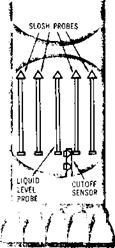

FUEL LEVEL SENSING AND ENGINE CUTOFF SYSTEMS

A cutoff sensor mounted on the bottom of the fuel tank provides signal voltages to shut off fuel after a predetermined level of depletion is reached. The fuel is measured during flight by four fuel slosh probes and a single liquid level measuring probe. Fuel levels are detected electronically and reported through the stage telemetry system. Telemetry

2-8

signals are transmitted to ground support either by radio frequency or, before launch, by coaxial cable. The cutoff sensor, mounted in the lower fuel tank bulkhead, initiates engine cutoff as fuel level falls below two sensing points on the probe. Engine cutoff will normally be initiated by sensors in the LOX system. The cutoff capability is provided as a backup system should fuel be depleted before LOX.

|

|

Fuel Level Sensing and Engine Cutoff

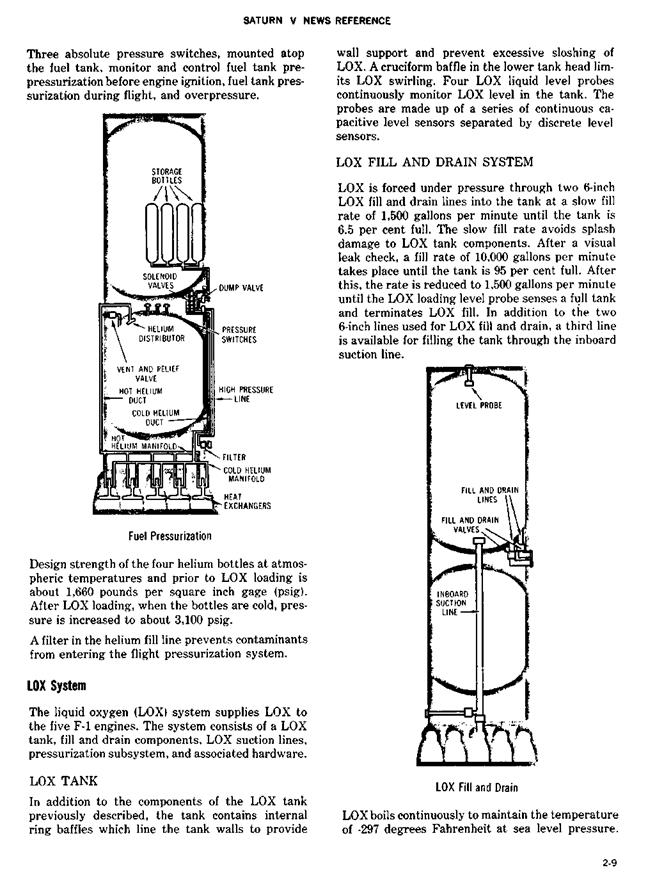

FUEL PRESSURIZATION SYSTEM

The fuel pressurization system maintains enough pressure in the fuel tank to provide proper suction at the fuel turbopumps to start and operate engines. The system consists of a helium supply, a helium flow controller, helium fill and drain components, a prepressurization subsystem, a fuel tank vent and relief valve, and associated ducts.

Four 31-cubic-foot, high pressure storage bottles in the LOX tank store the helium required for inflight pressurization of the fuel tank ullage. A high pressure line is used for filling the bottles and routing the helium to the flow controller. A solenoid dump valve is installed for emergencies. The helium flow controller uses five solenoid valves mounted parallel in a manifold to control helium flow to the fuel tank ullage. The cold helium duct routes helium from the flow controller to the cold helium manifold. From there, it is distributed to the heat exchangers on the five F-l engines. The hot helium manifold receives the heated, expanded helium from the engine heat exchangers and routes it to the hot helium duct which then carries it through the helium distributor and on to the fuel tank ullage.

|

|

SATURN V NEWS REFERENCE

It is replenished between the periods of loading and prepressurization through the fill and drain line.

Before LOX drain can be performed, the helium cylinders in the LOX tank must have their pressure decreased from about 3,100 psig to about 1,660 psig. Fill and drain valves are opened to complete drainage of the LOX tank although total evacuation of LOX from the tank requires draining the engines or waiting for boil-off of residual LOX. LOX drain can be speeded with the aid of a pressurizing gas, usually nitrogen.