembly Building Interior at Kennedy Space Center

The combined systems tests verify the flight-readiness of the overall vehicle. These tests include a malfunction sequence test, an overall test of the launch vehicle, an overall test of the spacecraft, and a simulated flight test. Prior to the simulated flight test, final ordnance installation is completed. After the test, vertical alignment is checked, a data review is held, and the vehicle is prepared for transfer to the pad. These preparations include disconnecting pneumatic, hydraulic, and electrical lines from the mobile launcher to the VAB.

After the lines are disconnected, the transporter is moved into position beneath the mobile launcher. Hydraulic jacks engage the fittings on the mobile launcher and raise it approximately 3 feet so that it clears its mount mechanisms. Then the transporter moves out of the VAB, over the crawlerway, to the launch pad.