RANGE SAFETY SYSTEM

The range safety system terminates vehicle flight upon command of the range safety officer. Redundant systems are used throughout to provide maximum reliability.

Four antennas, mounted around the periphery of the third stage forward skirt assembly, feed two redundant secure range receivers located in the forward skirt assembly. Both receivers have separate power supplies and circuits. A unique combination of coded signals must be transmitted, received, and decoded to energize this destruct system.

A safety and arming device prevents inadvertent initiation of the explosive train by providing a positive isolation of the EBW detonator and explosive train until arming is commanded. Visual and remote indications of SAFE and ARMED conditions are displayed at all times at the firing center. Upon proper command, EBW firing units activate EBW detonators.

A CDF, detonated by the safety and arming device, explodes a flexible linear-shaped charge which cuts through the tank skin to disperse both fuel and oxidizer.

![]()

|

I SATURN V NEWS REFERENCE

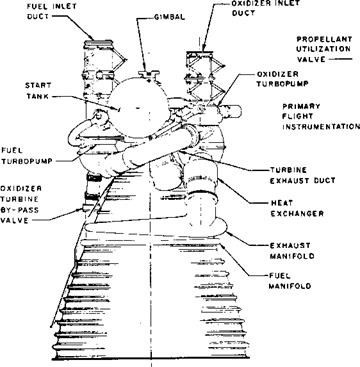

J-2 ENGINE FACT SHEET

|

LENGTH

WIDTH

NOZZLE EXIT DIAMETER THRUST (altitude)

SPECIFIC IMPULSE RATED RUN DURATION FLOWRATE: Oxidizer Fuel

MIXTURE RATIO CHAMBER PRESSURE (Pc)

WEIGHT, DRY, FLIGHT CONFIGURATION

EXPANSION AREA RATIO

COMBUSTION TEMPERATURE

Note: J-2 engines will be uprated to a maximum

11 ft. 1 in.

6 ft. SV2 in.

6 ft. 5 in.

225,0 lb.

424 sec. (427 at 5:1 mixture ratio)

500 sec.

449 lb sec (2,847 gpm)

81.7 lb sec (8,365 gpm)

5.5:1 oxidizer to fuel 763 psia 3,480 lb.

27.5:1

5,750°F

of 230,000 pounds of thrust for later vehicles.

I SATURN V NEWS REFERENCE