. LOX Tank

The 331,000-gallon liquid oxygen tank is the largest component of the first stage booster, standing more than 64 feet in height. Its content is 297 degrees below zero Fahrenheit and provides the oxidizer to support combustion of the kerosene. Mixing of the two propellants is in a proportion to ensure complete combustion. Each second during flight, the engines consume more than 2,000 gallons of liquid oxygen.

|

В 8219-3 |

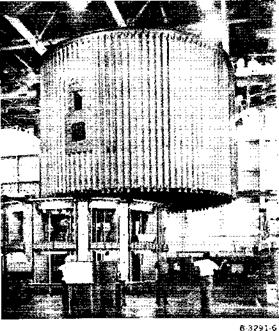

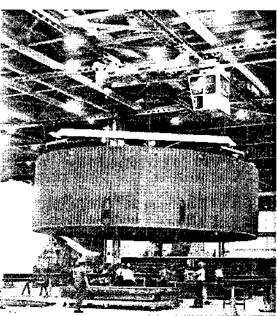

LOX Tank… The completed 331,000-gallon LOX tank is being

carried to the hydrostatic testing facility where it will be tested for leaks.

The LOX tank’s construction is similar to that of the fuel tank with the LOX tunnels beginning at the tank base, running through the intertank and fuel tank and to the engines. Dry weight of the LOX tank exceeds 19 tons.

Intertank

The intertank is not a tank in itself but serves as a 6-1/2-ton link between fuel and LOX tanks. Its composition is 18 corrugated skin panels supported by five frame ring assemblies.

The lower bulkhead of the LOX tank dips into the intertank while the upper bulkhead of the fuel tank extends upward into the intertank. Around the edges of the intertank are attached 216 fittings, which fasten the tank together with the Y-rings of the fuel and LOX tanks. The intertank structure also contains a personnel access door.

Umbilical Openings

An umbilical opening in the intertank provides for electrical and instrumentation requirements, emergency LOX drain, line pressurization, electrical conduit, and provisions for venting internal pressure. The thrust structure contains three of four other umbilical openings on the booster. The fourth is located in the forward skirt. The thrust structure umbilicals carry the fuel line, liquid oxygen drain, ground supply fluid lines, and all control functions essential in case of a vehicle abort.

|

|

|

|

|

|

|

|

|

|

|

|

|

|