Scramjets at NASA-Langley

The road to a Langley scramjet project had its start at North American Aviation, builder of the X-15- During 1962 manager Edwin Johnston crafted a proposal to modify one of the three flight vehicles to serve as a testbed for hypersonic engines.

This suggestion drew little initial interest, but in November a serious accident reopened the question. Though badly damaged, the aircraft, Tail Number 66671, proved to be repairable. It returned to flight in June 1964, with modifications that indeed gave it the option for engine testing.

The X-15 program thus had this flight-capable testbed in prospect during 1963, at a time when engines for test did not even exist on paper. It was not long, though, before NASA responded to its opportunity, as Hugh Dryden, the Agency’s Deputy Administrator, joined with Robert Seamans, the Associate Administrator, in approving a new program that indeed sought to build a test engine. It took the name of Hypersonic Research Engine (HRE).

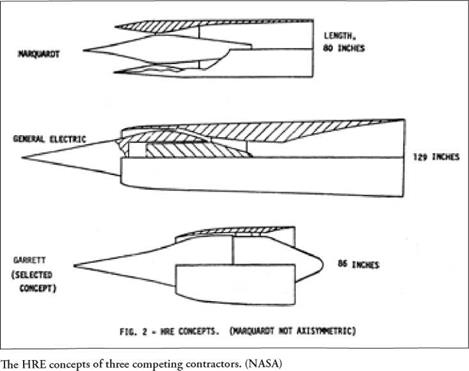

Three companies conducted initial studies: General Electric, Marquardt, and Garrett AiResearch. All eyes soon were on Garrett, as it proposed an axisymmet – ric configuration that was considerably shorter than the others. John Becker later wrote that it “was the smallest, simplest, easiest to cool, and had the best structural approach of the three designs.” Moreover, Garrett had shown strong initiative through the leadership of its study manager, Anthony duPont.15

He was a member of the famous duPont family in the chemical industry. Casual and easygoing, he had already shown a keen eye for the technologies of the future. As early as 1954, as a student, he had applied for a patent on a wing made of

|

|

composite materials. He flew as a co-pilot with Pan American, commemorating those days with a framed picture of a Stratocruiser airliner in his office. He went on to Douglas Aircraft, where he managed studies of Aerospaceplane. Then Clifford Garrett, who had a strong interest in scram – jets, recruited him to direct his company’s efforts.16

NASA’s managers soon offered an opportunity to the HRE competitors. The Ordnance Aerophysics Laboratory was still in business, and any of them could spend a month there testing hardware—if they could build scramjet components on short notice. Drawing on $250,000 in company funds, DuPont crafted a full-scale HRE combustor in only sixty days. At OAL, it yielded more than five hours of test data. Neither GE nor Marquardt showed similar adroitness, while DuPont’s initiative suggested that the final HRE combustor would be easy to build. With this plus the advantages noted by Becker, Garrett won the contract. In July 1966 the program then moved into a phase of engine development and test.17

Number 66671 was flying routinely, and it proved possible to build a dummy HRE that could be mounted to the lower fin of that X-15. This led to a flight – test program that approached disaster in October 1967, when the test pilot Pete Knight flew to Mach 6.72. “We burned the engine off,” Knight recalls. “I was on my way back to Edwards; my concern was to get the airplane back in one piece.” He landed safely, but historian Richard Hallion writes that the airplane “resembled

burnt firewood__ It was the closest any X-15 came to structural failure induced by

heating.”18

Once again it went back to the shops, marked for extensive repair. Then in mid – November another X-15 was lost outright in the accident that killed its test pilot, Mike Adams. Suddenly the X-15 was down from three flight-rated airplanes to only one, and while Number 66671 returned to the flight line the following June, it never flew again. Nor would it fly again with the HRE. This dummy engine had set up the patterns of airflow that had caused the shock-impingement heating that had nearly destroyed it.19

In a trice then the HRE program was completely turned on its head. It had begun with the expectation of using the X-15 for flight test of advanced engines, at a moment when no such engines existed. Now Garrett was building them—but

|

Test pilot William “Pete” Knight initiates his record flight, which reached Mach 6.72. (NASA) |

the X-15 could not be allowed to fly with them. Indeed, it soon stopped flying altogether. Thus, during 1968, it became clear that the HRE could survive only through a complete shift in focus to ground test.

Earlier plans had called for a hydrogen-cooled flightweight engine. Now the program’s research objectives were to be addressed using two separate wind-tunnel versions. Each was to have a diameter of 18 inches, with a configuration and flow path matching those of the earlier flight-rated concept. The test objectives then were divided between them.

A water-cooled Aerothermodynamic Integration Model (AIM) was to serve for hot-fire testing. Lacking provision for hydrogen cooling, it stood at the technical level of the General Electric and Pratt & Whitney test scramjets. In addition, continuing interest in flightweight hydrogen-cooled engine structures brought a requirement for the Structures Assembly Model (SAM), which did not burn fuel. It operated at high temperature in Langley’s eight-foot diameter High Temperature Structures Tunnel, which reached Mach 7-20

SAM arrived at NASA-Langley in August 1970. Under test, its inlet lip showed robustness for it stood up to the impact of small particles, some of which blocked thin hydrogen flow passages. Other impacts produced actual holes as large as 1/16

inch in diameter. The lip nevertheless rode through the subsequent shock-impingement heating without coolant starvation or damage from overheating. This represented an important advance in scramjet technology, for it demonstrated the feasibility of crafting a flightweight fuel-cooled structure that could withstand foreign object damage along with very severe heating.21

AIM was also on the agenda. It reached its test center at Plum Brook, Ohio, in August 1971, but the facility was not ready. It took a year before the program undertook data runs, and then most of another year before the first run that was successful. Indeed, of 63 test runs conducted across 18 months, 42 returned little or no useful data. Moreover, while scramjet advocates had hoped to achieve shock-free flow, it certainly did not do this. In addition, only about half of the injected fuel actually burned. But shocks in the subsonic-combustion zone heated the downstream flow and unexpectedly enabled the rest of the fuel to burn. In Becker’s words, “without this bonanza, AIM performance would have been far below its design values.”22

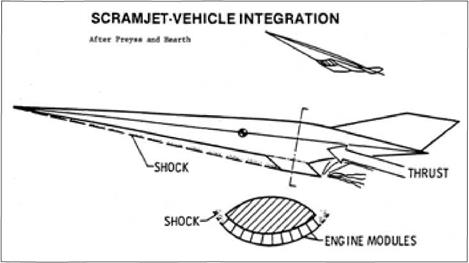

The HRE was axisymmetric. A practical engine of this type would have been mounted in a pod, like a turbojet in an airliner. An airliner’s jet engines use only a small portion of the air that flows past the wings and fuselage, but scramjets have far less effectiveness. Therefore, to give enough thrust for acceleration at high Mach, they must capture and process as much as possible of the air flowing along the vehicle.

Podded engines like the HRE cannot do this. The axisymmetry of the HRE made it easy to study because it had a two-dimensional layout, but it was not suitable for an operational engine. The scramjet that indeed could capture and process most of the airflow is known as an airframe-integrated engine, in which much of the aircraft serves as part of the propulsion system. Its layout is three-dimensional and hence is more complex, but only an airframe-integrated concept has the additional power that can make it practical for propulsion.

Podded engines like the HRE cannot do this. The axisymmetry of the HRE made it easy to study because it had a two-dimensional layout, but it was not suitable for an operational engine. The scramjet that indeed could capture and process most of the airflow is known as an airframe-integrated engine, in which much of the aircraft serves as part of the propulsion system. Its layout is three-dimensional and hence is more complex, but only an airframe-integrated concept has the additional power that can make it practical for propulsion.

Paper studies of airframe-integrated concepts began at Langley in 1968, breaking completely with those of HRE. These investigations considered the

Paper studies of airframe-integrated concepts began at Langley in 1968, breaking completely with those of HRE. These investigations considered the

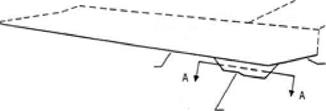

entire undersurface of a hypersonic aircraft as an element of the propulsion system. The forebody produced a strong oblique shock that precompressed the airflow prior to its entry into the inlet. The afterbody was curved and swept upward to form a half-nozzle. This concept gave a useful shape for the airplane while retaining the advantages of airframe-integrated scramjet operation.

Within the Hypersonic Propulsion Branch, John Henry and Shimer Pinckney developed the initial concept. Their basic installation was a module, rectangular in shape, with a number of them set side by side to encircle the lower fuselage and achieve the required high capture of airflow. Their inlet had a swept opening that angled backward at 48 degrees.

Within the Hypersonic Propulsion Branch, John Henry and Shimer Pinckney developed the initial concept. Their basic installation was a module, rectangular in shape, with a number of them set side by side to encircle the lower fuselage and achieve the required high capture of airflow. Their inlet had a swept opening that angled backward at 48 degrees.

This provided a cutaway that readily permitted spillage of airflow, which otherwise could choke the inlet when starting.

The bow shock gave greater compression of the flow at high Mach, thereby reducing the height of the cowl and the required size of the engine. At Mach 10 this reduction was by a factor of three. While this shock compressed the flow vertically, wedge-shaped sidewalls compressed it horizontally. This two-plane compression diminished changes in the inlet flow field with increasing Mach, making it possible to cover a broad Mach range in fixed geometry.

Like the inlet, the combustor was to cover a large Mach range in fixed geometry. This called for thermal compression, and Langley contracted with Antonio Ferri at New York University to conduct analyses. This brought Ferri back into the world of scramjets. The design called for struts as fuel injectors, swept at 48 degrees to parallel the inlet and set within the combustor flow path. They promised more effective fuel injection than the wall-mounted injectors of earlier designs.

The basic elements of the Langley concept thus included fixed geometry, airframe integration, a swept inlet, thermal compression, and use of struts for fuel injection. These elements showed strong synergism, for in addition to the aircraft undersurface contributing to the work of the inlet and nozzle, the struts also served as part of the inlet and thereby made it shorter. This happened because the flow from the inlet underwent further compression as it passed between the struts.23

|

Fuel-injecting strut. Arrows show how hydrogen is injected either parallel or perpendicular to the flow. (Garrett Corporation)

Experimental work paced the Langley effort as it went forward during the 1970s and much of the 1980s. Early observations, published in 1970, showed that struts were practical for a large supersonic combustor in flight at Mach 8. This work supported the selection of strut injection as the preferred mode.24

Initial investigations involved inlets and combustors that were treated as separate components. These represented preludes to studies made with complete engine modules at two critical simulated flight speeds: Mach 4 and Mach 7. At Mach 4 the inlet was particularly sensitive to unstarts. The inlet alone had worked well, as had the strut, but now it was necessary to test them together and to look for unpleasant surprises. The Langley researchers therefore built a heavily instrumented engine of nickel and tested it at GASL, thereby bringing new work in hypersonics to that center as well.

Mach 7 brought a different set of problems. Unstarts now were expected to be less of a difficulty, but it was necessary to show that the fuel indeed could mix and burn within the limited length of the combustor. Mach 7 also approached the limitations of available wind tunnels. A new Langley installation, the Arc-Heated Scramjet Test Facility, reached temperatures of 3,500°F and provided the appropriate flows.

![]()

|

|||

|

|||

|

|

||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

![]()

Airflow within an airframe-integrated scramjet. (NASA)

Separate engines operated at GASL and Langley. Both used heat sink, with the run times being correspondingly short. Because both engines were designed for use in research, they were built for easy substitution of components. An inlet, combustor, nozzle, or set of fuel-injecting struts could be installed without having to modify the rest of the engine. This encouraged rapid prototyping without having to construct entirely new scramjets.

More than 70 runs at Mach 4 were made during 1978, first with no fuel injection to verify earlier results from inlet tests, and then with use of hydrogen. Simple theoretical calculations showed that “thermal choking” was likely, with heat addition in the combustor limiting the achievable flow rate, and indeed it appeared. Other problems arose from fuel injection. The engine used three struts, a main one on the centerline flanked by two longer ones, and fuel from these side struts showed poor combustion when injected parallel to the flow. Some unwanted inlet-combustor interactions sharply reduced the measured thrust. These occurred because the engine ingested boundary-layer flow from the top inner surface of the wind-tunnel duct. This simulated the ingestion of an aircraft boundary layer by a flight engine.

The thermal choking and the other interactions were absent when the engine ran very fuel-lean, and the goal of the researchers was to eliminate them while burning as much fuel as possible. They eased the problem of thermal choking by returning to a fuel-injection method that had been used on the HRE, with some fuel being injected downstream as the wall. However, the combustor-inlet interactions proved to be more recalcitrant. They showed up when the struts were injecting only about half as much fuel as could burn in the available airflow, which was not the formula for a high-thrust engine.25

Mach 7 brought its own difficulties, as the Langley group ran off 90 tests between April 1977 and February 1979- Here too there were inlet-combustor interactions, ranging from increased inlet spillage that added drag and reduced the thrust, to complete engine unstarts. When the latter occurred, the engine would put out good thrust when running lean; when the fuel flow increased, so did the measured force. In less than a second, though, the inlet would unstart and the measured thrust would fall to zero.26

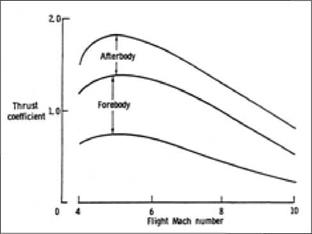

No simple solution appeared capable of addressing these issues. This meant that in the wake of those tests, as had been true for more than a decade, the Langley group did not have a working scramjet. Rather, they had a research problem. They addressed it after 1980 with two new engines, the Parametric Scramjet and the Step-Strut Engine. The Parametric engine lacked a strut but was built for ease of modification. In 1986 the analysts Burton Northam and Griffin Anderson wrote;

This engine allows for easy variation of inlet contraction ratio, internal area ratio and axial fuel injection location. Sweep may be incorporated in the

inlet portion of the engine, but the remainder of the engine is unswept. In fact, the hardware is designed in sections so that inlet sweep can be changed (by substituting new inlet sidewalls) without removing the engine from the wind tunnel.

The Parametric Scramjet explored techniques for alleviating combustor-inlet interactions at Mach 4. The Step-Strut design also addressed this issue, mounting a single long internal strut fitted with fuel injectors, with a swept leading edge that resembled a staircase.

Northam and Anderson wrote that it “was also tested at Mach 4 and demonstrated good performance without combustor – inlet interaction.”27

Northam and Anderson wrote that it “was also tested at Mach 4 and demonstrated good performance without combustor – inlet interaction.”27

How, specifically, did Langley develop a workable scramjet? Answers remain classified, with Northam and Anderson noting that “several of the figures have no dimension on the axes and a discussion of the figures omits much of the detail.”

A 1998 review was no more helpful. However, as early as 1986 the Langley researchers openly published a plot showing data taken at Mach 4 and at Mach 7. Curves showed values of thrust and showed that the scramjets of the mid-1980s indeed could produce net thrust. Even at Mach 7, at which the thrust was less, these engines could overcome the drag of a complete vehicle and produce acceleration. In the words of Northam and Anderson, “at both Mach 4 and Mach 7 flight conditions, there is ample thrust for acceleration and cruise.”28