The Aircraft: Tu-144LL SSSR-771114

![]() The Tu-144 was the world’s first Supersonic Transport, when it took off from Zhukovsky Airfield on December 31, 1968. The design of the aircraft had commenced in early 1963, after the Soviet Union selected the Tupolev Design Bureau for the task. The famed Andrei Tupolev named his son Aleksei Tupolev to be chief designer, and over 1,000 staff members from other design bureaus were temporarily assigned to Tupolev for this project of national prestige.[1479] For the researchers to evaluate the wing design, a Mig-21 fighter was configured with a scaled model of the wing for in-flight testing. The prototype was completed in the summer of 1968, and in December of that year, Eduard Yelian piloted serial No. SSSR-68001on the Tu-144’s first flight. The Tu-144 first exceeded the speed of sound on June 5, 1969 and achieved speeds in excess of Mach

The Tu-144 was the world’s first Supersonic Transport, when it took off from Zhukovsky Airfield on December 31, 1968. The design of the aircraft had commenced in early 1963, after the Soviet Union selected the Tupolev Design Bureau for the task. The famed Andrei Tupolev named his son Aleksei Tupolev to be chief designer, and over 1,000 staff members from other design bureaus were temporarily assigned to Tupolev for this project of national prestige.[1479] For the researchers to evaluate the wing design, a Mig-21 fighter was configured with a scaled model of the wing for in-flight testing. The prototype was completed in the summer of 1968, and in December of that year, Eduard Yelian piloted serial No. SSSR-68001on the Tu-144’s first flight. The Tu-144 first exceeded the speed of sound on June 5, 1969 and achieved speeds in excess of Mach

2.0 on May 26, 1970, in every case just beating Concorde.[1480]

The prototype was displayed at the Paris Air Show for the first time in June 1971. Tragically, the second production aircraft crashed spectacularly at the 1973 Paris Air Show. This, in combination with range capabilities only about half of what was expected (2,200 miles versus

4.0 miles), led to Aeroflot (the Soviet national airline company) having a diminishing interest in the aircraft. Still, a number of significant modifications to the aircraft occurred in the 1970s. The engine nacelles were move farther outboard, necessitating the relocation of the main landing gear to the center of the nacelles, and the original Kuznetsov NK-144 engines were replaced by Kolesov RD-36-51A variants capable of 44,092 pounds of thrust with afterburner. With these engines, the type was redesignated the Tu-144D, and serial No. SSSR-74105, the fifth

|

|

production aircraft, first flew with the new engines in November 1974. Cargo and mail service commenced in December 1975, but Aeroflot crews never commanded a single Tu-144. Only Tupolev test pilots ever flew as pilots-in-command. On November 1, 1977, the Tu-144 received its certificate of airworthiness, and passenger service commenced within the Soviet Union. Ten percent larger than the Concorde, the Tu-144 was configured with 122 economy and 11 first-class passenger seats. Only two production aircraft served on these passenger routes. The service was terminated May 31, 1978, after the first production Tu-144D crashed on a test flight from Zhukovsky while making an emergency landing because of an in-flight fire. After this crash, four more Tu-144s were produced but were used only as research aircraft. Two continued flying until 1990, including SSSR-771114. The fleet of 16 flyable aircraft accumulated 2,556 flights and 4,110 flying hours by 1990.[1481]

After the 1994 U. S.-Russian agreement enabling the HSR Tu-144 flight experiments, SSSR-77114 was selected to be refurbished for flight. The final production aircraft, 77114, was built in 1981 and flew only as a research aircraft, before being placed in storage in 1990. Amazingly, it had only accumulated 83 flight hours at that time. Because the RD-36-51A

engines were no longer being produced or supported, Tupolev switched to the Kuznetsov NK-321 engines from the Tu-160 Blackjack strategic bomber as powerplants. [1482] Redesignated the Tu-144LL, or Flying Laboratory, 77114 first flew under the command of Tupolev test pilot Sergei Borisov on November 29, 1996.[1483]

![]() The Tu-144, although it seems outwardly similar to the Concorde, was actually about 10-percent larger, with a different wing and engine configuration, and with low-speed retractable canard control surfaces that the Concorde lacked. It also solved the many challenges to sustained high-altitude, supersonic flight by different means. Where documentation in the West is complete with Concorde systems and operations manuals and descriptions, NASA and Boeing engineers and pilots could find no English counterparts for the Tu-144. This was due in part to the secrecy of the Tu-144 development in the 1960s and 1970s. Therefore, it is worth briefly describing the systems and operation of the Tu-144 in this essay.

The Tu-144, although it seems outwardly similar to the Concorde, was actually about 10-percent larger, with a different wing and engine configuration, and with low-speed retractable canard control surfaces that the Concorde lacked. It also solved the many challenges to sustained high-altitude, supersonic flight by different means. Where documentation in the West is complete with Concorde systems and operations manuals and descriptions, NASA and Boeing engineers and pilots could find no English counterparts for the Tu-144. This was due in part to the secrecy of the Tu-144 development in the 1960s and 1970s. Therefore, it is worth briefly describing the systems and operation of the Tu-144 in this essay.

This system description will also give insight into the former Soviet design philosophies. It should be noted that many of the systems on the Tu-144LL were designed in the 1960s, and though completely effective, were somewhat dated by the mid to late 1990s.[1484]

The Tu-144LL is a delta platform, low wing, four engine Supersonic Transport aircraft. Features of interest included a very high coefficient of lift retractable canard and three position-hinged nose structure. The retractable canard is just aft of the cockpit on top of the fuselage and includes both leading – and trailing-edge flaps that deflect when the canard is deployed in low-speed flight. The only aerodynamic control surfaces are 8 trailing-edge elevons, each powered by two actuators and upper and lower rudder segments. The nominal cockpit crew

|

|

consisted of two pilots, a navigator situated between the two pilots, and a flight engineer seated at a console several feet aft of the navigator on the right side of the aircraft.

The Tu-144LL was 215 feet 6 inches long with a wingspan of 94 feet 6 inches and a maximum height at the vertical stabilizer of 42 feet 2 inches. Maximum takeoff weight was 447,500 pounds, with a maximum fuel capacity of 209,440 pounds.

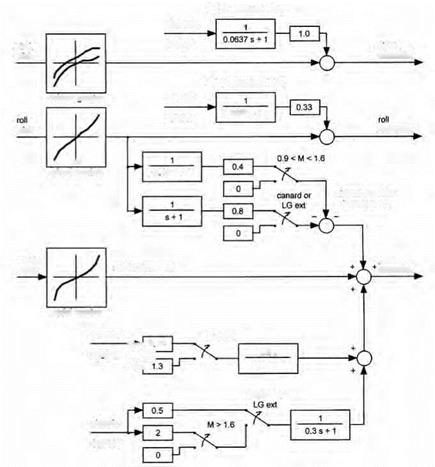

Quadruple redundant stability augmentation in all axes and an aileron-rudder interconnect characterized a flight control system that provided a conventional aircraft response. Control inceptors included the standard wheel-column and rudder pedals. Pitch and roll rate sensor feedbacks passed through a 2.5-hertz (Hz) structural filter to remove aeroservoelastic inputs from the rate signals. Sideslip angle feedback was used to facilitate directional stability above Mach 1.6 or when the canard or landing gear were extended. Similarly, and aileron-rudder interconnect provided additional coordination in roll maneuvers through first-order lag filters between Mach 0.9 and 1.6 and whenever the canard or landing gear were extended. A yaw rate sensor signal was fed back through a lead-lag filter to oppose random yaw motions and allow steady turn rates.

sideslip

sideslip

deg/sec

Schematic of the Tu-144LL flight control system as interpreted by NASA flight control engineer Bruce Jackson from conversations with Tupolev engineers in Zhukovsky, Russia. NASA.

Because the elevons provided both pitch and roll control, a mixer logic limited the combined pitch and roll commands to allowable ele – von travel while favoring pitch commands in the limit cases. Pitch-roll harmony was moderately objectionable by Western standards because of excessive pitch sensitivity contrasted with very weak roll sensitivity.

The installed Kuznetsov NK-321 engines were rated at 55,000 pounds sea level static thrust in afterburner and 31,000 pounds dry thrust. These engines are 5 feet longer and over 1/3 inch wider than the RD-36-51A engines in the Tu-144D, which necessitated extensive modifications to the engine nacelles and nozzle assemblies. The NK-321 engines were mounted 5 feet farther forward in the nacelles, and to accommodate the

larger nozzles, the inboard elevons were modified. The axisymmetric, afterburning, three-stage compressor NK-321 engines were digitally controlled, and this necessitated a redesigned flight engineer’s (FE) panel with eight rows of electronic engine parameter displays. The fuel control consisted of a two channel digital electronic control and a backup hydromechanical control. The pilot is only presented with N1 revolutions per minute (rpm) indications and throttle command information, which was used to set the desired thrust through power lever angle in degrees (referred to as throttle alpha by Tupolev). All other engine information, including fuel flows and quantities, oil pressures and temperatures, and exhaust gas temperatures, was displayed on the FE panel, which is not visible to the pilot. The pilot’s throttles mounted on the center console had a very high friction level, and in normal situations, the FE set the thrust as commanded by the pilot in degrees throttle alpha. Typical thrust settings in throttle alpha were 72 degrees for maximum dry power, 115 degrees for maximum wet power (afterburner), 98 degrees for Mach 2 cruise, and 59 degrees for supersonic deceleration and initial descent. For takeoff weights less than or equal to 350,000 pounds, 98 degrees throttle alpha was commanded, and for heavier takeoff weights, 115 degrees was used. Operations in the 88- to 95-degree range were avoided for undisclosed reasons.

![]() A fairly unsophisticated, 2-channel autothrottle (A/T) system was available for approach and landing characterized by a 20-second period and an accuracy of plus or minus 4 mph. The A/T control panel was on the center console, with a left/right selector switch, two selectors for channels, and a rocker switch to command the speed bug on the respective pilot’s airspeed indicator. A throttle "force” of 45 pounds was needed to override the A/T, or individual A/Ts could be deselected by microswitches in each throttle knob. If two or more were deselected, the system was disconnected. For the system to be engaged, the FE engaged A/T clutches on the FE throttle quadrant. The A/T could be used from 100 mph up to 250 mph indicated airspeed normally or up to 310 mph under test conditions.

A fairly unsophisticated, 2-channel autothrottle (A/T) system was available for approach and landing characterized by a 20-second period and an accuracy of plus or minus 4 mph. The A/T control panel was on the center console, with a left/right selector switch, two selectors for channels, and a rocker switch to command the speed bug on the respective pilot’s airspeed indicator. A throttle "force” of 45 pounds was needed to override the A/T, or individual A/Ts could be deselected by microswitches in each throttle knob. If two or more were deselected, the system was disconnected. For the system to be engaged, the FE engaged A/T clutches on the FE throttle quadrant. The A/T could be used from 100 mph up to 250 mph indicated airspeed normally or up to 310 mph under test conditions.

The variable geometry inlets were rectangular, with a moderate fore – to-aft rake. An internal horizontal ramp varied from an up position at speeds below Mach 1.25 to full down at Mach 2. Three shocks were contained in the inlet during supersonic flight to slow the inlet flow to subsonic speeds; unlike those of other supersonic aircraft, the Tu-144LL’s inlets showed no tendency to experience shock wave-displacing inlet

unstart or other undesired responses during supersonic flight. Even when pilots made full rudder deflections while maintaining a steady heading, generating supersonic sideslips at Mach 2, the inlets and engines continued to function normally. Likewise, when they made 30-degree banked turns and moderately aggressive changes in pitch angle, there were no abnormal results from either the engine or the inlet. This contrasted markedly with the Olympus engines in Concorde. While the Olympus engines were more efficient and were designed in conjunction with the inlets and nozzles to provide a complete, interrelated powerplant system, the Tu-144LL’s forced use of nonoptimized NK-321 engines required using afterburner to maintain Mach 2 cruise. Of interest was the fact that Concorde’s more efficient engines (Mach 2 cruise was sustained without the use of afterburner) were far more susceptible to inlet unstarts and stalls, and as a result, the aggressive engine maneuvers performed in the Tu-144 flight experiment at Mach 2 could not have been accomplished in the Concorde. The RD-36-51A engines did not require afterburner during supersonic cruise, even though the sea level static thrust rating was lower than that of the NK-321 engines. This was due to the optimized engine/inlet/nozzle system, in which 50 percent of the thrust at supersonic cruise was derived from the inlets and nozzles.[1485]

![]() The fuel system was comprised of 8 fuel storage areas, including 17 separate tanks. The nomenclature referred to fuel tanks 1 through 8, but only tanks 6, 7, and 8 were single units. Tanks 1, 2, and 8 were balance tanks used to maintain the proper center-of-gravity (CG) location through new, high-capacity fuel transfer jet pumps with peak pressure capacity of 20 atmospheres. These transfer pumps were hydraulically driven and controlled by direct current (DC) power. Fuel boost pumps in each tank were powered by the main alternating current (AC) electrical systems. Tank system No. 4 consisted of 6 tanks, 4 of which provide tank-to-engine fuel. A cross-feed capability was used to control lateral balance. Emergency fuel dumping could be accomplished from all fuel tanks. All fuel system information was displayed on the FE panel, and all fuel system controls were accessible only to the FE. Numerous fuel quantity probes were used to provide individual tank system quantity indications and provide inputs to the CG indicator com-

The fuel system was comprised of 8 fuel storage areas, including 17 separate tanks. The nomenclature referred to fuel tanks 1 through 8, but only tanks 6, 7, and 8 were single units. Tanks 1, 2, and 8 were balance tanks used to maintain the proper center-of-gravity (CG) location through new, high-capacity fuel transfer jet pumps with peak pressure capacity of 20 atmospheres. These transfer pumps were hydraulically driven and controlled by direct current (DC) power. Fuel boost pumps in each tank were powered by the main alternating current (AC) electrical systems. Tank system No. 4 consisted of 6 tanks, 4 of which provide tank-to-engine fuel. A cross-feed capability was used to control lateral balance. Emergency fuel dumping could be accomplished from all fuel tanks. All fuel system information was displayed on the FE panel, and all fuel system controls were accessible only to the FE. Numerous fuel quantity probes were used to provide individual tank system quantity indications and provide inputs to the CG indicator com-

puter on the FE panel, which continually calculated and displayed the CG location. Proper control of the Tu-144 CG during the transonic through supersonic flight regimes was critical in maintaining aircraft control as the center of lift rapidly changed during sonic transients.

![]() The Tu-144LL incorporated four hydraulic systems, all of which were connected to separate flight control systems. Up to two hydraulic systems could fail without adversely affecting flight control capability. The flight controls consisted of four elevons per wing and an upper and lower rudder. Each control surface had two actuators with two hydraulic channels each so that each hydraulic system partially powered each control surface. The four hydraulic systems were powered by variable displacement engine driven pumps. There were no electrically powered pumps. Engine Nos. 1 and 2 each powered the No. 1 and 2 hydraulic systems, and engine Nos. 3 and 4 each powered the No. 3 and 4 hydraulic systems. Systems No. 1 and 2 and systems No. 3 and 4 shared reservoirs, but dividers in each reservoir precluded a leak in one system from depleting the other. System pressure was nominally between 200 and 220 atmospheres, and a warning was displayed to the pilot if the pressure in a system fell below 100 atmospheres. In the event of the loss of 2 hydraulic systems, an emergency hydraulic system powered by an auxiliary power unit (APU) air-driven pump (or external pneumatic source) was available, but the APU could only be operated below 3-mile altitude (and could not be started above 1.8-mile altitude). For emergency operation of the landing gear (lowering only), a nitrogen system serviced to 150 atmospheres was provided. If one hydraulic system failed, the aircraft was required to decelerate to subsonic speeds. If a second system failed, the aircraft had to be landed as soon as possible.

The Tu-144LL incorporated four hydraulic systems, all of which were connected to separate flight control systems. Up to two hydraulic systems could fail without adversely affecting flight control capability. The flight controls consisted of four elevons per wing and an upper and lower rudder. Each control surface had two actuators with two hydraulic channels each so that each hydraulic system partially powered each control surface. The four hydraulic systems were powered by variable displacement engine driven pumps. There were no electrically powered pumps. Engine Nos. 1 and 2 each powered the No. 1 and 2 hydraulic systems, and engine Nos. 3 and 4 each powered the No. 3 and 4 hydraulic systems. Systems No. 1 and 2 and systems No. 3 and 4 shared reservoirs, but dividers in each reservoir precluded a leak in one system from depleting the other. System pressure was nominally between 200 and 220 atmospheres, and a warning was displayed to the pilot if the pressure in a system fell below 100 atmospheres. In the event of the loss of 2 hydraulic systems, an emergency hydraulic system powered by an auxiliary power unit (APU) air-driven pump (or external pneumatic source) was available, but the APU could only be operated below 3-mile altitude (and could not be started above 1.8-mile altitude). For emergency operation of the landing gear (lowering only), a nitrogen system serviced to 150 atmospheres was provided. If one hydraulic system failed, the aircraft was required to decelerate to subsonic speeds. If a second system failed, the aircraft had to be landed as soon as possible.

The landing gear was of the traditional tricycle arrangement, except the Tu-144 had eight wheels on each main truck. Each main landing gear was a single strut with a dual-twin tandem wheel configuration. The landing gear included a ground lock feature that prevented the strut from pivoting about the bogey when on the ground. This resulted in a farther aft ground rotation point, because the aircraft would have to pitch around the aft wheels rather than the strut pivot point, thus preventing the aircraft from tilting back on the tail during loading. The redesign of the Tu-144 in the early 1970s moved the engine nacelles farther out on the wings, placing the main landing gear in the middle of the engine inlet ducting. This issue was solved by having the gear bogey rotate 90 degrees about the strut longitudinal axis before retracting

into the tall but narrow wheel well nestled between the adjoining engine inlets.

![]() The wheel brake system was normally powered by the No. 1 hydraulic system, but a capability existed to interconnect to the No. 2 hydraulic system if necessary. An emergency braking capability using nitrogen gas pressurized to 100 atmospheres was provided. Independent braking levers on both the pilot and copilot’s forward center console areas allowed differential braking with this system. A locked wheel protection circuit prevented application of the brakes airborne above 110 mph airspeed. On the ground, full brake pressure was available 1.5 seconds after full pedal pressure was applied. Above 110 mph on the ground, the brake pressure was reduced to 70 atmospheres. Below 110 mph, brake pressure was increased to 80 atmospheres. A starting brake was available to hold the aircraft in position during engine runups. This was essential, as the engines had to be run for a minimum of 30 minutes on the ground prior to flight. The brakes had to be "burned in” by holding them while taxiing in order to warm them to a minimum temperature to be effective. Furthermore, the braking capability was augmented by a drag parachute on landing to save wear on the tires and brakes.

The wheel brake system was normally powered by the No. 1 hydraulic system, but a capability existed to interconnect to the No. 2 hydraulic system if necessary. An emergency braking capability using nitrogen gas pressurized to 100 atmospheres was provided. Independent braking levers on both the pilot and copilot’s forward center console areas allowed differential braking with this system. A locked wheel protection circuit prevented application of the brakes airborne above 110 mph airspeed. On the ground, full brake pressure was available 1.5 seconds after full pedal pressure was applied. Above 110 mph on the ground, the brake pressure was reduced to 70 atmospheres. Below 110 mph, brake pressure was increased to 80 atmospheres. A starting brake was available to hold the aircraft in position during engine runups. This was essential, as the engines had to be run for a minimum of 30 minutes on the ground prior to flight. The brakes had to be "burned in” by holding them while taxiing in order to warm them to a minimum temperature to be effective. Furthermore, the braking capability was augmented by a drag parachute on landing to save wear on the tires and brakes.

The Tu-144 was supplied with main AC power at 115 volts and 400 hertz, secondary AC power at 36 volts and 400 Hz, and DC power at 27 volts. Each engine was connected to its respective Integrated Drive Generator (IDG), rated at 120 kilovolt-amperes (KVA) and providing independent AC power to its respective bus. No parallel generator operation was allowed under normal circumstances. Most systems could be powered from more than one bus, and one generator could provide all of the electrical power requirements, except for the canard and inlet antiice. A separate APU generator rated at 60 KVA at 400 Hz and provisions for external AC power were provided. The many fuel tank boost pumps were the main electrical power consumers. Other important AC systems were the canard and the retractable nose. The DC system consisted of 4 transformer/rectifiers (TR) and 4 batteries. The normal DC load was 12 kilowatts, and DC power was used for communication units, relays, and signaling devices.

Fire detection sensors and extinguishing agents were available for all engines, the APU, and the 2 cargo compartments. The extinguishing agent was contained in 6 canisters of 8-liter capacity each. When an overheat condition was detected, an annunciation was displayed on the FE panel showing the affected area. The pilot received only a "fire”

light on the forward panel, without seeing which area was affected. In the case of APU fire detection, the extinguishing agent was automatically released into the APU compartment. In the case of an engine fire, the pilot could do nothing, because all engine fire extinguishing and shutdown controls were on the FE panel.

![]() The air-conditioning and pressurization system consisted of identical, independent left and right branches. Any one branch could sustain pressurization during high-altitude operations. Nos. 1 and 2 engines and Nos. 3 and 4 engines shared common ducts for their respective bleed air. The right system provided conditioned air to the cockpit and forward cabin areas, and the left system furnished conditioned air to the mid and aft passenger cabin areas. The pressurization system provided an air exchange rate of 33 pounds per person per hour, and the total air capacity was 9,000 pounds per hour. Air was not recirculated back into the cabin. The pressurization controller maximum change rate was 0.18 millimeters (mm) of mercury (Hg) per second.

The air-conditioning and pressurization system consisted of identical, independent left and right branches. Any one branch could sustain pressurization during high-altitude operations. Nos. 1 and 2 engines and Nos. 3 and 4 engines shared common ducts for their respective bleed air. The right system provided conditioned air to the cockpit and forward cabin areas, and the left system furnished conditioned air to the mid and aft passenger cabin areas. The pressurization system provided an air exchange rate of 33 pounds per person per hour, and the total air capacity was 9,000 pounds per hour. Air was not recirculated back into the cabin. The pressurization controller maximum change rate was 0.18 millimeters (mm) of mercury (Hg) per second.

Hot engine bleed air was cooled initially to 374 degrees Fahrenheit (°F) by engine inlet bleed air in an air-air heat exchanger, then compressed in an air cycle machine (ACM) to 7.1 atmospheres with an exit temperature of 580 °F, and finally cooled in a secondary heat exchanger to 375 °F or less. If the air temperature were in excess of 200 °F and fuel temperature less than 160 °F, the air would be passed through a fuel-air heat exchanger. Passage through a water separator preceded entry into the expansion turbine of the ACM. Exit temperature from the turbine must be less than or equal to 85 °F, or the turbine would shut down. The FE changed the cockpit and cabin temperature using a hot air mix valve to control the temperature in the supply ducts. An idle descent from high altitude could result in an ACM overheat. In this case, speed must be increased to provide more air for the inlet air heat exchanger. There were four outflow valves on the left side of the fuselage and two on the right. The landing gear and brakes were cooled on the ground with air from the outflow valves. The FE controlled the airconditioning and pressurization system. Desired cabin pressure was set in mm Hg, with 660 mm nominally being set on the ground. During high-altitude cruise, the ambient cabin altitude was nominally 1.7 to

1. 9 miles. Warnings were displayed in the cockpit for cabin altitudes in excess of 2 miles, and 2.5 miles was the maximum.

There was no provision for wing leading-edge anti-icing. Flighttesting of the Tu-144 prototype indicated this was not necessary, because

of the high speeds normally flown by the aircraft and the large degree of leading-edge sweep. The canard, however, was electrically heated for anti-ice protection requiring 20 KVA of AC power. No information was available on engine anti-icing, but the inlets were electrically heated for anti-ice protection.

![]() Communication capability consisted of standard frequency band UHF and VHF radios and an Interphone Communication System (ICS). A variety of aural tones and messages were available, including master warning messages, radio altitude calls, and marker beacon tones. The annunciation was in a synthetic female voice format in Russian. Navigation capability consisted of three Inertial Navigation Systems (INS), VOR/DME and ILS receivers, and a Russian version of TACAN. The ILS was not compatible with Western frequency bands. A navigation computer controlled the three INS units. The mutually independent INS units provided attitude and true heading information to the attitude and horizontal situation indicators provided to each pilot. The No. 3 INS provided inputs to the pilot’s instruments, No. 2 did the same for the copilot’s instruments, and No. 1 could be selected by either pilot if necessary. If the navigation computer failed, the pilot could select raw INS data. Each INS could only accept 20 waypoints. When within 60 miles of the base airport, magnetic heading was used, but outside of that distance, true heading was selected. The crew had the ability to correct the computed position of each INS separately, in 1-mile increments. The Sensitive Pitch Angle Indicator (SPI) mounted above the center glare shield was driven by the No. 3 INS. This provided the pilots with precise pitch angle information necessary for approach and landing. A pilot – designed Vertical Regime Indicator (VRI) was a clever instrument that provided guidance to the pilot for the complex climb and acceleration profiles and descent and deceleration profiles. Concorde, on the other hand, had no such instrument and relied instead charted data.

Communication capability consisted of standard frequency band UHF and VHF radios and an Interphone Communication System (ICS). A variety of aural tones and messages were available, including master warning messages, radio altitude calls, and marker beacon tones. The annunciation was in a synthetic female voice format in Russian. Navigation capability consisted of three Inertial Navigation Systems (INS), VOR/DME and ILS receivers, and a Russian version of TACAN. The ILS was not compatible with Western frequency bands. A navigation computer controlled the three INS units. The mutually independent INS units provided attitude and true heading information to the attitude and horizontal situation indicators provided to each pilot. The No. 3 INS provided inputs to the pilot’s instruments, No. 2 did the same for the copilot’s instruments, and No. 1 could be selected by either pilot if necessary. If the navigation computer failed, the pilot could select raw INS data. Each INS could only accept 20 waypoints. When within 60 miles of the base airport, magnetic heading was used, but outside of that distance, true heading was selected. The crew had the ability to correct the computed position of each INS separately, in 1-mile increments. The Sensitive Pitch Angle Indicator (SPI) mounted above the center glare shield was driven by the No. 3 INS. This provided the pilots with precise pitch angle information necessary for approach and landing. A pilot – designed Vertical Regime Indicator (VRI) was a clever instrument that provided guidance to the pilot for the complex climb and acceleration profiles and descent and deceleration profiles. Concorde, on the other hand, had no such instrument and relied instead charted data.

The autopilot used the same actuators as the manual flight control system and was considered a subsystem of the flight control system. The dampers in all three axes must be operative for the autopilot to be used. The autopilot was a simple two-axis system operated from mode control panels (MCP) on the pilots’ control wheels. Autopilot longitudinal and lateral modes included attitude hold, altitude hold, Mach hold, bank-angle hold, heading hold, localizer tracking, and glide-slope tracking. Each mode was selected by pressing a button on the MCP. As an example of the selector logic, for Mach or bank angle hold to be engaged,

|

|

TU-144LL FLIGHT EXPERIMENTS

AND INSTRUMENTATION

attitude hold must first have been selected. Altitude hold could be selected above 1,300-feet altitude but could not be used between 0.85 indicated Mach number (IMN) and 1.2 IMN, because of significant transonic effects. The lateral modes of the autopilot would command roll angles up to 30 degrees, but 25 degrees was the nominal limit. The longitudinal modes operated between 30-degrees nose-up to 11-degrees nose-down and possessed a 10-degree elevon trim range capability. Two autopilot disconnect switches were on each MCP, the left one to disconnect the lateral channel and the right one to disconnect the longitudinal channel. In addition, a red emergency disconnect switch was on each control wheel. The autopilot channels could be manually overridden or disconnected with a 1-inch pitch input or a 15-degree roll input.