The Space Shuttle Main Engines

Despite the experience with Centaur and the Saturn upper-stage engines, the main engines for the Space Shuttle presented a formidable challenge, mainly because of the extreme demands placed upon the engines in a system that also used solid-propellant rocket boosters

but still required a great deal of thrust from the main engines. In a partly reusable system, NASA’s requirements for staged combustion and extremely high chamber pressure made development of the space shuttle main engines (SSMEs) extraordinarily difficult.

The story of this development began in one sense on June 10, 1971, when—with the general configuration of the Space Shuttle still in flux—Dale D. Myers, NASA’s associate administrator for Manned Space Flight, communicated to the directors of the Manned Spacecraft Center (MSC), the Marshall Space Flight Center (MSFC), and the Kennedy Space Center (KSC) the management plan for the Space Shuttle. This gave lead-center responsibilities to MSC but retained general direction of the program at NASA Headquarters in Washington, D. C. MSC would have responsibility for system engineering and integrating the components, with selected personnel from MSFC and KSC collocated in Houston to support this effort. Marshall would have responsibility for the main propulsion elements, while Kennedy would manage the design of launch and recovery infrastructure and launch operations.77

Myers had managed the Navaho missile effort for North American and had become vice president of the Space Division, where he had been the general manager for the Apollo spacecraft. He had also overseen North American Rockwell’s studies for the Space Shuttle. In addition, he had experience with aircraft projects. Thus, he came to his new job with a strong background in all aspects of the shuttle (as launch vehicle, spacecraft, and airplane). At Marshall, von Braun had moved on in 1970 to become deputy associate administrator for planning at NASA Headquarters.

Myers had managed the Navaho missile effort for North American and had become vice president of the Space Division, where he had been the general manager for the Apollo spacecraft. He had also overseen North American Rockwell’s studies for the Space Shuttle. In addition, he had experience with aircraft projects. Thus, he came to his new job with a strong background in all aspects of the shuttle (as launch vehicle, spacecraft, and airplane). At Marshall, von Braun had moved on in 1970 to become deputy associate administrator for planning at NASA Headquarters.

His deputy director for scientific and technical matters, Eberhard Rees, had succeeded him as Marshall center director until Rees retired in 1973, to be succeeded by Rocco A. Petrone, who had earned a doctorate in mechanical engineering from MIT. Petrone had come from NASA Headquarters and returned there in 1974. He was succeeded by William R. Lucas, a chemist and metallurgist with a doctorate from Vanderbilt University who had worked at Redstone Arsenal and then Marshall since 1952 and become deputy director in 1971. Petrone reorganized Marshall, deemphasizing in-house capabilities to oversee and test large project components and giving more authority to project officers, less to lab directors, a change Myers approved. As Rees put it, Myers was “somewhat allergic to ‘too much’ government interference" with contractors, preferring less stringent oversight than Marshall had provided in the past.78

In February 1970, Marshall had released a request for proposals for the Phase B (project definition) study of the space shuttle main

engine. Contracts went to Rocketdyne, Pratt & Whitney, and Aerojet General. The engine was to burn liquid hydrogen and liquid oxygen in a 6:1 ratio at a combustion-chamber pressure of 3,000 pounds per square inch, well above that of any production engine, including the Saturn J-2, which had featured a pressure of about 787 pounds at the injector end of the 230,000-pound-thrust version. The shuttle engine was to produce a thrust of 415,000 pounds of force at sea level or 477,000 pounds at altitude. Although Rocketdyne had built the J-2 and a development version, the J-2S, with a thrust of 265,000 pounds and chamber pressure of 1,246 pounds per square inch, Pratt & Whitney had been developing an XLR129 engine for the Air Force Rocket Propulsion Laboratory. The engine actually delivered 350,000 pounds of thrust and operated at a chamber pressure of 3,000 pounds per square inch during 1970.79 Pratt & Whitney thus seemed to have an advantage in the competition.

At Rocketdyne, seasoned rocket engineer Paul Castenholz, who had helped troubleshoot the F-1 combustion-instability and injector problems and had been project manager for the J-2, headed the SSME 206 effort as its first project manager, even though he was a corporate Chapter 5 vice president. He saw that there was not time to build sophisticated turbopumps, so he decided to build a complete combustion chamber fed by high-pressure tanks. The NASA study contract did not provide funds for such an effort, so Castenholz convinced North American Rockwell to approve up to $3 million in company funds for the effort. By 1971, testing the engine at Nevada Field Laboratory near Reno, Rocketdyne had a cooled thrust chamber that achieved full thrust for 0.45 second. The thrust was 505,700 pounds at a chamber pressure of 3,172 pounds per square inch, exceeding the performance of Pratt & Whitney’s XLR129 by a considerable margin.80

Funding constraints led to combining Phase C and D contracts (to include actual vehicle design, production, and operations), so on March 1, 1971, Marshall released to the three contractors a request for proposals to design, develop, and deliver 36 engines. In July NASA selected Rocketdyne as winner of the competition, but Pratt & Whitney protested the choice to the General Accounting Office (GAO) as “manifestly illegal, arbitrary and capricious, and based upon unsound, imprudent procurement decisions." On March 31, 1972, the GAO finally decided the case in favor of Rocketdyne, with the contract signed August 14, 1972. This protest delayed development, although Rocketdyne worked under interim and letter contracts until the final contract signature.81

It was not until May 1972 that Rocketdyne could begin significant work on the space shuttle main engine in something close to its

final configuration, although some design parameters would change even after that. By then, however, NASA had decided on a “parallel burn" concept in which the main engines and the solid-rocket boosters would both ignite at ground level. The space agency had already determined in 1969 that the engine would employ staged combustion, in which the hydrogen-rich turbine exhaust contributed to combustion in the thrust chamber. It was the combination of high chamber pressure and staged combustion that made the SSMEs a huge step forward in combustion technology. In the meantime, they created great problems for the shuttle, but one of them was not combustion instability, the usual plague for engine development. Castenholz and his engineers had started development of the engine with an injector based on the J-2, which had shown good stability. For the shuttle, according to Robert E. Biggs, a member of the SSME management team at Rocketdyne since 1970, the firm had added “two big preventors [of instability] on an injector that was basically stable to begin with." He evidently referred to coaxial baffles, and they seem to have worked.82

The XLR129 had been a staged-combustion engine, and its success had given NASA and industry the confidence to use the same concept on the shuttle. But timing for such an engine’s ignition was both intricate and sensitive, as Rocketdyne and Marshall would learn. Rocketdyne’s design used two preburners with low – and high-pressure turbopumps to feed each of the propellants to the combustion chamber and provide the required high pressure. The XLR129 had used only a single preburner, but two of them provided finer control for the shuttle in conjunction with an engine-mounted computer, subcontracted to Honeywell for development. This computer monitored and regulated the propulsion system during start, automatically shut it down if it sensed a problem, throttled the thrust during operation, and turned off the engine at mission completion.83

The XLR129 had been a staged-combustion engine, and its success had given NASA and industry the confidence to use the same concept on the shuttle. But timing for such an engine’s ignition was both intricate and sensitive, as Rocketdyne and Marshall would learn. Rocketdyne’s design used two preburners with low – and high-pressure turbopumps to feed each of the propellants to the combustion chamber and provide the required high pressure. The XLR129 had used only a single preburner, but two of them provided finer control for the shuttle in conjunction with an engine-mounted computer, subcontracted to Honeywell for development. This computer monitored and regulated the propulsion system during start, automatically shut it down if it sensed a problem, throttled the thrust during operation, and turned off the engine at mission completion.83

By the winter and spring of 1974, development of the Honeywell controller had experienced difficulties relating to its power supply and interconnect circuits. These problems attracted the attention of NASA administrator James C. Fletcher and his deputy, George M. Low. The latter commented that Rocketdyne had done a “poor job" of controlling Honeywell, which itself had done a “lousy job" and was in “major cost, schedule, and weight difficulty." Rocketdyne had fallen behind in converting test stands at Santa Susana for testing components of the engine, including turbopumps. A cost overrun of about $4 million required congressional reprogramming. In a program that was underfunded to begin with, this was intolerable,

so pressured by Fletcher and Low, Rockwell International, as the firm became in 1973, shifted Castenholz to another position, replacing him ultimately with Dominick Sanchini, a tough veteran who had led development of the main-engine proposal in 1971. Despite 27 successful years devoted to the rocket business, with important achievements to his credit, Castenholz would no longer contribute directly to launch-vehicle development.

Meanwhile, about the same time, Marshall made J. R. Thompson its project manager for the space shuttle main engine. Trained as an aeronautical engineer at Georgia Institute of Technology, where he graduated in 1958, Thompson had worked for Pratt & Whitney before becoming a liquid-propulsion engineer at Marshall on the Saturn project in 1963, the year he earned his master’s degree in mechanical engineering at the University of Florida. He became the space engine section chief in 1966, chief of the man/systems integration branch in 1969, and main-engine project manager in 1974.84

In May 1975, both component testing (at Santa Susana) and prototype engine testing began, the latter at NASA’s National Space 208 Technology Laboratories (the former Mississippi Test Facility). Typ- Chapter 5 ically, there was about a month between testing of a component at Santa Susana and a whole engine in Mississippi. But test personnel soon learned that the highly complicated test hardware at Santa Susana was inadequate. As Robert Frosch, NASA administrator, said in 1978, “We have found that the best and truest test bed for all major components, and especially turbopumps, is the engine itself." Consequently, because of insufficient equipment to test components as well as engines, the program gradually ceased testing at Santa Susana between November 1976 and September 1977.85

There were many problems during testing, especially with turbopumps and timing. The timing problems involved “how to safely start and shut down the engine." After five years of analysis, as Biggs explained, Rocketdyne engineers had “sophisticated computer models that attempted to predict the transient behavior of the propellants and engine hardware during start and shutdown." Test personnel expected that the engine would be highly sensitive to minute shifts in propellant amounts, with the opening of valves being time-critical. Proceeding very cautiously, testers took 23 weeks and 19 tests, with replacement of eight turbopumps, to reach two seconds into a five-second start process. It took another 12 weeks, 18 tests, and eight more turbopump changes to momentarily reach the minimum power level, which at that time was 50 percent of rated thrust. Eventually Biggs’s people developed a “safe and repeatable start sequence" by using the engine-mounted computer, also

called the main-engine controller. “Without the precise timing and positioning" it afforded, probably they could not have developed even a satisfactory start process for the engine, so sensitive was it.

Following purging of the propulsion system with dry nitrogen and helium to eliminate moisture (which the propellants could freeze if left in the system), then a slow cooldown using the cryogenic propellants, full opening of the main fuel valve started the fuel flow that initially occurred from the latent heating and expansion that the hardware (still warmer than the liquid hydrogen) imparted to the cryogenic propellant. However, the flow was pulsating with a pressure oscillation of about two cycles per second (hertz) until chamber pressure in the main thrust chamber stabilized after 1.5 seconds. Then oxidizer flowed to the fuel and oxidizer preburners and the main combustion chamber in carefully timed sequence such that liquid oxygen arrived at the fuel preburner 1.4 seconds after the full opening of the main fuel valve, at the main combustion chamber at 1.5 seconds, and at the oxidizer preburner at 1.6 seconds. Test experience revealed that a key time was 1.25 seconds into the priming sequence. If the speed of turbine revolution in the high – pressure fuel turbopump at that precise moment was not at least 4,600 revolutions per minute, the engine could not start safely. So, 1.25 seconds became a safety checkpoint.

Following purging of the propulsion system with dry nitrogen and helium to eliminate moisture (which the propellants could freeze if left in the system), then a slow cooldown using the cryogenic propellants, full opening of the main fuel valve started the fuel flow that initially occurred from the latent heating and expansion that the hardware (still warmer than the liquid hydrogen) imparted to the cryogenic propellant. However, the flow was pulsating with a pressure oscillation of about two cycles per second (hertz) until chamber pressure in the main thrust chamber stabilized after 1.5 seconds. Then oxidizer flowed to the fuel and oxidizer preburners and the main combustion chamber in carefully timed sequence such that liquid oxygen arrived at the fuel preburner 1.4 seconds after the full opening of the main fuel valve, at the main combustion chamber at 1.5 seconds, and at the oxidizer preburner at 1.6 seconds. Test experience revealed that a key time was 1.25 seconds into the priming sequence. If the speed of turbine revolution in the high – pressure fuel turbopump at that precise moment was not at least 4,600 revolutions per minute, the engine could not start safely. So, 1.25 seconds became a safety checkpoint.

If any “combustor prime" coincided with a downward oscillation (dip) in the fuel flow, excessively high temperatures could result. Other effects of inaccurate timing could be destruction of the high-pressure oxidizer turbopump. Also, a 1 to 2 percent error in valve position or a timing error of as little as a tenth of a second could seriously damage the engine. Because of these problems, the first test to achieve 50 percent of rated thrust occurred at the end of January 1976. The first test to reach the rated power level was in January 1977. Not until the end of 1978 did the engineers achieve a final version of the start sequence that precluded the problems they encountered over more than three years of testing. There were also issues with shutdown sequencing, but they were less severe than those with safe engine start, especially critical because astronauts would be aboard the shuttle when it started.86

One major instance of problems with the high-pressure turbopumps occurred on March 12, 1976. Earlier tests of the high – pressure liquid-hydrogen pump, both at Santa Susana and in Mississippi, had revealed significant vibration levels, but not until the March 12 test had engineers recognized this as a major problem. The prototype-engine test on that day was supposed to last 65 seconds to demonstrate a 50 percent power level, rising to 65 percent

for a single second. The test did demonstrate 65 percent power for the first time, but engineers had to halt the test at 45.2 seconds because the high-pressure fuel turbopump was losing thrust. After the test, the pump could not be rotated with a tool used to test its torque. Investigation showed that there had been a failure of the turbine-end bearings supporting the shaft. Test data showed a major loss in the efficiency of the turbines plus a large vibration with a frequency about half the speed of the pump’s rotation. Experts immediately recognized this as characteristic of subsynchronous whirl, an instability in the dynamics of the rotors.

Although recognizing the problem, test personnel evidently did not know what to do about it in a system whose turbine-blade stresses and tip speeds were still close to the limits of technology in 1991 and must have been at the outskirts of the state of the engineering art 15 years earlier. In any event, to speed up a solution, the program assembled a team that ultimately included the premier ro – tordynamics experts in government, industry, and academia, from the United States and Great Britain. The pump was centrifugal, 210 driven by a two-stage turbine 11 inches in diameter that was deChapter 5 signed to deliver 75,000 horsepower at a ratio of 100 horsepower per pound, an order-of-magnitude improvement over previous turbopumps. The team studied previous liquid-hydrogen turbopumps like that on the J-2, which had exhibited subsynchronous whirl. Following a test program involving engine and laboratory tests, as well as those on components and subsystems, the investigators found 22 possible causes; the most likely appeared to be hydrodynamic problems involving seals that had a coupling effect with the natural frequency of the rotating turbines. Efforts to decrease the coupling effect included damping of the seals and stiffening the shaft. The fixes did not totally end the whirl but did delay its inception from 18,000 revolutions per minute, which was below the minimum power level, to 36,000 revolutions per minute, above the rated power level.

As these design improvements increased operating speeds, investigators learned that a mechanism unrelated to subsynchronous whirl was still overheating the turbine bearings, which had no lubrication but were cooled by liquid hydrogen. The team’s extensive analysis of the cooling revealed that a free vortex was forming at the bottom of the pump’s shaft where coolant flowed. This vortex reduced the pressure, hence the flow of coolant. In a piece of cut- and-try engineering, designers introduced a quarter-sized baffle that changed the nature of the vortex and allowed more coolant to flow. This fix and the elevation of the whirl problem to above the rated

power level permitted long-duration tests of the engine for the first time by early 1977.87

This problem with the fuel pump had delayed the program, but it was not as diabolical as explosions in the high-pressure liquid – oxygen turbopump. If a fire started in the presence of liquid oxygen under high pressure, it incinerated the metal parts, usually removing all evidence that could lead to a solution. After solution of the fuel-pump-whirl problem, there were four fires in the high-pressure oxygen turbopump between March 1977 and the end of July 1980. This turbopump was on the same shaft as the low-pressure oxygen turbopump that supplied liquid oxygen to the preburners. The common shaft rotated at a speed of nearly 30,000 revolutions per minute. The high-pressure pump was centrifugal and provided as much as 7,500 gallons of liquid oxygen at a pressure higher than 4,500 pounds per square inch. An essential feature of the pump’s design was to keep the liquid oxygen fully separated from the hydrogen – rich gas that drove its turbines. To ensure separation, engineers and technicians had used various seals, drains, and purges.

Despite such precautions, on March 24, 1977, an engine caught fire and burned so severely it removed most physical evidence of its cause. Fortunately, investigators used data from instrumentation to determine that the fire started near a complex liquid-oxygen seal. Since it was not evident what a redesign should involve, testing on other engines resumed, indicating that one of the purges did not prevent the mixing of liquid oxygen and fluids draining from hot gas. On July 25, 1977, engineers tried out a new seal intended as an interim fix. But it worked so well it became the permanent solution, together with increasing the flow rate of the helium purge and other measures.88

Despite such precautions, on March 24, 1977, an engine caught fire and burned so severely it removed most physical evidence of its cause. Fortunately, investigators used data from instrumentation to determine that the fire started near a complex liquid-oxygen seal. Since it was not evident what a redesign should involve, testing on other engines resumed, indicating that one of the purges did not prevent the mixing of liquid oxygen and fluids draining from hot gas. On July 25, 1977, engineers tried out a new seal intended as an interim fix. But it worked so well it became the permanent solution, together with increasing the flow rate of the helium purge and other measures.88

On September 8, 1977, there was another disastrous fire originating in the high-pressure oxygen turbopump. Data made it clear that the problem involved gradual breakdown of bearings on each end of the turbopump’s shaft, but there was no clear indication of the cause. Fixes included enhanced coolant flow, better balance in the rotors, heavier-duty bearings, and new bearing supports. The other two fires did not involve design flaws but did entail delays. In 1972, the shuttle program had expected to launch a flight to orbit by early March 1978. The engine and turbopump problems and many others involving the propulsion system were but some of the causes for not making that deadline, but engines would have kept the shuttle from flying that early if everything else had gone as planned.

By March 1978, the expected first-flight date had slipped to March 1979, but an engine fire and other problems caused even a Septem-

|

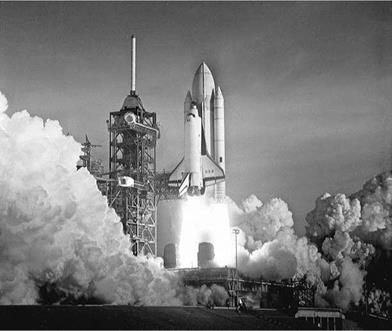

ber 1979 launch to be postponed. By early 1979, turbopumps were demonstrating longer periods between failures. By 1980, engines were expected to reach 10,000 seconds of testing apiece, a figure it had taken the entire program until 1977 to reach for all engines combined. But there continued to be failures in July and November 1980. Thus, not until early 1981 was the space shuttle main engine fully qualified for flight. Problems had included turbine-blade failures in the high-pressure fuel turbopump, a fire involving the main oxidizer valve, failures of nozzle feed lines, a burnthrough of the fuel preburner, and a rupture in the main-fuel-valve housing. But finally on April 12, 1981, the first Space Shuttle lifted off. After much troubleshooting and empirical redesign, the main engines finally worked.89

The large number of problems encountered in the development of the space shuttle main engines resulted from its advanced design. The high chamber and pump pressures as well as an operating life of 7.5 hours greatly exceeded those of any previous engine. Each shuttle had three main engines, which could be gimballed 10.5 degrees in each direction in pitch and 8.5 degrees in yaw. The engines could be throttled over a range from 65 to 109 percent of their rated power level (although there had been so many problems trying to demonstrate the 109 percent level in testing that it was not available on a routine basis until 2001). Moreover, the 65 percent minimum power

level (changed from the original 50 percent level) was unavailable at sea level because of flow separation. During launch, the three main engines ignited before the solid-rocket boosters. When computers and sensors verified that they were providing the proper thrust level, the SRBs ignited. To reduce vehicle loads during the period of maximum dynamic pressure (reached at about 33,600 feet some 60 seconds after liftoff) and to keep vehicle acceleration at a maximum of 3 Gs, the flight-control system throttled back the engines during this phase of the flight. Throttling also made it feasible to abort the mission either with all engines functioning or with one of them out.90

At 100 percent of the rated power level, each main engine provided 375,000 pounds of thrust at sea level and 470,000 pounds at altitude. The minimum specific impulse was more than 360 lbf-

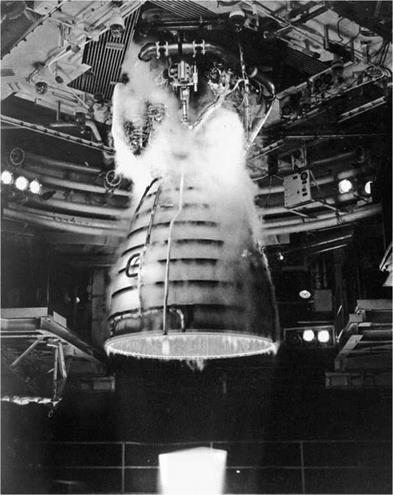

FIG. 5.4

FIG. 5.4

The space shuttle main engine firing during a test at the National Space Technologies Laboratories (later the Stennis Space Center), January 1, 1981, showing the regenerative cooling tubes around the circumference of the combustion chamber.

(Photo courtesy of NASA)

sec/lbm at sea level and 450 lbf-sec/lbm at altitude. This was substantially higher than the J-2 Saturn engine, which had a sea-level specific impulse of more than 290 lbf-sec/lbm and one at altitude of more than 420 lbf-sec/lbm. The J-2’s thrust levels were also substantially lower at 230,000 pounds at altitude. Not only were the SSMEs much more powerful than the earlier engines using liquid-hydrogen technology but they were also vastly more sophisticated.91