Getting Ready to Fly

One downside of creating something from scratch is that it doesn’t come with an instruction manual. As shuttle hardware development was winding down, astronauts began facing the next challenge—how do you teach people to fly a vehicle that no one has ever flown? Step one was figuring out how exactly the thing would fly and then developing procedures for flying it. That would be followed by step two, developing procedures for training people to follow the procedures for flying.

As the people who would have the job of actually flying the as-yet-unflown vehicle, the astronaut corps was tasked with providing operator input on the creation of both operating and training procedures. Since a large percentage of the corps at the time was rookie astronauts, in many cases procedures for flying a vehicle that had never been in space were being developed by astronauts who had also never been in space.

For example, the team of astronauts representing the Astronaut Office in figuring out how to use the shuttle’s robot arm, the remote manipulator system, was composed of astronauts John Fabian, Bill Lenoir, Bo Bobko, Sally Ride, and Norm Thagard. “One of the things that we worked on early,” recalled Fabian, “was the failure modes of the robotic arm and how to protect the orbit – er and the crew in the event one of these failure modes occurred. At the same time, we tried to figure out ways that we could continue on and do the job and do the mission at hand in the face of certain failures of the robotic arm.”

To tackle these issues, the team ran many simulations in Canada, where the arm was made, to work through procedures for nominal and off-nominal operations. Fabian recalled staying in Toronto quite a bit, around four hundred nights.

I used to try to change hotels about every one hundred nights up there because it got kind of old, staying in the same motel. And by far, I spent the most time

up there of the people that were working on it, because I was there in some very, very long simulations, trying to figure out the various workarounds. Some days were very long. Some days were seven o’clock in the morning until nine or ten at night, and we would take a break and go out and have dinner and then maybe go back to the plant. This wasn’t common. Usually it was close to an eight – to-fivejob, or a nine-to-sixjob or whatever. But ifyou were in the middle ofa long simulation, then you would work longer hours.

Fabian recalled that it was Sally Ride who wrote the procedures for the first flight of the arm on sts-2. The procedures, Ride said, came directly out of the simulations.

Until you actually start using something, it’s very difficult to make predictions on how well it’s going to work, what it’s used for, and how to accomplish the tasks that it’s designed to accomplish.

We did a lot of development of the visual cues. The astronaut controlling the arm looks at it out the window and also monitors its motion using several cameras. Often critical parts of the view are blocked, or the arm is a long ways from the window, or the work is delicate. In those cases, the astronaut needs reference points to help guide the direction he or she moves the arm. How do you know exactly that you’re lifting a satellite cleanly out of the payload bay and not bumping it into the structure? We also helped determine how you move the arm. What limits should be put on the use of the arm to make sure that it’s kept well within its design constraints? We did a lot of work on that. It was rewarding work, because it was at a time when the system was just being developed, and nobody had paid attention to those things yet.

Despite challenges like limited visibility, Fabian said that the work developing the interface and procedures resulted in the manipulator being “quite easy to use.” But, he noted, “it’s also a little bit intimidating, because you’ve got this thing which is fifty feet long out there in the cargo bay, and if you’re not careful, you could punch a hole in the wing or do something really stupid with it.”

Fabian views his contributions to rms development as one of his most significant accomplishments at NASA.

The rms has worked wonders on all of the flights. It’s really a great piece of equipment. The Canadians have gone on to design an arm now for the International Space Station, so they have gotten a big return out of their early investment in developing these electromechanical systems. We really had an opportunity with the rms to work on the human interface, to make it something which is straightforward and easy to use and intuitive in its application. That’s now followed over into the Space Station, and potentially it will go on to other applications. I think it’s the most significant thing that I did in my time, and I think it’s the thing I’m proudest of.

Fabian, along with astronaut Judy Resnik, was also involved in establishing how crew duty assignments would work during the Space Shuttle program. Previous nasa missions had carried crews no larger than three astronauts, and each astronaut had his own title and assignment. With the larger shuttle crews, there would be multiple mission specialists, and nasa had to decide how crew duties would be allocated and assigned. The system that was developed assigned mission specialist (ms) 1 overall responsibility for payloads and experiments in orbit. Mission specialist 2 was given primary responsibility for flight engineering, helping the pilot and commander during ascent and entry, and serving as backup for payloads. Mission specialist 3 had responsibilities for independent experiments and extravehicular activity, or eva.

“ms3 would be typically the most junior and the lowest training requirement but heavy on eva,” Fabian recalled. “ms1 would have the largest overall responsibility and, in principle, ought to be the most experienced member of the astronaut mission specialist crew. And MS2 had the most simulation time and spent an enormous amount of time in the simulator. . . . We split it that way in order to recognize the fact that the flight engineering role was the dominant training requirement for one of the mission specialists, and therefore that person shouldn’t be burdened with overall responsibility for the satellites.”

Astronaut input was also crucial in the development of the Shuttle Motion Simulator, or sms, which would become the primary system for training Space Shuttle crews. The sms was the only high-fidelity simulator capable of training crews for all phases of a mission, beginning at T minus thirty minutes and including simulated launch, ascent, abort, orbit, rendezvous, docking, payload handling, undocking, deorbit, entry, approach, landing, and rollout. The simulator could tilt up to ninety degrees, to the vertical position the orbiter would be in during launch, and could simulate the vibrations and noises of ascent.

Bryan O’Connor, who was selected as an astronaut in 1980 and assigned to sms development, described what it was like to see the more veteran Apollo-era astronauts apply their experience to the project.

All these guys had quite a history back through the Apollo program, and it was difficult not to pick up some of that climate and the cultural aspects of that, the pride that they had in that program, the frustrations they were having as we went forward, and things not being the same as they had been before, where it seemed like there was plenty of money. Now the environment we were in was a little different, but a lot of the cultural aspects that had made the Apollo program great were interesting to me to jump into and start learning about.

Since the Space Shuttle had yet to fly at the time, the development of the sms was based on analysis and ground-test data. “Part of what they were doing was to try to make things like the visual cues and the oral cues that they have for the crew as accurate as they could so that the environment in that trainer would be as close to real as they could get it,” O’Connor recalled.

I would be in the third seat taking notes and we would have two Apollo guys like John Young and T. K. Mattingly. . . trying to remember what it sounded like when the reaction control jets fired. The engineers would be outside the simulation putting in these models and turning up the volume and changing the pitch and the frequencies of these noises in the cockpit to make them sound space-like. Nobody knew what it would sound like on shuttle, but if they could make it sound something like what Apollo sounded like, they thought that was a good start. So it was fun to hear these guys arguing about whether some noise that was in there was accurate to the Apollo sounds when neither one of the two guys in the front had actually flown on the Apollo system for some years.

Determining how to calibrate the vibrations in the sms was another instance where O’Connor recalled the Apollo veterans really having a good time.

There was a fellow named Roger Burke, who was the head engineer in charge of developing the Shuttle Mission Simulator, and Roger had a little bit of a diabolical streak in him. One day we were trying to simulate what the vibrations might feel like during launch. Roger was asking these pros—and I think John Young was in the commander’s seat on this one——for advice on how much vibration seemed right. So we did several launches in a row and each time John would say, “No, you need some more. It’s going to vibrate more than that." So you can picture Roger Burke out there, turning this potentiometer up to get more vibration in there. Then we would fly another launch and John would say, “Nope, nope. That old Saturn, that had a lot more vibration than that. You’re going to have to tweak it up a little more, Roger."

So after about three or four of these things, Roger decided he was going turn it all the way to the max, and he did, and that was one hellacious ride. John and I both knew what he had done, and all we could do was just hold on. We were strapped in, but you still felt like you needed to hold on. You couldn’t see any of the displays at all. It was just a big blur, and we were bouncing around like it must have been the case in the old days, when people were going down the rutted dirt highways in buckboard wagons or something. Roger actually broke the system on that particular run.

O’Connor said that his role in the development of the sms taught him a valuable lesson that stayed with him throughout his time at nasa. “As I look back on it, I realize that what I thought was going to be a terrible job and not very much fun and out of the mainstream was just as important as any other job anybody else was doing. It was kind of an early learning event for me, because I realized then, and it came back to me many times later on, . . . that everybody’s important, no matter what their job is in the space program. There aren’t any nonimportant jobs.”

In regard to simulators like the sms, sTs-i pilot Bob Crippen noted that after the shuttle started flying, astronauts brought their experience back to the simulators to make them more accurate. “I know on the first flight we learned that the reaction control jets, which are used to maneuver the vehicle while you’re on orbit, really are loud,” Crippen said. “It sounds like a Howitzer going off outside the window. . . . I knew they’d be loud, but it was louder than I expected. It was a good thing to at least try to simulate that a little bit better in the simulator so that people weren’t really surprised by it.”

While ground-based simulators were used to train astronauts on the launch experience, a modified Gulfstream jet was used to re-create the experience of landing. The exterior of the Shuttle Training Aircraft (sta) was modified to better withstand the stresses of replicating the shuttle’s reentry profile. Changes to the cockpit echoed the layout of the shuttle’s flight deck and the view that astronauts would have while landing the shuttle.

Engine thrust reversers reproduced the “flying brick” aerodynamics of a gliding shuttle.

“The Gulfstream was extremely valuable,” said astronaut Joe Engle. “It was a very, very good simulation, a very accurate simulation of what the orbiter would do. The response was tuned as data would come back from the orbiter flights, but it was a very, very good training airplane and still considered by pilots as the very best single training tool that they have to land the shuttle.”

Astronaut Charlie Bolden praised the sta for giving him an excellent feeling for how the shuttle handled during entry and landing. “When I was Hoot’s [Gibson’s] pilot, sitting in the right-hand side, calling off airspeeds backwards, airspeed and altitude, putting the landing gear down, it was just like being in the sta. Combine that with the sms, it was just as if I had been there before. So, the world of simulation, even back then when it wasn’t as good as it is today, was awesome.”

Of course, an even better tool than an airplane for learning how an orbiter lands is an orbiter. In an unusual turn of events, the Space Shuttle landed before it ever launched for the first time.

The first orbiter completed was Enterprise, a flight-test vehicle ultimately incapable of flying into space but fully functional for atmospheric glides. Originally, Enterprise was to be a member of the operational orbiter fleet, a fact reflected in its official vehicle designation. Each of the operational orbiters has an Orbiter Vehicle, or ov, number. Enterprise, the first of the fleet, is ov-101. Enterprise was to be joined by three other orbiters: Columbia, ov-102; Discovery, ov-103; and Atlantis, ov-104. (Later would come Endeavour, ov-105.) An additional orbiter, the Static Test Article, was built as a ground-based test vehicle and was given the designation sTA-99. Enterprise was the first of the flying orbiters to be completed, but it was not given a space-worthy configuration. Rather, it was modified for use in glide flights to test how the vehicle would fly during entry and landing. The vehicle was also used for vibration testing at Marshall Space Flight Center in Huntsville, Alabama, to determine how an orbiter would withstand the stresses of launch, and to test the facilities at Kennedy Space Center in Florida to make sure they were ready for processing vehicles for launch. The plan was that all of those tests would be completed during the mid-1970s, and then Enterprise would be modified to take its place alongside Columbia as a spacecraft. However, it was determined that because of the weight of Enterprise, it would actually be easier to modify the Static Test Article instead, and thus sta-99 became ov-99, Challenger, while Enterprise would be used for other ground tests and ultimately would be the first orbiter to become a museum exhibit. Since the initial construction of ov-101 was completed in 1976, it was originally to be named Constitution, in honor of the U. S. bicentennial year. The name was changed as the result of a letter-writing campaign to the White House organized by fans of the television series Star Trek, which featured a starship named the uss Enterprise.

Between February and November 1977, Enterprise made a series of test flights, dubbed approach and landing tests (alts). The first flights were captive-carry tests, in which Enterprise was carried, unmanned, on the back of a specially modified Boeing 747 to study its aerodynamics. For later flights, the orbiter was released from the 747 during flight and piloted to the ground. Assigned as Enterprise’s crews for those flights were astronauts Dick Truly, Fred Haise, Gordon Fullerton, and Joe Engle.

Just prior to the start of the alt program, Fullerton was a key player in the design of the orbiter cockpit, which he believes contributed to his selection for the alt program. “I’d run across a lot of really crummy designs in learning to fly certain airplanes, and I thought I could do better,” Fullerton recalled.

As it turned out, that was a real challenge. With the shuttle, rather than lying on your back on the end ofa rocket riding into space, you had possibility ofcon – trolling it, both in the vertical mode and coming back as an airplane pilot at the end. The whole complexity of it is far more complex than the [earlier NASA ] rockets, as far as what the man could do. Putting all that together in a cockpit was really intriguing, and I enjoy working with stuffin an engineering sense, so it was perfect. I became the cockpit design czar, sort of, to go to really organize and set up and go to all the reviews. I had a big foam-core cardboard mockup of the entire cockpit built right there in the Astronaut Office, and I cycled all the other guys in there to say, “What can you see? What would you do if this was a checklist? Can you reach it?" So I did a human factor study on all that.

With Enterprise, Fullerton saw the designs and drawings he had signed off on come to life. “It’s very satisfying when you see [the results of what you did],” he said. “I can go get in an orbiter right now and look at the panels and think, ‘Oh, yeah, I remember all this.’ It’s a real feeling of personal pride.”

|

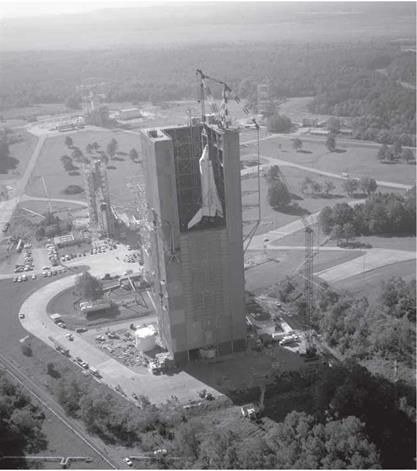

io. An aerial view of Enterprise hoisted into the Dynamic Test Stand at nasas Marshall Space Flight Center for the Mated Vertical Ground Vibration test. The test was the first time that all of the Space Shuttle elements were mated together. Courtesy nasa. |

As with the shuttle itself, training for the Enterprise test flights was very much a make-it-up-as-you-go-along process, Fullerton explained. “People say, ‘How do you train?’ thinking, well, you go to a school and somebody tells you how to do it. It’s not that at all. Somebody’s got to write the checklist, so you end up writing the checklist, working with each subsystems person and trying to come up with a prelaunch checklist for the approach and landing tests. So you’re doing the work, and the learning comes from doing jobs that needed to be done.”

The alt flights blurred the distinction between the crew members’ new careers as astronauts and their past experiences as test pilots. “[For] astronauts now, the orbiter’s a pretty stable configuration, so they go to a school with ground school instructors that know the system. . . . For alt and then subsequently on the Columbia, we were clearly test pilots because we were doing stuff that there wasn’t a procedure for. We were writing the procedure and then flying it for the first time.”

Not only did procedures have to be developed for the test, NASA had to decide exactly what the test would look like. On the one hand, for safety reasons, testing would have to be incremental, starting with the relatively low-risk captive-carry flights and ending with actual flight-profile landing tests. From that perspective, more flights were better, to assure safety at each step and to maximize the data results of the tests. On the other hand, the alt flights would use money and manpower that would otherwise be going toward preparations for the actual spaceflights of the shuttle, so more tests would delay the first flight. After a lengthy debate, the decision was made to not pick a number in advance, but to decide in real time what was needed. Ultimately, thirteen alt flights would be made.

“There were five captive, inert flights,” Fullerton explained,

where the orbiter was bolted on, completely inert, nothing moving, nothing running other than some instrumentation. Fitz Fulton and Tom McMurtry and flight engineers flew those five to the point where they said, “Okay, the combination is clear, and we understand what we’ve got here." So then they decided to have some x number of captive, active flights, where the crew got on board and powered up the apus and the electronics and all the subsystems, and those were dress rehearsals up to launch point. They had an open number of those. It turns out after three, they thought they’d learned all they needed to know. The systems were working. Had a couple offailures on number two, a big apupropellant leak. I was chasing that one. At three, they said, “Okay, it’s time to go do it," and they were trying to get to the end as quick as possible, so they could get on with the Columbia.

After the three crewed flights atop the 747, it was time to set Enterprise free and see how the vehicle and its crew would do on their own. Fullerton was pilot and responsible for monitoring the orbiter’s systems. With him, as commander, was astronaut Fred Haise. “On the very first flight, the instant we pushed the button to blow the bolts and hop off the 747, the shock of that actually dislodged a little solder ball and a transistor on one of the computers, and we had the caution tone go off and the red light. I mean instantly,” Fullerton recalled.

Im looking, and we had three CRTs, and one of those essentially went to halt. It was the one hooked to one of the four computers that monitored. This is pretty fundamental. All your control ofthe airplane is through fly-by-wire and these computers. So I had a cue card with a procedure if that happened, that we’d practiced in the simulator, and I had to turn around and pull some circuit breakers and throw a couple of switches to reduce your susceptibility to the next failure. I did that, and by the time I looked around, I realized, “Hey, this is flying pretty good, ” because I was really distracted from the fundamental evaluation ofthe airplane at first.

Haise recalled that it was surprising to him not to be able to see the 747 beneath him while Enterprise was still attached to the airplane. “No matter how you’d lean over and try to look out the side window you couldn’t view any part of it, not even a wingtip. It was kind of like a magic carpet ride. You’re just moving along the ground and then you take off. It was also deceptive sitting up that high. Things always looked like it was going slower than it was, for your taxiing and particularly the first takeoff, it didn’t look like we were going fast enough. I said to myself, ‘We’re not going fast enough to make it off the ground.’”

Leading up to this point, predictions and models had proposed how an orbiter would fly. There had been simulations, both in training equipment on the ground and on the Gulfstream in the air. But now it was time to move beyond the models and simulations. For the first time, nasa was about to learn how the orbiter would fly from the real thing.

“To me, even at the first flight, it was very clear it handled better in a piloting sense than we had seen in any simulation, either our mission simulators or the Shuttle Training Aircraft,” Haise explained.

It was tighter, crisper, in terms ofcontrol inputs and selecting a new attitude in any axis and being able to hold that attitude, it was just a better-handling vehicle than we had seen in the simulations, although they were close.

The landing also was a pleasant surprise from the standpoint of ground effect. Ground effect is a phenomenon you run into. When you get within one wingspan height ofthe ground, you start running into air-cushioning effects,

|

її. The Space Shuttle Enterprise participating in approach and landing tests. Courtesy nasa. |

which can, depending on the vehicle’s shape or configuration, be very different. It turned out the shuttle, in my view, was a perfect vehicle. If you get set up with the right sync rate, coasting along, you can literally almost go hands-off and it’ll settle on and land itself very nicely.

Flying two of the Enterprise flights—the second and fourth—were Joe Engle as commander and, as pilot, Dick Truly. Engle and Truly went on to crew the second shuttle flight, sts-2. Engle had participated in similar flights as part of another space plane program, the x-15, a joint endeavor by nasa and the air force, and had actually earned astronaut wings for flying into space with the air force before being brought in to nasa’s astronaut corps. As with the Enterprise test flights, the x-15 began its flight by being lofted by a larger aircraft. “I think one of the reasons that I was selected to fly the shuttle, initially,” Engle said, “was because of the experience that I’d had at Edwards (Air Force Base) with the x-15 and air launching from another vehicle, from a carrier vehicle.”

The orbiter’s aft section was covered with a tail cone on all of the captive flights and on the first three free flights. The tail cone reduced aerodynamic drag and turbulence and was used on all flights where the orbiter was

ferried cross-country. The last two free flights were flown without the tail cone, thus exposing the three simulated Space Shuttle main engines and two Orbital Maneuvering System (oms) engines, and most closely simulating actual conditions. The tail cone would continue to be used any time an orbiter was transported atop a 747 for upgrades or after a landing, up to and including their final flights to museum homes in 2012.

The tail cone not only made the orbiter easier to fly, it increased the time of the glide flight by reducing drag and slowing the vehicle’s descent rate. While the longer glide time—about five minutes with the cone versus about half that without—allowed nasa to gain more data on the orbiter systems in flight, the most important data would come when the cone was removed.

“The orbiter flew pretty benignly with that tail cone on,” Engle explained. “But that was not the configuration that we needed to really have confidence in, in order to commit for an orbital launch. So although we were getting more time on those systems with the tail cone on, from a performance standpoint and a piloting task standpoint, we really didn’t have what we needed until we flew it tail cone off.”

The fourth alt flight—the first without the tail cone—flew October 12, 1977. By that time the decision had been made that the program would end with the fifth free flight. While the first four landings had been on a dry lake bed, the final flight would land on the main concrete runway at Edwards Air Force Base. To ensure successful accomplishment of that more-challenging landing, the flight would be focused solely on that task. As a result, any last in-flight research would have to be conducted on the fourth flight.

For Engle, the development of the profile for that fourth flight was the most exciting and more rewarding time in the alt program. “Our goal on our flight was to pack as much meaningful flight-test data as we possibly could in that short period of time,” he explained. “We did work very hard, not only on the simulators, but at Edwards in both T-38s and the Gulfstream aircraft, in going through and tailoring and modifying and readjusting the profile so that we literally wasted no time at all from one data point to the other. We would go from one maneuver and make sure that we were set up for the subsequent maneuver. It was a very demanding, fun task.”

The grand finale of the alt program was free-flight five, with Haise and Fullerton making the first landing on a concrete runway. While largely successful, that flight test led to the discovery of a flaw in the design of the flight control software that led the pilot into a pilot-induced oscillation. “We bounced around and shocked a lot of people, probably more than [we realized],” Fullerton said. “It didn’t look that bad from inside the cockpit. But, again, that’s why you do tests. You find out. Then the debate was, should we fix that and test it some more—it was a strong feeling that was a pretty exciting landing, which shouldn’t be that exciting—or do we cut it off, fix it by testing and simulators, both airborne and on the ground. Do we know enough to press on? And it turned out that was the decision: you’ve got to cut the alt off so we can go on the Columbia and get into orbit.”

While the off-nominal landing—and the control problems that caused it—produced some concern, the experience was not without a silver lining. While most people had been pleased that, as a whole, Enterprise had flown and landed better than the models had predicted, the softer-than-predicted landings caused a problem for one particular team.

“The landing gear people were somewhat chagrined through most of that test program, because we were not landing hard enough to get them good data for the instrumentation they had on the landing gear struts,” Haise said. “I solved their problem on the fifth landing flight, where I landed on the runway and bounced the vehicle, and my second landing was about five or six foot a second. So that gave them the data, and they were very happy with that—although I wasn’t.”

Haise gave a lot of the credit for the success of the alt program to Deke Slayton, who agreed to run it after his return from his flight on the Apollo – Soyuz Test Project. “I frankly was very happy with Deke to volunteer for that role,” he reflected.

I mean, we had no one, in my mind, that was at Johnson Space Center at the time that was better suited to take on that role. And I think it was reflected in the way the program went. We missed the first free-flight release from the 747 [by] only two weeks from a schedule that had been made several years before. We completed the program like four or five months earlier than we’d planned, which is almost unheard ofin a test program, certainly something as complex as the orbiter. I think that was Deke’s leadership in pulling together both the contingent of NASA, which involved a lot of integration of Kennedy Space Center people and Dryden NASA people, as well as the contractor Rockwell in that phase.

Although the alt flights weren’t spaceflights, they were still seen as plum assignments by many in the astronaut corps. Hank Hartsfield recalled being disappointed that he wasn’t selected to one of the alt crews. “I was extremely disappointed that I wasn’t one of those, to be honest with you, and still don’t know why. I mean, I thought that having developed the flight control system, I’d be in a good position. So did a lot of other people, but we learned along the way. . . crew assignments are strange things. You don’t need to second-guess them. You just smile and press ahead.”

Astronaut Joe Allen recalled an interesting political side of the Enterprise tests involving Senator Barry Goldwater.

Senator Goldwater had been a pilot in the Second World War, and he knew a lot about aviation. He was very proud of the aviation success of America. He sat on several NASA committees, was interested in NASA, and was a strong supporter of NASA, but he thought this was the most cockamamie idea he had ever seen, affixing the orbiter to the top of the 747 and then exploding away the bolts that held it there. He knew in his gut that, once released, the orbiter would slide back and hit the tail of the 747, break it off and would be lost. He just knew it. He wanted hearings. I talked to his staffand said I would organize the hearing, but I requested fifteen minutes with the senator himself to go over the aerodynamics of the problem a little bit.

I brought a model and I said, “Senator Goldwater, I understand your concern, but Im a pilot as well. Let me just talk as one pilot to another. No science here; we’re just talking pilot talk. ”

Allen walked Goldwater through the process, step-by-step, explaining that because of the aerodynamics of the orbiter and the way it was mounted on the 747, its lift increased as the plane sped up, such that, on the ground, the plane was bearing the full weight of Enterprise, but toward the end of the flight, the orbiter was essentially weightless relative to the airplane. Shortly before the orbiter was released, the relationship changed so that Enterprise had enough lift that the orbiter was actually carrying some of the weight of the plane. Goldwater, he said, had no problem following when Allen broke the process down for him step-by – step.

“I said, ‘Now let me show you the calculations. The tail drops, and by the time it goes below where the orbiter is, the orbiter has moved back only an eighth of an inch toward the tail, so it’s not going to hit it.’ And he said, ‘I understand that. Why didn’t NASA tell me that before?”’

No hearing was ever held.

Allen’s political acumen came into play again in discussions with Indiana senator Birch Bayh, who sat on the Senate Appropriations Committee and whom Allen described as a rather liberal senator who was “not a friend of NASA.”

“I’m from Indiana; I know Indiana people,” Allen noted. “I got to know individuals in his office, including a most genuine lady who ran his office, and I discovered one day that she was from Rockville, Indiana. Rockville is a very tiny town. It has maybe two stoplights, or three, max. It is thirty miles from where I grew up in a somewhat bigger town, not much bigger. I knew something about Rockville that she did not know, and I got a photograph of the 747 with the Enterprise on top, flying along, a beautiful big photograph, and I took it in to this office.”

When he delivered the picture, Bayh’s secretary at first assumed it was for the senator. Allen corrected her.

I said, “No, this is for you. I brought this to you. I want to tell you something about this photo. This, of course, is the 747 and it’s worth $300 million, and this is the orbiter, even more valuable. "And I said, “The 747 on these tests is flown by an individual I think you know. His name is Tom McMurtry, and he grew up in Rockville, Indiana." He was a very skilled test pilot at NASA Dryden [Flight Research Center, Edwards, California]. And she said, “That’s being flown by Tommy McMurtry?" I said, “Yes, that’s correct." She said, “Golly. How much is all of that worth?" I said, “Well, it’s about a billion and a halfdollars." “Lordy," she says, “I remember when Tommy’s daddy wouldn’t let him drive the Buick. " She was older than Tom, but she knew him as a boy. She immediately put the picture up on the senator’s wall, and to my recollection the senator never voted against nasa again, ever, not once.

While the successful conclusion of the alt flights brought the shuttle to launch, back in Florida, work to prepare Columbia for its maiden voyage was running into problems. In particular, the vital thermal protection tiles required to safely shield the vehicle from the heat of reentry were proving not to work as well in practice as they did in theory.

“Initially, when they put the tiles on,” recalled Bob Crippen, they weren’t adhering to the vehicle like they should. In fact, Columbia, when they brought it from Edwards to the Kennedy Space Center the first time, it didn’t arrive with as many tiles as it left California with. People started working very diligently to try to correct that problem, but at the same time people said, “Well, if we’ve got a tile missing off the bottom of the spacecraft that’s critical to being able to come back in, we ought to have a way to repair it. ” So we started looking at various techniques, and I remember we took advantage of a simulator that Martin [Marietta Corporation] had out in Denver, where you could actually get some of the effect of crawling around on the bottom of the vehicle and what it would be like in zero g. I rapidly came to the conclusion I was going to tear up more tile than I could repair and that the only realistic answer was for us to make sure the tiles stayed on. . . . I concluded that at that time we couldn’t have realistically repaired anything.

Astronaut Charlie Bolden was part of Crippen’s team in that effort. “Ideally, what we wanted was something that would be like a spray gun or something that you could just squirt and it would go into place, and then you could use a trowel and smooth it out, and you could fly home,” he explained. “Everything seemed to be going very well initially, but every time we took whatever material was developed into vacuum, it just didn’t work. . . . The gases in the material would just start to bubble out and cause it to crack and pop, and we became seriously concerned that the repair material would probably do as much damage or more than we had by a missing tile.”

In the meantime, a new adhesive was developed that, it was believed, would greatly reduce the risk of tile loss. Additional analysis was also performed regarding the risks presented if there were tile loss in flight. Particular attention was paid to the possibility of a theoretical “zipper effect,” in which the loss of one tile would cause aerodynamic forces to rip off more tiles and most likely doom the vehicle. The team eventually determined that the zipper effect was unlikely.

Bolden noted that, in all of the analysis of potential thermal protection risks, he does not recall any discussion about damage to the reusable carbon – carbon on the leading edge of the wing, which in 2003 resulted in the loss of Columbia and its crew.

Never in my memory—and I’ve been through my notebooks and everything— never did we talk about the reusable carbon-carbon, the rcc, the leading edge of the wing, leading edge of the tail, and the nose cap itself. Nobody ever considered any damage to that because we all thought that it was impenetrable. In fact, it was not until the loss ofColumbia that I learned how thin it was. I grew up in the space program. I spent fourteen years in the space program flying, thinking that I had this huge mass that was about five or six inches thick on the leading edge of the wing. And to find after Columbia that it was fractions of an inch thick, and that it wasn’t as strong as the fiberglass on your Corvette, that was an eye-opener, I think, for all of us.

Based on the success of the alt program, NASA had looked to launch the first Space Shuttle mission by the end of 1979. However, a variety of issues, including those with the shuttle tiles, a problematic test firing of the Space Shuttle main engines, and an unexpected problem with insulation on the external tank after Columbia was stacked and on the launchpad, kept delaying the first launch of the Space Transportation System. While the delays were certainly not optimal, nasa and its astronauts worked to make the most of the extra time.

“Everybody wanted to get the bird in the air and show that it would fly okay, but the delays really provided us with more time to get ready for contingency situations,” recalled Engle, who was in line to command the second shuttle mission. “I remember very distinctly not having the impression of idling or spinning our wheels or treading water during those delays. We were engrossed in always new things to look at. . . . But we were very, very busy getting ready for things, overpreparing, I think in retrospect.”

According to Engle, the delays also helped the astronauts and Mission Control develop further into an effective team.

Because ofthe launch delays, we did have additional time to prepare for the flights and we got to work very closely and come to know and have a rapport with the controllers and, in fact, all the people in Mission Control, not just flight control, but all the people that were on the console, all [the] experts on the various systems. We knew them by voice, when we would hear transmissions. Of course, in the real flight, we only would talk to either the CapCom [capsule communicator, the astronaut in Mission Control who communicated with the crew], or sometimes pass information on to Don Puddy, the flight director. But we got to know pretty much who was on the console by what kind of response or direction we were given for certain simulated failures that we’d had during simulations. And that was good; that was really good. We worked as a very, very close-knit team, almost being able to think and read each other without a whole lot ofwords said.

Bob Crippen, the astronaut assigned to be pilot of the first shuttle launch, recalled touring nasa and its contractors during that period with sts-1 commander John Young to encourage the teams that were preparing their vehicle for flight.

The Space Shuttle is a pretty complicated vehicle, and certainly it was breaking some new frontiers, which, John and I being test pilots, it was a great mission for us. But when you have something that complicated, literally hundreds of thousands of people made sts-1 possible. You have to be depending on those folks doing their job right, because you cant check everything yourself. John and I spent a lot of time going to the various contractors and subcontractors, if nothing else, to try to put a human face on the mission; that we were flying it, and we appreciated all the work that they were doing.

Everywhere we went, the people really felt in their heart that they were doing something important for the nation, and that’s what John and I wanted them to feel, because that’s what they were doing. It doesn’t take but one person to do something wrong that can cost you a mission and cost lives. So when John and I climbed aboard the vehicle to go fly, we had been eyeball to eyeball with, I would say, maybe not all hundred thousand, but we had been eyeball to eyeball with thousands of folks.

The visits not only served to encourage the workforce responsible for preparing the vehicle for flight, they gave the shuttle’s first crew a unique, up – close look at what went into what the astronauts would be flying.

“We knew the vehicle pretty good,” Crippen said.

We knew its risks, but we also knew that it had a great deal to offer if it was successful. So when we climbed aboard, I think both of us felt very confident that the vehicle would fly and fly well.

So when I say that we literally rode on the shoulders ofhundreds of thousands of people, that’s what we did, and I felt good about it…. I did have the opportunity after the first mission to go around again and thank a lot of the people that made the mission a success. Signed lots of autographs and did those kinds of things, to hopefully make them feel good about the work they had done. That continues today with the program of Spaceflight Awareness, because it’s important that they get feedback about how important their work is. .. . We’re proud of what they’re doing, and what they’re doing is something great for the nation, and not only the nation, for the world, in my perspective. I’m proud of the shuttle. I’m proud to have been a part of it since almost its inception… . I think all the people that have been part of it ought to be proud of the job they’ve done.