AUGMENTED SPARK IGNITER

The augmented spark igniter (ASI) is mounted to the injector face. It provides the flame to ignite the propellants in the thrust chamber. When engine start is initiated, the spark exciters energize two spark plugs mounted in the side of the igniter chamber. Simultaneously, the control system starts the initial flow of oxidizer and fuel to the spark igniter. As the oxidizer and fuel enter the combustion chamber of the ASI, they mix and are ignited.

Mounted in the ASI is an ignition monitor which indicates that proper ignition has taken place. The ASI operates continuously during entire engine firing, is uncooled, and is capable of multiple reignitions under all environmental conditions.

Propellant Feed System

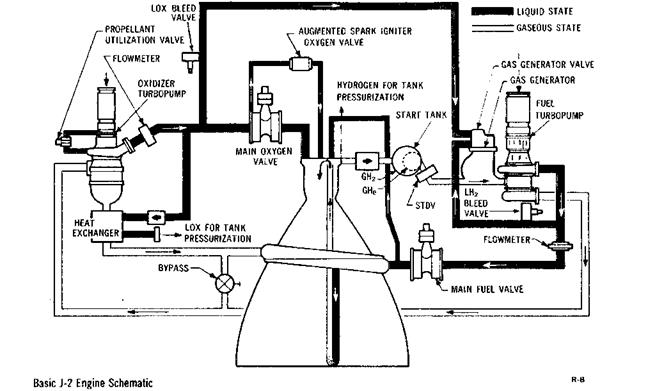

The propellant feed system consists of separate fuel and oxidizer turbopumps, main fuel valve, main oxidizer valve, propellant utilization valve, fuel and oxidizer flowmeters, fuel and oxidizer bleed valves, and interconnecting lines.

FUEL TURBOPUMP

The fuel turbopump, mounted on the thrust cham-

|

SATURN V NEWS REFERENCE

SATURN V NEWS REFERENCE

ber, is a turbine-driven, axial flow pumping unit consisting of an inducer, a seven-stage rotor, and a stator assembly. It is a high-speed pump operating at 27,000 rpm, and is designed to increase hydrogen pressure from 30 psia to 1,225 psia through high – pressure ducting at a flowrate which develops 7,800 brake horsepower.

Power for operating the turbopump is provided by

a high-speed, two-stage turbine. Hot gas from the gas generator is routed to the turbine inlet manifold which distributes the gas to the inlet nozzles where it is expanded and directed at a high velocity into the first stage turbine wheel.

After passing through the first stage turbine wheel, the gas is redirected through a ring of stator blades and enters the second stage turbine wheel. The gas leaves the turbine through the exhaust ducting.

Three dynamic seals in series prevent the pump fluid and turbine gas from mixing. Power from the turbine is transmitted to the pump by means of a one-piece shaft.

OXIDIZER TURBOPUMP

The oxidizer turbopump is mounted on the thrust chamber diametrically opposite the fuel turbopump.

|

It. is a single-stage centrifugal pump with direct

J-2 Major Component Breakdown

SATURN V NEWS

above the fuel inlet manifold. Power from the turbine is transmitted by means of a one-piece shaft to the pump. The velocity of the liquid oxygen is increased through the inducer and impeller. As the liquid oxygen enters the outlet volute, velocity is converted to pressure and the liquid oxygen is discharged into the outlet duct at high pressure.

Bearings in the liquid hydrogen and liquid oxygen turbopumps are lubricated by the fluid being pumped because the extremely low operating temperature of the engine precludes use of lubricants or other fluids.