The NACA and the Wind Tunnel

For the United States, the Great War highlighted the need to achieve parity with Europe in aeronautical development. Part of that effort was the creation of the Government civilian research agency, the NACA, in March 1915. The committee established its first facility, Langley Memorial Aeronautical Laboratory—named in honor of aeronautical experimenter and Smithsonian Secretary Samuel P. Langley—2 years

|

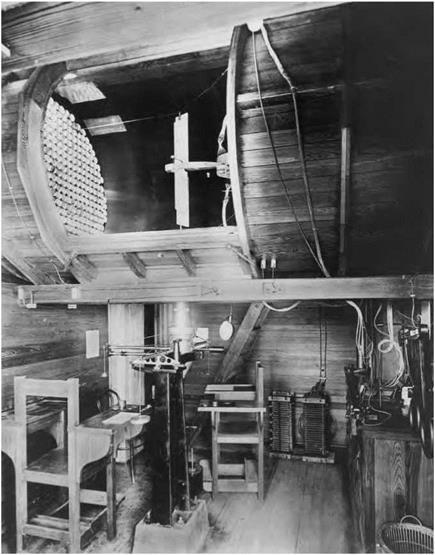

NACA Wind Tunnel No. 1 with a model of a Curtiss JN-4D Trainer in the test section. NASA. |

later near Hampton, VA, on the Chesapeake Bay. In June 1920, NACA Wind Tunnel No. 1 became operational. A close copy of a design built at the British National Physical Laboratory a decade earlier, the tunnel produced no data directly applicable to aircraft design.[536]

One of the major obstacles facing the effective use of a wind tunnel was scale effects, meaning the Reynolds number of model did not match the full-scale airplane. Prandtl protege Max Munk proposed the construction of a high-pressure tunnel to solve the problem. His Variable Density Tunnel (VDT) could be used to test a 1/20th-scale model in an airflow pressurized to 20 atmospheres, which would generate identical Reynolds numbers to full-scale aircraft. Built in the Newport News shipyards, the VDT was radical in design with its boilerplate and rivets. More importantly, it proved to be a point of departure from previous tunnels with the data that it produced.[537]

The VDT became an indispensable tool to airfoil development that effectively reshaped the subsequent direction of American airfoil research and development after it became operational in 1923. Munk’s successor in the VDT, Eastman Jacobs, and his colleagues in the VDT pioneered airfoil design methods with the pivotal Technical Report 460, which influenced aircraft design for decades after its publication in 1933.[538] Of the 101 distinct airfoil sections employed on modern Army, Navy, and commercial airplanes by 1937, 66 were NACA designs. Those aircraft included the venerable Douglas DC-3 airliner, considered by many to be the first truly "modern” airplane, and the highly successful Boeing B-17 Flying Fortress of World War II.[539]

The NACA also addressed the fundamental problem of incorporating a radial engine into aircraft design in the pioneering Propeller Research Tunnel (PRT). Lightweight, powerful, and considered a revolutionary aeronautical innovation, a radial engine featured a flat frontal configuration that created a lot of drag. Engineer Fred E. Weick and his colleagues tested full-size aircraft structures in the tunnel’s 20-foot opening. Their solution, called the NACA cowling, arrived at the right moment to increase the performance of new aircraft. Spectacular demonstrations—such as Frank Hawks flying the Texaco Lockheed Air Express, with a NACA cowling installed, from Los Angeles to New York nonstop in a record time of 18 hours 13 minutes in February 1929—led to the organization’s first Collier Trophy, in 1929.

With the basic formula for the modern airplane in place, the aeronautical community began to push the limits of conventional aircraft design. The NACA built upon its success with the cowling research in the PRT and concentrated on the aerodynamic testing of full-scale aircraft in wind tunnels. The Full-Scale Tunnel (FST) featured a 30- by 60-foot test section and opened at Langley in 1931. The building was a massive structure at 434 feet long, over 200 feet wide, and 9 stories high. The first aircraft to be tested in the FST was a Navy Vought O3U-1 Corsair observation airplane. Testing in the late 1930s focused on removing as much drag from an airplane in flight as possible. NACA engineers—through an extensive program involving the Navy’s first monoplane fighter, Brewster XF2A-1 Buffalo—showed that attention to details such as air intakes, exhaust pipes, and gun ports effectively reduced drag.

In the mid – to late 1920s, the first generation of university-trained American aeronautical engineers began to enter work with industry, the Government, and academia. The philanthropic Daniel Guggenheim Fund for the Promotion of Aeronautics created aeronautical engineering schools, complete with wind tunnels, at the California Institute of Technology, Georgia Institute of Technology, Massachusetts Institute of Technology, University of Michigan, New York University, Stanford University, and University of Washington. The creation of these dedicated academic programs ensured that aeronautics would be an institutionalized profession. The university wind tunnels quickly made their mark. The prototype Douglas DC airliner, the DC-1, flew in July 1933. In every sense of the word, it was a streamline airplane because of the extensive amount of wind tunnel testing at Guggenheim Aeronautical Laboratory at the California Institute of Technology used in its design.

By the mid-1930s, it was obvious that the sophisticated wind tunnel research program undertaken by the NACA had contributed to a new level of American aeronautical capability. Each of the major American manufacturers built wind tunnels or relied upon a growing number of university facilities to keep up with the rapid pace of innovation. Despite those additions, it was clear in the minds of the editors at the influential trade journal Aviation that the NACA led the field with the grace, style, and coordinated virtuosity of a symphonic orchestra.[540]

World War II stimulated the need for sophisticated aerodynamic testing, and new wind tunnels met the need. Langley’s 20-Foot Vertical Spin Tunnel (VST) became operational in March 1941. The major difference between the VST and those that came before was its vertical closed-throat, annular return. A variable-speed three-blade, fixed-pitch fan provided vertical airflow at an approximate velocity of 85 feet per second at atmospheric conditions. Researchers threw dynamically scaled, free-flying aircraft models into the tunnel to evaluate their stability as they spun and tumbled out of control. The installation of remotely actuated control surfaces allowed the study of spin recovery characteristics. The NACA solution to spin problems for aircraft was to enlarge the vertical tail, raise the horizontal tail, and extend the length of the ventral fin.[541]

The NACA founded the Ames Aeronautical Laboratory on December 20, 1939, in anticipation of the need for expanded research and flight – test facilities for the West Coast aviation industry. The NACA leadership wanted to reach parity with European aeronautical research based on the belief that the United States would be entering World War II. The cornerstone facility at Ames was the 40 by 80 Tunnel capable of generating airflow of 265 mph for even larger full-scale aircraft when it opened in 1944. Building upon the revolutionary drag reduction studies pioneered in the FST, Ames researchers continued to modify existing aircraft with fillets and innovated dive recovery flaps to offset a new problem encountered when aircraft entered high-speed dives called compressibility.[542]

The NACA also desired a dedicated research facility that specialized in aircraft propulsion systems. Construction of the Aircraft Engine Research Laboratory (AERL) began at Cleveland, OH, in January 1941, with the facility becoming operational in May 1943.[543] The cornerstone

facility was the Altitude Wind Tunnel (AWT), which became operational in 1944. The AWT was the only wind tunnel in the world capable of evaluating full-scale aircraft engines in realistic flight conditions that simulated altitudes up to 50,000 feet and speeds up to 500 mph. AERL researchers began first with large radial engines and propellers and continued with the new jet technology on through the postwar decades.[544]

The AERL soon became the center of the NACA’s work on alleviating aircraft icing. The Army Air Forces lost over 100 military transports along with their crews and cargoes over the "Hump,” or the Himalayas, as it tried to supply China by air. The problem was the buildup of ice on wings and control surfaces that degraded the aerodynamic integrity and overloaded the aircraft. The challenge was developing de-icing systems that removed or prevented the ice buildup. The Icing Research Tunnel (IRT) was the largest of its kind when it opened in 1944. It featured a 6- by 9-foot test section, a 160-horsepower electric motor capable of generating a 300 mph airstream, and a 2,100-ton refrigeration system that cooled the airflow down to -40 degrees Fahrenheit (°F).[545] The tunnel worked well during the war and the following two decades, before NASA closed it. However, a new generation of icing problems for jet aircraft, rotary wing, and Vertical/Short Take-Off and Landing (V/STOL) aircraft resulted in the reopening of the IRT in 1978.[546]

During World War II, airplanes ventured into a new aerodynamic regime, the so-called "transonic barrier.” American propeller-driven aircraft suffered from aerodynamic problems caused by high-speed flight. Flight-testing of the P-38 Lightning revealed compressibility problems that resulted in the death of a test pilot in November 1941. As the Lightning dove from 30,000 feet, shock waves formed over the wings and hit the tail, causing violent vibration, which caused the airplane to plummet into a vertical, and unrecoverable, dive. At speeds approaching Mach 1, aircraft experienced sudden changes in stability and control,

extreme buffeting, and, most importantly, a dramatic increase in drag, which created challenges for the aeronautical community involving propulsion, research facilities, and aerodynamics. Bridging the gap between subsonic and supersonic speeds was a major aerodynamic challenge.[547]

The transonic regime was unknown territory in the 1940s. Four approaches—putting full-size aircraft into terminal velocity dives, dropping models from aircraft, installing miniature wings mounted on flying aircraft, and launching models mounted on rockets—were used in lieu of an available wind tunnel in the 1940s for transonic research. Aeronautical engineers faced a daunting challenge rooted in developing tools and concepts because no known wind tunnel was able to operate and generate data at transonic speeds.

NACA Manager John Stack took the lead in American work in transonic development. As the central NACA researcher in the development of the first research airplane, the Bell X-1, he was well-qualified for highspeed research. His part in the first supersonic flight resulted in a joint award of the 1947 Collier Trophy. He ordered the conversion of the 8- and 16-Foot High-Speed Tunnels in spring 1948 to a slotted throat to enable research in the transonic regime. Slots in the tunnels’ test sections, or throats, enabled smooth operation at high subsonic speeds and low supersonic speeds. The initial conversion was not satisfactory. Physicist Ray Wright and engineers Virgil S. Ritchie and Richard T. Whitcomb hand-shaped the slots based on their visualization of smooth transonic flow. Working directly with Langley woodworkers, they designed and fabricated a channel at the downstream end of the test section that reintroduced air that traveled through the slots. Their painstaking work led to the inauguration of operations in the newly christened 8-Foot Transonic Tunnel (TT) 7 months later, on October 6, 1950.[548]

Rumors had been circulating throughout the aeronautical community about the NACA’s new transonic tunnels: the 8-Foot TT and the 16-Foot TT. The NACA wanted knowledge of their existence to remain confidential among the military and industry. Concerns over secrecy were

deemed less important than the acknowledgement of the development of the slotted-throat tunnel, for which John Stack and 19 of his colleagues received a Collier Trophy in 1951. The award specifically recognized the importance of a research tool, which was a first in the 40-year history of the award. When used with already available wind tunnel components and techniques, the tunnel balance, pressure orifice, tuft surveys, and schlieren photographs, slotted-throat tunnels resulted in a new theoretical understanding of transonic drag. The NACA claimed that its slotted – throat transonic tunnels gave the United States a 2-year lead in the design of supersonic military aircraft.[549] John Stack’s leadership affected the NACAs development of state-of-the-art wind tunnel technology. The researchers inspired by or working under him developed a generation of wind tunnels that, according to Joseph R. Chambers, became "national treasures.”[550]