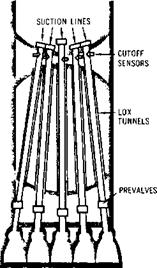

LOX DELIVERY SYSTEM

LOX is delivered to the engines by five 17-inch suction lines which pass through the fuel tank in five LOX tunnels. LOX suction ducts make up the lines from the LOX tank to the prevalves in the thrust structure. The ducts are equipped with gimbals and sliding joints to counteract vibration and swelling or contraction caused by temperature. Inside the tunnels, air acts as the insulation between the LOX-wetted lines and the fuel-wetted tunnels.

|

|

LOX Delivery

LOX level engine cutoff sensors in the suction lines assure safe engine shutdown and leave a minimum amount of unused LOX in the system.

In case of emergency, LOX prevalves in each suction line can stop the flow of LOX to the engines.

LOX CONDITIONING SYSTEM

it will result in gaseous oxygen (GOX). If heat is increased, the result is boiling and not temperature increase since evaporation is a cooling process. Depth in a body of LOX can increase due to the increase in hydrostatic pressure.

|

|

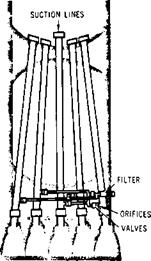

LOX Conditioning

The greatest chance for overheating in the LOX system is in the transmission surface of the suction lines. Also, the suction lines are too slender for maintenance of self-contained convection currents. This situation is unacceptable since intense boiling can lead to LOX geysering, which in turn can damage the LOX tank structurally. In addition, too high a LOX temperature near the engine inlets can cause a cavity in the LOX pumps and interfere with normal engine starting. Emergency bubbling or thermal pumping is used to correct this situation.

The bubbling technique sends helium into all five suction lines to cool the LOX rapidly. Ground support supplies helium through an umbilical coupling, and filter valves and orifices control the flow of helium into the suction lines. Thermal pumping is a term used to define pumping relatively cold LOX from the LOX tank into the suction lines.