INSTRUMENT UNIT FACT SHEET

|

DIAMETER: 260 in.

HEIGHT: 36 in.

WEIGHT: 4,500 lb. (approx.)

MAJOR SYSTEMS

ENVIRONMENTAL CONTROL SYSTEM: Provides cooling for electronic modules and

components within the IU and forward compartments of third stage

GUIDANCE AND CONTROL SYSTEM: Determines course of Saturn V through space

and adapts that course to fulfill mission requirements

INSTRUMENTATION SYSTEM: Measures vehicle conditions and reactions during

mission and transmits this information to ground for subsequent analysis,

as well as providing for ground station-to-vehicle communication

ELECTRICAL SYSTEM: Provides basic operating power for all electronic and

electrical equipment in the IU; also monitors vehicle performance and

may initiate automatic mission abort if an emergency arises

STRUCTURAL SYSTEM: Serves as a load bearing part

of the launch vehicle, supporting both the components

within the IU and the spacecraft; composed of three

120-degree segments of thin-wall aluminum alloy face

sheets bonded over a core of aluminum honeycomb

about an inch thick

|

|

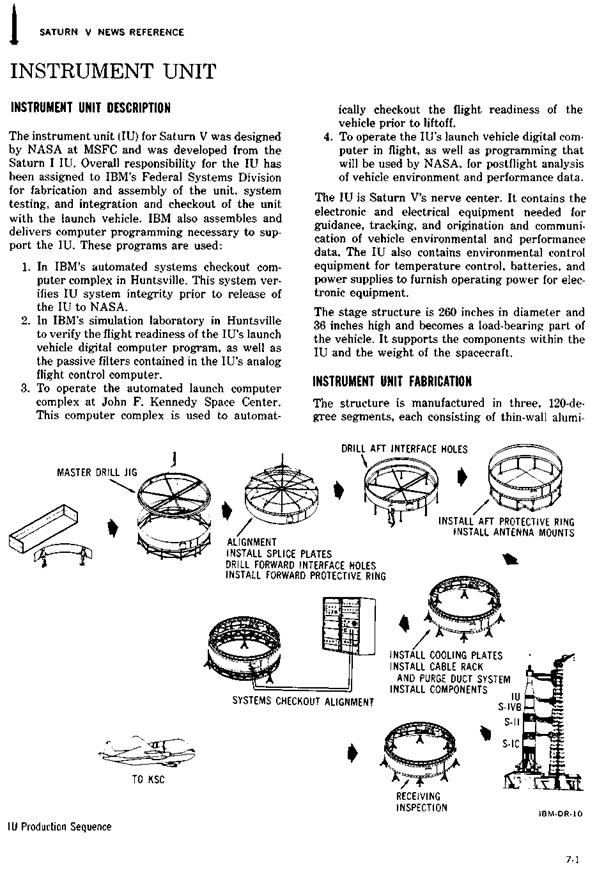

SATURN V NEWS

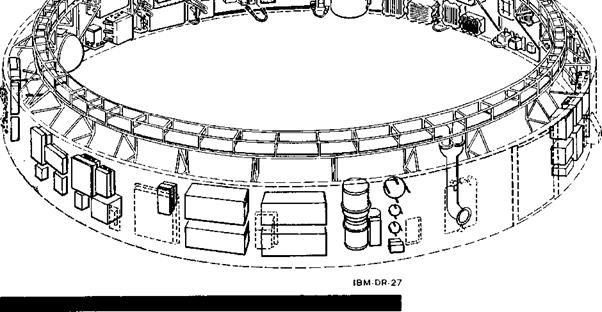

num honeycomb. An aluminum alloy channel ring, bonded to the top and bottom edge of each segment, provides mating surfaces between the IU, the third stage, and the payload adapter. Mounted, inner skin brackets provide attachment points for the environmental control system’s cold plates or for cold plate installation.

Segments are aligned and joined by splice plates bolted both inside and outside the joints. A spring – loaded umbilical door provides access to electrical connections between IU equipment and ground test areas. A larger access door, bolted in place, permits personnel to enter the IU after vehicle mating.

Assembly of an IU begins when the three curved structural segments, three feet high by 14 feet long, arrive at IBM’s Huntsville, Ala., facility. Each segment weighs only 140 pounds.

|

IBM-DR-22 |

REFERENCE

structure. Components are mounted on the cold plates and ECS system pumps, storage tanks (called accumulators), heat exchangers, and plumbing are installed. Two nitrogen supply systems are installed: one for gas bearings of the inertial platform and the other for pressurization of the ECS. Finally, ducts, tubing, and electrical cables complete the assembly and the IU now weighing in excess of 4,000 pounds is ready for a long series of tests.