Skylab Takes Shape

Well before the key decision was made to launch a dry workshop space station with a Saturn v, NASA went through a series of other decisions that shaped what was to eventually become Skylab. Though there had been many different ideas within NASA in the first half of the i960 s as to just what the space station should be like, one thing that many of those ideas had in common was the idea that a proper space station would involve the use of artificial gravity to be generated by the creation of a rotating station. By causing the facility to spin around a central axis, the centrifugal force generated would pull crewmembers toward the outside of the station, creating a sensation of some fraction of Earth gravity.

“There was quite an argument in the early stages, do you have artificial gravity or not,” said Mueller, who found himself a rare dissenter from the conventional wisdom. To make his point, Mueller decided to give others in the agency an idea of what life would be like for astronauts on such a facility. He had them join him at the Slow Rotation Room at the Naval Aerospace Medical Institute in Pensacola, Florida. The room spins around, generating

a centrifugal force pulling its occupants toward its perimeter. The experience is tolerable at first, even novel as the room seems to shift as the centrifugal force causes the direction of gravity to seem to change. However, after time the spinning can become increasingly uncomfortable. “And I had Bob Gilruth, and Wernher, and Sam [Phillips, head of the Apollo Program Office], and I riding in one of these rooms that spin, and after about half an hour, the great desire for artificial gravity dissipated,” he said. “I was having trouble convincing Wernher and Bob of [the disadvantages], but I inherently knew it.” Mueller said that his conviction regarding artificial gravity applied to missions to Mars as well as space stations—that it would be better to use techniques to mitigate the atrophying effect of weightlessness than to subject a Mars-bound crew to the rotation necessary to generate artificial gravity.

Because the Marshall-managed s-ivb stage was to be used as the basis for the workshop, Marshall was given the responsibility for hardware development for the workshop. Houston’s Manned Spacecraft Center, which had previously had the responsibility for spacecraft development, was tasked with overseeing the crew operations for the space station. “That really started the Marshall Space Flight Center into the space station business,” Mueller said. This arrangement had the additional benefit of allowing Mueller to keep many of the engineers on the Saturn team in NASA’s workforce. “Marshall was running out of work,” he said. It also, Mueller said, took the most advantage of the centers’ management resources. “Wernher was very enthusiastic about space stations, and Gilruth was sort of not very enthusiastic.”

Leland Belew, an engineer who had been involved in Saturn propulsion development at Marshall, was tapped to serve as the center’s Skylab program director. Belew said that he was talked into taking the job during an offsite discussion in 1966 during which he was relieved of concerns about how the program would be developed, including how much discretion Marshall would be given in a program centered around crew operations, then the exclusive domain of the Manned Spacecraft Center. “I got involved in Skylab basically with a meeting with von Braun and George Mueller down on Guntersville Lake [about a half-hour from Huntsville], and they talked me into taking the job after some arm twisting,” Belew said. “We stayed up all night in that activity. And, let me tell you, they absolutely stood behind

everything that they said. No questions asked. They lived up to everything they said they’d do.”

Belew said that the relationship between Marshall and msc evolved over the course of the Skylab program, with the Houston center gradually sharing its traditional crew operations duties with its Huntsville counterpart. “It changed with time. I know that from time to time they would pose a question of, ‘We can’t do that because. . .’ and we’d take it over. That sort of thing. We took them over one by one.”

However, he noted that in addition to the Apollo spacecraft, there were other areas where msc led the effort. “On the biomedical, we did everything that they wanted, no questions asked,” he said. “We absolutely did everything possible in all the biomedical stuff. That was their main thrust. They wanted to baseline that. We knew that was priority number one. And on the solar stuff, we did everything that they wanted.”

As the program developed, the two centers began working more and more closely together. The cooperation was facilitated by an aircraft that NASA scheduled to make daily runs between Huntsville and Houston, allowing Skylab team members at either center to work face-to-face with their counterparts at the other. “We used that airplane a lot,” Belew said, “because we had a close relationship with them.”

For a center that had been focused almost solely on developing propulsion hardware prior to that point, the transition to working with crew operations proved not to be a difficult one, Belew said. “No, it sort of flowed pretty naturally. Astronauts were always here, in the neutral buoyancy, and that sort of thing. And they enjoyed the heck out of it.”

On the subject of the origin of that neutral-buoyancy tank, George Hardy’s recollection echoed Mueller’s: “There is a story, too, about how that tank came into being. I don’t know all the details of that. In fact, I don’t want to know them; I’m not sure it’s safe to know them. That’s about as much as I know. There were some facilities that were approved and so forth, but somehow or another it turned out to be a water tank. And it was a very, very, extremely useful tool.”

Hardy also recalled the relationship between the two centers as one that evolved over time. He said, “There was some reluctance on having Marshall, who knew about big boosters with fire coming out the end of them but nothing about astronauts and what it takes to keep astronauts alive and

working. There were occasionally some pretty heated debates on how things were going to be done. I don’t know that there was a single time that we tried to contradict jsc on anything having to do with flight crew.

“But we started working closer together. Initially jsc had a contract with McDonnell Douglas for the Airlock Module, but that was transferred to Marshall. So Marshall ended up with basically all the workshop: the Airlock Module, the Multiple Docking Adapter, and the atm [Apollo Telescope Mount], which was basically the cluster, short of the Command Module.

“We worked very closely with jsc, and astronauts were very much involved in it. I can remember when we first started working with flight crew on the control panel on the atm, it seemed like we changed the configuration of the switches and the location of the switches by the week. Crew would come up, and they’d want it this way, and we’d fix it that way. Next week, they’d want it that way, we’d fix it that way.”

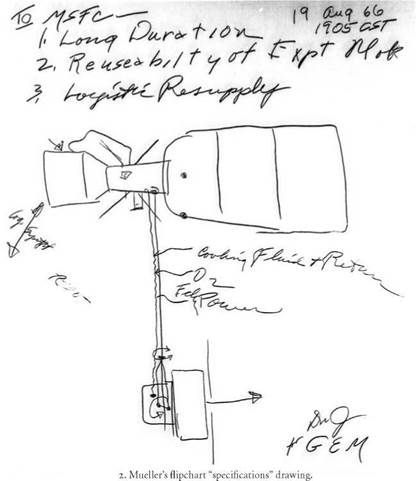

The decision to use an s-ivb stage as the basis for the workshop established its basic parameters, but the rough design for the station was formalized on 19 August 1966 in a meeting at Marshall Space Flight Center’s headquarters, Building 4200. Debate over the design of the station had been going on for some time. “That was the culmination of a series of meetings that we had,” Mueller said. “But we were not closing in.” During the meeting, Mueller did a quick sketch of what the space station was going to look like. The crude felt pen drawing on a flip chart showed the large cylindrical workshop with an Apollo spacecraft connected to it via a smaller docking cylinder. Connected to the docking cylinder by a tether was an Apollo Telescope Mount solar observatory. Mueller had to leave the meeting early, but before the meeting adjourned, his deputy, Maj. Gen. David Jones, initialed it for him, and the sketch became law—NASA had a design for its space station.

George Hardy described the meeting in which Mueller introduced the cluster concept: “It was here at Marshall, again at a management council meeting, where again the primary subject was a lunar mission, and Skylab got tacked on to the end of the day for a little discussion. Mueller was great at that; he could take one meeting and put an add-on to it for something that he wanted to spend a lot of time on. That’s when he first introduced us to the so-called cluster concept. Because even though a lot of missions had been brought together and integrated, we still had a so-called orbital workshop mission, and we still had an atm mission.

“So that’s when he got up from his chair, and he went up to a flipchart with a magic marker, and he actually drew the sketch. And General Jones, who was his deputy, came up and signed it. We [had] all kind of kidded about it, talked about it, and said ‘Is that our new specification?’ And he said, ‘Yeah, that’s your new specification,’ and Jones got up and signed it. That’s what we got as our direction. That was the original direction. That really solidified the program.”

In 1965 NASA was still pursuing the wet workshop option, which was then seen as the best way to develop an orbital workshop program as quickly as possible. Mueller had been working to get a wet workshop-based space station into orbit as quickly as possible with an original target date set for early 1968, which would have established an orbital workshop during the early phase of the Apollo flight program. Everything changed though on 27 January 1967 with the Apollo 1 pad fire. During a routine rehearsal for their upcoming mission, astronauts Gus Grissom, Ed White, and Roger Chaffee were killed when a fire started in their spacecraft and spread rapidly in its pure oxygen atmosphere. “It obviously had a real effect. We were scrambling to get AAP pulled together,” Mueller said. “That abruptly disappeared from the agenda.”

The delay allowed time to further think through the debate involving the wet and dry workshops. One of the arguments for the wet workshop program had been its perceived benefits in fast-tracking the workshop program, allowing it to begin concurrent with the early Apollo missions. After the fire, however, with the efforts to get Apollo back on track, aap became a lower priority in the agency. With the loss of that supposed advantage, the pros and cons of the debate received a closer look. Each side had its proponents. “The dry workshop was really pushed forward by a scientist, Homer Newell,” Belew said, adding that Newell was to heavily influence another major decision in the program as well. “Homer Newell insisted that we have two workshops, fully equipped. He insisted that we make them identical in every way.” Newell was to get his way in that also; two workshops were built.

The astronaut office also came out in support of switching to the dry workshop, largely at the recommendation of Apollo 7 astronaut Walt Cunningham, who had been the corps’ representative on Apollo Applications. “I give him credit for supporting it from our office,” said Skylab 11 commander Alan

|

|

Bean, who had been involved in Apollo Applications himself prior to being moved to the Apollo program, leading up to his assignment to Apollo 12. “He was the guy that was pushing to have it on a Saturn v and everything, which I thought was real great. And also I give him credit for going against the general office hierarchy position and convincing them that would be a better way. I think that’s good, too, if you can struggle against Deke [Slayton] and Al [Shepard] and others and turn out to be right.”

In addition to Gilruth another outspoken advocate of the wet workshop option was NASA spacecraft designer Max Faget, who had been instrumental in the development of the Mercury, Gemini, and Apollo vehicles. “We

sort of pinned him down in one of our management council missions, and he backed off a little bit,” Belew said.

The debate culminated with Mueller’s hands-on experience in the neutral-buoyancy tank at Marshall. From that moment the future was set. Mueller made the recommendation to the agency’s administrator that the Apollo Applications Program space station be a dry workshop and be launched on a Saturn v. The announcement that his recommendation had been accepted was made on 22 July 1969, two days after the Apollo 11 moon landing. “Maybe my credibility went up enough [after the landing],” Mueller said. “After the fire, it took a while to get my credibility back.”

The decision was to prove one of the most vital, if not the single most important, turning points in the development of Skylab. It not only made the program possible by avoiding tasks that may have proved impossible, but it also gave the workshop new purpose. From that moment all the various parts of what had been the diverse Apollo Applications Program missions began becoming a part of one unified program—the space station. (It was in February 1970 that the consolidated space station program was given the name “Skylab.” An Air Force employee working with nasa, Donald L. Steelman, had submitted the idea when the agency solicited suggestions. While other suggestions included such things as continuations of the mythological nomenclature used for Mercury, Gemini, and Apollo, Steelman’s straightforward suggestion was based on the fact the facility would be a laboratory in the sky.)

What had been planned as an entire series of Apollo Applications spaceflights could all be manifested aboard a single launch of a Saturn v. Missions included in the bailiwick of Apollo Applications included microgravity science, long-duration spaceflight, solar astronomy, and Earth observations. A number of the flights originally discussed were lunar missions, including continued surface exploration after the initial landings. These flights were later transferred to the Apollo program. Originally, each of those fields was to be conducted independently, each with its own flight program. The dry workshop decision allowed the series of dozens of flights to be consolidated into just four—the launch of the Skylab space station and the three crew launches. Experiments that would have required numerous Saturn IB boosters to carry them into space were all launched on just one Saturn v.

While the consolidation of the various Apollo Applications plans into one facility was of huge benefit to the space station program, in retrospect Mueller believes it had a long-lasting detrimental effect on American spaceflight. Before the decision was made to use the Saturn v, he envisioned Apollo Applications as an ongoing series of scientific missions. With the Saturn v, however, that ongoing series was transformed into one complete package. As a result the focus shifted toward what would be included in that package and away from continuing research afterwards. “Unfortunately, that was when we quit,” he said. “It’s a great mistake to get an endpoint without working out what’s going to happen then. One thing I learned is you ought to have the next two generations in planning.”

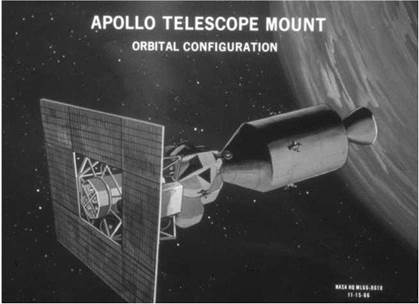

Nonetheless, there is no question that the Saturn v and the dry workshop enabled a Skylab scientific program that would not have been possible otherwise. An example of the changes the use of the Saturn v enabled is the Apollo Telescope Mount, a battery of eight astronomical observation tools that was attached to the outside of the Skylab facility. “The atm started out as one of the aap ideas, which was a major telescope in space,” Mueller said.

The Apollo Telescope Mount, he said, had its roots in a conversation he had with an official from the Mount Wilson Observatory, during which Mueller noted that “with the Saturn v, we could put the Mount Wilson Observatory up in space, and really get some real good views. And that led to a number of different looks at space observation. The atm came from that kind of set of thoughts.” Mueller said the subsequent research and development served as the foundation for the work that later led to other space – based observatories including the Hubble Space Telescope.

Though that conversation and the atm played an important role in the history of space telescopes, the idea of the space telescope predated them. In 1946 eleven years before Sputnik became the first object placed in Earth orbit, astronomer Lyman Spitzer Jr. wrote a paper in which he proposed that a telescope placed in orbit, beyond the interference of Earth’s atmosphere, would be able to perform observations superior to a terrestrial facility.

Originally, the Apollo Telescope Mount missions were not going to be a part of the space station program. Instead an orbital observatory was to be used in a series of independent Apollo missions. In keeping with the philosophy of the Apollo Applications Program, the atm was intended to make use of existing Apollo hardware and was originally designed to incorporate the telescopes into a free-flying spacecraft. There was a debate as to which

|

3- An early concept for a nonstation-based Apollo Telescope Mount. |

existing Apollo spacecraft should be used to carry the telescopes: the Service Module or the Lunar Module. Some argued that it would be cheaper and easier to integrate the atm into the Service Module. Mueller though was dedicated to the idea of eventually using the then-still-in-development Lunar Module as a multipurpose space-based laboratory and saw the atm as a step toward that goal. In addition the Lunar Module provided another advantage. While the Service Module reentered the Earth’s atmosphere and burned up when the Command Module landed, the Lunar Module could remain in orbit. This meant that while a Service Module-based atm would have a maximum life span of a fourteen-day Apollo mission, a Lunar Module-based facility could be reused. However, concerns were raised about the idea of a free-flying atm, arguing that it would be unsafe for the astronauts involved. Since the Lunar Module was designed for descent to the surface of the airless moon, it was incapable of operating within Earth’s atmosphere and would not withstand reentry. If a problem developed during a free-flying Lunar Module-based atm mission, the crew would be trapped, unable to return to Earth.

In order to avoid this dangerous situation, the proposal was made to incorporate the Apollo Telescope Mount into the orbital workshop program.

When plans still centered on a wet workshop, this would have required separate launches. The Saturn IB that would carry the s-ivb stage into orbit would not be able to carry the telescope mount as well. Instead, the atm would still be configured as a separate free-flying spacecraft, which would be launched later and would then rendezvous with the workshop. With the decision to go with the dry workshop and the introduction of the Saturn v to the equation, however, this became unnecessary. The larger booster was capable of carrying the atm into orbit along with the station. As a result, the atm no longer needed to be designed as an independent spacecraft but could be incorporated into Skylab.

The evolution of the Apollo Telescope Mount contributed to the development of another of Skylab’s modules. Though not needed for this purpose in the final configuration of the station, Skylab’s Multiple Docking Adapter was originally intended to support the atm. When the decision was initially made to incorporate the telescope into the space station program, mission planners were unsure exactly how to do this, since they weren’t sure how to attach the atm craft to the station. The proposal was made to tether the telescope mount spacecraft to the workshop, essentially floating freely but “tied” to the station. However, this would also have suffered from some of the disadvantages of the independent Apollo Telescope Mount missions and was thus still considered too dangerous.

To avoid that situation, the docking adapter was developed—essentially an empty metal cylinder with ports for multiple spacecraft to dock with the station. This would provide a place for not only the Apollo spacecraft crew taxi to dock with the facility but the atm spacecraft as well, allowing astronauts to transfer easily between the workshop and the observatory. With the use of the Saturn v, however, this too became unnecessary. Since the Apollo Telescope Mount was to be attached to Skylab at launch, there was no longer any need for a docking port for it.

However, mission planners realized that the docking adapter could still be beneficial to the space station. Since it would allow two Apollo spacecraft to be docked with Skylab at the same time, it could be used if there were ever a need for a rescue mission. As it turned out, the second docking port was never needed, and the module ended up being used primarily for the additional enclosed volume it provided.

Another decision that Mueller said had a major impact on Skylab—and

a lasting impact on human spaceflight—was the involvement of the Raymond Loewy/William Snaith, an industrial design firm, which looked at human factors on the space station. Loewy, who was seventy-four years old when approached to work on the space station, was a legend in the field of industrial design, having had a hand in everything from Coke bottles to office buildings.

Mueller described Loewy’s effect on the program, “One of the things that probably people don’t appreciate is, early on, I took a look at what Marshall was planning to do with Skylab, and I said, ‘I don’t think people are going to want to live there.’ I said we needed to get a human factors genius. So I got them to bring Raymond Loewy to really take a look at how to make it habitable. And I must say I think he had a positive effect on the design and probably had a lasting effect on how to go about designing for space living. His contributions to livability were one of the keys to the success of the Skylab.” Loewy’s contributions were “mostly man-machine interface – type things,” everything from a warmer color scheme for the interior of the station to a more agreeable design for its toilet system. Skylab’s wardroom —the area where the crew could eat, relax, and take care of routine tasks—was another of Loewy’s suggestions. Mueller said that Loewy later told him that his work on Skylab was one of the accomplishments of which he was most proud.

Not all of Loewy’s recommendations were readily received, however. “He wanted a window,” Mueller said, but he was unable to get engineers to agree that it was worth carving a hole in the side of the s-ivb stage for it. “He tried convincing them.”

According to George Hardy, however, concerns about the crew’s happiness on the station eventually won out: “I know of one meeting that was quite amusing. This was when we were in the process of going from the wet workshop to the dry workshop, and it was a meeting at Kennedy [Space Center in Florida], a management council meeting. It was a week or so before one of the latter lunar missions. [The workshop] got put on the agenda; it was just an add-on late at the end of the day. It wasn’t the major focus; not too many people interested in it. But von Braun and Mueller wanted to talk about it, so they did. Bob Gilruth acknowledged the subject, but he didn’t have a lot to say about it. He still had some lunar missions to work. So the discussion was we’re going to keep this simple. We’re not going to do a lot of things to modify this hardware; we’re going to do minimum modifications on it and so forth. And we had some artist’s concepts of an s-ivb stage that could be inhabited in some way.

“And von Braun got up in the discussion; this was late in the evening, maybe 6:30, 7:00 or so. And anyway, von Braun got a little carried away with it, ’cause he was so excited about it. He went up to one of the sketches that was on the board and said, ‘We can put a porthole right here where the crew can see out.’ And Gilruth said, ‘Yeah, there we go, now we’re going to modify the whole thing.’

“So Mueller kind of called the meeting to a halt, and he said, ‘Well, it’s getting about cocktail time.’ He wanted to keep those two apart, so he worked on both of them, I think, that evening. Then came back the next day, and everybody was back together again. And after all that, they got a window.”

The process of making the decisions regarding the project that became Skylab proved to be more complicated than implementing those decisions. “I can’t think of one thing that I’d say was a real hard task,” Hardy said. The biggest challenge came not in the process of the engineering work for any one component or system but in integrating all the components together.

And in order for the systems to work together, the people responsible for them had to work together as well. “I used to tell my people that the technical integration of the hardware was about 30 percent of the job, and the integration of the people was about 70 percent of the job,” Hardy said. “To me, that was one of the most fun things about Skylab, the integration part of it. You had the integration of two centers that had worked together, but worked together in a much different way on this program.”

Working to integrate those two centers, Hardy said, is one of the things he’s most proud of in the role he played in Skylab. “This was going to be the first manned spacecraft that was going to be operated in space with msc astronauts, of course, and msc flight controllers and that was designed and built under another center. The tradition and the history was that the flight controllers started getting involved, not necessarily at the very beginning of the design but in the design process, such that flight operations requirements flowed into the design and development in a very real way in much the same way as flight crew requirements.” About a year before the launch of Skylab, the Marshall engineering team realized that while there had been some collaboration with the Houston operations team, it had not occurred on the scale that it would have on a program handled entirely in-house at the Houston center. Hardy got in touch with Gene Kranz, chief of Flight Operations at msc, and planned a massive review process, which lasted around three or four months. “For each major system area, like crew systems, instrumentation, electrical systems, propulsion systems, we took the designers of that system, whether they be Marshall guys or [contractors] or whatever, and the operators, the msc guys who were going to handle primary flight operations, and we put those people together with some structure to the review but a lot of opportunities for interaction and questions and discussions, and conducted these reviews.”

The review process provided two major benefits. First, it enabled the two teams to provide feedback to identify and correct problems so that they wouldn’t arise after the station had already been launched. But in addition the process provided a second benefit. When the mission controllers had problems or questions during the operational phase of Skylab, they were able to ask them of engineers whom they had met face-to-face and worked alongside. Those relationships had developed naturally on spacecraft programs managed entirely in-house at msc but had to be forged deliberately on such an unprecedented cross-center program.

“That was very, very effective,” Hardy said. “I think because of that, we developed a relationship with flight operations people that was invaluable during the course of the mission, and I think it paid off from Day i, when we lost the heat shield. And then of course the continued operations of Sky – lab were again a testament to the centers working together.”

Those continued operations required that Marshall, which had already been providing engineering support to mission controllers for the boosters it managed, greatly increase its operations support efforts. Hardy began discussing with Kranz what would be needed for this project. The two quickly reached the opinion that the level of support that would be required was much greater than either center had realized.

Hardy set about gearing up the Huntsville Operations Support Center (hosc ) at Marshall to provide twenty-four-hour-a-day, seven-days-a-week engineering support for the operations team at msc, setting up a three-shift – a-day rotation schedule, with a fourth shift set up to give the other three time off.

In addition to the integration of the two groups from the two centers, the teamwork between NASA civil servants and contractors proved to be vital to the success of the engineering support efforts. Hardy cited as an example contractors from IBM, which worked on the atm and the instrument unit. While NASA had three senior civil servants (as it worked out, one for each shift) with expertise in the gyroscopes used to control Skylab’s orientation, most of the know-how for the gyros on the operations support team resided with the IBM contractors, and that knowledge proved extremely useful as the program progressed.

“We got down to losing rate gyros and losing control moment gyros,” Hardy said. “And those guys, along with the Marshall guys, would come in with different control schemes that just a week before we said would be impossible. We’d say, ‘If we lose this rate gyro, then we’re done.’ And we would lose it, and they’d come in with a control scheme that would work. The greater the demand got for more ingenuity in that area, the more they produced.”

None of that is to say, though, that the relationship between the two centers in the area of operations was always seamless. While Marshall and msc would eventually establish good working guidelines for what responsibilities fell into which bailiwick, there were a few snags that had to be ironed out in the process of reaching that point. msc director Chris Kraft recalls his involvement in making sure that the program made the best use of each center’s strengths: “As we in Flight Operations began to come to grips with Skylab and the fact that we were going to be responsible for taking care of it and the astronauts who would be involved, several sticky issues came to light. In typical msec fashion, they had set up what they intended to be their own flight operations group with the intent of flying the machine themselves. There is no doubt in my mind that they saw this as their opportunity to get directly involved in manned spaceflight.

“They were building what they perceived as their own Mission Control Center [mcc] . This became obvious as their budget submissions were made and in their relationships with us. When this became apparent, I challenged this at both the management council meetings and directly with the management at msec. I don’t think headquarters was willing to support this approach, but I wasn’t about to sit still for what I saw as an infringement on the center responsibility (roles and missions). The lead manager for msec in their flight control work was Fridtjof A. Speer. Fred, as we addressed him,

was a typical German from the old school. That is he was very competent, knew his business, but was equally stubborn in his approach to the issue. He had obviously been given his marching orders and was adamant about taking over this aspect of the program.

“After several meetings with him and his engineers, it was obvious we would have to confront him head on, and we did. He insisted that it was msec’s responsibility to do the flight control on all of the hardware they were responsible for, and he intended to carry out these functions. I and my people were equally adamant that msc was responsible for all NASA manned spaceflight control and that we intended to control Skylab from the mcc in Houston. It took a number of months to bring this to a point where headquarters recognized the duplication of effort going on here, and I’m sure the press of the budget for operations activities finally forced their hand to step in and adjudicate the issue. Speer did not give up easily, but I think Eber – hard Rees recognized they would lose this argument and directed Speer to cooperate.

“From the beginning we had made it clear that we had no objections to msec having their people familiar with the various Skylab systems perform these flight control functions in the Houston mcc. Speer, after a direct meeting with me on this subject, finally agreed to this concept. Even so, Huntsville Operations Center spent a lot of NASA’s money on an elaborate set up and manned it throughout the program. As might be expected, as the time for detail flight control training became imminent, Speer backed away from having his people in Houston full-time and had the msec rep in Houston fulfill most of these responsibilities. We ran the program, but msec had their Hose operational practically full-time. In all fairness, Fred Speer supported the mcc very well and spent a lot of time there personally throughout the program. He was also very helpful in the conduct of the missions.”

In one of the more interesting aspects of the relationship between the two centers, the materials laboratory at Marshall Space Flight Center essentially took on the role of primary contractor to the Houston center on some of the biomedical experiments. The Manned Spacecraft Center had sought a company interested in developing and building the flight hardware for the experiments but found none willing to take on the work. “They couldn’t get anybody to take that research on to build the bicycle ergometer and

the metabolic analyzer, because industry viewed it as a one-shot,” said Bob Schwinghamer, who was the head of the Marshall materials lab. “They didn’t know what the potential was for it, and hell, they didn’t want to do all that stuff. So von Braun goes down there and tells Gilruth, ‘Yeah, we can do that for you.’ Those guys in Houston just couldn’t get anybody interested. But von Braun could do anything. ‘Yeah, we can do that.’ He was something else.

“So he calls me up there in the office one day, and he’s got the project manager from here [Lee Belew] sitting in there with him. And he said, ‘Bob, we want you to build some biomedical experiments. I want you to deal directly with Houston on this. Go to [msc’s Skylab program manager] Kenny Kleinknecht and whoever the doctor is down there.’ He looks at Lee, and said, ‘Lee, I want to do it this way ’cause I want to cut all the horseshit paperwork out of this in between.’ And we were off and running the next day.”

The msfc materials lab was tasked with developing and building the lower body negative pressure device, the bicycle ergometer, and the biomedical experiment support system. While he sent his Marshall superiors courtesy copies of his paperwork, Schwinghamer said things worked well with his lab reporting directly to officials at msc on the work. “It got to where they were demanding a report once a month,” he said. “And that was pretty frequently when you’re trying to build hardware. So one time, I told John Massey, ‘Go right in the middle, and leave thirty-two pages out, and ship it.’ And so he shipped it. Then I waited a couple of days, and I called down there and said ‘What did you think of that last report?’ They said, ‘Everything’s all right, just keep it coming.’ I said, ‘You didn’t worry about the thirty-two pages missing in the middle?’ We both had a big laugh. After that, things got a lot easier.”

Schwinghamer noted that private business missed out on a great opportunity by not developing some of the equipment. The metabolic analyzer that his team built proved to have Earth-bound applications for doctors, who used it for tests on patients. “That spin-off turned out to be a pretty good thing,” he said. “But they just weren’t interested.”

It was during work on a urine sample volume measuring system that Schwinghamer first developed a relationship with a man who was to provide him with some rather unique—but ultimately invaluable—assistance. “One day, a guy called up, Bill Thornton,” Schwinghamer said. “He says on

the phone, very innocently, ‘I’d like to help you if I could.’ I said, ‘I’m looking for any help I can get.’ What can I say?”

Thornton was a member of the sixth group of astronauts selected, the second group of scientist astronauts. Even before joining the corps though, Thornton already had a background in spaceflight and specifically in microgravity biomedical research, having performed research for both NASA and the Air Force’s space program. A brilliant researcher and a physically powerful man, Thornton proved quite capable of both building equipment during the development phase and breaking it during the testing phase. His tall, muscular build contributed to his distinctive ability for finding potential bugs by pushing equipment to—and past—the breaking point, which would play an important role in the Skylab program.

The materials lab had been working to try to figure out how much volume the urine system should be able to handle. “I had some really good people,” Schwinghamer said. “I even had some biologists in my lab. And I thought, ‘Okay, how much volume should it handle?’ And nobody seemed to know.”

The male members of the materials lab workforce were called upon to help determine the answer. Cups were placed in the men’s room, and the staff was asked to use those cups whenever they needed to urinate. Each worker initialed his cups so that his daily output could be tracked. They were then asked to estimate how their output at home in the evening compared to the amount being measured at work.

“We did the means and standard deviation of the cup and added a third or something,” Schwinghamer said. “Over a sample of fifty-sixty people, I came up with a mean and a standard deviation, and I took the mean, and added three standard deviations, and it came out to be about 900 to 920 cc [cubic centimeters], just under a liter. And Thornton comes up, and guess what, he pees 1,200. He peed 1,200, and I had to redesign the damn thing.”

It would not be the last time Thornton would send one of the Schwing – hamer’s lab’s projects back to the drawing board. “Then he said, ‘I’d like to look at this bicycle ergometer you’re doing.’ And I thought, ‘Oh man, I’m in trouble,’ ” Schwinghamer said. “So I took him back to the lab, and Dr. Ray Gauss was working on it back there, doing a good job. He had that feedback circuit so he could maintain a constant heart rate and all that stuff and adjust the torque on the pedals automatically. Thornton gets on that, and what does he do, he breaks the shaft holding the pedals.” The team went back and increased the thickness of the pedal shaft from a half-inch to five – eighths of an inch. “And that was enough, he couldn’t break that one. He tried like hell, but he couldn’t break that one.” (Thornton would have a continuing relationship with the bicycle ergometer later in the program, however, during which he picked up some unfinished business with it.)

“He was something else,” Schwinghamer said. “But you know what, I’m glad he was there. That stuff functioned flawlessly. I kept an eye on how the biomeds were doing [during flight], and they did very well. Nobody reported any deficiencies or malfunctions even. And I always thought, ‘Thornton, you did me a big favor, buddy.’ He was a ninety-ninth percentile man. If he couldn’t break it, nobody could break it. The guys out in the lab, they’d say, ‘Hey Pop, when’s King Kong coming back?’—they called him King Kong.

“After it was all said and done and over and the missions were accomplished, I thought, I don’t know if everything would have functioned that flawlessly without having him really run it through its paces. And he did the job superbly. He was a good one.”

In theory, countdowns are pretty straightforward things—time goes by, and the launch gets closer. For quite a while, however, that didn’t seem to be the case with Skylab. Time would pass, but the launch would get no closer, something that became known as “the T minus one year phenomena,” Flight director Phil Shaffer recalled, “Lots of us, as Apollo started stretching out, would finish an Apollo thing, and then we’d go work on Skylab for awhile. And when we came back to it, it was still T minus one year. Part of it was this craziness with the funding, but it was like they couldn’t get their act together to decide what they were going to go fly. It really got to be a joke. ‘Maybe we’ll get to work on the Shuttle, and it will still be T minus one year.’ We weren’t making any progress. We’d go away for two or three months and work on the next Apollo flight, and we’d come back, and the schedule would have been reworked, and we were at T minus one year again. It seemed like it just went on forever. It was never going to be anything other than T minus one year.”

Finally, though, the countdown did tick away. The Marshall materials lab was to perform one of the last steps in the development and construction of Skylab. “Three days before liftoff, somebody noticed that we didn’t have an American flag on Skylab,” Schwinghamer said. “So somebody said, ‘Oh hell, that’s no problem. We’ll just make a nylon flag and stick it on there with Velcro.’ I said, ‘Nylon? You gotta be kidding me. You ever have your nylon – covered chair sitting out in the sun? That ain’t gonna work.’ ”

Among the equipment in the lab was a solar irradiator, which could not only simulate the light and radiation produced by the sun but could be turned up to levels several times greater than actual exposure levels experienced at Earth. Schwinghamer had some nylon tested in the machine at a ten-sun level. “In about two hours, the nylon crapped out,” he said. “So I knew that wasn’t going to work.

“I had this boat that I used in the Gulf of Mexico to fish all the time, about a twenty-footer, white,” he said. “And I had found this paint, and you could buy it in the paint store in Huntsville. So I gave the guy some money. I said, ‘Go down and get red, white and blue. I know that stuff can stand the ultraviolet.’ So he did that, and we started building the flag.”

The team used the paint to create a flag on a thin sheet of aluminum. The completed flag was then tested in the solar irradiator at ten suns, but did not change color.

“Two days before launch, they flew it down there and stuck it on the side with Velcro,” he said. “It didn’t come off in flight, either. That was another thing everybody got excited about, but that Velcro hung in there like gangbusters.”

Schwinghamer recalls informing the owner of the store of the unusual application of his paint. “I went back after it was in orbit, and I said, ‘Hey, you know what, your paint’s in orbit on the Skylab.’ ‘Oh, is that right?’ He didn’t think a thing of it. I’ll be. Can you imagine: paint from a little old paint store in Huntsville, Alabama, is in orbit, and he doesn’t think a thing about it.”