THIRD STAGE

STAGE DESCRIPTION

Basically, the Saturn V third stage, the S-IVB, is an aluminum air-frame structure powered by a single, J-2 engine, which burns liquid oxygen and liquid hydrogen. The engine has a maximum thrust of 225.000 pounds. The structure has a bipropellant capacity of 228,000 pounds of fuel and oxidizer.

STAGE FABRICATION AND ASSEMBLY

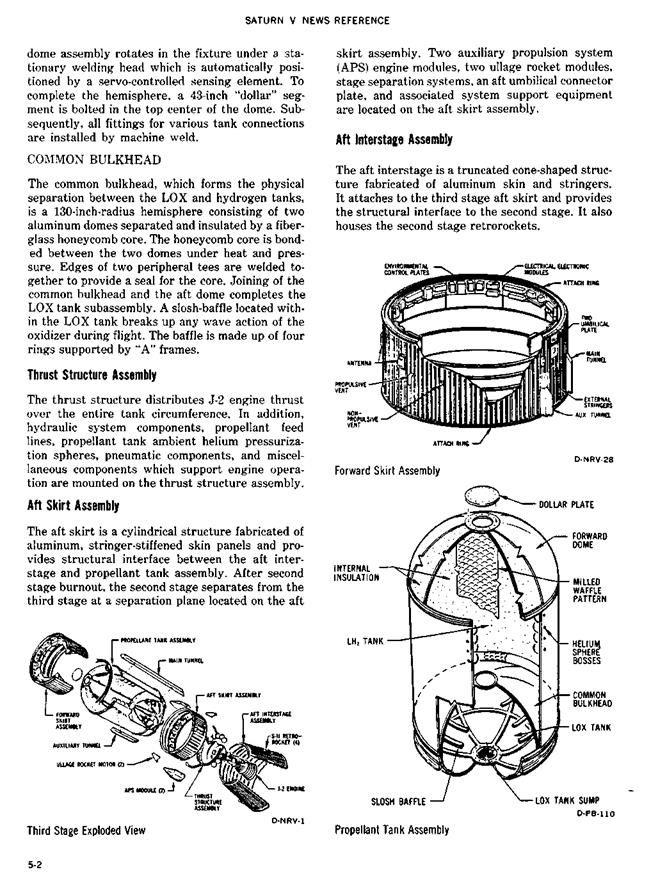

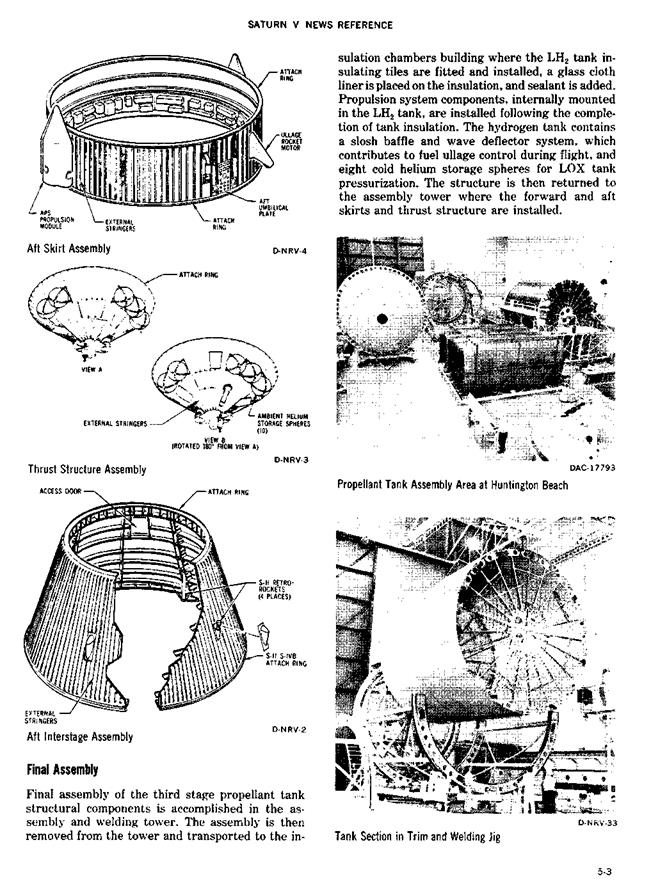

The third stage structure consists of a forward skirt assembly, propellant tank assembly, thrust structure assembly, aft skirt assembly, and aft interstage assembly. The propellant tank assembly consists of a single tank separated by a common bulkhead into a fuel compartment and an oxidizer compartment.

Forward Skirt Assembly

The forward skirt is a cylindrical aluminum skin and stringer structure that provides a hard attach point for the instrument unit. In addition, the for

ward skirt provides an interior mounting structure for electrical and electronic equipment that requires environmental conditioning, as well as range safety and telemetry antennas mounted around the exterior periphery. Environmental conditioning for electronic equipment is provided by cold plates which utilize a coolant supplied from the IU thermoconditioning system.

Propellant Tank Assembly

Structural elements of the propellant tank assembly are a cylindrical tank section, common bulkhead, aft dome, and forward dome. Seven segments are machined from aluminum alloy plate to form the tank section. A waffle pattern is then machine – milled into each segment to reduce weight and provide shell stiffness. The formed segments are joined into a complete cylinder by single-pass internal weld on a Pandjiris welding machine.

Aft and forward domes are made by forming "orange peel” segments on a stretch press. Orange peel segments are then joined in a dome welder. Each

|

Third Stage Production Sequence

6-і

|

|

|

|

|

|

D-NRV-40 |

Slosh Baffle…. Horizontal rings are installed inside LH2 tank for

propellant stabilization during flight.

|

D-NRV-42 |

Third stage vehicles reach end of assembly sequence with final assembly and checkout in 115-foot vertical towers.

Engine I nstalled—J-2 engine is attached to stage in final assembly tower at Huntington Beach.

Final installation of various subsystem components is performed in a checkout tower, along with the installation and alignment of the,1-2 engine. The stage is in a vertical position in the tower where a complete stage checkout of subsystems and systems is conducted except for actual ignition of engine. After satisfactory checkout, the stage is removed from the tower, placed on a dolly, and ground support rings are installed at each end of the stage. It is then painted, weighed, and prepared for shipment to the Douglas Sacramento Test Center for simulated and static firing of APS engines and J-2 engine.