Energy Efficient Engine Project

Taking everything learned to date by NASA and the industry about making turbo machinery more fuel efficient, the Energy Efficient Engine (E Cubed) project sought to further reduce the airlines’ fuel usage and its effect on direct operating costs, while also meeting future FAA regulations and Environmental Protection Agency exhaust emission standards for turbofan engines. Research contracts were awarded to GE and Pratt & Whitney, which initially focused on the CF6-50C and JT9D-7A engines, respectively. The program ran from 1975 to 1983 and cost NASA about $200 million.[1311]

Similar to the goals for the Engine Component Improvement project, the E Cubed goals included a 12-percent reduction in specific fuel consumption (SFC), which is a measure of the ratio between the mass of fuel used to the output power of the jet engine—much like a miles per gallon measurement for automobiles. Other goals of the E Cubed effort included a 5-percent reduction in direct operating costs and a

|

|

50-percent reduction in the rate at which the SFC worsens over time as the engine ages. In addition to making these immediate improvements, it was hoped that a new generation of fuel-conservative turbofan engines could be developed from this work.[1312]

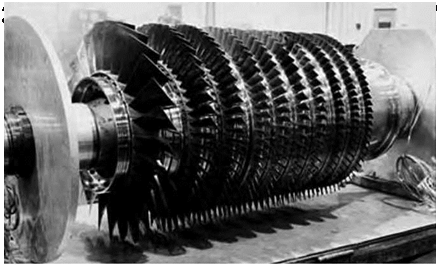

Highlighting that program was development of a new type of compressor core and an advanced combustor made up of a doughnut-shaped ring with two zones—or domes—of combustion. During times when low power is needed or the engine is idling, only one of the two zones is lit up. For higher thrust levels, including full power, both domes are ignited. By creating a dual combustion option, the amount of fuel being burned can be more carefully controlled, reducing emissions of smoke, carbon monoxide, and hydrocarbons by 50 percent, and nitrogen oxides by 35 percent.[1313]

As part of the development of the new compressor in particular, and the E Cubed and Engine Component Improvement programs in general, the Lewis Research Center developed first-generation computer programs for use in creating the new engine. The software helped engineers

with conceptualizing the aerodynamic design and visualizing the flow of gases through the engine. The computer programs were credited with making it possible to design more fuel-efficient compressors with less tip and end-wall pressure losses, higher operating pressure ratios, and the ability to use fewer blades. The compressors also helped to reduce performance deterioration, surface erosion, and damage from bird strikes.[1314]

![]() History has judged the E Cubed program as being highly successful, in that the technology developed from the effort was so promising—and proved to meet the objectives for reducing emissions and increasing fuel efficiency—that both major U. S. jet engine manufacturers, GE and Pratt & Whitney, moved quickly to incorporate the technology into their products. The ultimate legacy of the E Cubed program is found today in the GE90 engine, which powers the Boeing 777. The E Cubed technology is directly responsible for the engine’s economical fuel burn, reduced emissions, and low maintenance cost.[1315]

History has judged the E Cubed program as being highly successful, in that the technology developed from the effort was so promising—and proved to meet the objectives for reducing emissions and increasing fuel efficiency—that both major U. S. jet engine manufacturers, GE and Pratt & Whitney, moved quickly to incorporate the technology into their products. The ultimate legacy of the E Cubed program is found today in the GE90 engine, which powers the Boeing 777. The E Cubed technology is directly responsible for the engine’s economical fuel burn, reduced emissions, and low maintenance cost.[1315]