LIQUID OXYGEN MANUFACTURING PLANT

To provide for the large consumption of liquid oxygen, a manufacturing plant has been constructed at Spadeadam. The plant is capable of producing a total of approx. 100-tons of liquid oxygen per 24-day in addition to liquid and gaseous nitrogen. The liquid oxygen is transported by road tankers from the plant to the storage tanks in the test areas, the nitrogen gas is pumped by pipeline to high pressure reservoirs in each of the areas.21

|

Figure 41. Rocket test stands at Spadeadam. |

Spadeadam was built by the Ministry of Works under the supervision of the Ministry of Supply. It was one of the few areas of the whole MRBM programme over which the Treasury had direct control. (It was probably also the most expensive – the estimate of the cost at the time of cancellation was around £24 million). They kept spending under a tight rein, an example of this being when PFG Twinn of the Ministry of Supply wrote to the Treasury asking to be able to spend up to £10,000 on particular items without seeking direct Treasury authorisation. Reluctantly, the Treasury agreed.

Spadeadam was obviously extremely remote, which is why it was chosen in the first place. This did lead to transport difficulties, particularly when showing visitors round. Twinn requested authorisation for some transport in the form of:

1 Ford Consul Black with Heater Saloon 4-6 seats £556

1 Ford Prefect ditto ditto 4 seats £42422

To which the Treasury replied:

We approve the purchase of the Ford Consul, but would be grateful if you would substitute a Ford Popular for the proposed Ford Prefect. Hundreds of Populars are in use in Government service, and we would rather keep to this cheaper 4-seater model.

It really is quite extraordinary that the ministries should be debating the relative merits of a Ford Prefect or a Ford Popular. One cannot quite see the same problem arising at Cape Canaveral.

In July 1959, an official from the Treasury, Mr JA Marshall, set off to inspect Spadeadam in the company of Mr William Downey from the Ministry of Supply. ‘The visit was enjoyable (in spite of almost continual rain) and instructive,’23 he remarked.

In general, he approved: ‘The administrative block is a modest and simple construction as far as I saw it, and there certainly appears to be nothing lavish here.’

But later he was to observe one example of:

… what I would regard as some extravagance.

This is in the housing of the lines which run from the control and recording centre to each of the four stands. It has been put wholly underground. in a tunnel some 400 yards along.

Other cables had been put in an over ground duct. Mr Marshall enquired why this had not been done here. He was told: ‘. had it not been so placed, it would have obscured the view of those in the control centre’.

It also had to be carried under a road, but Mr Armstrong was not entirely convinced it had been necessary to put the entire length of cable underground.

Despite this particular example of ‘extravagance’, Mr Marshall seemed satisfied with his visit. He was ‘well impressed by all I saw’, which included the control rooms, full of:

electronic instrumentation provided to record every possible facet of the test for subsequent analysis. To the layman this produces a hopelessly bewildering mass of knobs, buttons, recording graphs, lights etc’

He goes on:

Mr. Downey had the courage to ask the schoolboy question: “Which is the button which actually sets it going?”. The scientist who was showing us round was utterly at a loss for about a quarter of a minute!

There were other problems. ‘Commander Williams, the senior Rolls Royce representative, who is the general manager of the place, had a go at me on two minor things’.

This related to the housing which had been built for those working at Spadeadam.

He said he thought the Treasury were unduly mean in not allowing them to build a higher proportion of garages… a number of people who have no garages… do have cars and keep them standing in the street… Since the streets are fairly narrow – the whole estate is on very modest lines – this could be a serious nuisance…

And also:

He also thought we underestimated the difficulties they faced when we insisted on a certain proportion of the houses having two bedrooms instead of allowing them to be all three, or in a small number of cases, four-bedroomed.

How much was the Treasury saving? Mr Marshall noted that ‘… the additional capital cost of the three bedroomed house is only £70 …’, but on the other hand, ‘we get an extra 5s. a week rent back from it’.

5s. means 5 shillings, or 25p in decimal money. The extra room would have paid for itself in just over five years.

If Blue Streak had gone ahead in its military guise, then a considerable number (no figure has been found, but a reasonable estimate might be between 10 and 20) of experimental and proving vehicles would be needed, as well as the 60 or so production missiles, starting in 1960 and ending by about 1966. Somewhat optimistically, the development schedule had called for the first missile to be fired from Woomera around mid-1960. As it was, the first vehicle was not fired until 1964, and there were a total of 11 firings by 1971 (in practice, more were built and tested, as there were some basic, non-flight, development vehicles, and also some which were used to check at the sites at Woomera and Kourou).

Thus after the cancellation, the tempo of work slowed considerably, and only one of the missile test stands, C3, was completed. There were also inevitable redundancies and a considerable drop in morale. In May 1967, Val Cleaver, Chief Engineer of the Rocket Department at Rolls Royce, wrote of the need ‘to raise morale and inspire some confidence in the future of the establishment’24, but apart from the test site for the liquid hydrogen RZ 20 motor, no further development work was carried out at Spadeadam.

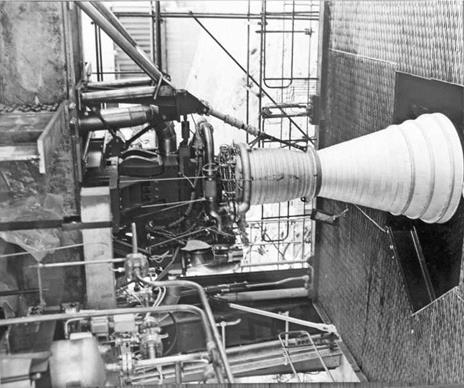

|

Figure 42. RZ 1 chamber on P site at RPE Westcott. |

Spadeadam would take time to build, so whilst it was being constructed, Rolls Royce used the P stand at Westcott for preliminary testing of the Rocketdyne derived RZ 1. Most of the runs were of very short duration – usually just a few seconds. Progress was delayed by a spillage of liquid oxygen onto the steel girders, which caused them to crack. One of the longest test runs was also the last, on an open day at which the Press was present. A motor was fired for 20 seconds, and on being checked after the firing, it was found that the gear box between the turbines and the pumps had disintegrated. A fraction of a second more, and the firing might have become very spectacular.

So from mid-1957, testing and development proceeded apace. At Hatfield in

Hertfordshire, large structures were built to house the testing of early, non-flight vehicles. These were for checking the strength of the vehicle structure and for such tasks as determining whether half a ton of fuel could be pumped from the tanks each second. Engine testing was carried out separately by Rolls Royce, first at a test site at Westcott and then at the purpose-built facility at Spadeadam in Cumbria. Here, in addition to engine development, assembled vehicles could be static fired. Once tested, they would then be taken apart for transport to Woomera.

Transport proved to be a difficulty. The large size of the tanks meant that very few aircraft would be suitable, and those which were, such as the Bristol Freighter, had limited range. This meant a great many countries would be overflown on the route from the UK to the Antipodes, and, given the nature of the cargo, political difficulties were foreseen. The problem was solved when the RAAF bought Fockheed Hercules aircraft: one of these could be leased from Australia for the purpose. And given the extra range of the Hercules, the overflying problem could be reduced by going westward round the world, over Canada and the US. As it would turn out, the tank of the first missile was at Fos Angeles when the cancellation was announced, and it was returned to the UK. All subsequent civil vehicles were transported by road and sea.

Another of the major problems in the early development was that of guidance. The contract had been given to Sperry, but they were struggling: ‘… accuracies being demanded from the inertial equipment for this project are extremely high and very marginal. It does seem that these accuracies are just

Figure 43. Cutaway view about obtainable,..’25 in January 1956. There is a of Blue Streak. despairing cry from the Director of Air Navigation in

October 1956: ‘There does not yet exist, I believe, anywhere in the world a gyroscope suitable for Blue Streak.’26 This was not quite true: American gyroscopes were very much more advanced, and Ferranti was eventually given the job of adapting Kearfott gyroscopes for the guidance system. Although these were probably not the best the Americans had under development, they were perhaps the best they were prepared to make available to the UK. And in November 1956: ‘It will thus be seen that, though the Blue Steel situation is parlous, the Blue Streak position is even more desperate’. A working design was finally produced, although in the end it was never used: the guidance system was cancelled at the same time as the missile. A satellite launcher needed a much less complicated system, and scrapping the Blue Streak inertial guidance could save money.

As the 1960s progressed, inertial navigation was to become much improved: a system designed for the TSR 2 aircraft was adapted for Black Arrow. Blue Steel was left to soldier on with a much earlier design, which, with its valves, was very power hungry. Again, the penalty was being paid for being early in the field.

But the next, and most controversial, point about Blue Streak was to be its proposed means of deployment. To have the missile sited on the ground in the open, as the Thor missiles were, was pointless. A preemptive strike by relatively few Russian missiles would have destroyed every site before a missile could be fired in retaliation. As all sides in the Cold War realised, land-based missiles would have to be sited in ‘invulnerable’ silos, although the word ‘silo’ was not in usage in the UK at that time. Indeed, the two phrases used became code phrases, showing which side of the controversy you were on. ‘Underground launcher’ was the phrase used by those in

But the next, and most controversial, point about Blue Streak was to be its proposed means of deployment. To have the missile sited on the ground in the open, as the Thor missiles were, was pointless. A preemptive strike by relatively few Russian missiles would have destroyed every site before a missile could be fired in retaliation. As all sides in the Cold War realised, land-based missiles would have to be sited in ‘invulnerable’ silos, although the word ‘silo’ was not in usage in the UK at that time. Indeed, the two phrases used became code phrases, showing which side of the controversy you were on. ‘Underground launcher’ was the phrase used by those in

favour of the project, ‘fixed sites’ if you were against. ‘Fixed sites’ were perceived as being vulnerable. Airfields, somehow, were not perceived as being vulnerable – although they were as ‘fixed’ as any missile launcher. [4]

favour of the project, ‘fixed sites’ if you were against. ‘Fixed sites’ were perceived as being vulnerable. Airfields, somehow, were not perceived as being vulnerable – although they were as ‘fixed’ as any missile launcher. [4]

23 TNA: PRO T 225/1424. ‘Blue Streak’ medium range ballistic missile: test site, Spadeadam. JA Marshall 10 July 1959.

24 TNA: PRO AVIA 92/232. Spadeadam: liquid hydrogen-liquid oxygen thrust chamber test facility. Cleaver to CGWL.

25 TNA: PRO AVIA 54/2135. Blue Streak development: inertia guidance.

26 Ibid.