Venting Subsystem

The venting subsystem is used during loading and flight operations. While the propellant tanks are being loaded, the vent valves (two for each tank) are opened by electrical signals from ground equipment to allow the gas created by propellant boil-off to leave the tanks. The valves are spring-loaded to be normally closed, but a relief valve will open them if pressure in the tanks reaches an excessive level. Each valve is capable of venting enough gas to

|

|

|

The LH2 recirculation subsystem pumps the propellants through the feed lines and valves and back to the LIL tank through a single return line. The pumps are powered from a 56-volt DC battery system located in the interstage; the batteries are ejected with the interstage approximately 30 seconds after first plane separation. Refore liftoff, power for the LH2 recirculation subsystem is supplied by ground equipment.

The LOX recirculation system works on the basis of a thermal syphon; heat entering the system is used to provide pumping action by means of fluid density differences across the system. Helium gas is used to supplement the density differences and thereby improve the pumping action.

Recirculation of oxygen begins at the start of tanking; LIL recirculation begins just before launch. The propellants continue to circulate through first stage firing and up until just before the first stage and second stage separate. While the subsystems are operating, the LH2 prevalves which lead to the combustion chambers are closed; as soon as the recirculation subsystem stops, the LH2 prevalves open and the engines ignite.

Propellant Management System

The propellant management system controls loading, flow rates, and measurement of the propellants. It includes propellant utilization, propellant loading, propellant mass indication, engine cutoff, and propellant level monitoring subsystems.

PROPELLANT UTILIZATION SUBSYSTEM

The propellant utilization subsystem controls the flow rates of liquid hydrogen and liquid oxygen in such a manner that both will be depleted simultaneously. It controls the mixture ratio so as to minimize propellant residuals (propellant left in the tanks) at engine cutoff. Propellant utilization bypass valves at the liquid oxygen turbopump outlets control flow of liquid oxygen in relation to the liquid hydrogen remaining. Control of the engine mixture ratio increases the stage’s payload capability. The propellant utilization subsystem is interrelated with the propellant loading subsystem and uses some of the same tank sensors and ground checkout equipment.

PROPELLANT LOADING SUBSYSTEM

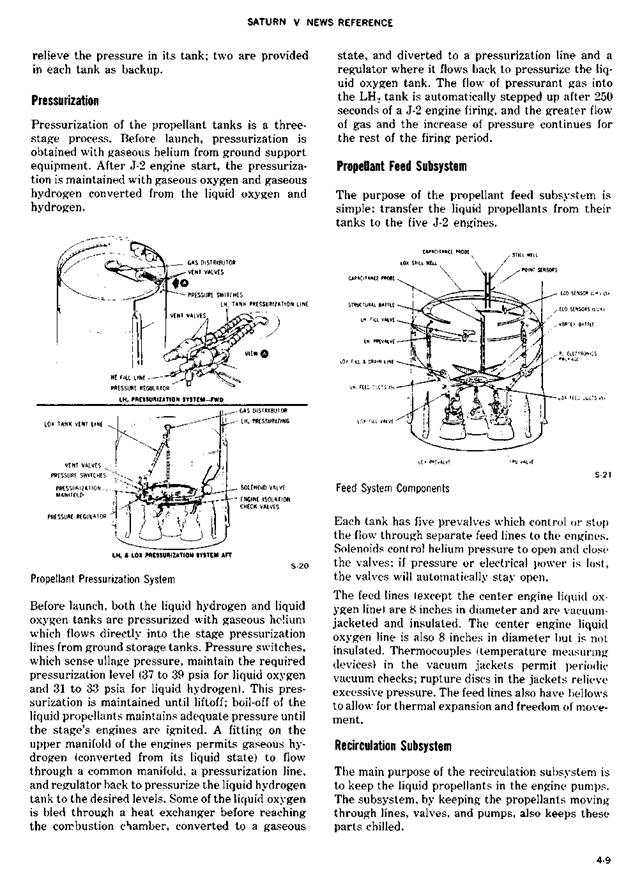

The loading subsystem is used to control propellant loading and maintain the quantity of propellants

in the tanks. Capacitance probes (sensors) running the full length of the propellant tanks sense liquid mass in the tanks and send signals to an airborne computer, which relays them to a ground computer to control loading. They also send signals to an airborne computer for the propellant utilization subsystem’s control of flow rates.

PROPELLANT MASS INDICATION SUBSYSTEM

The propellant mass indication subsystem is integrated with the propellant loading subsystem and is used to send signals to the flight telemetry system for transmission to the ground. It utilizes propellant loading sensors to determine propellant levels.

ENGINE CUTOFF SUBSYSTEM

The main function of the engine cutoff subsystem is to signal the depletion point of either propellant. It is an independent subsystem and consists of five sensors in each propellant tank and associated electronics. The sensors will initiate a signal to shut down the engines when two out of five sensors in the same tank signal that propellant is depleted.