Cooling

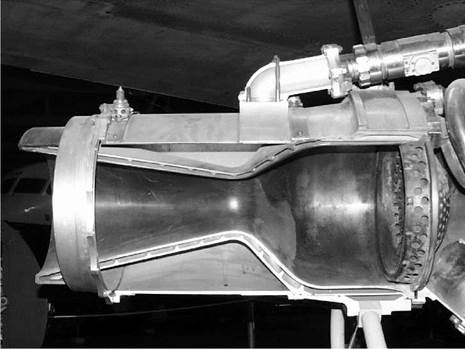

Rocket chambers will, not surprisingly, get very hot, and ways have to be found to stop them getting too hot. One method is to use film cooling. At the top of the chamber is an injector, where the fuel and oxidant enter the chamber, and it usually resembles a shower head. It is designed so that the fuel and oxidant can mix and burn as quickly as possible. In film cooling, the injector feeds in only fuel at the very edge of the chamber, so that the sides of the chamber wall will be in contact with relatively cool unburnt gas. This usually means a slightly reduced efficiency, as the motor is running fuel rich. The next and most obvious method is to use the incoming fuel to cool the chamber walls before being injected into the chamber. This is called regenerative cooling. One way to do this is to have a double walled chamber, with the fuel flowing between the two walls. This tends to be rather heavy – the pressure in the chamber is obviously quite high, and so the walls need to be robust. This is illustrated in the de Havilland Spectre motor shown in Figure 6.

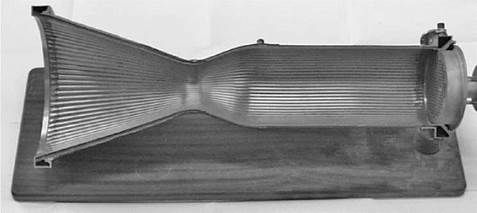

A refinement on this method was to make a chamber of thin nickel tubes brazed together. Reinforcing bands were usually attached around the tubes, but overall, the construction was much lighter. This technique was first used in the RZ 2 motor for Blue Streak and the chambers of the Stentor motor for the Blue Steel missile. Fuel or oxidant then flows through the tubes to cool the chamber.

Sometimes the expansion cone for upper stages is left as plain metal, and this is sometimes referred to as ‘radiation cooling’ – in other words, the metal is left to glow red hot and literally radiates its heat away into the vacuum of space.

|

Figure 5. A double walled chamber. In this de Havilland Spectre motor, HTP is used as the coolant. |

|

Figure 6. A sectioned example of a liquid hydrogen chamber made at RPE. It has been fabricated from a series of nickel tubes pressed into shape and brazed together. Fuel would flow through the tubes as a coolant. |

Lubbock and his co-workers at the Fuel Oil Technical Laboratory in Fulham, London, were the first in the UK to work on liquid fuelled rocket motors. Their first design, called Lizzie, was fuelled by LOX (liquid oxygen) and petrol. It was a very simple device: the propellants were forced into the combustion chamber using high pressure nitrogen, so no pumps and other ancillary equipment were needed. It was intended for rocket assisted take-off in aircraft such as the Wellington. In 1946 it was the first liquid fuelled rocket motor to be test fired at the RPD Westcott, and was eventually developed to give thrusts of up to 2000 lb.

Lizzie was used to power the Liquid Oxygen Petrol/

Lizzie was used to power the Liquid Oxygen Petrol/

Guided Aerial Projectile, or LOP/GAP, which was an

early test vehicle, fired from

Aberporth in Wales, and later, the Rocket Test Vehicle 1 or RTV-1. Problems cooling the engine led to a change of fuel to a methanol/water mixture. As a consequence of work with Lizzie, it was realised that hydrocarbons did not act as good coolants for rocket engines, and that their flame temperatures are also relatively high, exacerbating the cooling problem. Kerosene was not considered again for rocket motors in Britain for some years.