Taming Microburst: NASA’s Wind Shear Research Effort Takes Wing

The Dallas crash profoundly accelerated NASA and FAA wind shear research efforts. Two weeks after the accident, responding to calls from concerned constituents, Representative George Brown of California requested a NASA presentation on wind shear and subsequently made a fact-finding visit to the Langley Research Center. Dr. Jeremiah F. Creedon, head of the Langley Flight Systems Directorate, briefed the Congressman on the wind shear problem and potential technologies that might alleviate it. Creedon informed Brown that Langley researchers were running a series of modest microburst and wind shear modeling projects, and that an FAA manager, George "Cliff” Hay, and NASA Langley research engineer Roland L. Bowles had a plan underway for a comprehensive airborne wind shear detection research program. During the briefing, Brown asked how much money it would take; Creedon estimated several million dollars. Brown remarked the amount was "nothing”; Creedon

replied tellingly, "It’s a lot of money if you don’t have it.” As the Brown party left the briefing, one of his aides confided to a Langley manager "NASA [has] just gotten itself a wind shear program.” The combination of media attention, public concern, and congressional interest triggered the development of "a substantial, coordinated interagency research effort to address the wind shear problem.”[64]

![]() On July 24, 1986, NASA and the FAA mandated the National Integrated Windshear Plan, an umbrella project overseeing several initiatives at different agencies.[65] The joint effort responded both to congressional directives and National Transportation Safety Board recommendations after documentation of the numerous recent wind shear accidents. NASA Langley Research Center’s Roland L. Bowles subsequently oversaw a rigorous plan of wind shear research called the Airborne Wind Shear Detection and Avoidance Program (AWDAP), which included the development of onboard sensors and pilot training. Building upon earlier supercomputer modeling studies by Michael L. Kaplan, Fred H. Proctor, and others, NASA researchers developed the Terminal Area Simulation System (TASS), which took into consideration a variety of storm parameters and characteristics, enabling numerical simulation of microburst formation. Out of this came data that the FAA was able to use to build standards for the certification of airborne wind shear sensors. As well, the FAA created a flight

On July 24, 1986, NASA and the FAA mandated the National Integrated Windshear Plan, an umbrella project overseeing several initiatives at different agencies.[65] The joint effort responded both to congressional directives and National Transportation Safety Board recommendations after documentation of the numerous recent wind shear accidents. NASA Langley Research Center’s Roland L. Bowles subsequently oversaw a rigorous plan of wind shear research called the Airborne Wind Shear Detection and Avoidance Program (AWDAP), which included the development of onboard sensors and pilot training. Building upon earlier supercomputer modeling studies by Michael L. Kaplan, Fred H. Proctor, and others, NASA researchers developed the Terminal Area Simulation System (TASS), which took into consideration a variety of storm parameters and characteristics, enabling numerical simulation of microburst formation. Out of this came data that the FAA was able to use to build standards for the certification of airborne wind shear sensors. As well, the FAA created a flight

safety program that supported NASA development of wind shear detection technologies.[66]

![]() At NASA Langley, the comprehensive wind shear studies started with laboratory analysis and continued into simulation and flight evaluation. Some of the sensor systems that Langley tested work better in rain, while others performed more successfully in dry conditions.[67] Most were tested using Langley’s modified Boeing 737 systems testbed.[68] This research airplane studied not only microburst and wind shear with the Airborne Windshear Research Program, but also tested electronic and computerized control displays ("glass cockpits” and Synthetic Vision Systems) in development, microwave landing systems in development, and Global Positioning System (GPS) navigation.[69]

At NASA Langley, the comprehensive wind shear studies started with laboratory analysis and continued into simulation and flight evaluation. Some of the sensor systems that Langley tested work better in rain, while others performed more successfully in dry conditions.[67] Most were tested using Langley’s modified Boeing 737 systems testbed.[68] This research airplane studied not only microburst and wind shear with the Airborne Windshear Research Program, but also tested electronic and computerized control displays ("glass cockpits” and Synthetic Vision Systems) in development, microwave landing systems in development, and Global Positioning System (GPS) navigation.[69]

NASA’s Airborne Windshear Research Program did not completely resolve the problem of wind shear, but "its investigation of microburst detection systems helped lead to the development of onboard monitoring systems that offered airliners another way to avoid potentially lethal situations.”[70] The program achieved much and gave confidence to those pursuing practical applications. The program had three major goals. The first was to find a way to characterize the wind shear threat in a way that would indicate the hazard level that threatened aircraft. The second was to develop airborne remote-sensor technology to provide accurate, forwardlooking wind shear detection. The third was to design flight management systems and concepts to transfer this information to pilots in such a way that they could effectively respond to a wind shear threat. The program had to pursue these goals under tight time constraints.[71] Time was of the essence, partly because the public had demanded a solution to the scourge of microburst wind shear and because a proposed FAA regulation stipulated that any "forward-looking” (predictive) wind shear detection technology produced by NASA be swiftly transferred to the airlines.

An airborne technology giving pilots advanced warning of wind shear would allow them the time to increase engine power, "clean up”

the aircraft aerodynamically, increase penetration speed, and level the airplane before entering a microburst, so that the pilot would have more energy, altitude, and speed to work with or to maneuver around the microburst completely. But many doubted that a system incorporating all of these concepts could be perfected. The technologies offering most potential were microwave Doppler radar, Doppler Light Detecting and Ranging (LIDAR, a laser-based system), and passive infrared radiome – try systems. However, all these forward-looking technologies were challenging. Consequently, developing and exploiting them took a minimum of several years. At Langley, versions of the different detection systems were "flown” as simulations against computer models, which re-created past wind shear accidents. However, computer simulations could only go so far; the new sensors had to be tested in actual wind shear conditions. Accordingly, the FAA and NASA expanded their 1986 memorandum of understanding in May 1990 to support flight research evaluating the efficacy of the advanced wind shear detection systems integrating airborne and ground-based wind shear measurement methodologies. Researchers swiftly discovered that pilots needed as much as 20 seconds of advance warning if they were to avert or survive an encounter with microburst wind shear.[72]

![]() Key to developing a practical warning system was deriving a suitable means of assessing the level of threat that pilots would face, because this would influence the necessary course of action to avoid potential disaster. Fortunately, NASA Project Manager Roland Bowles devised a hazard index called the "F-Factor.” The F-Factor, as ultimately refined by Bowles and his colleagues Michael Lewis and David Hinton, indicated how much specific excess thrust an airplane would require to fly through wind shear without losing altitude or airspeed.[73] For instance, a typical twin-engine jet transport plane might have engines capable

Key to developing a practical warning system was deriving a suitable means of assessing the level of threat that pilots would face, because this would influence the necessary course of action to avoid potential disaster. Fortunately, NASA Project Manager Roland Bowles devised a hazard index called the "F-Factor.” The F-Factor, as ultimately refined by Bowles and his colleagues Michael Lewis and David Hinton, indicated how much specific excess thrust an airplane would require to fly through wind shear without losing altitude or airspeed.[73] For instance, a typical twin-engine jet transport plane might have engines capable

of producing 0.17 excess thrust on the F-Factor scale. If a microburst wind shear registered higher than 0.17, the airplane would not be able to fly through it without losing airspeed or altitude. The F-Factor provided a way for information from any kind of sensor to reach the pilot in an easily recognizable form. The technology also had to locate the position and track the movement of dangerous air masses and provide information on the wind shear’s proximity and volume.[74] Doppler-based wind shear sensors could only measure the first term in the F-Factor equation (the rate of change of horizontal wind). This limitation could result in underestimation of the hazard. Luckily, there were several ways to measure changes in vertical wind from radial wind measurements, using equations and algorithms that were computerized. Although error ranges in the device’s measurement of the F-Factor could not be eliminated, these were taken into account when producing the airborne system.[75] The Bowles team derivation and refinement of the F-Factor constituted a major element of NASA’s wind shear research, to some, "the key contribution of NASA in the taming of the wind-shear threat.” The FAA recognized its significance by incorporating F-Factor in its regulations, directing that at F-Factors of 0.13 or greater, wind shear warnings must be issued.[76]

![]() In 1988, NASA and researchers from Clemson University worked on new ways to eliminate clutter (or data not related to wind shear) from information received via Doppler and other kinds of radar used on an airborne platform. Such methods, including antenna steering and adaptive filtering, were somewhat different from those used to eliminate clutter from information received on a ground-based platform. This was

In 1988, NASA and researchers from Clemson University worked on new ways to eliminate clutter (or data not related to wind shear) from information received via Doppler and other kinds of radar used on an airborne platform. Such methods, including antenna steering and adaptive filtering, were somewhat different from those used to eliminate clutter from information received on a ground-based platform. This was

because the airborne environment had unique problems, such as large clutter-to-signal ratios, ever-changing range requirements, and lack of repeatability.[77]

![]() The accidents of the 1970s and 1980s stimulated research on a variety of wind shear predictive technologies and methodologies. Langley’s success in pursuing both enabled the FAA to decree in 1988 that all commercial airline carriers were required to install wind shear detection devices by the end of 1993. Most airlines decided to go with reactive systems, which detect the presence of wind shear once the plane has already flown into it. For American, Northwest, and Continental— three airlines already testing predictive systems capable of detecting wind shear before an aircraft flew into it—the FAA extended its deadline to 1995, to permit refinement and certification of these more demanding and potentially more valuable sensors.[78]

The accidents of the 1970s and 1980s stimulated research on a variety of wind shear predictive technologies and methodologies. Langley’s success in pursuing both enabled the FAA to decree in 1988 that all commercial airline carriers were required to install wind shear detection devices by the end of 1993. Most airlines decided to go with reactive systems, which detect the presence of wind shear once the plane has already flown into it. For American, Northwest, and Continental— three airlines already testing predictive systems capable of detecting wind shear before an aircraft flew into it—the FAA extended its deadline to 1995, to permit refinement and certification of these more demanding and potentially more valuable sensors.[78]

From 1990 onwards, NASA wind shear researchers were particularly energetic, publishing and presenting widely, and distributing technical papers throughout the aerospace community. Working with the FAA, they organized and sponsored well-attended wind shear conferences that drew together other researchers, aviation administrators, and—very importantly—airline pilots and air traffic controllers. Finally, cognizant of the pressing need to transfer the science and technology of wind shear research out of the laboratory and onto the flight line, NASA and the FAA invited potential manufacturers to work with the agencies in pursuing wind shear detector development.[79]

The invitations were welcomed by industry. Three important avionics manufacturers—Allied Signal, Westinghouse, and Rockwell Collins—sent engineering teams to Langley. These teams followed NASA’s wind shear effort closely, using the Agency’s wind shear simulations to enhance the capabilities of their various systems. In 1990, Lockheed introduced its Coherent LIDAR Airborne Shear Sensor (CLASS), developed under contract to NASA Langley. CLASS was a predictive system allowing pilots to avoid hazards of low-altitude wind shear under all weather conditions. CLASS would detect thunderstorm downburst early in its development

and emphasize avoidance rather than recovery. After consultation with airline and military pilots, Lockheed engineers decided that the system should have a 2- to 4-kilometer range and should provide a warning time of 20 to 40 seconds. A secondary purpose of the system would be to provide predictive warnings of clear air turbulence. In conjunction with NASA, Lockheed conducted a 1-year flight evaluation program on Langley’s 737 during the following year to measure line-of-sight wind velocities from many wind fields, evaluating this against data obtained via air – and ground-based radars and accelerometer-based systems and thus acquiring a comparative database.[80]

![]() Also in 1990, using technologies developed by NASA, Turbulence Prediction Systems of Boulder, CO, successfully tested its Advance Warning Airborne System (AWAS) on a modified Cessna Citation small, twin-jet research aircraft operated by the University of North Dakota. Technicians loaded AWAS into the luggage compartment in front of the pilot. Pilots intentionally flew the plane into numerous wind shear events over the course of 66 flights, including several wet microbursts in Orlando, FL, and a few dry microbursts in Denver. On the Cessna, AWAS measured the thermal characteristics of microbursts to predict their presence during takeoff and landing. In 1991, AWAS units were flown aboard three American Airlines MD-80s and three Northwest Airlines DC-9s to study and improve the system’s nuisance alert response. Technicians also installed a Honeywell Windshear Computer in the planes, which Honeywell had developed in light of NASA research. The computer processed the data gathered by AWAS via external aircraft measuring instruments. AWAS also flew aboard the NASA Boeing 737 during summer 1991. Unfortunately, results from these research flights were not conclusive, in part because NASA conducted research flights outside AWAS’s normal operating envelope, and in an attempt to compensate for differences in airspeed, NASA personnel sometimes overrode automatic features. These complications did not stop the development of more sophisticated versions of the system and ultimate FAA certification.[81]

Also in 1990, using technologies developed by NASA, Turbulence Prediction Systems of Boulder, CO, successfully tested its Advance Warning Airborne System (AWAS) on a modified Cessna Citation small, twin-jet research aircraft operated by the University of North Dakota. Technicians loaded AWAS into the luggage compartment in front of the pilot. Pilots intentionally flew the plane into numerous wind shear events over the course of 66 flights, including several wet microbursts in Orlando, FL, and a few dry microbursts in Denver. On the Cessna, AWAS measured the thermal characteristics of microbursts to predict their presence during takeoff and landing. In 1991, AWAS units were flown aboard three American Airlines MD-80s and three Northwest Airlines DC-9s to study and improve the system’s nuisance alert response. Technicians also installed a Honeywell Windshear Computer in the planes, which Honeywell had developed in light of NASA research. The computer processed the data gathered by AWAS via external aircraft measuring instruments. AWAS also flew aboard the NASA Boeing 737 during summer 1991. Unfortunately, results from these research flights were not conclusive, in part because NASA conducted research flights outside AWAS’s normal operating envelope, and in an attempt to compensate for differences in airspeed, NASA personnel sometimes overrode automatic features. These complications did not stop the development of more sophisticated versions of the system and ultimate FAA certification.[81]

After analyzing data from the Dallas and Denver accidents, Honeywell researchers had concluded that temperature lapse rate, or the drop in temperature with the increase in altitude, could indicate wind shear caused by both wet and dry microbursts. Lapse rate could not, of course, communicate whether air acceleration was horizontal or vertical. Nonetheless, this lapse rate could be used to make reactive systems more "intelligent,” "hence providing added assurance that a dangerous shear has occurred.” Because convective activity was often associated with turbulence, the lapse rate measurements could also be useful in warning of impending "rough air.” Out of this work evolved the first – generation Honeywell Windshear Detection and Guidance System, which gained wide acceptance.[82]

![]() Supporting its own research activities and the larger goal of air safety awareness, NASA developed a thorough wind shear training and familiarization program for pilots and other interested parties. Flightcrews "flew” hundreds of simulated wind shears. Crews and test personnel flew rehearsal flights for 2 weeks in the Langley and Wallops areas before deploying to Orlando or Colorado for actual in-flight microburst encounters in 1991 and 1992.

Supporting its own research activities and the larger goal of air safety awareness, NASA developed a thorough wind shear training and familiarization program for pilots and other interested parties. Flightcrews "flew” hundreds of simulated wind shears. Crews and test personnel flew rehearsal flights for 2 weeks in the Langley and Wallops areas before deploying to Orlando or Colorado for actual in-flight microburst encounters in 1991 and 1992.

The NASA Langley team tested three airborne systems to predict wind shear. In the creation of these systems, it was often assisted by technology application experts from the Research Triangle Institute of Triangle Park, NC.[83] The first system tested was a Langley-sponsored Doppler microwave radar, whose development was overseen by Langley’s Emedio "Brac” Bracalente and the Langley Airborne Radar Development Group. It sent a microwave radar signal ahead of the plane to detect raindrops and other moisture in the air. The returning signal provided information on the motion of raindrops and moisture particles, and it translated this information into wind speed. Microwave radar was best in damp or wet conditions, though not in dry conditions. Rockwell International’s Collins Air Transport Division in Cedar Rapids, IA, made the radar transmitter, extrapolated from the standard Collins 708 weather radar. NASA’s Langley Research Center in Hampton, VA, developed

the receiver/detector subsystem and the signal-processing algorithms and hardware for the wind shear application. So enthusiastic and confident were the members of the Doppler microwave test team that they designed their own flight suit patch, styling themselves the "Burst Busters,” with an international slash-and-circle "stop” sign overlaying a schematic of a microburst.[84]

![]() The second system was a Doppler LIDAR. Unlike radio beam – transmitting radar, LIDAR used a laser, reflecting energy from aerosol particles rather than from water droplets. This system had fewer problems with ground clutter (interference) than Doppler radar did, but it did not work as well as the microwave system does in heavy rain. The system was made by the Lockheed Corporation’s Missiles and Space Company in Sunnyvale, CA; United Technologies Optical Systems, Inc., in West Palm Beach, FL; and Lassen Research of Chico, CA.[85] Researchers noted that an "inherent limitation” of the radar and LIDAR systems was their inability to measure any velocities running perpendicular to the system’s line of sight. A microburst’s presence could be detected by measuring changes in the horizontal velocity profile, but the inability to measure a perpendicular downdraft could result in an underestimation of the magnitude of the hazard, including its spatial size.[86]

The second system was a Doppler LIDAR. Unlike radio beam – transmitting radar, LIDAR used a laser, reflecting energy from aerosol particles rather than from water droplets. This system had fewer problems with ground clutter (interference) than Doppler radar did, but it did not work as well as the microwave system does in heavy rain. The system was made by the Lockheed Corporation’s Missiles and Space Company in Sunnyvale, CA; United Technologies Optical Systems, Inc., in West Palm Beach, FL; and Lassen Research of Chico, CA.[85] Researchers noted that an "inherent limitation” of the radar and LIDAR systems was their inability to measure any velocities running perpendicular to the system’s line of sight. A microburst’s presence could be detected by measuring changes in the horizontal velocity profile, but the inability to measure a perpendicular downdraft could result in an underestimation of the magnitude of the hazard, including its spatial size.[86]

The third plane-based system used an infrared detector to find temperature changes in the airspace in front of the plane. It monitored carbon dioxide’s thermal signatures to find cool columns of air, which often indicate microbursts. The system was less expensive and less complex than the others but also less precise, because it could not directly measure wind speed.[87]

NASA 51 5, the Langley Boeing 737, on the airport ramp at Orlando, FL, during wind shear sensor testing. NASA.

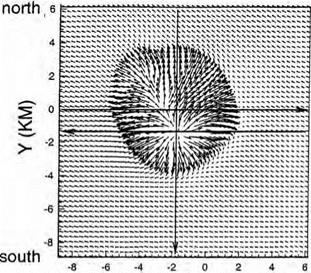

CASE #2-37: 06/20/91 ORLANDO MICROBURST

VELOCITY VECTORS AT 50 M AGL

|

|

|

|

A June 1991 radar plot of a wind shear at Orlando, showing the classic radial outflow. This one is approximately 5 miles in diameter. NASA.

![]() In 1990-1992, Langley’s wind shear research team accumulated and evaluated data from 130 sensor-evaluation research flights made using the Center’s 737 testbed. [88] Flight-test crews flew research missions in the Langley local area, Philadelphia, Orlando, and Denver. Risk mitigation was an important program requirement. Thus, wind shear investigation flights were flown at higher speeds than airliners typically flew, so that the 737 crew would have better opportunity to evade any hazard it encountered. As well, preflight ground rules stipulated that no penetrations be made into conditions with an F-Factor greater than 0.15. Of all the systems tested, the airborne radar functioned best. Data were accumulated during 156 weather runs: 109 in the turbulence-prone Orlando area. The 737 made 15 penetrations of microbursts at altitudes ranging from 800 to 1,100 feet. During the tests, the team evaluated the radar at various tilt angles to assess any impact from ground clutter (a common problem in airborne radar clarity) upon the fidelity of the airborne system. Aircraft entry speed into the microburst threat region had little effect on clutter suppression. All together, the airborne Doppler radar tests collected data from approximately 30 microbursts, as well as 20 gust fronts, with every microburst detected by the airborne radar. F-Factors measured with the airborne radar showed "excellent agreement” with the F-Factors measured by Terminal Doppler Weather Radar (TDWR), and comparison of airborne and TDWR data likewise indicated "comparable results.”[89] As Joseph Chambers noted subsequently, "The results of the test program demonstrated that Doppler radar systems offered the greatest promise for early introduction to airline service. The Langley forward-looking Doppler radar detected wind shear consistently and at longer ranges than other systems, and it was able to provide 20 to 40 seconds warning of upcoming microburst.”[90] The Burst Busters clearly had succeeded. Afterward, forward-looking Doppler radar was adopted by most airlines.

In 1990-1992, Langley’s wind shear research team accumulated and evaluated data from 130 sensor-evaluation research flights made using the Center’s 737 testbed. [88] Flight-test crews flew research missions in the Langley local area, Philadelphia, Orlando, and Denver. Risk mitigation was an important program requirement. Thus, wind shear investigation flights were flown at higher speeds than airliners typically flew, so that the 737 crew would have better opportunity to evade any hazard it encountered. As well, preflight ground rules stipulated that no penetrations be made into conditions with an F-Factor greater than 0.15. Of all the systems tested, the airborne radar functioned best. Data were accumulated during 156 weather runs: 109 in the turbulence-prone Orlando area. The 737 made 15 penetrations of microbursts at altitudes ranging from 800 to 1,100 feet. During the tests, the team evaluated the radar at various tilt angles to assess any impact from ground clutter (a common problem in airborne radar clarity) upon the fidelity of the airborne system. Aircraft entry speed into the microburst threat region had little effect on clutter suppression. All together, the airborne Doppler radar tests collected data from approximately 30 microbursts, as well as 20 gust fronts, with every microburst detected by the airborne radar. F-Factors measured with the airborne radar showed "excellent agreement” with the F-Factors measured by Terminal Doppler Weather Radar (TDWR), and comparison of airborne and TDWR data likewise indicated "comparable results.”[89] As Joseph Chambers noted subsequently, "The results of the test program demonstrated that Doppler radar systems offered the greatest promise for early introduction to airline service. The Langley forward-looking Doppler radar detected wind shear consistently and at longer ranges than other systems, and it was able to provide 20 to 40 seconds warning of upcoming microburst.”[90] The Burst Busters clearly had succeeded. Afterward, forward-looking Doppler radar was adopted by most airlines.

|

|

NASA Langley’s wind shear team at Orlando in the cockpit of NASA 515. Left to right: Program Manager Roland Bowles, research pilot Lee Person, Deputy Program Manager Michael Lewis, research engineer David Hinton, and research engineer Emedio Bracalente. Note Bracalente’s "Burst Buster” shoulder patch. NASA.