AUXILIARY PROPULSION SYSTEM

The APS provides auxiliary propulsive thrust to the stage for three-axis attitude control and for ullage control. Two APS modules are mounted 180c apart on the aft skirt assembly. Two solid propellant rocket motors are mounted 180° apart between the APS modules on the aft skirt assembly and provide additional thrust for ullage control.

APS Modules

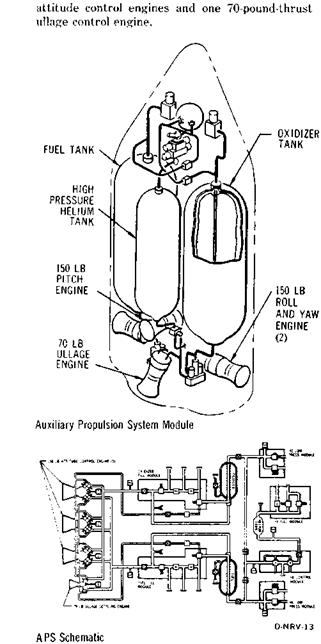

Each APS module contains three 150-pound-thrust

5-9

SATURN V NEWS REFERENCE

The attitude control engines are fired upon command from the IU in short duration bursts for attitude control of the stage during the orbital coast phase of flight. Minimum engine-firing pulse-duration is approximately 70 milliseconds. The attitude control engines are approximately 15 inches long with exit cones approximately 6.5 inches in diameter. Engine cooling is accomplished by an ablative process.

The ullage control engines are fired also upon command from the IU during the transition between J-2 engine first burn and the coast phase of flight to prevent undesirable propellant movement within the tanks. Firing continues for approximately 50 seconds until activation of the LH, continuous propulsive vent system. The ullage engines are again fired at the end of the third stage coast phase of flight and prior to J-2 engine restart to assure proper propellant positioning at inlets to the propellant feed lines during propellant tank repressurization.

The ullage control engines are similar to the attitude control engines and are approximately 15 inches long wuth an exit cone approximately 5.75 inches in diameter. Engine cooling is accomplished by an ablative process.

Each APS module contains an oxidizer system, fuel system, and pressurization system. The modules are self-contained and easily detached for separate checkout and environmental testing.

An ignition system is unnecessary because fuel and oxidizer are hypergolic (self-igniting). Nitrogen tetroxide lN,04), the oxidizer, is stable at room temperature.

Separate fuel and oxidizer tanks of the expulsion bellows type are mounted within the APS module along with a high-pressure helium bottle, which provides pressurization for both the propellant tanks and the associated plumbing and control systems.

The fuel, monomethyl hydrazine (CH. NTH.,), is stable to shock and extreme heat or cold. The APS module carries approximately 115 pounds of usable fuel and about 150 pounds of usable oxidizer.

Ullage Control

Two solid propellant Thiokol TX-280 rocket motors, each rated at 3,390 pounds of thrust, are ignited during separation of the second and third stages for ullage control approximately 4 seconds before J-2 ignition. This thrust produces additional positive stage acceleration during separation and positions LOX and LH2 propellants toward the aft end of the tanks. In addition, propellant boil-off vapors are forced to the forward end where they are safely vented overboard. Tank outlets are covered to ensure a net positive suction head (NPSH) to the propellant pumps, thus preventing possible pump cavitation during J-2 engine start. Ullage rockets ignite upon command from the stage sequencer and fire for approximately 4 seconds. At about 12 seconds from ignition, the complete rocket motor assemblies, including bracketry, are jettisoned from the stage, upon command from the stage sequencer.

|

SATURN V NEWS REFERENCE

Electrical Power and Distribution System

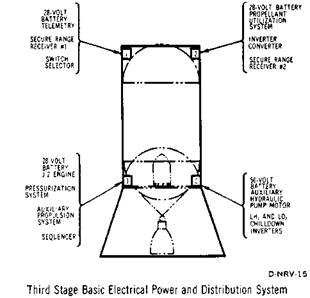

Four battery-powered systems provide electrical requirements for third stage operation. Forward Power System No. 1 includes a 28 VDC battery and power distribution equipment for telemetry, secure range receiver No. 1, forward battery heaters, and a power switch selector located in the forward skirt area.

Forward Power System No. 2 includes a 28 VDC battery and power distribution equipment for the PU assembly, inverter-converter, and secure range receiver No. 2.

Aft Power System No. 1 includes a 28 VDC battery and power distribution equipment for the J-2 engine, pressurization systems, APS modules, TM signal power, aft battery heaters, hydraulic system valves, and stage sequencer.

Aft Power System No. 2 includes a 56 VDC battery and power distribution equipment for the auxiliary hydraulic pump, oxidizer chilldowm inverter, and fuel chilldowm inverter.

Silver-oxide, zinc batteries used for electrical power and distribution systems are manually activated. The batteries are “one-shot” units, and not interchangeable due to different load requirements.

Electrical power and distribution systems are switched from ground power to the batteries bycommand through the aft umbilical prior to liftoff.

Telemetry and Instrumentation System

Radio frequency telemetry systems are used for transmission of stage instrumentation information to ground receiving stations. Five transmitters, using two separate antenna systems, are capable of returning information on 45 continuous output data channels during third stage flight. The telemetry transmission links consist of five systems using three basic modulation schemes: Pulse Amplitude Modulated/FM/FM (PAM/FM/FM); Single Side – band/FM (SS/FM); and Pulse Code Modulated/FM (PCM/FM). There are three separate systems using PAM/FM/FM modulation.

A Digital Data Acquisition System (DDAS) airborne tape recorder stores sampled data normally – lost during staging and over-the-horizon periods of orbital missions, and plays back information w-hen in range of ground stations.