NACA-Langley and John Becker

During the war the Germans failed to match the Allies in production of airplanes, but they were well ahead in technical design. This was particularly true in the important area of jet propulsion. They fielded an operational jet fighter, the Me-262, and while the Yankees were well along in developing the Lockheed P-80 as a riposte, the war ended before any of those jets could see combat. Nor was the Me – 262 a last-minute work of desperation. It was a true air weapon that showed better speed and acceleration than the improved P-80A in flight test, while demonstrating an equal rate of climb.28 Albert Speer, Hitler’s minister of armaments, asserted in his autobiographical Inside the Third Reich (1970) that by emphasizing production of such fighters and by deploying the Wasserfall antiaircraft missile that was in development, the Nazis “would have beaten back the Western Allies’ air offensive against our industry from the spring of 1944 on.”29 The Germans thus might have prolonged the war until the advent of nuclear weapons.

Wartime America never built anything resembling the big Mach 4.4 wind tunnels at Peenemunde, but its researchers at least constructed facilities that could compare with the one at Aachen. The American installations did not achieve speeds to match Aachen’s Mach 3-3, but they had larger test sections. Arthur Kantrowitz, a young physicist from Columbia University who was working at Langley, built a nine-inch tunnel that reached Mach 2.5 when it entered operation in 1942. (Aachen’s had been four inches.) Across the country, at NACA’s Ames Aeronautical Laboratory, two other wind tunnels entered service during 1945- Their test sections measured one by three feet, and their flow speeds reached Mach 2.2.30

The Navy also was active. It provided $4.5 million for the nation’s first really large supersonic tunnel, with a test section six feet square. Built at NACA-Ames, operating at Mach 1.3 to 1.8, this installation used 60,000 horsepower and entered service soon after the war.31 The Navy also set up its Ordnance Aerophysics Laboratory in Daingerfield, Texas, adjacent to the Lone Star Steel Company, which had air compressors that this firm made available. The supersonic tunnel that resulted covered a range of Mach 1.25 to 2.75, with a test section of 19 by 27-5 inches. It became operational in June 1946, alongside a similar installation that served for high-speed engine tests.32

Theorists complemented the wind-tunnel builders. In April 1947 Theodore von Karman, a professor at Caltech who was widely viewed as the dean of American aerodynamicists, gave a review and survey of supersonic flow theory in an address to the Institute of Aeronautical Sciences. His lecture, published three months later in the Journal of the Aeronautical Sciences, emphasized that supersonic flow theory now was mature and ready for general use. Von Karman pointed to a plethora of available methods and solutions that not only gave means to attack a number of important design problems but also gave independent approaches that could permit cross-checks on proposed solutions.

John Stack, a leading Langley aerodynamicist, noted that Prandtl had given a similarly broad overview of subsonic aerodynamics a quarter-century earlier. Stack declared, “Just as Prandtl’s famous paper outlined the direction for the engineer in the development of subsonic aircraft, Dr. von Karmans lecture outlines the direction for the engineer in the development of supersonic aircraft.”33

Yet the United States had no facility, and certainly no large one, that could reach Mach 4.4. As a stopgap, the nation got what it wanted by seizing German wind tunnels. A Mach 4.4 tunnel was shipped to the Naval Ordnance Laboratory in White Oak, Maryland. Its investigators had fabricated a Mach 5.18 nozzle and had conducted initial tests in January 1945- In 1948, in Maryland, this capability became routine.34 Still, if the U. S. was to advance beyond the Germans and develop the true hypersonic capability that Germany had failed to achieve, the nation would have to rely on independent research.

The man who pursued this research, and who built Americas first hypersonic tunnel, was Langleys John Becker. He had been at that center since 1936; during

the latter part of the war he was assistant chief of Stack’s Compressibility Research Division. He specifically was in charge of Langleys 16-Foot High-Speed Tunnel, which had fought its war by investigating cooling problems in aircraft motors as well as the design of propellers. This facility contributed particularly to tests of the B-50 bomber and to the aerodynamic shapes of the first atomic bombs. It also assisted development of the Pratt & Whitney R-2800 Double Wasp, a widely used piston engine that powered several important wartime fighter planes, along with the DC-6 airliner and the C-69 transport, the military version of Lockheed’s Constellation.35

It was quite a jump from piston-powered warbirds to hypersonics, but Becker willingly made the leap. The V-2, flying at Mach 5, gave him his justification. In a memo to Langley’s chief of research, dated 3 August 1945, Becker noted that planned facilities were to reach no higher than Mach 3. He declared that this was inadequate: “When it is considered that all of these tunnels will be used, to a large extent, to develop supersonic missiles and projectiles of types which have already been operated at Mach numbers as high as 5.0, it appears that there is a definite need for equipment capable of higher test Mach numbers.”

Within this memo, he outlined a design concept for “a supersonic tunnel having a test section four-foot square and a maximum test Mach number of 7.0.” It was to achieve continuous flow, being operated by a commercially-available compressor of 2,400 horsepower. To start the flow, the facility was to hold air within a tank that was compressed to seven atmospheres. This air was to pass through the wind tunnel before exhausting into a vacuum tank. With pressure upstream pushing the flow and with the evacuated tank pulling it, airspeeds within the test section would be high indeed. Once the flow was started, the compressor would maintain it.

A preliminary estimate indicated that this facility would cost $350,000. This was no mean sum, and Becker’s memo proposed to lay groundwork by first building a model of the big tunnel, with a test section only one foot square. He recommended that this subscale facility should “be constructed and tested before proceeding with a four-foot-square tunnel.” He gave an itemized cost estimate that came to $39,550, including $10,000 for installation and $6,000 for contingency.

Becker’s memo ended in formal fashion: “Approval is requested to proceed with the design and construction of a model supersonic tunnel having a one-foot-square test section at Mach number 7-0. If successful, this model tunnel would not only provide data for the design of economical high Mach number supersonic wind tunnels, but would itself be a very useful research tool.”36

On 6 August, three days after Becker wrote this memo, the potential usefulness of this tool increased enormously. On that day, an atomic bomb destroyed Hiroshima. With this, it now took only modest imagination to envision nuclear – tipped V-2s as weapons of the future. The standard V-2 had carried only a one-ton conventional warhead and lacked both range and accuracy. It nevertheless had been technically impressive, particularly since there was no way to shoot it down. But an advanced version with an atomic warhead would be far more formidable.

John Stack strongly supported Beckers proposal, which soon reached the desk of George Lewis, NACA’s Director of Aeronautical Research. Lewis worked at NACA’s Washington Headquarters but made frequent visits to Langley. Stack discussed the proposal with Lewis in the course of such a visit, and Lewis said, “Lets do it.”

Just then, though, there was little money for new projects. NACA faced a postwar budget cut, which took its total appropriation from $40.9 million in FY 1945 to $24 million in FY 1946. Lewis therefore said to Stack, “John, you know I’m a sucker for a new idea, but don’t call it a wind tunnel because I’ll be in trouble with having to raise money in a formal way. That will necessitate Congressional review and approval. Call it a research project.” Lewis designated it as Project 506 and obtained approval from NACA’s Washington office on 18 December.37

A month later, in January 1946, Becker raised new issues in a memo to Stack. He was quite concerned that the high Mach would lead to so low a temperature that air in the flow would liquefy. To prevent this, he called for heating the air, declaring that “a temperature of 600°F in the pressure tank is essential.” He expected to achieve this by using “a small electrical heater.”

The pressure in that tank was to be considerably higher than in his plans of August. The tank would hold a pressure of 100 atmospheres. Instead of merely starting the flow, with a powered compressor sustaining in continuous operation, this pressure tank now was to hold enough air for operating times of 40 seconds. This would resolve uncertainties in the technical requirements for continuous operation. Continuous flows were still on the agenda but not for the immediate future. Instead, this wind tunnel was to operate as a blowdown facility.

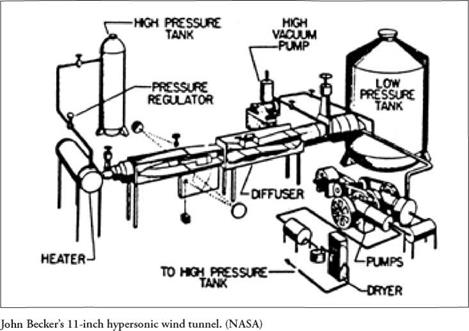

Here, in outline, was a description of the installation as finally built. Its test section was 11 inches square. Its pressure tank held 50 atmospheres. It never received a compressor system for continuous flow, operating throughout its life entirely as a blowdown wind tunnel. But by heating its air, it indeed operated routinely at speeds close to Mach 7.38

Taking the name of 11-Inch Hypersonic Tunnel, it operated successfully for the first time on 26 November 1947. It did not heat its compressed air directly within the pressure tank, relying instead on an electric resistance heater as a separate component. This heater raised the air to temperatures as high as 900°F, eliminating air liquefaction in the test section with enough margin for Mach 8. Specialized experiments showed clearly that condensation took place when the initial temperature was not high enough to prevent it. Small particles promoted condensation by serving as nuclei for the formation of droplets. Becker suggested that such particles could have formed through the freezing of C02, which is naturally present in air. Subsequent research confirmed this conjecture.39

|

|

The facility showed initial early problems as well as a long-term problem. The early difficulties centered on the air heater, which showed poor internal heat conduction, requiring as much as five hours to reach a suitably uniform temperature distribution. In addition, copper tubes within the heater produced minute particles of copper oxide, due to oxidation of this metal at high temperature. These particles, blown within the hypersonic airstream, damaged test models and instruments. Becker attacked the problem of slow warmup by circulating hot air through the heater. To eliminate the problem of oxidation, he filled the heater with nitrogen while it was warming up.40

A more recalcitrant difficulty arose because the hot airflow, entering the nozzle, heated it and caused it to undergo thermal expansion. The change in its dimensions was not large, but the nozzle design was highly sensitive to small changes, with this expansion causing the dynamic pressure in the airflow to vary by up to 13 percent in the course of a run. Run times were as long as 90 seconds, and because of this, data taken at the beginning of a test did not agree with similar data recorded a minute later. Becker addressed this by fixing the angle of attack of each test model. He did not permit the angle to vary during a run, even though variation of this angle would have yielded more data. He also made measurements at a fixed time during each run.41

The wind tunnel itself represented an important object for research. No similar facility had ever been built in America, and it was necessary to learn how to use it most effectively. Nozzle design represented an early topic for experimental study. At Mach 7, according to standard tables, the nozzle had to expand by a ratio of 104.1 to 1. This nozzle resembled that of a rocket engine. With an axisymmetric design, a throat of one-inch diameter would have opened into a channel having a diameter slightly greater than 10 inches. However, nozzles for Beckers facility proved difficult to develop.

Conventional practice, carried over from supersonic wind tunnels, called for a two-dimensional nozzle. It featured a throat in the form of a narrow slit, having the full width of the main channel and opening onto that channel. However, for flow at Mach 7, this slit was to be only about 0.1 inch high. Hence, there was considerable interest in nozzles that might be less sensitive to small errors in fabrication.42

Initial work focused on a two-step nozzle. The first step was flat and constant in height, allowing the flow to expand to 10 inches wide in the horizontal plane and to reach Mach 4.36. The second step maintained this width while allowing the flow to expand to 10.5 inches in height, thus achieving Mach 7. But this nozzle performed poorly, with investigators describing its flow as “entirely unsatisfactory for use in a wind tunnel.” The Mach number reached 6.5, but the flow in the test section was “not sufficiently uniform for quantitative wind-tunnel test purposes.” This was due to “a thick boundary layer which developed in the first step” along the flat parallel walls set closely together at the top and bottom.43

A two-dimensional, single-step nozzle gave much better results. Its narrow slitlike throat indeed proved sensitive; this was the nozzle that gave the variation with time of the dynamic pressure. Still, except for this thermal-expansion effect, this nozzle proved “far superior in all respects” when compared with the two-step nozzle. In turn, the thermal expansion in time proved amenable to correction. This expansion occurred because the nozzle was made of steel. The commercially available alloy Invar had a far lower coefficient of thermal expansion. A new nozzle, fabricated from this material, entered service in 1954 and greatly reduced problems due to expansion of the nozzle throat.44

Another topic of research addressed the usefulness of the optical techniques used for flow visualization. The test gas, after all, was simply air. Even when it formed shock waves near a model under test, the shocks could not be seen with the unaided eye. Therefore, investigators were accustomed to using optical instruments when studying a flow. Three methods were in use: interferometry, schlieren, and shadowgraph. These respectively observed changes in air density, density gradient, and the rate of change of the gradient.

Such instruments had been in use for decades. Ernst Mach, of the eponymous Mach number, had used a shadowgraph as early as 1887 to photograph shock waves produced by a speeding bullet. Theodor Meyer, a student of Prandtl, used schlie – ren to visualize supersonic flow in a nozzle in 1908. Interferometry gave the most detailed photos and the most information, but an interferometer was costly and difficult to operate. Shadowgraphs gave the least information but were the least costly and easiest to use. Schlieren apparatus was intermediate in both respects and was employed often.45

Still, all these techniques depended on the flow having a minimum density. One could not visualize shock waves in a vacuum because they did not exist. Highly rarefied flows gave similar difficulties, and hypersonic flows indeed were rarefied. At Mach 7, a flow of air fell in pressure to less than one part in 4000 of its initial value, reducing an initial pressure of 40 atmospheres to less than one-hundredth of an atmosphere.46 Higher test-section pressures would have required correspondingly higher pressures in the tank and upstream of the nozzle. But low test-section pressures were desirable because they were physically realistic. They corresponded to conditions in the upper atmosphere, where hypersonic missiles were to fly.

Becker reported in 1950 that the limit of usefulness of the schlieren method “is reached at a pressure of about 1 mm of mercury for slender test models at M = 7-0.”47 This corresponded to the pressure in the atmosphere at 150,000 feet, and there was interest in reaching the equivalent of higher altitudes still. A consultant, Joseph Kaplan, recommended using nitrogen as a test gas and making use of an afterglow that persists momentarily within this gas when it has been excited by an electrical discharge. With the nitrogen literally glowing in the dark, it became much easier to see shock waves and other features of the flow field at very low pressures.

“The nitrogen afterglow appears to be usable at static pressures as low as 100 microns and perhaps lower,” Becker wrote.48 This corresponded to pressures of barely a ten-thousandth of an atmosphere, which exist near 230,000 feet. It also corresponded to the pressure in the test section of a blowdown wind tunnel with air in the tank at 50 atmospheres and the flow at Mach 13.8.49 Clearly, flow visualization would not be a problem.

Condensation, nozzle design, and flow visualization were important topics in their own right. Nor were they merely preliminaries. They addressed an important reason for building this tunnel: to learn how to design and use subsequent hypersonic facilities. In addition, although this 1 l-inch tunnel was small, there was much interest in using it for studies in hypersonic aerodynamics.

This early work had a somewhat elementary character, like the hypersonic experiments of Erdmann at Peenemunde. When university students take initial courses in aerodynamics, their textbooks and lab exercises deal with simple cases such as flow over a flat plate. The same was true of the first aerodynamic experiments with the 11-inch tunnel. The literature held a variety of theories for calculating lift, drag, and pressure distributions at hypersonic speeds. The experiments produced data that permitted comparison with theory—to check their accuracy and to determine circumstances under which they would fail to hold.

One set of tests dealt with cone-cylinder configurations at Mach 6.86. These amounted to small and simplified representations of a missile and its nose cone. The test models included cones, cylinders with flat ends, and cones with cylindrical afterbodies, studied at various angles of attack. For flow over a cone, the British researchers Geoffrey I. Taylor and J. Ml Maccoll published a treatment in 1933- This quantitative discussion was a cornerstone of supersonic theory and showed its merits anew at this high Mach number. An investigation showed that it held “with a high degree of accuracy.”

The method of characteristics, devised by Prandtl and Busemann in 1929, was a standard analytical method for designing surfaces for supersonic flow, including wings and nozzles. It was simple enough to lend itself to hand computation, and it gave useful results at lower supersonic speeds. Tests in the 11-inch facility showed that it continued to give good accuracy in hypersonic flow. For flow with angle of attack, a theory put forth by Antonio Ferri, a leading Italian aerodynamicist, produced “very good results.” Still, not all preexisting theories proved to be accurate. One treatment gave good results for drag but overestimated some pressures and values of lift.50

Boundary-layer effects proved to be important, particularly in dealing with hypersonic wings. Tests examined a triangular delta wing and a square wing, the latter having several airfoil sections. Existing theories gave good results for lift and drag at modest angles of attack. However, predicted pressure distributions were often in error. This resulted from flow separation at high angles of attack—and from the presence of thick laminar boundary layers, even at zero angle of attack. These finds held high significance, for the very purpose of a hypersonic wing was to generate a pressure distribution that would produce lift, without making the vehicle unstable and prone to go out of control while in flight.

The aerodynamicist Charles McLellan, who had worked with Becker in designing the 11-inch tunnel and who had become its director, summarized the work within the Journal of the Aeronautical Sciences. He concluded that near Mach 7, the aerodynamic characteristics of wings and bodies “can be predicted by available theoretical methods with the same order of accuracy usually obtainable at lower speeds, at least for cases in which the boundary layer is laminar.”51

At hypersonic speeds, boundary layers become thick because they sustain large temperature changes between the wall and the free stream. Mitchel Bertram, a colleague of McLellan, gave an approximate theory for the laminar hypersonic boundary layer on a flat plate. Using the 11-inch tunnel, he showed good agreement between his theory and experiment in several significant cases. He noted that boundary – layer effects could increase drag coefficients at least threefold, when compared with

values using theories that include only free-stream flow and ignore the boundary layer. This emphasized anew the importance of the boundary layer in producing hypersonic skin friction.52

These results were fundamental, both for aerodynamics and for wind-tunnel design. With them, the 1 l-inch tunnel entered into a brilliant career. It had been built as a pilot facility, to lay groundwork for a much larger hypersonic tunnel that could sustain continuous flows. This installation, the Continuous Flow Hypersonic Tunnel (CFHT), indeed was built. Entering service in 1962, it had a 31-inch test section and produced flows at Mach 10.53

Still, it took a long time for this big tunnel to come on line, and all through the 1950s the 11-inch facility continued to grow in importance. At its peak, in 1961, it conducted more than 2,500 test runs, for an average of 10 per working day. It remained in use until 1972.54 It set the pace with its use of the blowdown principle, which eliminated the need for costly continuous-flow compressors. Its run times proved to be adequate, and the CFHT found itself hard-pressed to offer much that was new. It had been built for continuous operation but found itself used in a blowdown mode most of the time. Becker wrote that his 11-inch installation “far exceeded” the CFHT “in both the importance and quality of its research output.” He described it as “the only ‘pilot tunnel’ in NACA history to become a major research facility in its own right.”55

Yet while the work of this wind tunnel was fundamental to the development of hypersonics, in 1950 the field of hypersonics was not fundamental to anything in particular. Plenty of people expected that America in time would build missiles and aircraft for flight at such speeds, but in that year no one was doing so. This soon changed, and the keyyearwas 1954. In that year the Air Force embraced theX-15, a hypersonic airplane for which studies in the 11-inch tunnel proved to be essential. Also in that year, advances in the apparently unrelated field of nuclear weaponry brought swift and emphatic approval for the development of the ICBM. With this, hypersonics vaulted to the forefront of national priority.